Advantages and disadvantages of boilers Kiturami

The products of the South Korean concern Kiturami are distinguished by:

- high quality;

- modern design;

- functionality;

- acceptable prices.

, which act as the controller of all important processes. They are manufactured using a unique technology for the removal of combustion products.

The Turbo series includes floor-standing diesel heating boilers that cope with two tasks at once, namely, they heat the room and heat water for household needs. At the same time, the owners no need to purchase the necessary equipment

, because this device has a boiler-type system. The undoubted advantages include a high level of protection, it is achieved by working:

- sensors;

- control panel;

- thermostat;

- exhaust gas systems.

The advantages of all equipment of the Kiturami concern is its stability of operation under various operating conditions. This quality is especially pleasant for the domestic consumer. Since Kiturami has many dealerships, it is not difficult to get the failed parts of the Kiturami diesel boiler.

Kiturami diesel boilers have a number of advantages over similar products from other manufacturers. Data on the consumption of diesel raw materials devices have high efficiency indicators

- per minute, with an average performance, the device creates 20 liters of hot water.

But Kiturami's biggest win is the comparatively low price market. A kiturami diesel boiler will cost 20 - 30 thousand rubles. In addition, the range of diesel equipment is quite wide, due to which the demand for it is high both among owners of private houses and industrialists.

The single-circuit diesel boiler Kiturami (kiturami) is the heating equipment of the South Chinese concern, which has been producing such equipment for half a century. The company is constantly improving its models, and also guarantees users their high quality. The manufacturer's liquid fuel boilers have repeatedly received prizes, awards and diplomas for reliability and safety.

The equipment is manufactured in two types: Turbo and KSO. Turbo series units are used for domestic needs. They are classified according to the amount of heat generated. Boilers of the KSO series have a design similar to gas appliances. However, when replacing the burner and electronic equipment, they can work using other types of fuel. These models of boilers are equipped with a turbocyclone burner, which ensures high efficiency, since the fuel is completely burned in them. Diesel boilers "Kiturami" are distinguished by their simplicity of design, so they are convenient to operate and maintain. The units are easy to install and come with a remote control panel. In addition, the price of these heating devices is quite democratic.

Features of Kiturami boilers:

- High quality.

- Functionality.

- Light weight.

- Compact dimensions.

- Strength and durability.

- Attractive design.

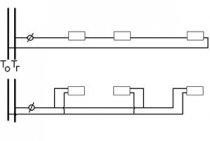

Kiturami single-circuit diesel boilers are equipped with only one water heating circuit, consisting of one to three heat exchangers, each of which is filled with water and heats it. Such boilers can also provide a household with hot water, but with an indirect heating boiler. For double-circuit models of boilers, the installation of such a boiler is not required.

Presentation of Kiturami products (Kiturami):

Even at the heating design stage in the house, one has to operate with the generalized technical characteristics of the boiler, but in the end it is still necessary to go to the store and choose a very specific model from the huge range on the market.

It will be useful to find out in more detail what the Kiturami diesel boiler is, what models are in the line, and how they can be better than other offers on the market.

Specifications

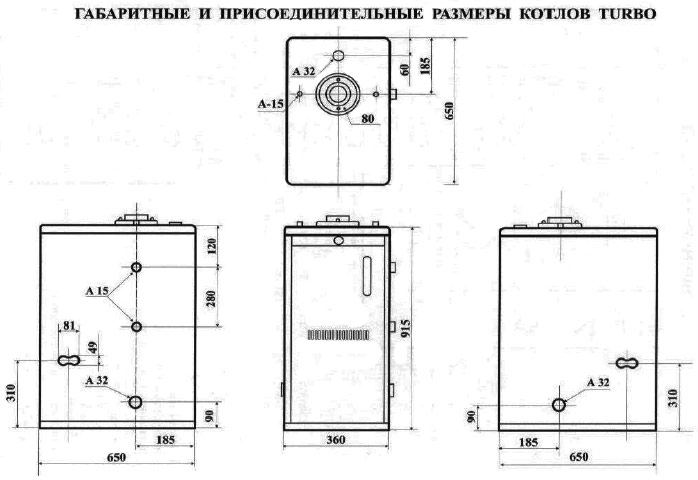

The operational characteristics, dimensions and parameters of the Turbo series boilers are presented in the table below. It is clearly seen that a series of floor standing diesel boilers covers a power range from 10 to 35 kW, which is quite enough for heating houses up to 250-275 square meters. Part of the heat will go to the preparation of hot water, which must be taken into account in the calculations.

