How to properly load fuel and operate the unit

The long-burning unit differs from the traditional furnace in the increased volume of loading and the restriction of oxygen access to the working area. The operating time of the boiler depends on the amount of fuel loaded, so the firewood is stacked as tightly as possible, without leaving large gaps between the logs. If, however, materials such as peat, fine coal, shavings, sawdust or pallets are used as fuel, then they are poured to the level of the smoke channel without tamping. The necessary sealing of the fuel will provide a heavy metal piston.

Fuel is loaded in the following order:

- remove the top cover from the unit;

- take out the air distribution device;

- load the furnace to the level of the chimney;

- spraying the top layer of combustible material with lighter fluid;

- install an air regulator;

- return the cover to its place;

- a piece of rag soaked in a flammable liquid is thrown into the air channel.

Stable combustion is accompanied by smoke that evenly exits the chimney. As the firewood burns, the duct pipe goes down. It can be used to judge the remaining operating time of the solid fuel unit.

During operation, ash and ash accumulate at the bottom of the barrel. It must be said that their quantity does not have any effect on the combustion process. However, the combustion products of the fuel must be periodically removed, as they reduce the thickness of the filling layer. To do this, open the lower door and rake out the ash with a conventional metal scoop.

When removing the ash, leave a layer 10-20 mm thick on the bottom of the oven. This will not have a special effect on the amount of firewood, however, it will create an excellent heat-insulating cushion that will protect the bottom of the unit from burning out.

Advantages and disadvantages

With all its undoubted advantages, a long-burning device with an afterburner has certain disadvantages. Before choosing a suitable model, we recommend that you familiarize yourself with the strengths and weaknesses of the equipment. This will help you find the best option.

The advantages of such units include the following:

- High efficiency is the main advantage of this type of furnaces.

- Ease of maintenance. If conventional units require frequent filling of fuel, then in the devices under consideration it burns very slowly, because the frequency of loading a combustible substance varies from 5 hours to 2 days.

- High efficiency.

- Large selection of models. To date, there are many similar furnaces on the market of various shapes, sizes and capacities.

- Unpretentiousness in fuel. The equipment successfully operates on various types of combustible substances. Combined ovens are also on sale.

As for the shortcomings, among them it is worth noting the following:

- The need to insulate the chimney. This is a prerequisite for the normal operation of long-burning furnaces. The fact is that hot gases enter the channel from the combustion chambers. In cold weather, this causes instant condensation, which quickly leads to the accumulation of soot and severe clogging of the pipe. In order for the stove to work properly, the chimney will have to be cleaned frequently.

- The need for customization. If the equipment is poorly adjusted, then the combustion of fuel in it will be incomplete, which will prevent the achievement of the main goal.

- High price. This disadvantage can be compensated, on the one hand, by independent production, and on the other hand, by significant fuel savings, due to which such a furnace will quickly pay off.

More in Metal

Types of long burning stoves.We choose a simple and productive heating unit for do-it-yourself manufacturing

We are talking about varieties of long-burning stoves because of the need to decide on the design that is most suitable for making your own hands. Therefore, we will consider all options for new generation solid fuel boilers, and also study the features of their work.

When classifying heating furnaces according to the method of combustion, several main schemes are distinguished.

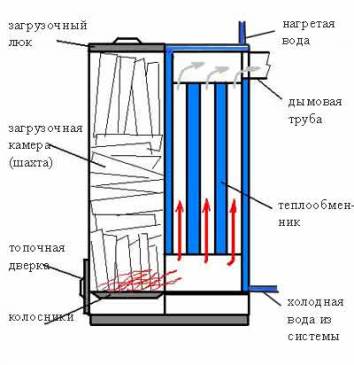

1. The traditional design with flame propagation from the bottom up, in which burning gases pass through the entire layer of fuel and are discharged into the chimney. On the way of the combustion products, a heat exchanger and an afterburner are equipped, into which an additional amount of air is supplied. Heating equipment of this type includes the world-famous buleryan or breneran, Professor Butakov's oven and variations of these units with modified heat exchangers.

2. Shaft furnace, in which the combustion zone is shifted to the grate, and the combustion products are discharged through the adjacent chamber, where afterburning and heat exchange take place. Such a configuration is extremely convenient for the manufacture of a brick heating unit, which is facilitated by centuries of experience in the construction of wood-burning stoves with air channels (coarse stove).

