Panel mounting

There is nothing difficult in self-finishing a house with siding. This is a simple sequential job. You only need to successfully complete each step in accordance with the instructions.

First step. Proceed with the installation of the starting strip of siding. To do this, find the lowest point of the wall of your house, step back 40 mm from it and draw a horizontal line at this level along all the walls of the building.

Place the starting strip of siding edge-to-edge on this marking line and nail the strip to the wall with stud nails.

If the length of one starting strip is not enough, fill the second with an indent of about 0.5 cm from the first.

Second step. Nail special corner finishing elements to the wall joints. Fix with nails, hammering them in increments of about 20-30 cm.

Third step. Install special J-rails around doors and windows.

Fourth step. Proceed to the main stage of wall cladding with siding. To do this, take the panel, insert it into the previously fixed starting strip with the lower edge, and nail the upper one to the crate.

The panel must not reach the corner home for a few millimeters to be able to expand and contract.

Fasten the next rows in the same way: hook the lower edge of the new row to the ledges of the previously laid panels, nail the upper edge to the crate.

Facade decoration, siding

Panels can be fastened using a special connecting profile or simply overlapped. If you prefer the second option, fix the panels with an overlap of about 20-30 mm. At the same time, the installation of the cladding must be planned in such a way that the joints are placed apart - it is impossible to equip them one above the other.

With the number of nails required to fix one panel, as well as with the placement of fasteners, you can easily decide during the installation process. The siding has factory holes for nails, be guided by them. Drive the nail strictly in the middle of the hole so that the panels can move normally during temperature deformations.

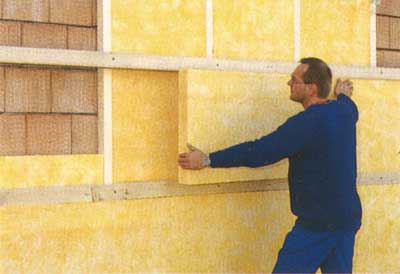

Photo of installing siding on top of the insulation

Drive the last nail at a distance of no more than 80-100 mm from the edge of the siding panel. If there is no suitable mounting hole at this distance, make it yourself.

Siding is perfect for walls and facades. A rich variety of textures, sizes and colors will allow you to choose a finish that fits perfectly into the landscape. Follow the recommendations received, and you will be able to create a durable and beautiful design of your own home with your own hands.

crate

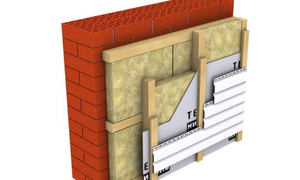

To carry out a high-quality installation of siding on the walls of a brick, frame or wooden house with your own hands, you need to create a frame, and there are good reasons for this:

- You can make the imperfections of the walls outside the building invisible.

- It is possible to install insulation and waterproofing, which will help save on heating residential premises.

- A ventilated facade appears, eliminating condensation and moisture.

The crate is assembled from a wooden material or a metal corner, which is given an advantage in the event of protruding parts, although it costs more and its installation is more difficult. The crate made of metal does not swell from moisture, does not deform, does not rot, which allows it to serve for a very long time. When starting to install the frame on the walls of a wooden house with your own hands, do not forget to treat them with antiseptics, as required by the technology.

The choice of fasteners, with which the frame will be mounted, directly depends on the material of the crate.The technological gap between the wall and the slats of the crate can be 15 cm, and it depends on what kind of insulation will be laid. If only waterproofing is installed additionally, only a couple of centimeters may be enough, while the insulation will draw more space (up to 15 cm).

The step between the elements of the vertical crate is usually 50 cm, and the installation of the frame itself is carried out under strict level control using guides.

Wall insulation procedure

For the installation of siding with simultaneous insulation, crates made of wooden bars and metal profiles are suitable. Most often, wooden crates are used. Metal ones are used mainly at the request of the owner, mainly when facing brick houses.

Using a wooden crate

Using a wooden crate

First step. Prepare your home for finishing work. If you are working not with a new building, but with an already built and used house, remove various elements such as trim, window shutters, drainpipes and everything else that will interfere with installation.

Second step. Get rid of any kind of defects and damage on the wall surface. Modern silicone sealants will help you with this.

Third step. Proceed with the installation of horizontal rails of the crate. Select the spacing of the bars so that it is approximately 1-1.5 cm less than the width of the insulation boards.

Fourth step. Lay the insulation boards in the cells of the crate. Mineral wool and more modern heaters based on it are optimal for thermal insulation. Lay the plates as tightly as possible without gaps at the joints.

Lay the insulation boards in the cells of the crate

Lay the insulation boards in the cells of the crate

Fifth step. Lay a waterproofing material over the insulation. The best option is a special diffusion membrane. Such material will simultaneously protect the insulation from moisture and provide the necessary ventilation of the space.

Sixth step. Proceed to fixing the rails of the vertical crate. Place vertical racks with a mandatory level check. Eliminate irregularities with special linings.

For arranging a vertical crate, 2.5 cm thick boards are suitable. You will attach your siding to them. Before installation, the boards also need to be impregnated with an antiseptic.

Using a metal crate

Using a metal crate

Metal lathing is usually used in the case of siding of brick houses.

First step. Get rid of all elements that may interfere with installation. The principle of operation is the same as in the case of a wooden crate.

Second step. Thoroughly clean the surface of the walls. Continue cleaning the walls until nothing is peeling off the sides of the walls.

Third step. Run your palm along the wall. If there is a mark on the skin, prime and plaster the wall. The surface of the walls should be slightly rough. This will ensure the highest quality adhesion of the insulation to the walls.

Fourth step. Fasten hangers to the walls for installing galvanized profiles.

Fifth step. Line the walls with insulation. In this case, it is more convenient to use foam plates. They can be attached without a crate. To fix the plates, use glue specially designed for this.

Sixth step. Fix the elements of the metal crate on the hangers. Siding panels will be attached to them in the future.

Thus, you need to choose the appropriate version of the crate, lay the insulation, and only after that proceed with the installation of the cladding.

Do-it-yourself insulation and siding installation

External insulation of the facade is carried out in strict sequence:

- begin work with the dismantling of all elements (platbands, shutters, gutters) from the walls, clean their surface from protrusions, chipped plaster and dirt. The same applies to a wooden house;

- a layer of vapor barrier is attached to a clean surface with a construction stapler. The membrane is placed with the rough side against the wall;

- a vertical crate made of wooden material is fixed at the same distance, which is a couple of centimeters less than the width of the insulation (for tight placement). As fasteners, choose nails or self-tapping screws intended for woodworking;

- the insulation is fixed (pressed between the slats), which can be additionally strengthened with your own hands using dowels with a wide cap;

- the insulation is covered with an overlapping waterproofing film, and its edges are folded inward;

- on the planks of the crate (50/30 mm), a wooden frame is perpendicularly mounted, on which decorative trim will be installed;

- decorative trim (in our case, siding) is installed outside the house. Then you can carry out the installation of finishing elements and communications (downpipes).

If you do all the installation procedures correctly, without missing a single step, then you will get a beautiful and reliable decoration of the exterior walls of the house for insulation, created by yourself.

Siding is a popular PVC-based finishing material. It is mainly used for finishing facades and walls of various buildings, including private houses. It has many advantages, including the possibility of fastening panels with the simultaneous performance of work on the thermal insulation of the finished surfaces. In this case, all the necessary activities can be done by hand.

DIY siding with insulation

Contents of step by step instructions:

Types and characteristics

The term "siding" is understood as ordinary panels intended for cladding the facade of buildings and auxiliary home structures. In addition to the decorative task, the panels are often part of a multi-layer wall covering, mounted for the purpose of waterproofing, reducing noise penetrating into the premises, and improving the performance of the building.

At first, siding was made of wood; currently, the variety of types of such exterior cladding is quite large.

Natural wood remains extremely popular until now. Of course, modern wood panels are significantly different from the board that was used before.

Despite the processing of wood, it remains the most environmentally friendly material for the exterior cladding of buildings. No other type of material can be compared with it in terms of thermal insulation properties.

Almost all types of modern cladding have a locking part with grooves, which allows the installation of panels with almost no gaps that require sealing.

Metal cladding houses are not very popular. It is more often used in the decoration of public buildings, commercial and social buildings, industrial enterprises, offices and other similar buildings.

Most often, galvanized steel is used for the production of such panels. The most expensive types are made of aluminum and zinc. The advantages of metal cladding are its reliability (with high-quality anti-corrosion treatment), ease of installation, non-flammability, mechanical strength (however, if the material is inattentively transported or with a point impact, it may well be deformed).

Plastic siding is the most popular.More than half of the sales of all facade panels falls on this group. Most often, the base material in them is polyvinyl chloride (PVC) - a polymer that has excellent performance properties.

Installation of siding is so simple and intuitive that anyone, even an inexperienced builder, can handle it.

The best heaters

Those house owners who ignore the issue of insulating the outer walls of the structure are deeply wrong.

No matter how hard you try, there will certainly be voids between the wall and the cladding. They will not add heat in the house, but they will collect dampness and create conditions for the appearance of mold, moss, fungi, insect nests, the proximity to which can be not only unpleasant, but also dangerous.

Any houses should be insulated, even country houses, where you live only in the summer. This will ensure the safety of the building and freshness in the house in the heat. After all, thermal insulation protects from heat no worse than from frost.

Distinctive qualities of cladding

Plastic lamellas can easily withstand high temperatures (up to +50 C) and are fire resistant. They are not afraid of moisture and are not infected by pathogens, are not damaged by moderate mechanical stress, do not attract insects and are environmentally friendly.

Such decoration on the outside of the house looks attractive and can transform even dilapidated buildings, as it allows you to hide all the flaws in the facade. Siding is easy to install, but still, its installation requires certain skills. Siding perfectly masks pipes, curved walls and plaster errors.

Modern lamellas are distinguished by a variety of colors that allow you to show your design skills and create an interesting decorative solution. To match the skin, you can pick up drainpipes, storm drains, extensions and various related elements.

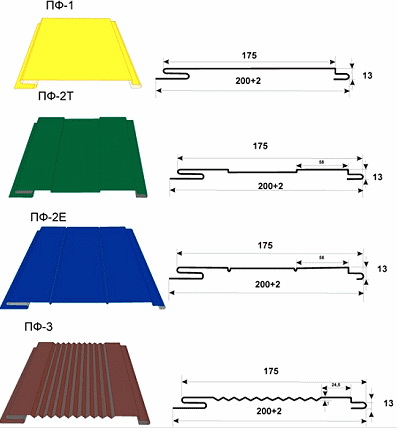

When choosing a panel decorative material, you should know that there are several types of it on the construction market:

What siding to use for cladding

On the modern market there is a huge selection of panels in a wide variety of colors and textures. Siding can successfully imitate wood, brick and stone surfaces.

What siding to use for cladding

The standard thickness of the cladding panel is 1 mm. Width and length indicators are not subject to standardization and depend on the preferences of a particular manufacturer. Most often there are facing panels with a length of about 3-4 m and a width of about 20-25 cm. A large dimensional grid will allow you to choose panels that will be most convenient to use for facing your home.

Residential buildings are usually finished with vinyl or any other basement siding. When choosing a specific option, ceteris paribus, give preference to vinyl panels.

When choosing vinyl siding, be sure to pay attention to the appearance of the elements - the color of the panels must be strictly uniform.

Expensive siding usually has the same color on both sides. In a more budgetary material, the inside is often a little lighter than the outside.

It is not recommended to perform cladding with panels with a glossy tint. Such material will be very hot in the sun, up to deformation. Therefore, the best choice is siding with a matte finish.

Check that all panels have the same thickness. The parameters of their nail holes should also be identical.

Before buying a material, check its plasticity. To do this, you can bend the thin part of the panel near the hole for the nail connection. If the edge breaks, the purchase of such panels should be discarded. If the material is bent, but at the same time remains intact, you can safely use such siding for cladding with insulation.

Helpful Hints

We advise you to start work from the rear facade of the building - firstly, possible errors will be less visible here, and secondly, if you reach the front facade, you will already have a good practice in installing siding. When the first panel is securely defined, we move on to building.

So, it is quite possible to install siding with insulation with your own hands, most importantly, follow the technology and in the process do not forget to once again check the quality of work - this will save you from having to rework in the future.

Korovin Sergey Dmitrievich

Master of Architecture, graduated from the Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Siding is becoming more and more popular every day. Lamellas from qualitative raw materials differ in durability and a practicality. This material has replaced wood paneling and, thanks to its affordability, has become a real favorite in the construction market. Unlike natural cladding, it does not need additional protection from external factors.

Probably, many will be interested to know how houses are insulated from the outside with siding, and we will try to give a detailed answer to this question. To begin with, I would like to take a closer look at the technical characteristics of the material, and they are quite good here.