Boiler installation

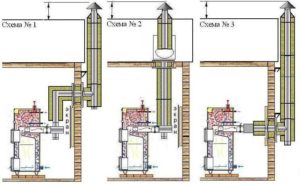

At this stage, you have to take care of the arrangement of the boiler room and the smoke exhaust system.

Arrangement of the boiler room

The floor and walls of the boiler room must be made of non-combustible material. The floor can be made of concrete. If desired, pave it with ceramic tiles.

Install the boiler on a strictly flat surface. Choose a place so that the distance from the front side of the unit to the nearest wall is at least 100 cm. Select the distance from the other walls so that in the future it will be convenient for you to carry out preventive maintenance, maintenance and repair of equipment.

Chimney device

Pay special attention to the arrangement of the smoke exhaust system. Not only the efficiency of the home-made pellet boiler, but also the safety of the residents of the house directly depends on the correctness and quality of the chimney.

Choose the length of the chimney so that it rises at least 50 cm above the roof of the building, preferably more.

For the manufacture of the chimney, use a sealed pipe

It is important that the pipe material does not support combustion and endure high temperatures.

The chimney must be insulated. To protect the pipe from atmospheric precipitation, install a protective cone on it.

Make a hole at the bottom of the chimney to remove condensate. For greater convenience, you can connect a tap to the hole. Also prepare a hole for cleaning the pipe from soot.

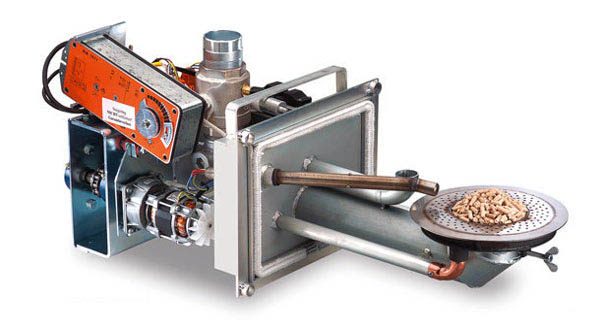

Device

Any burner has one goal - to create a powerful flame to heat the air or water jacket of the boiler. At the same time, the combustion power itself can be adjusted independently.

The pellet burner has similar goals. The device is a wind tunnel into which solid fuel is supplied and combustion air is forced. Fuel is fed into the pipe using a special screw-type conveyor. The fuel itself before burning is in the hopper. The bunker can have a different volume, and it depends on the volume how long the burner can burn on its own without human intervention (fuel addition).

Air is forced into the combustion zone by means of injection by means of a fan.

The combustion chamber in the burner can be round or rectangular. Round burners are the most common due to their ease of manufacture. Outside, a pipe branch pipe is attached to the combustion chamber, through which fuel is supplied from the conveyor.

The design also provides for an ash pan in which combustion wastes accumulate. In the process of burning pellets, a little ash is formed, therefore it is necessary to clean the ash pan no more than once a week with the active use of the burner.

There are several types of pellet burners, each of which has its own advantages and disadvantages.

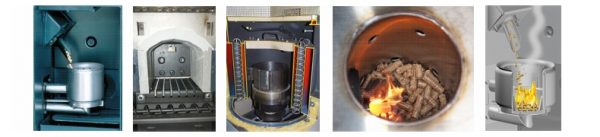

Flare type

Initially, the device was used to generate heat by burning grain, later it was converted to burn solid compressed fuel.

- Small overall dimensions;

- Can be used in conjunction with boilers in which the combustion chamber is small;

- Simplified operation;

- Increased reliability;

- Poor quality pellets can be burned.

- Low power compared to other burners;

- The flame is directed horizontally, due to which it heats the boiler locally.

Bulk type

Unlike the previous model, they have increased power and high efficiency. The disadvantages of the device include a complicated design, large overall dimensions, dependence on the quality of the pellets used.

Such designs are mainly used in domestic conditions, installed in fireplaces and boilers. The principle of operation of the device is as follows: pellets fall into a special bowl, where they are burned under the action of air supplied from below.

The disadvantages of the model include the size of the device and the need for point adjustment for proper combustion.

Principle of operation

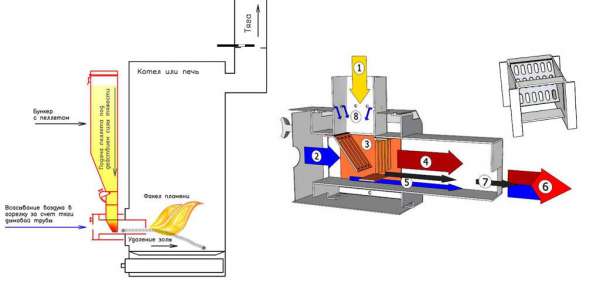

The principle of operation of the pellet boiler (click to enlarge)

However, it is seriously competing with alternative heat sources, among which a pellet boiler for home heating is the most profitable solution. There are no fundamental differences at first glance. In the heat exchanger, which is built into the combustion chamber, water is heated, which heats the house.

Why do the most productive gas boilers, made using innovative technologies, lose economically to self-made counterparts that work on pellets? The answer is simple, the cost of 1 kW of energy when burning gas will be higher than the same amount of heat when using alternative fuels.

The raw material for pellets is wood waste, the cost of which is minimal, since the issue of their disposal is very acute and the production of fuel pellets is one of the ways to get rid of unwanted products of the main activity. Pellets can be made with your own hands, but this will require special equipment.

About the pellet burner

Pellet burner is a special heating device that generates heat by burning pellets or fuel pellets in a boiler. In some cases, these burners use waste dry grain.

There are manual and automatic burners, in automatic burners, fuel is fed into the combustion hopper using a special auger, and the whole process is controlled by sensors, due to which the device needs minimal control from the user. Pellet burners have found their application not only in everyday life, but also in industry. They are used for space heating, water heating and a number of other needs.

Pellets, or fuel pellets, are a special solid fuel that is obtained from wood waste or agricultural production by pressing and granulating under high temperatures.

In countries where agriculture and the woodworking industry occupy a leading position, the cost of pellet fuel is much lower than that of coal. The only exceptions are those regions in the immediate vicinity of which coal mining enterprises are located.

When burning pellets, dangerous fumes are not emitted, as is the case when burning liquid fuels.

Production of a pellet burner

Pellet plants are often ignored by buyers due to their high cost compared to gas and electric equipment, and the problem is solved by making the device at home.

General scheme for self-production of a pellet burner

The combustion chamber can be equipped with a square or round pipe. It is better to give preference to heat-resistant steel that can withstand elevated temperatures, the wall thickness should be at least 4 mm.

The self-made installation is fastened to the boiler with a flange plate made of heat-resistant steel with a thickness of 3 mm or more.

A container for supplying fuel to the combustion chamber can be purchased or made by hand. The best option is to immediately make an installation in which fuel will be supplied automatically. To do this, we place an auger in the purchased pipe of the desired diameter. The rotation of the device will be carried out due to the bearing, gearbox and engine running at low speeds.

Additionally, a fan is purchased in the store, which will pump air. The fan is mounted on a plate, which is made depending on the size and design of the door of the boiler used in your home.

It is also important to take care of adjusting the amount of incoming fuel and the volume of air blown by the fan, otherwise the home-made device will work unstably. In home devices, the adjustment of the air supply force and the number of pellets is done manually

This method is inconvenient due to the fact that it requires constant supervision of the burner.

For automation, an electric incandescent element and a photo sensor are purchased. The first device ignites the flame in case the pellets are extinguished and also regulates the activation of the device. The photo sensor monitors the appearance of the flame: if the flame is stable, the sensor sends a signal to the incandescent element to stop ignition.

To automate the system, a filling sensor is also purchased. It will notify the electronic filling of the device about the degree of filling of the combustion chamber with pellets.

Pellet burners are modern equipment for boilers that improve the environmental friendliness of the process and reduce fuel costs. At the same time, the equipment itself in the store has a high cost. For basic household needs, it is better to give preference to home-made devices, the operation of which, if necessary, can be automated.

Minimizing the cost of maintaining housing today is one of the most important tasks. The search for cost optimization tools is ongoing. Heating at home, with regularly rising tariffs, is a significant item in the family budget.

You can reduce it in several ways. With the help of energy-saving technologies in the construction of a house and the use of efficient heating systems. A pellet boiler is more economical than gas-fired counterparts, not to mention electricity and other energy sources. The reason lies in the low cost of consumables and the high energy efficiency of the device.

We make ourselves

Having decided to do everything with your own hands, you should first develop a project. Guided by the drawings, you should purchase everything you need, as well as prepare a tool.

What will be required?

The most complex elements are best purchased already assembled. So, a factory-assembled pellet burner is always preferable to a self-assembled one. The same applies to sensors and programmers, a fan, an electric motor for a screw, a grate, two oven doors, if they are not planned to be manufactured independently. You will also need:

- steel sheet 3mm and 6mm thick;

- steel square and round pipes (wall thickness 4 mm);

- sheet asbestos and in the form of a sealing cord;

- fireclay brick for the combustion chamber;

- round bar (20 mm);

- electrodes.

To perform the work, it is necessary to prepare a grinder, a welding machine, a ruler, a drill.

Pellet feeding unit

We cook the bunker for pellets. We connect it to the auger shaft. The latter may be in the form of a pipe. If a dispenser for fuel supply is provided, we install it at the entrance to the screw shaft and connect it to the electric motor.

heat exchanger

Square pipes are used as front pipes, round pipes are used as connecting pipes. In the front, round holes are cut for the supply and removal of the coolant.

The spatial arrangement of the connecting pipes at the time of their welding is carefully controlled. After completion of welding work, the tightness of the seams should be checked by filling the heat exchanger with water.

Case manufacturing and assembly

The body is made of sheet steel 6 mm thick. We provide two doors for the subsequent maintenance of the equipment, located in the front and rear. We lay fireclay bricks inside the chamber.

We place the heat exchanger inside the housing, providing a small gap between the outer surface of the first and the inner surface of the second. Install the fan at the top of the case.

In many regions, the problem of heating private houses is still relevant. Of course, on the modern market there is a huge range of equipment that uses a wide variety of materials as fuel, be it gas, wood, electricity or oil, etc. However, access to gas pipelines and stable power grids is far from being everywhere, so solid fuel heating remains the most preferable in many regions.

One of the best options for a solid fuel heating unit is a pellet boiler, which you can assemble with your own hands.

Contents of step by step instructions:

Advantages and disadvantages

The equipment has several advantages:

- Pellets are a safe fuel compared to gas and electricity;

- Allows you to significantly reduce the cost of space heating compared to using electric boilers. At the same time, pellet plants are more expensive than gas equipment, but do not forget that it is not always possible to conduct gas and purchase gas cylinders;

- Home-made installations guarantee high efficiency - 95%. Some store installations have over 97%;

- They are used not only for heating the room, but also for obtaining hot water;

- There are no regulations for the transport and storage of fuel. Being close to a person, pellets do not cause allergic reactions, and there are no toxic fumes during combustion;

- Fuel is available for purchase. Equipment owners complained about the lack of fuel and the need to prepare a supply of pellets from the winter when devices appeared, now there is no need to store a large amount of pellets at home, they can be bought everywhere if necessary;

- The price of pellets is on average at the same level, unlike gas and electricity, the tariffs for which periodically experience seasonal fluctuations;

- Installation of the device does not require special skills, and it is not necessary to coordinate the installation with the authorized bodies;

- After the combustion of pellets, natural mineral ash is formed, which does not require special rules for disposal.

Along with the advantages of such equipment, there are a number of disadvantages:

- The high cost of finished store equipment. Despite the popularization of devices in recent years and some price reductions, pellet boilers are still more expensive than gas or electric equipment of similar power;

- The equipment needs constant care (especially outdated models). The user will have to clean the ash pan and heat exchanger from the accumulated ash once a week.In modern models, cleaning is provided at the automatic level;

- In the absence of automatic fuel supply, the user has to load the pellets into the bunker manually;

- It is necessary to ensure minimum humidity conditions in the premises where the pellets will be stored while waiting for use;

- Imported equipment is practically not designed for the conditions of a harsh domestic winter, as a result of which breakdowns and malfunctions often occur;

- In remote areas, fuel for the winter still has to be stored due to unstable supplies.

Starting up and maintaining the boiler

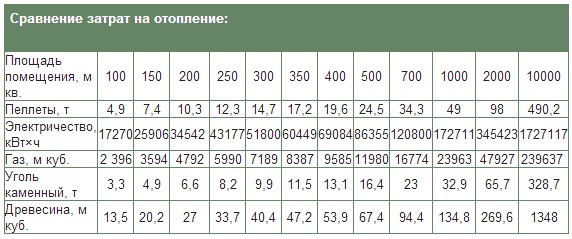

Comparison of heating costs

The equipment can only be started after the pellet boiler has been installed and the appropriate pipes of the heating system have been connected to it. After the above tasks are completed, turn on the cold water supply to the heating system.

Watch the boiler work. If you have any kind of unusual symptoms, turn off the equipment and stop using it until troubleshooting.

Watch the boiler work

Homemade pellet boilers, as well as any other heating units, need appropriate care.

Empty the ash pan every 2-3 weeks. Clean the flue duct every 2-4 weeks. This will not take you long, but ignoring such simple maintenance will significantly reduce the efficiency of the boiler and make the equipment potentially unsafe.

If desired, additional automation equipment can be connected to the pellet boiler. This will make the operation of the equipment more convenient - you can simply forget about the need to reload fuel and other related activities for a while.

Modern automation tools even allow you to establish remote control of the heating unit, which is also very convenient.

And these are not the only possible additions. How do you, for example, self-cleaning systems for boilers? Be sure to study the available modifications and, if desired, buy such additions for your boiler.

Boiler with pellet hopper

You can assemble a simple pellet boiler with your own hands, following the instructions received earlier.

Video - The principle of operation of a pellet boiler

The unique smell of natural wood, a clean and decorated room in a modern style - this is what a boiler room in a house can look like if you choose the right equipment. Innovative heat-generating equipment that will create the described conditions in the room is a pellet boiler or an automatic pellet burner operating on special fuel pellets, which are created from agro-industrial or woodworking waste.

If a few years ago pellet plants were used only in 20% of houses in Europe, then at the moment the figure has increased to 70%. The use of pellet boilers and burners is the most beneficial option for residential heating from an environmental and economic point of view. Today we will talk about the principles of operation of the equipment, its advantages and disadvantages, and also consider the scheme for making a pellet burner with our own hands.

Instructions for installing a pellet boiler

The main and important stage in the installation is a professionally executed design. It is followed by the following steps for installing heating equipment:

- Preparatory stage. Includes the preparation of the boiler room, the erection of a hill for the boiler, the installation of a chimney, ventilation;

- Installation of the heating unit on a hill;

- Connection to the boiler pipes of the heating system and hot water supply;

- Connection of the chimney channel;

- Adjustment and start-up of the heating device.

Preparatory work

It is necessary to prepare the boiler room - level and strengthen the base, which must withstand weight up to 200 kilograms. According to the requirements, the boiler is installed vertically, so there should not be any slope. The base must have a fireproof surface.

Laying electrical wiring is needed to automate the heater and to illuminate the boiler room, which will ensure convenience during operation. The construction of a chimney of the sandwich type, at least 5 meters high. A chimney and ventilation are also installed.

Boiler installation and piping

- The brought boiler is mounted on the podium;

- A fuel compartment and an auger supplying pellets are mounted;

- The distribution comb is connected;

- An expansion tank and shutoff valves are being installed;

- The boiler is connected to the circuit supplying the coolant and the return circuit.

Chimney connection, start-up and adjustment

The appropriate diameter will provide good traction regardless of wind strength and air temperature. Good traction is the key to the efficient operation of pellet equipment. But this type of boiler is afraid of strong traction, but too small will not work either. Therefore, to solve this problem, a thrust stabilizer or a slide gate is used.

Most often, the chimney is made of a metal pipe, in which hatches are built for further cleaning. Also, the chimney should be equipped with a device for removing condensate and insulating it. An important step is pressure testing, if it is done poorly, pyrolysis gases will leak, which will lead to a decrease in efficiency.

After that, a test run and adjustment are carried out. An improperly tuned device will entail such problems: the boiler will smoke, smoke, go out and the pellets will not burn out to the end.

Boiler Assembly Manual

Pellet boilers have a fairly complex design. The instructions for assembling them will also be difficult and multi-stage. For greater convenience, the assembly process of each main unit is considered separately. Buy or make the necessary elements, and then simply assemble them into a single system.

This element of the pellet boiler is highly recommended to buy ready-made. It is on the burner that you will spend the most money.

Self-manufacturing of the burner is almost impossible for the reason that this part of the boiler is not just a container for igniting loaded pellets, but a complex control and regulation mechanism.

Pellet burners are equipped with special sensors and have several pre-installed programs that allow you to achieve the most rational fuel consumption and provide the most efficient home heating.

Housing and heat exchanger

You can handle the assembly of the case and the manufacture of the heat exchanger yourself. The boiler body is best done horizontally - with this placement of the unit, maximum heating efficiency is achieved.

For the manufacture of the case, it is recommended to use fireclay bricks. You simply assemble a kind of box without a top cover and place a heat exchanger in it with connected pipes and other elements. Brick is recommended for the reason that it accumulates heat much more efficiently than cast iron, steel sheets and other popular materials.

The pellet boiler heat exchanger is a system of pipes interconnected and connected to the heat supply pipes of a private house.

First step. Assemble a rectangular heat exchanger from square pipes. To do this, cut the pipes into pieces of the desired length and weld them into a single structure.

Second step. Make holes in the profile that acts as a vertical rack for connecting round pipes.

Third step. Prepare holes in the remaining front pipes for the water outlet and connection pipes. Hot water will be discharged through the top hole, cold water will be supplied from the bottom.

Use metal pipes with a length of 150 mm or more. Further it will be possible to use polypropylene pipes. In places where pipes are connected to the boiler, be sure to install ball valves. Additionally, you can set filters if you need them.

Fourth step. Weld the back of the unit to its front and weld the side pipes.

At the same stage, choose a convenient place for connecting a chimney pipe with a diameter of 10 cm. At the bottom of the heating unit, provide a small chamber for collecting ash. Also, the design of the pellet boiler necessarily includes a firebox. About him further.

In the firebox, as already noted, pellets are stored and from here they are fed into the burner.

First step. Prepare the necessary materials and fixtures. You will need an auger with a diameter of 7.5 or 10 cm, an electric motor and a metal casing. You will connect the engine to the pellet burner control unit.

The function of a metal casing can be performed by any container of a suitable volume with sufficiently thick walls.

Second step. Install the inlet of your auger into the outlet of the casing. Connect a corrugated plastic pipe to the other part of the auger to supply granular fuel to the burner.

In conclusion, you just have to assemble all the listed elements into a single design. Do this and proceed to the installation of the boiler.

Principle of operation

All pellet plants that can be purchased at the store are equipped with additional units:

- Auger - supplies fuel from the bunker to the combustion chamber;

- Controllers for automating the work process;

- Bunker - a place in which the fuel is located before being fed into the combustion chamber;

- Lambda probe is a special sensor that monitors the oxygen content in the smoke chambers and independently controls the fuel combustion process depending on the conditions.

The pellet burner must be protected with a plastic corrugated pipe. It acts as a fuse in the event of reverse thrust. If the fire starts moving towards the bunker, the pipe will burn out, preventing the flame from spreading.

Additionally, a fan is used, which enhances the combustion of pellets by forcing air, as well as a thermoelectric heater, which allows you to ignite the fuel without human intervention.

In automated devices, pellets are fed into the combustion chamber automatically; a person only needs to monitor the amount of fuel in the bunker. The need to supply fuel to the combustion chamber is determined using temperature sensors (they can monitor the air temperature in the room, the water temperature, or any other environmental indicators, depending on the operating mode of the equipment).

The desired temperature of the heat carrier is set by the user, all further increases and decreases are controlled using automated equipment. As soon as the temperature reaches the set level, the burner starts to work in standby mode (the pellets do not go out, they start to smolder). If the temperature, on the contrary, has dropped, the controller activates the built-in fan. Under the action of air, the pellets flare up, the burner goes into operating mode.If during the downtime the pellets go out for any reason, the heating element is activated, which re-ignites.

Device

The device of a pellet boiler with the designation of the most important elements and assemblies (click to enlarge)

In addition to the pellet burner for the boiler, which is almost impossible to make at home, all other structural elements will have to be done independently. It will take a lot of work to achieve the desired result.

Having experience in such work, assembling a heat exchanger and laying out a combustion chamber from fireclay bricks is quite feasible work. The installation of the burner can also be dealt with, but the fuel supply system will have to work hard. This most important node in each case is exclusive. It is necessary to ensure uninterrupted and reliable supply of fuel pellets to the burner (read about boilers with automatic fuel supply here).

The density of pellets is high, and a large number of them cannot burn at the same time.

It is almost impossible to ensure the correct mode with manual control, unless you are constantly nearby. Therefore, the device is equipped with automatic systems, and they cost a lot.

This is a factor in the high cost of the entire structure. One or more programmers cope with the task without outside interference. Even a small fuel bunker is able to heat a house offline for up to three days. If you assemble a more solid structure with a large supply of pellets, then the period of use can be increased significantly.

Additional costs will also be incurred for the purchase of an engine for the screw mechanism and its automatic connection. Before assembling a pellet boiler with your own hands, you need to draw up drawings of the future boiler, calculate its dimensions depending on the area of \u200b\u200bthe available space for its installation.

The main part of the pellet boiler is the burner

Similar to factory models, the focus is on assembling the body and fitting all the components. Assembly kit includes:

- Sheet steel 4-6 mm for the manufacture of the boiler body.

- Bunker material. It can be made from sheet metal (1-2 mm thick will be enough), plywood, wood.

- Screw. It is selected according to size or, with existing skills, it is done independently.

- Chimney pipes. Metal or asbestos and mounting kit.

- Control system. Provides automatic control over the operation of the boiler.

- Engine for the operation of the screw mechanism.

- Pipes for heat exchanger. Square sections are recommended.

- Pipes and fittings for connecting the heating system.

- Chamotte brick, if the combustion chamber is made stationary.

- Grate. It will provide air access to the place of combustion.