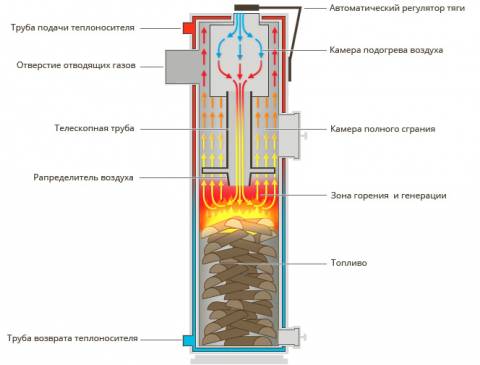

3. Upper combustion units, in which the top of the fuel bookmark is ignited, and the flame is directed downward. As it burns out, air is required to be supplied under the ash layer, so this design requires special solutions to deliver oxygen to the combustion zone. The simplicity of this oven and the efficiency of its operation has contributed to the emergence of many options available for repetition at home. Moreover, the material for the manufacture of such a heating unit can be either an ordinary metal barrel or a household gas cylinder. I would like to highlight the design of a “long-playing” potbelly stove known on the Web called Bubafonya - a modification of the Lithuanian boiler “Stropuva”, extremely popular with home craftsmen.

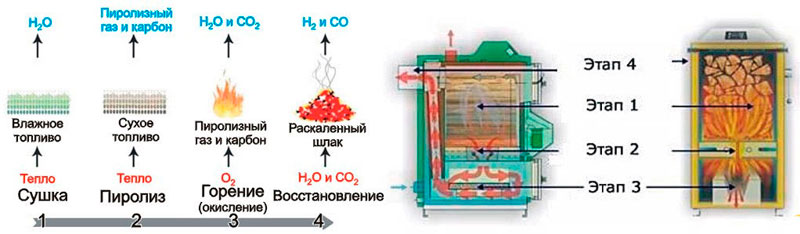

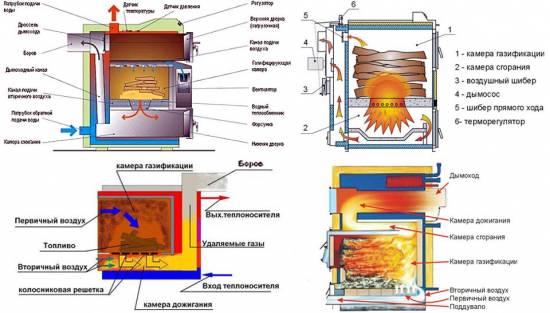

4. Furnaces operating in the mode of gas-generating or pyrolysis fuel combustion. Firewood burns at high temperature and lack of oxygen, which contributes to the release of a large amount of combustible gases. Volatile compounds obtained as a result of the so-called dry distillation are burned in a separate chamber, where a secondary portion of air is supplied. This scheme is the most complex in terms of design, but in terms of efficiency and ease of use, it has no equal.

If we talk about other features of long-burning stoves, they are square or round, and they can be made of both metal and brick.

The high temperature of gases during pyrolysis combustion requires mandatory lining of the working area, which is performed using refractory bricks or protective coatings.

When choosing a scheme and design of a long-burning furnace, it is necessary to take into account not only the advantages and effectiveness of existing options, but also the possibility of repeating one or another design at home. For example, the manufacture of Buleryan or Butakov's furnace cannot be imagined without the use of a powerful pipe bending machine. Due to the complex configuration of the equipment, a lot of welding experience will be required and additional costs for the purchase of thick steel plates and large diameter pipes.The construction of a pyrolysis boiler, in addition to financial investments and the skill of a welder, imposes requirements on the accuracy of calculations and knowledge of all the nuances of dry distillation of firewood. As for the top combustion units, they are the ideal option as the first do-it-yourself design. Firstly, practically no costs will be required, and secondly, a device such as Stropuva or Bubafoni will forgive all miscalculations and imperfections in welds. Its design is so workable that it will not let even a novice home master be disappointed in his abilities.

The nuances of the control system of the upper combustion boiler

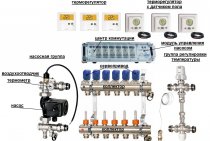

In long-burning boilers with top combustion, the main control principle is the regulation of air flows entering the combustion chamber. Standard units are equipped with a mechanical device for this. The chain driven damper is actuated by the operation of the thermostat.

The thermostat in the boiler is adjusted to a certain temperature regime. When the coolant is heated to the desired level, the damper is automatically set to a certain position, reducing the intensity of heating. It is impossible to sharply reduce the temperature, because the coolant will continue to heat up by inertia, heating the room.

Devices with fans work a little differently. If you need to increase the heat transfer force, then this can be done precisely due to the fan. The device will blow air. Due to it, it is also possible to reduce the inertia of the boiler. The control is automatic, and the sensors record the slightest changes in the temperature of the coolant.

The principle of operation of wood stoves

One of the features of heating devices is the secondary combustion chamber, which is characterized by slow combustion of fuel. Simply put, the logs in the furnace do not burn, but smolder. This effect is achieved by adjusting the amount of air entering the fuel chamber.

