Aerators on the roof

The main purpose of the aerator for roof ventilation is to remove moisture from the under-roof space, as well as to ventilate all layers of the roofing pie. The soft roof is the most sensitive to moisture. Its design is a multilayer structure, during the construction of which materials are laid in layers. The basis is a reinforced concrete floor slab, it acts as a barrier between the interior of the premises and the external environment. During operation, the roofing may swell and peel off due to the penetration of wet fumes from inside the building. To prevent such situations, aerators are installed on the roof as a preventive measure.

General information about pond aeration

The aerator in its traditional sense is a hydromechanical device, through which the forced supply of oxygen to the reservoir is carried out and the water flow is organized, which minimizes the risk of the pond "blooming" due to stagnation.

Aerator for a pond and a reservoir in work

There is no need to talk about the need to supply air to the reservoir: firstly, the inhabitants of the pond breathe oxygen, and secondly, aeration contributes to additional water purification - reacting with oxygen, pollution collects in foam on the surface of the water or accumulates in sediment.

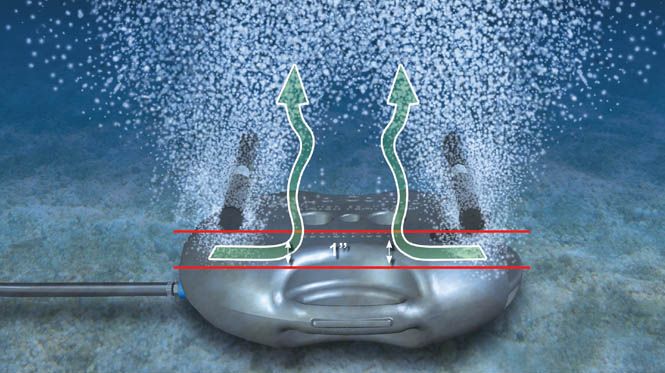

The principle of operation of the bottom aerator

Factory-made aerators are relatively expensive - they, in fact, account for one of the most significant cost items for arranging a private reservoir. But here, as they say, it is better to spend money once and not know the problems than to constantly think about how you can once again reanimate the pond.

AirFlo Pond Aerator

Aerator for septic tank

The best option is to use a sump that has a forced aeration function. For this device to work, you will need a special device - an aerator.

purpose

Why is it needed? To do this, consider the processes of cleaning the drain masses in the device of the sump.

A septic tank can be with one, two or three compartments.

The principle of operation of all sedimentation tanks is similar. In fact, all are represented by a conventional sealed container with cleaning processes of drain masses occurring inside. The contaminated liquid from your house is pumped into it, processed and initially cleaned.

Another septic tank made of concrete rings can vary in size. So one and two-chamber septic tanks contain a different volume of wastewater. Whatever design would be used, the treatment property of the septic tank lies in the ongoing internal process, because of it, the wastewater is cleaned.

These devices contain 2 types of bacteria - aerobic, which need oxygen to maintain life, and anaerobic, which do not need it.

Ventilation of the sump is necessary because these bacteria form toxic gases.

Conventional energy-dependent installations are designed in such a way that the cleaning processes proceed at the expense of anaerobic microorganisms. But they do not completely decompose organic matter, and they also act rather slowly.

The normal operation of a septic tank depends, in addition to ventilation, also on oxygen saturation. And if your task is to bring benefit to the sump, then you need to make a normally working aeration and ventilation to remove toxic gases lingering in it.

Therefore, a ventilation pipe is built into the septic tank, the function of which is to remove these gases with the help of pressure. An important point - the pipe must be at least half a meter above the ground. This contributes to the removal of all poisonous elements that cause harm and clog the sump.

And to do the job, you need an aerator. This device is installed on the bottom of the tank, produces internal ventilation and, accordingly, air ingress. The treated oxygen is removed by a conventional ventilation system.

