copper products

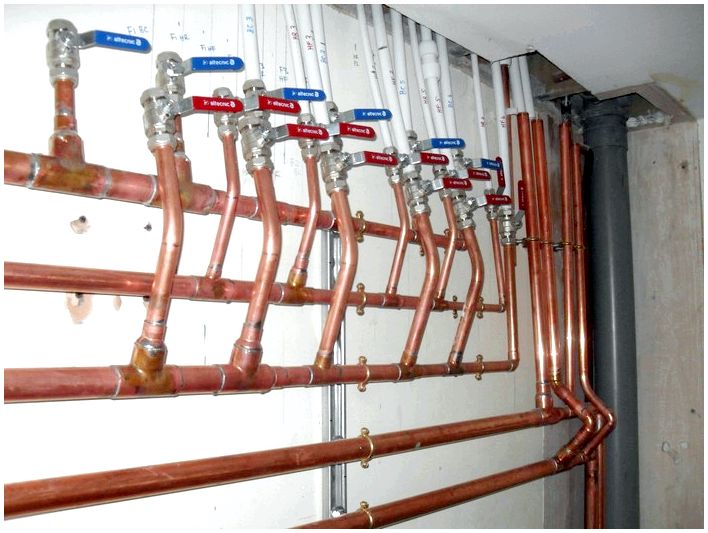

More expensive, but also more durable and safer, will be a steam heating system when using copper pipes. Products have a bright red tint. What can advantageously complement the interior. Over time, the color changes, the surface becomes covered with a patina.

If the highway will distort the overall design of the room, then the pipes can be hidden under the floor. The material is reliable. With proper implementation of installation work, emergencies are extremely rare. What properties does copper have?

The pipeline will last more than 100 years. Copper is resistant to moisture, does not corrode. There is no salt deposit left on the walls, scale.

The material withstands high and low temperatures: range from -200 0С to +500 0С.

The pipeline does not deform under increased loads: steam pressure of more than 170 kg / m2, sudden pressure surges at which water hammer can occur

This is especially important with a single-pipe heating system. It is necessary to choose the correct diameter of the product.

Smooth walls contribute to the unhindered passage of steam: the friction force is minimal, the coolant speed is high, and heating is efficient.

Pipes are connected by soldering or by fittings. When soldering, hard solder is used. A certain skill is required to carry out the work. When installing, it is recommended to contact a specialist. An improperly formed seam can lead to an accident in the pipeline.

I choose fittings and adapters from the same material. Steel or aluminum products are not used. Instead of copper connecting elements, brass can be used.

Instead of soldering, you can use a collet connection: choose compression type adapters. They have an internal sleeve that prevents deformation of the material at the junction. During installation, a union nut and a split ring are put on the pipe. The pipe is placed on the sleeve. The nut is tightened to the stop: use an adjustable wrench. Soldering is not required.

In addition to soldering and collet connections of pipes, press mounting is used. To do this, purchase special press fittings made of copper. The connection process takes place using press tongs. The advantage of this technique is the reliability of the seam, but this connection cannot be repaired. In the event of a breakdown, you will have to cut a section of the pipe along with the fitting.

Copper pipes

Pipe diameter calculation

For the line, it is required to select pipes with a certain diameter. The indicator depends on many parameters: the heat transfer of the material, the speed of passage of the coolant, the power of the heating equipment. It is difficult to calculate the diameter of the pipe yourself. They turn to specialists. For the calculation, certain tables are used.

If you choose a product of a smaller diameter, then under steam pressure the material may deform, the seams will not withstand heavy loads and will break. When choosing too large a diameter, with a low boiler power, incomplete steam condensation may occur. The coolant will be used inefficiently.

Choose pipes for heating the house.

- header

- Choose pipes for heating the house.

- header

- A little trick when welding heating pipes in awkward places

- header

- Autonomous heating with your own hands. Economical boiler from a PIPE for underfloor heating

Two schemes for installing steam heating

Currently used single-circuit and double-circuit heating schemes. The first is designed to provide the house with only heat, and the second - in addition to heat, can act as a source of hot water.

In such systems, special batteries of steam equipment and boilers are used.Their two most important characteristics are increased strength and the ability to withstand the highest operating temperatures, which can exceed one hundred degrees Celsius.

The piping of steam systems can be either vertical or horizontal, and the wiring of the mains is carried out in any of the ways: top or bottom.

Versions of GMSH with end fittings

Execution GMSh with end fittings for welding

100. Execution GMSh with fittings for welding101. Execution GMSh with fittings for welding102. Execution GMSh with fittings for welding103. Execution GMSh with fittings for welding104. Execution GMSh with fittings for welding

Execution GMSh with flange ends

500. GMSh - with fittings "Flat welded flange" GOST 12820-80 isp.1501. GMSh - with fittings "Free flange on the welded ring" GOST 12822-80 isp.1502. GMSh - with fittings "Weld collar flange" GOST 12821-80 isp.1503. GMSh - with fittings "Free flange on the welded ring" GOST 12822-80 version 4

Version GMSh with threaded fittings

300. GMSh - with fittings "Nipple with external cylindrical pipe thread"301. GMSh - with fittings "Nipple with external pipe conical thread"

Execution GMSh with fittings "nipple - union nut"

400. GMSh - with fittings "Flat nipple, union nut with metric thread"401. GMSh - with fittings "Flat nipple, union nut with cylindrical pipe thread" 410. GMSH - with fittings "Nipple-cone 24 degrees with an o-ring, a union nut with a metric thread"411. GMSh - with fittings "Nipple-cone 24 degrees, union nut with metric thread"420. GMSh - with fittings "Nipple for an external cone of 74 degrees, a union nut with a cylindrical pipe thread"421. GMSh - with fittings "Nipple for external cone 74 degrees, union nut with metric thread"430. GMSh - with fittings "Nipple-sphere 60 degrees, union nut with cylindrical pipe thread"431. GMSh - with fittings "Nipple-sphere 60 degrees, union nut with metric thread"

Execution GMSh with end fittings "American"

600. GMSh - with fittings "Threaded connection for welding with a flat seal"601. GMSh - with fittings "Threaded connection for welding with a cone-shaped seal"610. GMSh - with fittings "Threaded connection with adapter with internal thread and cone-shaped seal"620. GMSh - with fittings "Threaded connection with an adapter with an external thread and a cone-shaped seal"621. ГМШ - with fittings "Connection with adapter with external thread and flat seal"611. ГМШ - with fittings "Threaded connection with adapter with female thread and flat seal"

GMSh version with quick couplings

200-207. GMSh - with quick-release cam-type connections210. GMSh - with quick couplings for pipelines, 1.6 MPa211. GMSh - with quick couplings for pipelines, 6.3 MPa212. connection PMT for main pipelines

PIPING SYSTEMS

Bypass line for oil wells

Calculation of the technical parameters of the flexible pipelineInstructions for installation and operationVisual instructions for the installation of flexible pipelinesExamples of flexible pipelines applicationsFlexible pipeline for two different types of transported media

How to choose a steam boiler

From the correct choice of the boiler directly depends on what will be the heating system in the house. In this case, it is necessary to take into account the area of \u200b\u200bthe house and its features. Boilers for such heating systems operate on different types of fuel, including peat, coal, gasoline, diesel fuel, natural gas supplied by pipelines or in cylinders. In addition, there are combined type devicesoperating on several types of fuel at once, for example, solid and liquid.

An important criterion when choosing a boiler is the level of pressure measured in atmospheres.In steam heating systems, the pressure level can be either higher or lower than six atmospheres.

As for the design of steam boilers, its main components are burner, furnace and ash pan. A large load is borne by the so-called drum, on which pipes, fuses and various additional equipment are fixed.