The combustion chamber is divided into two compartments. With smoldering firewood, unburned combustible gas enters the second compartment of the chamber, where additional air enters from the injection tubes, after which the gas burns out completely, and the firewood remains to smolder further.

Among the advantages of the system, it is worth noting: an increase in the operational resources of devices, greater efficiency - the stove works 8-9 hours on one tab of firewood.

There are a few more disadvantages: the system only works on dry wood, the combustion mode will have to be constantly adjusted, which is somewhat inconvenient. It is also necessary to constantly monitor the cleanliness of the chimney and periodically clean it.

Types of long burning devices

Conventional heating units require a constant supply of fuel, which burns out very quickly. If this happens at night, then by morning the stove has time to cool down, and the room needs to be warmed up again.

In such devices, solid fuel does not burn so rapidly. In fact, it simply smolders, while releasing heat for a long time. In such furnaces, various types of solid fuels can be used:

- firewood;

- coal;

- pellets;

- sawdust, etc.

The most popular long burning furnaces are the following models:

- potbelly stoves on waste oil;

- heating devices Butakov;

- Buleryan.

These units differ significantly in their design, but are similar in the benefits that their owner receives. They are characterized by ease of maintenance, cost-effectiveness, fire safety and durability. The equipment is able to work without fuel for a long time and quickly heat up the room.

Buying such a stove is not difficult: there are many different models on the market. They have a neat appearance, are compact, but at the same time they are very expensive. You can save a lot by building such a unit yourself, using improvised materials.

Furnace business

§ 3. Furnaces of continuous combustion

If the stove is heated continuously in such a way that it takes hourly from the combustible fuel and transfers to the room such an amount of heat that is required for its heating, then there will be no need for accumulation (reserve) of heat, i.e., there will be no need for a large amount of brick array.

The continuous combustion furnace will evenly give off heat to the room air, since the temperature of its walls will be the same.

In terms of their mode of operation and the uniformity of heating, continuous furnaces correspond to central heating radiators.

The reduction in the volume of the continuous combustion furnace is very significant (by a factor of 3-5) compared with the volume of a heat-intensive furnace. Savings in materials, labor, transportation costs - all this is the result of a reduction in the volume of the furnace

And, last but not least, the continuous combustion furnace takes up little space.

Continuous combustion furnaces have some distinctive features. These include:

- loading shaft (bunker), where the fuel supply required for the entire period of operation of the furnace is placed;

- hermetic headset for tight closing of all holes in the walls of the furnace (furnace, blower, etc.);

- a device with which the air supply is regulated to change the burning rate;

- a device for skimming fuel and cleaning the ash pan without interrupting the operation of the furnace.

In continuous combustion furnaces, the so-called "lower" combustion takes place.

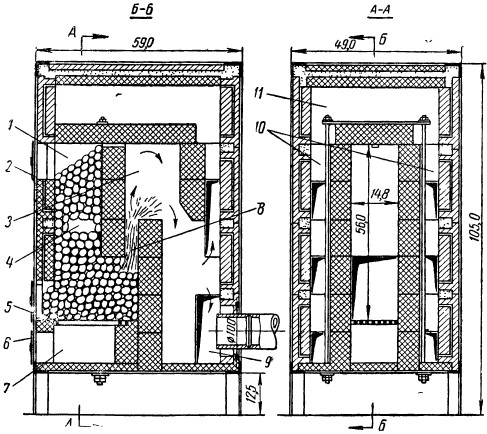

Long-burning furnace of the Academy of Public Utilities (AKH-9) (Fig. 82). Furnace dimensions 49 x 59 x 105 cm. Heat transfer - 2400 kcal / hour; weight - 350 kg. The outside of the oven is tiled.

Rice. 82. Tiled stove AKH-9 long burning

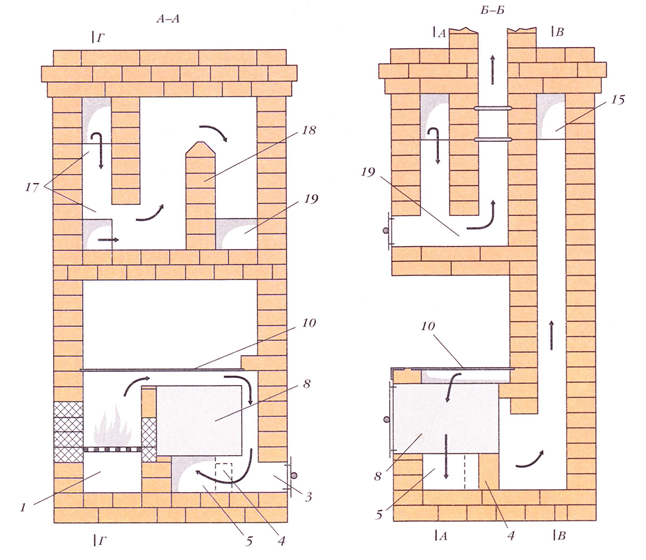

The furnace consists of a shaft 1, a firebox 4, an ash pan 7, an average gas duct 8, an intermediate chamber 5, side gas ducts 10, two upper 11, a collector 9

