Why is the splash of water heard in the tank

This can be heard in winter. Know that this is not water, but the butane component of SPBT. At the slightest frost, butane ceases to be converted into a vaporous fraction. It is she who "splashes" in the form of a liquid inside.

Butane component of SPBT in a gas cylinder

In the warm season, this problem does not arise: almost the entire propane-butane mixture is used. In order to avoid this in frost, it is recommended, when filling the container, to ask the refueller about the availability of a passport for the used SPBT. This document must contain information that the mixture contains at least 80 percent propane, which passes from liquid to vapor during cold weather. If you use such a dressing, then there should be no problems.

How to fill a gas bottle

Refuel such devices on the territory of special points, which can be located autonomously and enter the gas station. In the conditions of the latter, it is possible to refuel with gas motor fuel.

Device for filling gas cylinders

The most important nuance in this process is the fact that you need to refuel not by volume, but by weight. As a safety precaution, gas containers should be filled to a maximum of 85 percent of the total volume, in order to avoid excessive pressure.

In order to follow safety precautions and its standards, such a device with any volume is marked with a number with a maximum allowable weight, corresponding to the same allowable 85 percent. The tanks are placed on the scales, including fuel injection. The process stops after reaching the required weight.

Refueling point for household gas cylinders

But even when refueling relative to the mass, overflows are not excluded, which is especially important for small-volume containers - by 5 or 12. They should be refueled by 2 and 6 kilograms, respectively. The high speed of refueling sometimes does not allow you to see the achievement of the limit rate. If this happened to you, be sure to ask for the excess gas to be drained. In the future, it is better to choose another place for refueling.

In general, the basic criterion for choosing a tanker is the availability of license documents for the use of fire and explosive objects. If the documents are present, then we can conclude that you are served by qualified specialists who annually undergo special certification.

Conveyor for filling gas cylinders

In other cases, you take responsibility for the operation of the refilled container. And you risk not only your money, but also the safety of your home and life. In addition, an unlicensed gas station is a violation of the law and may entail not only administrative, but also criminal liability regarding the article on illegal entrepreneurial activity.

The information provided in the review does not claim to be accurate encyclopedic data and is largely dictated by our experience. But we are sure that it can help you save a lot of time and money.

LPG consumption

To understand how efficient and expedient it is to heat a house with LPG, let's calculate the bottled gas consumption for a house with an area of 100 sq.m. In such a house, according to thermal calculations, it is recommended to install a boiler with a capacity of 10 kW. To obtain 1 kW of heat, the boiler consumes an average of 0.12 kg / hour of gas. Gas consumption for heating the entire area will be 1.2 kg/hour, and 28.8 kg per day. If we take into account that a standard 50 l cylinder contains about 22 kg of gas, then the weekly consumption will be about 9 cylinders, and this is absolutely impractical.

Gas cylinders with a volume of 50 liters

But in this mode, the boiler only works to heat the heating system.The rest of the time, a properly adjusted boiler consumes 3-4 times less gas, i.e. about 8-9 kg of gas per day or approximately half of the cylinder. A week for heating a well-insulated house of 100 square meters. m will need about 3 cylinders of gas. At the same time, the temperature inside the room will be maintained at +22 degrees (at -18-20 degrees outside).

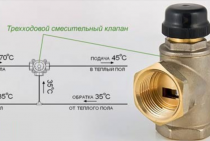

You can increase the efficiency of heating through the use of automation.

Note! A decrease in temperature at night by 6-7 degrees leads to a decrease in gas consumption by 25-30%. This means that about 2 cylinders will be needed per week to provide such a system with liquefied gas.

This means that about 2 cylinders will be needed per week to provide such a system with liquefied gas.

In the case of heating a country house, during the absence of the owners, you can set the temperature regime to + 5 + 7 degrees (only to maintain the heating system in working order). Then the gas consumption per week will generally decrease to 1 cylinder.

With an increase in the heating area, the required number of cylinders is calculated in a proportional ratio.

What you need to connect

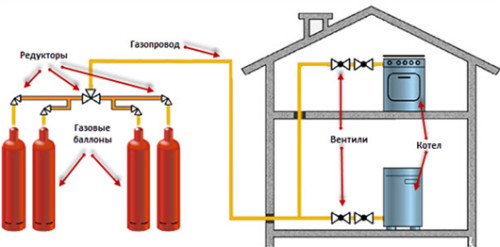

To install a heating system on gas cylinders, you will need:

- Gas boiler equipped with a burner for liquefied gas;

- Gas cylinders with a capacity of 50 liters;

- Reducers;

- Ramp if several cylinders are connected;

- Shut-off valves;

- Gas pipeline in the form of pipes and hoses for connecting equipment to the system.

Equipment for the heating system of a private house with gas cylinders

When choosing a gas boiler, you should pay attention to models with the lowest operating pressure and high efficiency. Many models of boilers are already equipped to work with natural and liquefied gas

If connection to the main gas pipeline is not expected, then it is better to choose just such a boiler to work on LPG.