All Kuturami boilers are double-circuit and heat exchangers, by the way, are ideally designed specifically for these tasks.

| Boiler model | Unit ism | TURBO-9R | TURBO-13R | TURBO-17R | TURBO-21R | TURBO-30R | |

| Power | kcal/hour | 9000 | 13000 | 17000 | 21000 | 30000 | |

| Power | kW | 10,5 | 15,1 | 19,8 | 24,4 | 34,9 | |

| Fuel consumption | liter/hour | 1,13÷1,5 | 1,6÷1,97 | 1,87÷2,15 | 2,28÷2,80 | 3,75÷4,30 | |

| efficiency | % | 92 | 92 | 92.2 | 92.4 | 91.8 | |

| DHW consumption | ∆t=25ºC | 6,0 | 9,7 | 11,3 | 14,0 | 23,3 | |

| ∆t=40ºC | 3,8 | 6,1 | 7,1 | 8,7 | 14,6 | ||

| Heating supply and return | mm | 25 | 25 | 25 | 25 | 25 | |

| Hot water inlet/outlet | mm | 15 | 15 | 15 | 15 | 15 | |

| Chimney diameter | mm | 80 | |||||

| Power supply | V/Hz | 220/50(60) | |||||

| Power consumption | Tue | 80 | 160 | ||||

| External size | w×d×h | 325×600×835 | 365×650×930 | ||||

| Weight | kg | 60 | 79 | 85 | 85 | 85 |

Fuel consumption

Fuel consumption is specified in the table with technical requirements. However, please note that the actual flow rate depends on individual settings. Under the actual power required for heating the house, the appropriate nozzle is selected from the set proposed by the manufacturer.

The thermal power, fuel consumption and fuel combustion mode are set. The parameter indicated in the table displays factory presets sufficient to ensure proper performance if only high-quality fuel is used, more often it means diesel fuel already with winter additives that do not allow it to thicken or stand out paraffin in excess.

In a real situation, for a boiler model with a power of up to 15 kW, one can expect fuel consumption at the level of 8 liters per day

taking into account the frequency of the burner and the optimal temperature in the house. However, this is not the limit.

The right approach to choosing the heating mode, as well as installing a controller with a variable temperature regime, for example, depending on the time of day and day of the week, can reduce consumption even more.

Chimney

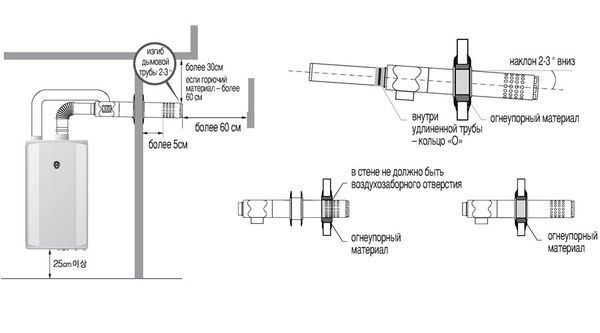

Boilers Kuturami, gas, diesel, floor or wall-mounted, for the most part, are equipped with a closed combustion chamber and, accordingly, a forced exhaust gas system. The Turbo series, which we are currently reviewing, is no exception.

The chimney for boilers is used coaxial for the simultaneous supply of fresh air from the street and the removal of exhaust gases. Since the exhaust temperature after passing through the heat exchangers is no longer high, the requirements for the heat resistance of the chimney are reduced, and the list of acceptable materials is expanding.

In the best case, a steel coaxial chimney is still used, however, a ceramic vertical chimney with a group of internal separate channels for air supply, exhaust gases from the combustion chamber and ventilation of the boiler room can be effectively used in the same capacity.

The size of the chimney is strictly specified in the boiler specification and operating instructions. For the entire Turbo series, this is 80 mm.

It is possible, if desired, to make a chimney of a slightly larger diameter, but not more than 50% in excess of the specified value, that is, up to 120 mm.

In no case can the size and cross section be reduced.

Even though the removal of combustion products is forced, the resistance of the chimney will greatly affect the combustion mode and the quality of the fuel burnout.

Equipment information Diesel boilers Kiturami TURBO-13R

Outdoor diesel boiler Kiturami Turbo-13R. Power 15 kW

Diesel boilers Kiturami TURBO R are small-sized floor-standing diesel-fueled boilers designed for heating and hot water supply of residential and industrial premises. The Kiturami TURBO R heat exchanger is made of special high-alloy steel, which surpasses other types in its properties and quality. Any type of coolant can be used in the heat exchanger, both water and antifreeze. The power of Kiturami TURBO R boilers is from 9 kW to 35 kW.

Technical features:

- The DHW circuit is made of 99% copper, which provides a higher efficiency of the hot water preparation process

- The turbocyclone burner installed on this heating boiler allows to achieve the highest efficiency of fuel consumption due to the aerodynamic flow in the combustion zone

- Sensors for monitoring temperature, overheating, lack of coolant provide an optimal control system

- The self-diagnosis system displays all information about the operation of the boiler and about malfunctions on the display of the room thermostat

- All boiler control functions are set from the control panel, which can be installed in any convenient place

- Possibility of degree-by-degree adjustment of hot water temperature in the range from 41 °С to 75 °С

- The effect of turbocharging contributes to the forced removal of exhaust gases into the chimney, which eliminates dependence on the presence of draft and on the size of the chimney

Contents of delivery

Basic equipment:

- Heating boiler Kiturami TURBO

- Diesel burner

- Boiler control unit

- Fuel filter

- Room thermostat CTR 5000

- The passport

Technical certificate

User manual

Certificate of conformity

Buy with this product

Product code: 70690

Metal-plastic pipes Stout metal-plastic in the bay diameter 16 mm

65

Buy

Buy

in 1 click

Available >10 000 m

-25%

Product code: 112730

Circulation pumps Pumpman GRS 25/6

3 790

2 843

Buy

Buy

in 1 click

Available 16 pcs

Number of discounted items 16 pcs !

Safety, convenience and satisfaction of all customer needs has been the main goal of KITURAMI for 40 years

To increase the efficiency of boilers Kiturami (KITURAMI) TURBO, the design of multiple passage of combustion products inside the heat exchanger is used.

The KITURAMI TURBO boiler has the "Absence", "Shower", "Sleep" functions, which can significantly reduce fuel consumption. As well as the presence of safety devices such as a low water level sensor, overheating and other devices will ensure complete safety when using the boiler.

The design of multiple passage of combustion products inside the heat exchanger increases efficiency, and also reduces the level of acoustic noise.

Thanks to the stainless steel DHW heat exchanger, scale formation is prevented and clean hot water is provided.

The turbocyclone burner achieves the highest efficiency of fuel combustion due to a special plate (FCH₂) heated up to 800°C, thus reducing fuel consumption.

The capacitive heat exchanger of the heating circuit of the Kiturami TURBO boiler allows you to almost instantly get hot water from the DHW circuit.

The Kiturami (KITURAMI) TURBO boiler does not require a lot of space for its installation, and is also easy to carry.

|

Model of boilers Kiturami (Kiturami) Turbo |

13R |

17R |

21R |

30R |

||

|

Heating capacity/DHW |

||||||

|

Average consumption of diesel fuel for the heating season |

||||||

|

Hot water capacity |

dT=25°C |

|||||

|

dT=40°C |

||||||

|

Heat exchanger area |

||||||

|

Heat exchanger capacity |

||||||

|

Pipe diameter |

heating input/output |

|||||

|

DHW inlet/outlet |

||||||

|

chimney |

||||||

|

Width |

||||||

|

Length |

||||||

|

Height |

||||||

|

Weight |

||||||

|

Consumed e. energy |

Combining simplicity of design with high quality workmanship and low price, Turbo diesel boilers are the undisputed leader in their class of boiler equipment. And the use of a turbocyclone burner makes it possible to achieve complete combustion of fuel and high efficiency of the boiler. The boiler works in conjunction with a circulation (incentive) pump; this allows a high heat transfer rate and maximum fuel combustion efficiency to be achieved.Turbo boilers are designed for heating and hot water supply. The maximum working pressure in the heating circuit is 2 kg / cm, in the hot water circuit - 3.5 kg / cm. All models have successfully passed certification tests, comply with GOST 20548-87, GOST 27824-88 and have permission from Gostekhnadzor to use this equipment on the territory of the Russian Federation. To ensure safety and determine the operation parameters of Turbo boilers, various sensors are used: coolant level in the coolant temperature heat exchanger; coolant overheating; control of the presence of a flame; the temperature of the heated air in the room; seismicity. Design features of boilers Turbo: heat exchanger made of special high-quality steel; turbocyclone burner; fuel filter; fuel pump; electronic control unit CTX-1500G; thermostat-regulator CTR-5000.