From the shaft to the grate, as it burns, fuel enters under the action of its own weight. The firebox maintains a constant thickness of the fuel layer and a small combustion mirror. The uniform combustion process creates a uniform temperature of the outer walls of the furnace,

The shaft is equipped, in its upper part, with a door for loading fuel. In its lower part there is a firebox with a grate and a furnace door. The middle part of the grate rotates freely. This makes it easier to clean up the ash. The furnace is assembled in a metal frame. The outer walls of the furnace are made of glazed tiles. Their voids are filled with ceramic tiles and rubble on mortar. The internal filling of the furnace is made of fireclay bricks mounted on edge. Intermediate chamber 3 protects the side walls and roof of the furnace from local overheating.

In the rear wall, at the level of the prefabricated manifold, there is a flue pipe. On the front and side walls of the furnace, holes are made for cleaning the collector and gas ducts. The openings are closed with glazed ceramic plugs.

Combustion products rise from the firebox through the middle gas duct 8 into the intermediate chamber 3, from which they flow into the side gas ducts. Then the combustion products rise along the outer surfaces of the walls of the intermediate chamber and fill the space of two gas ducts 11 under the roof of the furnace. Cooled gases, as heavier ones, descend through the same side gas ducts 10, but already along the inner surfaces of the outer walls of the furnace. The cooled combustion products are collected through special openings in the collector 9, and from here they are removed through the pipe into the chimney.

The fuel is ignited and the firebox is cleaned through the kindling door 5. Fuel is loaded through the door 2. The ash is removed through the blower door 6. All three doors are cast iron, hermetically closing. The intensity of the furnace is regulated by a greater or lesser supply of air under the grate using a slider in the blower door.One full load of the furnace with anthracite is enough for round-the-clock continuous combustion with a heat output of 1600 kcal / hour. During severe frosts, fuel should be loaded into the furnace shaft twice a day.

The furnace is manufactured in the factory and delivered to the installation site in finished form. The furnace can work steadily on coke, anthracite, peat briquettes or coal fines, shavings and sawdust.

Furnaces for heating cottages

The range of heating stoves is wide, it is easy to get confused in it, so even before going to the store you need to clearly understand what functions the stove should have. To do this, it is worth understanding the capabilities of heating units.

Power

The most important characteristic, the wrong choice of which will make the oven inefficient. All heaters have a certain thermal power, it is expressed in kW. For a normally insulated residential building, the calculation is usually made by area: divide the total number of square meters of the house by 10 and get the required power in kW.

For a country house, this calculation is not entirely suitable. When selecting power, the following subtleties must be taken into account:

- wall, floor and ceiling material and its thermal insulation properties;

- seasonality - whether the house will be used in winter, or heating is needed only on cool days in spring, summer and autumn.

The greatest power of the stove will be required if the house is made using lightweight technology, and visits to the dacha are planned in winter, in frosts. In this case, it is necessary to choose a furnace with a capacity greater than the calculated one or install additional heating devices.

Long burning mode

Some wood-burning stoves can operate in long-burning mode. It is due to a special mode of fuel combustion - pyrolysis. Pyrolysis type stoves can run on wood or pellets. When ignited, the firewood heats up, and the process of decomposing them into a solid fraction - coals and ash, and gaseous - smoke begins.

The flue gases contain many combustible elements; they are not completely used in conventional stoves and exit through the chimney, heating it strongly and giving off heat to the atmosphere. Thus, the thermal resource is used at best by 60%.

In stoves equipped with a long-burning mode, flue gases are burned in a special zone, it is called smoke circulation. The smoke passes through these channels, and its combustible components burn out, giving off heat to the walls of the stove.

For the successful flow of this process, it is necessary to limit the flow of air into the furnace in order to cause the firewood to smolder and increase the formation of smoke. It is regulated by a valve on the furnace door, while the optimal mode is selected empirically.

Housing and firebox material

- The debate about which stove is better, cast iron or steel, has been going on for a long time. What is the difference?

Weight. Cast iron models have thicker walls and a massive structure, so they are heavier, their weight can exceed 250 kg. If the floor in the country house is wooden, it may be necessary to strengthen it, which will lead to additional costs. Steel models are about twice as light.

Corrosion resistance. Cast iron is not susceptible to corrosion in a slightly acidic environment - for furnaces used periodically, this is a big plus. The temperature difference during kindling leads to the formation of condensate in the furnace. Mixing with the soot that has settled on them, water forms a weak carbonic acid. Steel structures corrode under these conditions.

Burn-out resistance. