How to choose a pump for heating

Best suited for installation are special low-noise centrifugal-type circulation pumps with straight blades. They do not create excessively high pressure, but push the coolant, accelerating its movement (the working pressure of an individual heating system with forced circulation is 1-1.5 atm, the maximum is 2 atm). Some models of pumps have a built-in electric drive. Such devices can be installed directly into the pipe, they are also called "wet", and there are devices of the "dry" type. They differ only in the rules of installation.

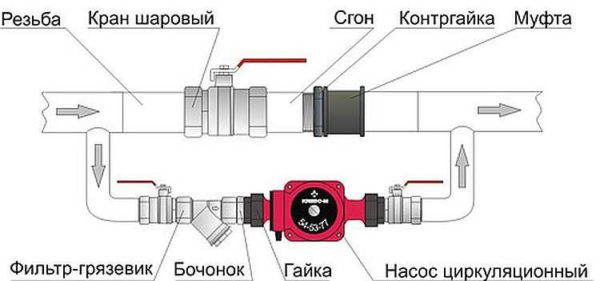

When installing any type of circulation pump, an installation with a bypass and two ball valves is desirable, which allows the pump to be removed for repair / replacement without shutting down the system.

It is better to connect the pump with a bypass - so that it can be repaired / replaced without destroying the system

Installing a circulation pump allows you to adjust the speed of the coolant moving through the pipes. The more actively the coolant moves, the more heat it carries, which means that the room heats up faster. After the set temperature is reached (either the degree of heating of the coolant or the air in the room is monitored, depending on the capabilities of the boiler and / or settings), the task changes - it is required to maintain the set temperature and the flow rate decreases.

For a forced circulation heating system, it is not enough to determine the type of pump

It is important to calculate its performance. To do this, first of all, you need to know the heat loss of the premises / buildings that will be heated

They are determined based on losses in the coldest week. In Russia, they are normalized and installed by public utilities. They recommend using the following values:

- for one- and two-story houses, losses at the lowest seasonal temperature of -25 ° C are 173 W / m 2. at -30 ° C, losses are 177 W / m 2;

- multi-storey buildings lose from 97 W / m 2 to 101 W / m 2.

Based on certain heat losses (denoted by Q), you can find the pump power using the formula:

c is the specific heat capacity of the coolant (1.16 for water or another value from the accompanying documents for antifreeze);

Dt is the temperature difference between supply and return. This parameter depends on the type of system and is: 20 o C for conventional systems, 10 o C for low-temperature systems and 5 o C for underfloor heating systems.

The resulting value must be converted into performance, for which it must be divided by the density of the coolant at operating temperature.

In principle, when choosing the pump power for forced circulation of heating, it is possible to be guided by averaged norms:

- with systems that heat an area up to 250 m 2. use units with a capacity of 3.5 m 3 / h and a head pressure of 0.4 atm;

- for an area from 250m 2 to 350m 2, a power of 4-4.5m 3 / h and a pressure of 0.6 atm are required;

- pumps with a capacity of 11 m 3 / h and a pressure of 0.8 atm are installed in heating systems for an area from 350 m2 to 800 m2.

But you need to take into account that the worse the house is insulated, the greater the power of the equipment (boiler and pump) may be required and vice versa - in a well-insulated house, half of the indicated values \u200b\u200bmay be required. These data are average. The same can be said about the pressure created by the pump: the narrower the pipes and the rougher their inner surface (the higher the hydraulic resistance of the system), the higher the pressure should be. Full calculation is a complex and dreary process, which takes into account many parameters:

The power of the boiler depends on the area of the heated room and heat loss.

- resistance of pipes and fittings (read how to choose the diameter of heating pipes here);

- pipeline length and coolant density;

- number, area and type of windows and doors;

- the material from which the walls are made, their insulation;

- wall thickness and insulation;

- the presence / absence of a basement, basement, attic, as well as the degree of their insulation;

- type of roof, composition of the roofing cake, etc.

In general, heat engineering calculation is one of the most difficult in the field. So if you want to know exactly what power you need a pump in the system, order a calculation from a specialist. If not, choose based on average data, adjusting them in one direction or another, depending on your situation. It is only necessary to take into account that at an insufficiently high speed of movement of the coolant, the system is very noisy. Therefore, in this case, it is better to take a more powerful device - the power consumption is small, and the system will be more efficient.

Options for single-pipe heating of a private house

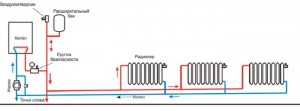

The simplest diagram with the bottom connection of radiators is shown below.

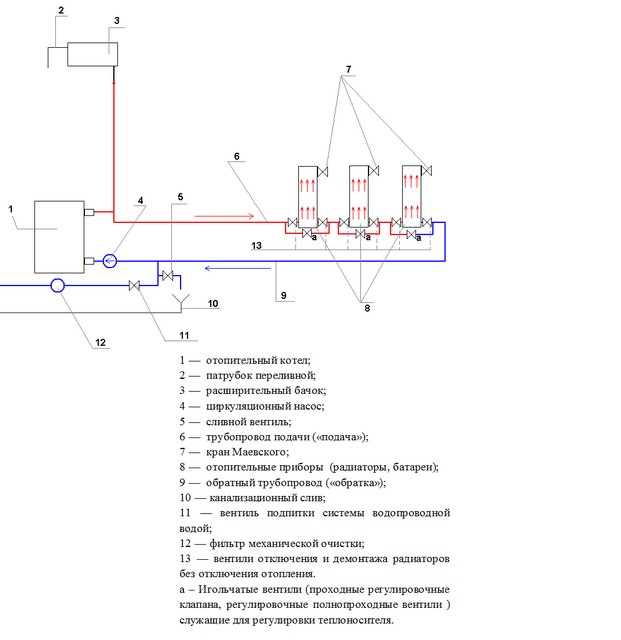

Typical single-pipe heating system of a private house.

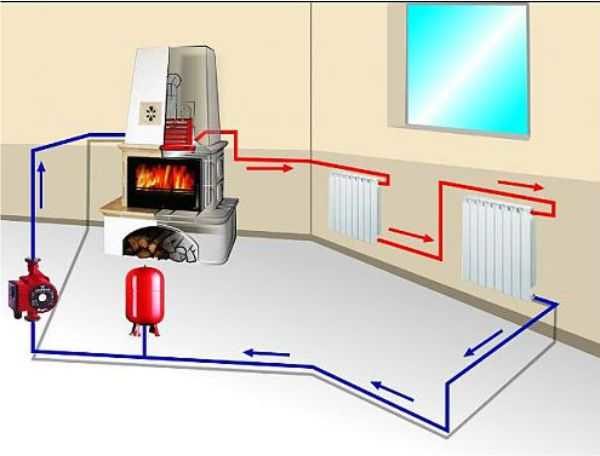

The system belongs to the open type - its expansion tank 3 is connected to the atmosphere. Overflow pipe 2 is used to exit air and drain water during the initial filling of the circuit. Above is a single-pipe heating system with forced circulation, which is provided by the circulation pump 4, installed on the "return" in front of the boiler. This is due to the fact that the temperature of the liquid in the "return" is lower than in the "supply", and the operation of the pump at a lower temperature of the pumped coolant simply increases its service life.

Supply of network water through the filter 12 and the make-up valve 11 is provided (the primary filling of the system is also carried out through them). Water is drained (for repairs and at the end of the heating season) through valve 5 and sewer drain 10 with valve 11 closed.

The bottom connection of radiators 7 is used, i.e. only their lower collectors are connected to the pipes, and the outlets of the upper ones are muffled. The bypasses are equipped with devices (indicated by the letter “a” in the diagram) for flow control (needle valves), but a simpler circuit without them is also possible. It is shown below and is called "Leningrad".

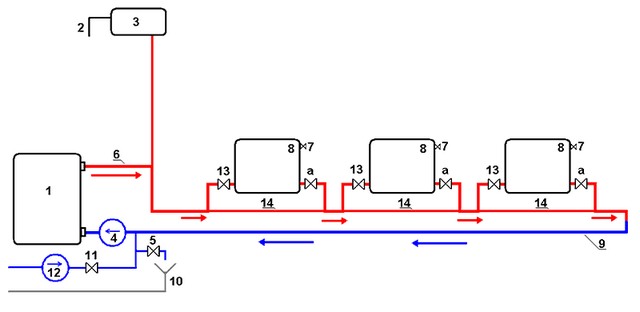

Scheme of the "Leningrad" one-pipe heating system with forced circulation.

In it, the closing sections 14 are pure bypasses without shut-off or control valves with a diameter smaller than the main pipeline. At the same time, part of the flow through the batteries increases, but it also cools down faster, since more cooled water is mixed into the total flow along its course. In private houses, this is done in order to reduce its total consumption (and, accordingly, the electricity consumption of pump 4 for forced circulation), as well as to increase the heat transfer of the batteries, although they warm up very unevenly.

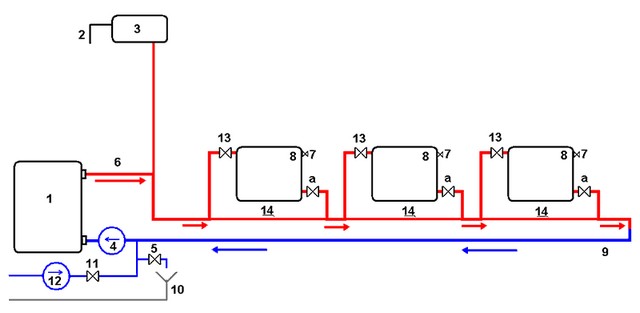

It is possible to connect radiators diagonally, as shown in the diagram below.

One-pipe system with diagonal connection of radiators.

Here, the uneven heating of the batteries in the chain remains (and even becomes higher), but the heat transfer of each of them increases by several percent due to the intensive flow of water around them with the simultaneous presence of forced and natural circulation. After all, its temperature at the inlet to the upper collector is several degrees higher than at the outlet of the lower one, due to cooling in the device itself. Therefore, conditions arise for the natural circulation of water through the batteries (as in the corresponding systems without pumps). The pressure in the bypass 14 will not close this flow, but it will rise up to the valves 13 quite intensively.

How to implement alternative heating of a private house

Two-pipe heating system of a private house - classification, varieties and practical design skills

Single-pipe and two-pipe heating distribution in a private house

Basic heating schemes

Heating systems, where forced circulation of the coolant is provided, can be organized according to a variety of schemes. Below are the most common. You should start with single-pipe water heating schemes:

Figure 2: Single-pipe horizontal system with end sections.

Flowing (Fig. 1). For small houses, a single-pipe horizontal flow-through water heating system is perfect. It provides for the following operation scheme: the coolant enters the main riser, and then is distributed between all horizontal risers and begins to flow sequentially through the batteries, cooling, it immediately returns through the return line.

With closing sections (Fig. 2). There is another horizontal one-pipe system, which provides for the creation of sections that are subsequently closed. In the course of its organization, a valve designed to remove air is necessarily mounted on each radiator. To control the temperature of the heating elements, shut-off valves are provided, which are installed at the beginning of the heating system with forced circulation on each floor of a country house.

Single pipe (Fig. 3). The water heating system, which provides for the organization of forced circulation, can be vertical. In this case, the coolant immediately enters the uppermost floor of the house, then it enters the installed radiators through the risers, then the liquid goes into the heating elements located on the previous floor, and so on, until it drops to the very bottom. Such a water heating system can be organized both according to the flow scheme, and according to the one where there are closing sections.

At the same time, it is important to consider that it has one significant drawback: the heating of the batteries in the house on the floors occurs unevenly.

Figure 3: Single pipe vertical heating system.

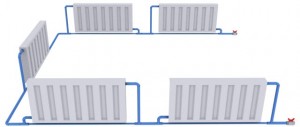

There are also two-pipe water heating systems, which provide for forced circulation of the coolant (Fig. 4). They can be organized in 3 ways:

- Dead end. Here, each subsequent element of the heating system in the direction of movement of the coolant is located at the farthest distance from the heating element. Such a scheme leads to an increase in the circulation circuit, which makes it difficult to control the operation of heating equipment. However, this system provides for a short pipeline length, which minimizes the costs associated with organizing heating for the home.

- Passing. There is an equality of circulation circuits. This factor facilitates the adjustment of the operation of the heating system, where forced circulation is provided. However, here the length of the pipeline, compared with the dead-end scheme, increases significantly, which leads to additional costs during the installation of heating.

- Collector. It provides for the connection to the heating system of each heating element individually. Due to this, the coolant enters the radiators at the same temperature. However, this also implies a large consumption of pipes during the installation of the system.

Figure 4: two-pipe horizontal system.

In addition, there is another scheme for the vertical organization of forced heating (Fig. 5). It implies the presence of a lower wiring. Here, the coolant enters the boiler with the help of a pump, then it enters the pipeline and is distributed throughout the system, and then passes into the heating elements, giving up its heat, the liquid returns through the return pipeline through the pump and expansion tank to the heating element. A vertical heating system can also be organized with an upper wiring (Fig. 6).This implies the location of the main pipelines above the heating elements (in the attic or under the ceiling of the upper floor). The water that circulates with the help of a pump enters the boiler, then it is distributed through the risers to the heating elements, the liquid, having given up its heat, goes into the return line, which is located in the basement or under the floor of the lower floor.

Elements of the system with forced circulation

Forced circulation is a process that requires the installation of not only a pump, but also other mandatory elements.

- These include:

expansion tank to compensate for the volume of the coolant when the temperature changes;

safety group including pressure gauge, thermometer, safety valve;

radiators connected according to one of the wiring diagrams;

Mayevsky taps or air separator;

check valve;

taps for filling and draining the system;

coarse filter.

In addition, when using a solid fuel boiler as a heater. without the function of automatic fuel loading, it is recommended to include a heat accumulator in the system - a storage tank of the required volume. This will equalize the temperature of the coolant and avoid its daily fluctuations.

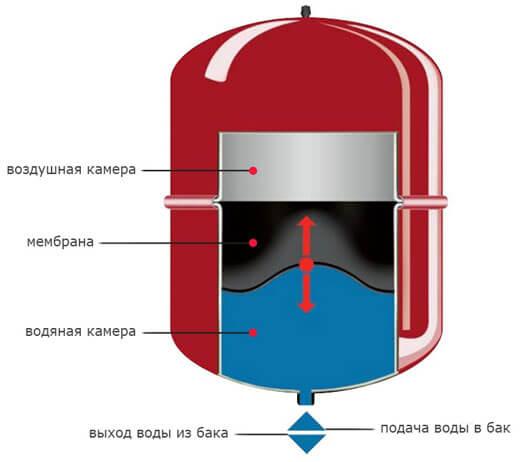

Choice of expansion tank for closed heating

The heat carrier in the heating systems of private houses is usually ordinary water. When heated, water tends to expand, thereby increasing the pressure in the system. If the pressure in the sealed system exceeds the critical point, the pipeline may burst. How to make a closed heating system that will not damage pipes?

To solve this problem, expansion tanks were created that allow you to eliminate excess fluid, thereby preventing pressure build-up.

The expansion tank consists of two parts: a metal body and an elastic diaphragm, which is located inside and divides the body into two halves. The "rear" part of the tank is filled with air or gas, and the expanded liquid enters the lower part. As the temperature rises, the water continues to expand, affecting the membrane, which begins to shrink.

Membranes in tanks can be of two types:

- fixed. Such a membrane is fixed around the perimeter of the expander and ensures stable operation, but if it is damaged, it will be necessary to change the entire tank.

- Replaceable. Membranes of this type are usually produced in the form of bulky rubber products that are filled with water. Replaceable membranes are installed on the tank flange, and in case of their rupture, you can replace them yourself.

Conclusion

The heating system is an important element of the house, and its calculation must be carried out in accordance with all the rules. The question of which is better: a do-it-yourself closed heating system or one built by professionals remains open, but it is not the most important.

It is very important to choose the right elements of the system, which will provide maximum efficiency and economy, will be reliable and of high quality. A closed heating system, the diagram of which is shown in the photo, can be an excellent choice that ensures that all requirements are met.

If everything was done correctly, then the closed heating system will heat the building for many years, creating a cozy and comfortable environment.

The nuances of calculating the installation scheme of a heating system with forced circulation

It depends on the competent installation of the heating circuit how long and trouble-free the heating in the house will work. Since the liquid in a closed system does not come into contact with the environment, it cannot evaporate. When heated, the coolant expands, thereby increasing the pressure inside the system.Since a closed heating system with forced circulation does not imply the possibility of water leaving the circuit, an expansion tank is needed that will take over the excess volume.

The tank is connected to the return pipeline, in the same way as the circulation pump, because. it is in this area that the heating of the coolant is minimal. Since hot liquid shortens the life of the pump, it is best to install it in a location where the water temperature is at its lowest.

Due to the fact that the pipes in the system with a pump have a smaller cross-sectional diameter, the volume of coolant circulating through them is less than the volume of liquid needed to heat a similar house without the participation of a pump. This factor has a positive effect on the operating conditions of the expansion tank; in a system with a pump, the tank does not fail longer. A forced circulation heating system does not cause as much inconvenience as natural circulation.

Also, modern models of heating boilers often have mechanisms for regulating the water temperature depending on the time of day, which work automatically. This nuance allows you to make the circuit work more economical.

A modern heating boiler has great capabilities and various adjustments, which facilitates its operation.

In order to increase the heating surface, a finned heating tube can be installed in the circuit. The well-known cast iron radiators are a type of finned tubes. Such designs, by increasing the surface of the heater, provide more uniform and high-quality heating of the room. Finned tubes are best installed in non-residential premises, because. due to their complex shape, they easily accumulate dust.

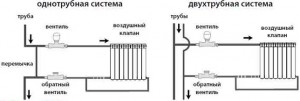

Unlike a gravity circuit, where there is no circulation in the heating system, a design with a pump requires a careful approach. One of the primary tasks that needs to be solved when designing is whether it will be a one-pipe forced circulation heating system or a two-pipe one. The first option is more economical and easier to install, but a two-pipe forced circulation heating system is more productive.

The heating circuit of a three-story house with gravity circulation is easily converted into a circuit with forced water circulation. To do this, attach a water pump and an expansion tank to it. Thus, they modernize the heating scheme and maintain a comfortable temperature in the home, regardless of the weather outside the window.

Choosing a circulation pump

When buying a circulation pump, take into account its reliability, the amount of electricity consumed and the clear principle of operation. Forced heating depends on the power of the unit and the pressure that it is able to create. When evaluating these characteristics, they start from the size of the room for which the pump is purchased for heating. So, for a private house with an area of 250 sq.m. you will need a pump with a pressure of 0.4 atmospheres and a capacity of 3.5 cubic meters. m/hour. If the house is spacious and its area exceeds 500 sq. m, then the required pump power is 11 cubic meters. m / h, and the pressure is 0.8 atmospheres. When buying a pump for a particular room, it is advisable to carry out an individual calculation that will take into account individual characteristics: the length of the circuit, the number of heating batteries, the diameter of the pipeline, the material of the pipes, the type of fuel.

WATCH VIDEO

Heating with forced circulation reduces heat transfer when air pockets form inside the pipeline. The movement of the coolant along the circuit is difficult. Air congestion occurs near radiators, in vertical sections of the circuit. To avoid this problem, a Mayevsky crane and automatic air vents are installed on each radiator. This is an effective way to eliminate system malfunctions associated with air entering the pipes. The forced circulation heating system is always on top.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branching in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer-mud filter is necessarily placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

Varieties of circulation pumps

The wet rotor pump is available in stainless steel, cast iron, bronze or aluminium. Inside is a ceramic or steel engine

To understand how this device works, you need to know the differences between the two types of circulation pumping equipment. Although the fundamental scheme of the heating system based on a heat pump does not change, two types of such units differ in their operation features:

- The wet rotor pump is available in stainless steel, cast iron, bronze or aluminium. Inside is a ceramic or steel engine. The technopolymer impeller is mounted on the rotor shaft. When the impeller blades rotate, the water in the system is set in motion. This water simultaneously acts as an engine coolant and lubricant for the working elements of the device. Since the “wet” device circuit does not provide for the use of a fan, the operation of the unit is almost silent. Such equipment only works in a horizontal position, otherwise the device will simply overheat and fail. The main advantages of the wet pump are that it is maintenance-free and has excellent maintainability. However, the efficiency of the device is only 45%, which is a small drawback. But for domestic use, this unit is perfect.

- A dry rotor pump differs from its counterpart in that its motor does not come into contact with the liquid. In this regard, the unit has a lower durability. If the device will work "dry", then the risk of overheating and failure is low, but there is a threat of leakage due to abrasion of the seal. Since the efficiency of a dry circulation pump is 70%, it is advisable to use it for solving utility and industrial problems. To cool the engine, the circuit of the device provides for the use of a fan, which causes an increase in the noise level during operation, which is a disadvantage of this type of pump. Since in this unit water does not perform the function of lubricating the working elements, during the operation of the unit it is periodically necessary to carry out technical inspection and lubricate the parts.

In turn, "dry" circulating units are divided into several types according to the type of installation and connection to the engine:

- Console. In these devices, the engine and housing have their own place. They are separated and firmly fixed on it. The drive and working shaft of such a pump is connected by a coupling. To install this type of device, you will need to build a foundation, and the maintenance of this unit is quite expensive.

- Monoblock pumps can be operated for three years. The hull and engine are located separately, but are combined as a monoblock. The wheel in such a device is mounted on the rotor shaft.

- Vertical. The term of use of these devices reaches five years. These are sealed advanced units with a seal on the front side made of two polished rings. For the manufacture of seals, graphite, ceramics, stainless steel, aluminum are used.When the device is in operation, these rings rotate relative to each other.

Also on sale there are more powerful devices with two rotors. This dual circuit allows you to increase the performance of the device at maximum load. In the event that one of the rotors exits, the second one can take over its functions. This allows not only to enhance the operation of the unit, but also to save energy, because with a decrease in heat demand, only one rotor works.

One and two-pipe heating systems

Many heating schemes have been developed and installed. But they are all modifications or combinations of two system options that can be defined as basic options.

Basic or basic schemes can be considered:

One-pipe heating circuit

- uneven heating of radiators;

- to replace the battery, you need to turn off the system.

When organizing a heating circuit for a two-story house with forced circulation, a vertical wiring diagram is mounted.

The pipeline rises to the second floor, water enters the batteries arranged horizontally in series. Then, from the last radiator, the pipeline goes down and is connected to a horizontal line of radiators, and then the coolant that has cooled down and given up its energy enters the boiler. The disadvantage of such a system is the uneven heating of the radiators. This drawback is especially noticeable if "gravity" is used, but if a circulation pump is installed, the difference in temperature is almost imperceptible.

Two-pipe heating circuit

Vertical two-pipe scheme

The vertical closed heating system with forced circulation is implemented in two versions - with a lower (horizontal) or upper wiring. Horizontal wiring is organized as follows. The "supply" pipe rises to the top floor, all batteries that are connected to the "return" are connected to it. The disadvantage is the presence of two pipes in the room.

Vertical two-pipe system second option