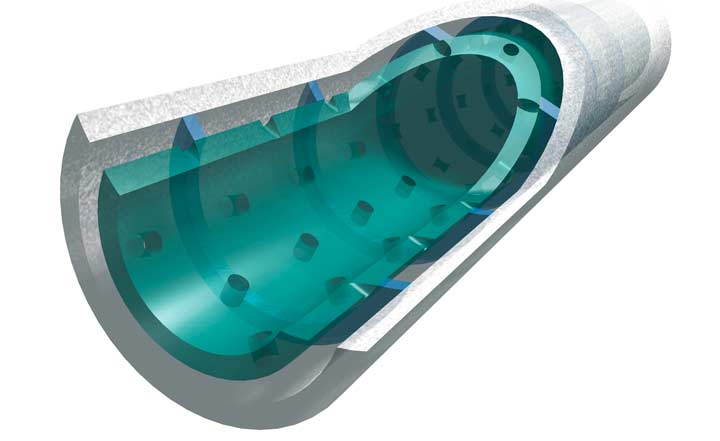

Principle of operation

The principle of operation is that the aerator has many tiny holes through which oxygen passes, which is supplied by the compressor. Oxygen passes through the aerator and forms many bubbles that are distributed throughout the liquid. The environment is saturated with air, due to the fact that, according to the law of physics, oxygen bubbles tend upwards, and a purification process takes place.

The active biological mass is mixed with contaminated water, which ensures complete water purification. In the process of purification, unpleasantly smelling gases are not emitted and the operation of the septic tank does not create uncomfortable conditions for residents.

A septic tank can also be with intermittent aeration. But you need to take into account such a nuance that at the moment when air does not enter, the holes must be in the closed position, otherwise silt particles may enter the device.

Types of aerators

Aerator device diagram

If you have determined that it is urgent to save the living creatures in your pond, then special devices will come to the rescue that allow you to do this - aerators. They are divided into two large groups:

The first are mounted and used constantly. The second option can be applied to several reservoirs. Aerators are also distinguished by location methods.

Aerator-geyser

Surface. These include units that move freely on the surface of the water. Their principle of action can be gushing. The pump draws water into itself and throws it out in the form of a geyser above the surface. Water, being in the air, is saturated with oxygen, ionized. When the water flows back into the pond, it transfers air to the inhabitants of the pond. In other embodiments, an ejector aeration method is used. The design of such a device can be provided with an engine with blades, which, hitting the surface with great force and speed, lead to the formation of air bubbles and mixing of the layers. In other cases, a pump is used that sucks water into itself, mixes it with air and returns it to the reservoir.

Donny

Bottom or coastal. This type is the most efficient. The principle of its operation is reduced to the fact that there is a compressor on the shore near the reservoir. Its purpose is to supply air through pipes to special diffusers that are mounted in several places at the bottom of the pond.The bubbles, passing through the space, saturate the entire water column with oxygen, the layers are also mixed and the sludge rises for further filtration. In order to prevent the backflow of liquid and its entry into the electrical appliance, a valve is installed.

Combined

Combined. They are often referred to as superficial. Here, as in the previous version, there is a compressor unit, which is located on the shore, it supplies compressed air, which is dispersed into the upper layers of water through a floating head. In another option, a pump is installed. Through the moving module, water is taken in, it mixes with air and is fed back from the shore in the form of a fountain or waterfall.

Wind

Wind aerators. They are a floating or supported structure. The wind drives the blades, which transmit the moment of rotation to the underwater part, it creates a current, as a result of which air bubbles form on the surface.

Video

The following video shows how to assemble an ejector aerator from improvised means:

https://youtube.com/watch?v=zajecdTrEdg

How to assemble a windmill for a wind aerator, see below:

The popularity of artificial ponds has never faded. Now such reservoirs have reached a new level, they can be found in many private properties. Sizes can be very diverse, depending on the purpose of their creation. For the normal functioning of reservoirs, it is necessary to take care of creating an aerator for the pond with your own hands, which is quite possible so as not to spend money on ready-made models.

What are aerators for?

First of all, they provide purification and simultaneous saturation of water with oxygen, and this, in turn, prevents water from stagnating. In addition, without purification, the water will bloom, and the smell from it will become unbearable.

sewer aerator

Types and arrangement of aerators

The tubular device has positive qualities:

- are flexible;

- long service life;

- the minimum likelihood that the holes may become clogged;

- it has a function of maintaining the supplied pressure;

- evenly distributes oxygen throughout the environment;

The material is mold resistant.

The disk model is no less convenient to use.

Disk device properties:

- very durable and reliable;

- does not have a connection, i.e. it has structural integrity;

- simple installation;

- resistant to corrosion formations;

- has maintainability;

- there is no risk that water or dirt can get into the device;

- a slight decrease in pressure;

- it can be used in high performance systems.

Making an aerator with your own hands

You can modify a conventional septic tank, manufacture and install an aerator installation with your own hands. It will not be difficult and even an inexperienced master can do it. Moreover, there are a lot of instructional videos on the Internet.

The principle of manufacturing a tubular aerator

The principle of manufacturing a tubular aerator:

- The base is taken. For this, a one or two meter pipe fifty centimeters in diameter is suitable, depending on the volume of the container;

- A plug is placed on one pipe end;

- The other side is supplied with a branch pipe for connecting the pipe and the compressor hose;

- From 200 to four hundred holes are drilled in the pipe, always with the same size and equally spaced around the entire perimeter. This is necessary to ensure proper air exchange.

- The aerator is installed in the 2nd chamber of the sump, where the sewage already cleared of large masses of sewage, which settle at the bottom of the primary compartment, enters.

Is it even worth doing this modification? What gives this aeration?

The installation of an aerator, firstly, significantly reduces the time of wastewater processing and improves the quality of treatment.

Summing up, we get that thanks to the aerator system in the sump, the environment is saturated with oxygen, which contributes to the favorable existence of aerobic bacteria. The improvement of the septic tank with this installation and compressor significantly increases the efficiency of the cleaning device and eliminates unpleasant odors.

Features of installing an aerator

First, let's decide on constructive solutions. Aerators can be point and continuous. The first are located over the entire surface of the roof, they provide ventilation for individual sections of the roof. Installation of the second aerators on a soft roof is carried out along its entire length, so that it is possible to ventilate the entire roof.

Point devices are made in two versions:

- Pitched installed on a solid surface of the roof. Places for their location are chosen where it is necessary to increase the movement of air. Particular attention is required to individual components of complex roofs: valleys, skylights, lanterns, ridges. In these areas, it makes sense to install aerators for a soft or other roof on both sides of the obstacle.

- Skate shoes are mounted on a skate. The mass of warm moist air, as a rule, rises from the inside of the premises and goes out through the ridge structures. At the same time, eaves ventilation ducts supply portions of fresh air from outside. Thus, the air mass is renewed. Ridge aerators for soft roofs contribute to the enhancement of these processes, as well as the removal of bituminous fumes from the roofing material.

Installation of aerators can be carried out during the construction of a building, during the replacement of roofing, or as an independent procedure for an existing roof. An aerator for a flat soft roof can be installed independently, but it is better to entrust this matter to specialists. The process itself looks like this:

- First you need to determine the installation location of the deflectors and choose their design.

- In the roofing, a window is cut out 10-20 mm wider than the diameter of the pipe.

- The perimeter of the hole obtained over the entire thickness must be abundantly smeared with bituminous mastic.

- In the same way, the roof aerator pipe for soft roofing should be treated.

- The pipe is inserted into the window, fixed, and then the entire structure is assembled.

Fastening to the main coating is carried out using special roofing fasteners (self-tapping screws, dowels)

Particular attention should be paid to the places where the aerator meets the roof. For a guarantee, it is better to lay an additional layer of waterproofing or roofing material under the aerator skirt

Features of the creation process

Aeration makes it possible to obtain a healthy and attractive vegetative lawn cover. Thanks to him, the number of dry stems is noticeably reduced, and the lawn is covered with moss in a smaller amount. Upon completion of such a procedure, the plantations will be provided with moisture even during the period of drought. And in case of excessive moisture, the water will not stagnate, which will prevent the plants from rotting.

Aeration will be necessary if the soil layer is compacted, due to which the root system does not receive the required amount of oxygen, moisture, and nutrients. Difficult gas exchange is a common cause of liquid stagnation on the surface.Because of this, there is an accumulation of carbon dioxide in the humus, and this leads to oxygen deficiency. He, in turn, is involved in the process of decomposition of organic components and the oxidation of mineral elements. Plant diseases are the result of this process.

https://youtube.com/watch?v=zajecdTrEdg

Aeration is performed in two ways:

- The first involves piercing the soil using metal teeth. This creates the necessary holes through which the air flow into the soil to the roots of the plants is restored.

- In accordance with the second method, aeration is carried out using hollow pins, with the help of which fragments of 1 cm - 2 cm in size are removed from the soil. The second method is considered more effective than the first, because such aerator nozzles make it possible to remove a layer of dried grass from the ground. The timing of aeration is at least 2 times a year. However, the procedure can be carried out more often if the quality of the soil or its condition requires it.

Previously, aeration was carried out with pitchforks and rakes, but today the industrial development of agricultural tools has taken a big step forward. Currently, for this purpose, the market offers special devices - aerators. These devices have their own varieties, differing in several indicators.

Equipment for the procedure

Experts distinguish between devices with a motor and mechanical aerators.

Mechanical structures are divided, in turn, into:

- sandal aerators;

- roller units;

- aerator rakes.

Roller devices are made in the form of a rake, but they are equipped with rollers, which gives additional comfort in the process.

Aerator sandals are distinguished by their shape, which resembles the sole. It is attached to the legs with straps. Its lower part is equipped with protrusions and spikes. Work with such devices should be as follows: sandals should be attached to the leg and just walk on the lawn.

Rotary aerators, which are equipped with a motor, are multifunctional. In addition to piercing the earth and saturating it with oxygen, such devices eliminate heterogeneous debris and dead grass.

There is also a distinction between aerators by engine type. According to this criterion, one can distinguish:

- gasoline;

- electrical devices.

Each of these types has both advantages and disadvantages. The device with an electric motor is characterized by noiselessness during operation and low weight. It is very convenient to work with such an aerator. But at the same time, only small areas can be processed with it, since the device is powered by an electrical network and its movement is limited by a cord.

Water aeration

Water can stagnate in ponds

Under natural conditions, where water bodies flow one into another, water is saturated with oxygen. Continuously spouting springs replenish reservoirs with microelements. But for ponds, forced aeration may be required. This is necessary for a number of reasons:

- Seasonal and daily temperature fluctuations. The warmer the water, the faster the metabolism of the inhabitants of flora and fauna. This leads to more oxygen consumption.

- Too much sludge. This sediment interferes with normal oxygen exchange.

- Excess vegetation. If the pond is not cleaned in time, then the algae occupy a large area and impede free gas exchange.

- Too many inhabitants. The more representatives of the fauna, the more active the vital activity and the more its products stand out.

- Rare precipitation. Rainwater is also a source of minerals and provides an opportunity to increase oxygen levels.

- The need to mix the layers of water so that stagnation does not occur.

- During aeration, the temperature regime is normalized.

The fish may be out of breath.

In order to determine whether the installation of an aerator is really necessary in your case, it is enough to observe a little what is happening in the pond:

- If there is a fish, does it constantly rise to the surface to swallow air?

- Has a film appeared that indicates stagnation?

- Watch the snails. If they move freely on the stones - then everything is fine, if they are all on algae and try to climb as high as possible - there is reason to worry.