Otherwise, additional equipment is purchased: nozzles for the burner or a complete burner for liquefied gas, and in some models a gas valve. The burner of a natural gas boiler is designed for a lower system pressure and has a valve with a large orifice, which can lead to an emergency.

Boiler connection diagram

The cylinders are connected to the system through a special reducer, which converts the gas from a liquid state into a gaseous state for further supply to the boiler.

Gas cylinders with separate reducers

Note! The gas flow rate through the reducer should be 1.8-2.0 cubic meters / hour, a conventional gas reducer with a flow rate of 0.8 m

cube / hour is not suitable for this system.

When connecting cylinders to the boiler, two options are used: one common reducer for all cylinders or a separate reducer for each. The latter option is safer, but also more expensive.

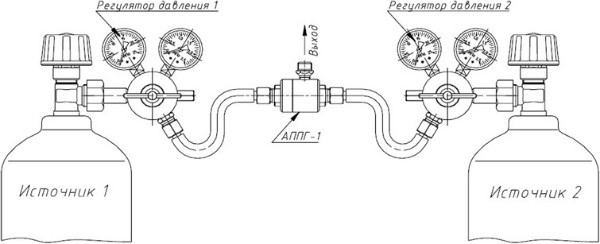

Several cylinders can be connected to the gas boiler at once, which allows you to increase the time between their refueling. For this, a ramp is used - a two-arm collector that distributes the capacities of the cylinders into two groups, the main and the reserve.

First, gas is selected from the cylinders of the main group, and when it runs out, the ramp automatically switches the boiler to the reserve group. The moment of switching is accompanied by a signal. After connecting already filled cylinders to the ramp, the boiler automatically switches to work from the main group.

Scheme of connecting cylinders to the ramp

Note! Gas cylinders are installed at a distance of at least 2 m from the boiler, but the best option for placing them is in a separate non-residential premises or insulated gas cabinet on the north side of the house. Gas bottles must not be exposed to direct sunlight.

Gas cylinders must not be exposed to direct sunlight.

The wall thickness of the metal pipes of the gas pipeline must be at least 2 mm. In places of passage through the walls, the pipe is placed in a special case and foamed.The boiler is connected to the gas pipeline using a flexible connection, and a rubber-fabric sleeve (durite hose) is used for the reducer.

Connecting the cylinder to consumption devices

Connecting gas cylinders to consumption devices

The device must be connected via a reducer. Inside a conventional gas cylinder, the pressure is not constant and depends on the ambient temperature. It can vary from 4 to 6 atm. The reducer is able to reduce and equalize the pressure to the optimum operating level of the cooker.

A hose is connected to the reducer, and a plate is connected to it. The place of fixation is fixed with clamps, after which it is necessary to check the tightness of the connection with soap suds. Any foam will do. The fixation points must be covered with soapy water: if bubbles form on the surface, then the connection is leaky.

We eliminate the leak: tighten the nut even more at the junction of the fitting with the gearbox. If a leak is found in the sleeve area, then tighten the clamps. After adjustment, it is necessary to check again with soap suds to finally make sure that there is no leakage. Such a check is carried out whenever a gas cylinder is connected - this is the golden rule of safe use.

Correct connection of gas cylinders on the street, figure 1

Correct connection of polymer-composite gas cylinders, figure 2

IMPORTANT! You should not act like some especially “experienced” gas masters: in no case do not check the tightness with lit paper. This results in small flames at the leaks.

This is strictly prohibited by safety regulations. In addition, such flames are very small and in daylight can go unnoticed and lead to sad consequences.

Gas cylinders in winter

If gas cylinders are outside the house, then in winter at negative temperatures, the pressure of liquefied gas decreases, and the boiler may simply turn off. To prevent this from happening, the cylinders are installed in a special cabinet with good ventilation, insulated with non-combustible materials. Also, for this purpose, stand-alone non-residential buildings with minimal heating are suitable. When using cylinders, the following safety precautions must be observed:

Special cabinet for installation of cylinders

- It is forbidden to warm gas containers with an open flame;

- There should not be a basement or cellar near the cylinders, since liquefied gas descends when leaking, has no smell and can accumulate to an explosive concentration;

- It is advisable to install a gas leak sensor;

- Storage of full containers is allowed at a distance of 10 m from the dwelling;

- Storage of empty cylinders in the house is prohibited;

- Once every 4 years, it is necessary to check the cylinders for integrity and tightness.

Choosing a boiler for cylinder heating

LPG boilers

Currently, manufacturers do not produce narrow-profile heating boilers for bottled (liquefied) gas. However, equipment designed for natural gas cannot be used without prior modification.

Before purchasing the boiler, you must make sure that the package includes a kit for adapting equipment for propane. The set includes nozzles with a wider nozzle and a kit for attaching them to the burner. The reinstallation procedure can be performed independently only if it is provided for by the design.

There are several types of gas-fired heating boilers for bottled gas, which differ in operational and technical indicators:

- Burner type - open or closed. It is best to purchase heat supply boilers on a gas cylinder with a closed burner. For their operation, air is taken from the street using a coaxial pipe;

- Mounting - wall or floor.Most models up to 24 kW are wall mounted;

- The number of contours. To supply heat to the dacha with gas cylinders, you can purchase an inexpensive single-circuit boiler. If permanent residence is planned in the house, it is recommended to buy a two-circuit model with hot water supply.

You can pre-calculate the flow rate for heat supply with gas cylinders by reading the technical data sheet of the equipment. However, often manufacturers give the maximum flow at the maximum power of the equipment. The lower the intensity of the burner, the less fuel will be consumed.

The best performance indicators are gas-fired heating boilers on bottled (liquefied) gas with a cast-iron heat exchanger. It will last much longer than steel.

How much gas is enough

Here you can use primitive mathematical rules. If we start from the power of the stove, where 4 burners work at once, then 8 kWh of energy is used in 60 minutes. If you burn 1 kg of gas, you can get 12.8 kWh of energy. The first result must be divided by the second figure, resulting in the amount of "liquid" fuel necessary for the full operation of the stove for an hour. This figure is 0.625 kilograms of gas. Therefore, a 50 liter container with 21 kilograms of gas will be used to run the stove for 33.6 hours. If the power in kg of fuel burned is indicated in the passport of your equipment, then the calculations are greatly simplified.

In the future, everything depends on the intensity of use of the plate. If you often brew jellied meat, then the degree of consumption will be one, if you are content with only brewing morning coffee, then another. Based on practical experience, we can say that 12 liters of gas, which will be used by a small family on weekends in the country, will be enough for the whole summer. You will find more detailed information about autonomous gasification in this section.

Why are the cylinders covered with frost

Here you can also debunk one of the most common misconceptions. It is generally accepted that if such a device "freezes", then it becomes covered with frost. Some even argue that it is necessary to insulate such equipment with blankets, old coats and other improvised devices. So, the frost will disappear faster if the gas container is left as it is, without helping it to “thaw” with warm clothes.

The bottom of the gas cylinder, which is covered with frost

The appearance of frost can be explained by a number of physical processes that occur inside the structure when it is connected to furnaces or burners. At such moments, active fuel consumption is observed, therefore, large volumes of gas liquid turn into a vapor fraction. And such a phenomenon is always accompanied by a large consumption of heat, it is for this reason that the surface of the cylinder becomes much colder than the temperature in the surrounding space. Moisture in the air space begins to appear in the form of condensate on the walls of the installation, subsequently turning into frost. This is a completely natural phenomenon, with which nothing needs to be done.

Moreover, all attempts to use artificial "insulation" violate safety standards during operation, and also affect the deterioration of the heat exchange of the device with the environment and affect the conditions of gas supply. If your burner did not please with a grandiose flame, then after your “maneuvers” with a blanket, it may stop working altogether.

Do not insulate gas cylinders with anything!

In general, when connecting gas devices with high power, you need to be aware that the gas cylinder has limitations in terms of recoil speed. This means that the liquid fuel is converted into the steam stage gradually. For example, a 50 liter tank can provide about 500 grams of gas in 60 minutes. This is equivalent to a power of 6-7 kW.In the cold season, this figure is halved if the equipment is located outside. In summer, the situation is reversed: the maximum flow rate increases.

In any case, it can be concluded that frost is evidence that the cylinder cannot cope with high fuel consumption. This can cause a temporary drop in gas pressure and equipment failure. If this happens, it is better to stop consumption and wait until a sufficient head of steam has formed.

Calculation of the number of gas cylinders for heating

Types of cylinders for heating

One of the significant disadvantages of such heat supply is the constant replenishment of fuel reserves. Therefore, it is necessary to calculate in advance how many cylinders are needed for the boiler. There is no exact methodology for this. But there are a number of ways in which you can determine the approximate fuel consumption.

To determine the flow rate when heating with gas cylinders, it is necessary to familiarize yourself with the technical documentation of the boiler. It shows the fuel consumption for both natural and liquefied gas. Usually in the latter case, manufacturers give the consumption in kg / h. For boilers with a capacity of 24 kW, it is about 3.5 kg / h.

In addition, the intensity of fuel consumption is taken into account. On average, to maintain a normal temperature in winter, the heating of a private house with bottled gas works from 12 to 16 hours a day. If the heating season is about 100 days, the total consumption for a 24 kW boiler will be:

Those. on average, 1 cylinder for a heating boiler with a capacity of 50 liters per day will be needed. This is the maximum fuel consumption that can be reduced as follows:

- Installation of automation for gas supply;

- Acquisition of modern models of boilers with high efficiency;

- Insulation of the house to reduce heat loss.

But even these measures will not greatly affect fuel consumption. Almost all reviews of heating with gas cylinders indicate the relevance of installing this type of heat supply only in houses with a small area and non-permanent residence.

The table shows how many cylinders are needed for a heat supply boiler, depending on the area of \u200b\u200bthe house.

Number of cylinders 50 l, pcs.

These are not final numbers. For each heating system, an individual calculation is made of how many cylinders are needed for the boiler. It is also necessary to take into account the correct filling of the container. All liquid is previously removed, the weight of the empty cylinder is measured.

When filling the cylinder, you can check the level of its filling by measuring the temperature level. The area where there is a gas mixture will cool the balloon.