Diesel boilers Kiturami TURBO are double-circuit boilers for heating systems with a diesel burner, floor-mounted, the best option for space heating and hot water supply. The Kiturami turbo heat exchanger is made of high-alloy steel, which is superior in its properties and quality to other materials. Both water and antifreeze are used as a heat carrier. The copper heat exchanger of the DHW circuit ensures high hot water performance.

The main advantages of Kiturami TURBO boilers:

- Profitability - the diesel boiler Kiturami TURBO is one of the most economical boilers on the Russian market. The turbocyclone burner makes it possible to ensure the efficiency of fuel consumption due to the aerodynamic flow in the combustion zone.

- Safety and reliability - the boiler is equipped with sensors for monitoring temperature, overheating, lack of coolant.

- The self-diagnosis system displays all information about the operation of the boiler and malfunctions on the display of the room thermostat.

- All boiler control functions are set from the control panel, which can be installed in any convenient place. The thermostat built into the remote control allows you to regulate the operation of the boiler according to room temperature and coolant.

- The boilers provide for the possibility of degree-by-degree adjustment of the temperature of hot water in the range from 41 °C to 75 °C.

- The effect of turbocharging contributes to the forced removal of exhaust gases into the chimney, which eliminates dependence on the presence of draft and on the size of the chimney.

- The boiler type of the boiler allows you to generate enough hot water, so the installation of additional equipment is not required for hot water supply.

Power 15.1 kW.

Heating area 150 sq.m. DHW at dT =25 С° 8.4 l/min..

Height 920 mm. Width 360 mm. Depth 640 mm.

Weight 64 kg. D

Chimney 80 mm. ..

Setting

It is better to entrust the initial start-up and configuration of Kiturami boilers to a specialist who can correctly determine the optimal operating mode, select the desired type of nozzle and calibrate fuel consumption depending on its characteristics and even the connection method and location of the fuel tank.

For self-installation, complete with the boiler, a detailed instruction is attached, according to which you can determine the operating mode closest to the design value.

The main thing is to follow the sequence of actions defined in the technical documentation and visual aids for putting the equipment into operation.

It is necessary to adjust and adjust the boiler settings not only at the first start-up, but also during maintenance before each new season and for switching to summer mode, in which only the DHW circuit will be used.

Faults

Kuturami boiler equipment is equipped with a full-fledged self-diagnosis system built on the operation of a number of sensors. The controller is able to evaluate the condition of the equipment as well as the current mode of operation and respond to any deviations or problems that arise during operation.

In any emergency situation, the main action determined by the boiler controller is to stop the burner in order to prevent significant consequences.

A well-developed self-diagnosis algorithm allows you to identify the problem and indicate the error code on the display so that the user can take all the necessary actions to repair and restore performance as quickly as possible.

Among the frequent breakdowns of diesel boilers Kiturami:

- No ignition (error code 01);

- Does not start, no messages on the display.;

- Coolant leakage (depressurization of the heat exchanger or one of the pipeline connections);

- The flame goes out periodically with an emergency stop of the boiler;

- There is no draft, the operation of the boiler is accompanied by the flow of smoke and exhaust into the room.

Error 01 and solution

If error code 01 appears on the boiler display screen, it means that for some reason the fuel did not ignite, there is no torch, the controller forcibly stops the fuel supply, issues an error message, and signals the problem to the user.

Solving the problem requires the exact implementation of a procedure that can identify the source of the problem and eliminate the obstacle in the boiler as efficiently as possible.

Briefly, the procedure looks like this:

Quite often, the fuel-air mixture is supplied under too much pressure into the chamber and therefore does not have time to ignite from the electrode. The problem is solved even at the 5th step of the algorithm by adjusting the air damper, which causes a mixture with a changed concentration to enter the chamber.

Doesn't start

The most unpleasant situation is when the boiler simply does not turn on. There are no signals on the display, and accordingly there is no error code by which it would be possible to determine the malfunction.

In such a situation, it would be adequate to call a service center specialist who will be able to understand the situation and issue the correct verdict, as well as determine the repair procedure. On your own, you can only check the presence of voltage in the network, as well as the fuses in the boiler.

leak

Most often, a leak means that a gasket seal has been damaged in some connection of the pipeline inside the boiler. It is enough to inspect the equipment and determine the place of leakage, replace the gasket.

The heat exchanger in Kiturami boilers is made of alloyed steel and copper, so it does not leak without obvious errors in the selection of the coolant or mechanical damage.

Burner goes out intermittently

The most common cause is a burner setting failure.

It is important to adjust it in terms of power and, using a gas analyzer, determine the optimal air / fuel ratio for proper combustion. Such work cannot be done on your own, so it is better to contact the service center

No draft, smoke and exhaust enters the room

It is most likely that the burner fan is not working for some reason.

It is important first of all to check that the impeller is intact and scrolls normally

It is possible that debris has accumulated inside the fan, or the impeller shaft is jammed. Next, the electrical part and the control unit are checked.

As a small conclusion

When analyzing some models, we found a lot of advantages for boilers of this brand over their competitors, although even here they could not do without drawbacks.

This applies in particular to liquid fuel (diesel) appliances. Each boiler that consumes diesel fuel is necessarily equipped with a special fuel tank, which in most cases has a very significant volume - from 2,000 to 5,000 liters. Boilers are equipped with such tanks, but in the absence of the latter, you will also have to fork out for the purchase of a “tank for diesel fuel”.

To install such a boiler, it is necessary to have a room with excellent ventilation, so that the user does not accidentally get poisoned by fuel combustion waste.In some cases, heat generators even smoke, which is why they need special care. Finally, one should not forget about the cost of diesel heating appliances - it is often higher than that of appliances using other types of fuel (even though Kiturami boilers are cheaper).

Despite all the strengths and weaknesses of such boilers, modern technologies make it possible to significantly increase the safety in the operation of space heating devices. And we all know that safety should come first. Moreover, this equipment can work autonomously, maintain the required temperature for a long time, even if there are no people nearby.

Video - Kiturami Turbo-30R

Assortment of Kiturami

All heating boilers from this Korean manufacturer are divided into three categories, each of which has its own characteristics, strengths and weaknesses. This:

- diesel;

- solid fuel;

- gas heaters.

Let's get acquainted with each of the types.

- Diesel devices, as the name suggests, operate on diesel fuel, which increases the efficiency of heating. The model range of such boilers will be discussed in more detail in the next paragraph.

- Solid fuel appliances are an alternative to the previous option, since they are quite capable of operating on both diesel and solid fuel, which is especially important in conditions of an unstable supply of energy resources. These boilers are made in such a way that after solid fuel is used, they begin to burn diesel itself. All diesel devices are combined into one model range - KRM. There is an automatic control, it is possible to use for domestic hot water purposes.

- Gas appliances use natural gas, which is why they are now very popular. They are floor or wall, for one or two circuits. They are quite convenient to operate, and the savings in their use are obvious.

Even at the heating design stage in the house, one has to operate with the generalized technical characteristics of the boiler, but in the end it is still necessary to go to the store and choose a very specific model from the huge range on the market.

It will be useful to find out in more detail what the Kiturami diesel boiler is, what models are in the line, and how they can be better than other offers on the market.

Diesel boiler Kiturami

To date, Kiturami is already a concern, considered one of the basic South Korean manufacturers of heating equipment. The company developed from a small production, which in 50 years grew into a huge empire.

Such a venerable age allows us to constantly work on improving our products, guaranteeing their highest quality.

Diesel boilers "Kiturami" have repeatedly become winners, were awarded various diplomas for impeccable and reliable technical characteristics. Products of the Kiturami concern has international certificates

, which gives it the right to be present on the markets in many countries of the world.

Maintaining its status as a leader in the production of heating equipment, the Kiturami concern is constantly looking for new forms and content. What types of boilers are included in the Kiturami range?

Types of boilers Kiturami:

- diesel;

- gas;

- bi-fuel.

The KSO series is similar in design to gas appliances. But, if you replace the burner and electronic equipment, they are quite capable of adapting to a different type of fuel.These Kiturami models are equipped with a turbocyclone burner, which results in high efficiency and almost complete combustion of raw materials. Diesel boilers "Kiturami" are endowed with a simple design

, in connection with which the convenience of operation and maintenance increases, while the affordable price attracts more and more new consumers.

However, the most interesting development of the Kiturami concern was a dual-fuel diesel boiler. This type of boiler is ideal for areas with unstable electricity supplies, as it is able to work on both liquid and solid raw materials. At the same time, when wood or coal burns out, the dual-fuel boiler automatically starts burning diesel. Diesel boiler "Kiturami" has a forced circulation system

resulting in maximum efficiency. These designs are made in two versions, which differ in power:

- model KRM-30R;

- model KRM-70R.