We create an aerator for the pond with our own hands

Making an aerator for a pond on your own is not difficult. The main thing is to study the assembly instructions, as well as stock up on the necessary materials. The cost of ready-made installations is not small, but with self-production you can save a lot of money.

For small ponds, it is enough to use an aerator of a simple design, which can be assembled from materials that the summer resident always has at hand.

Assembling the ejector aerator

Materials:

- drainage pump with low power;

- a piece of sewer pipe with a cross section of 32 mm and a length of 2 m;

- branch pipe 40 cm long and 32 mm in cross section;

- tee angle 45º;

- double braided cable.

Note.

Assembly process:

- The sewer tee is attached to the drainage pump using a fitting for connecting pond aerator hoses. To ensure the reliability of the connection, a silicone-based sealant is used.

- On the reverse side, a branch pipe is inserted into the tee, the length of which should be less.

- An angle of 45º is inserted into the upper outlet, then a two-meter pipe is fixed.

- An electrical cable is connected to the aerator. The wire must be sealed with electrical tape, which is wound in several layers, after which it is placed in a corrugation.

- The pump is placed at a depth of 70 - 100 cm of the water surface, and the water intake pipe should be on the surface of the water. In order for you to succeed, make a kind of mast from a steel pipe and fix it at the bottom of the reservoir.

- At the last stage, an aerator is attached to the mast and electric current is supplied.

Assembling the bottom aerator

The cost of assembling an aerator of this type with your own hands is small. To do this, you will need to find a compressor from a car with a receiver.

Materials:

- Compressor;

- High pressure hose;

- collar;

- Tees;

- Nozzles, sprayer.

Note.

Assembly process:

- The compressor is placed near a reservoir or hidden in a nearby outbuilding.

- The central hose is connected to the compressor and stretched to the pond.

- With the help of tees, bends are made depending on the number of nozzles. Staples are used for secure fixation.

- Diffusers are attached to tees and placed at the bottom of the reservoir. To prevent them from rising to the surface, you can put heavy stones on them or fix them at the bottom with pins with curved ends.

Note.

The work of bottom aerators for the pond cannot be continuous, in addition, the unit makes an annoying loud sound. Devices of this type are used to periodically saturate the water in ponds with oxygen.

Assembling a wind aerator for a pond in winter with your own hands

Installations of this type are best suited for operation in the winter season. It is not difficult to assemble it, you will need the most common parts that can be found on the farm.

Materials:

- A piece of square-shaped metal measuring 30 x 30 cm.

- Steel bar with a diameter of 20 mm.

- Sealed bearings, which must correspond to the cross section of the rod.

- Metal strips are 2 mm thick, and the length should be slightly larger than the size of the bearing.

- Plastic barrel.

- Cooling fan.

- Fasteners.

Assembly process:

- Cut out eight pieces of squares from metal and connect them into cubes. A cross member is installed inside each of them, in which a hole is cut out and a bearing is inserted. The central parts of the bearings must be in line.

- A steel bar is placed in bearings.

- A plastic barrel is cut into two parts and blades for a windmill are obtained.

- With the help of metal loops, the blades are fixed at the top of the rod.

- At the bottom of the steel bar, blades are attached, which as a result will be located above the surface of the water.

- The assembly of the mast for the wind-type aerator is carried out at the last stage and after that it is installed in the reservoir.

A floating wind aerator for a pond is created using plastic barrels, bottles or polystyrene attached to the mast.

Now there are more than one or two methods used to purify drinking and domestic water from all kinds of impurities that are contained in the liquid and harm both the person and the equipment of water supply systems.

The simplest scheme of the water aeration process.

Water purification by aeration is the most effective technology of water iron removal today. The essence of this process is the artificial creation of intensive air exchange, as a result of which the water is saturated with oxygen, which leads to purification and normalization of the chemical composition of drinking water.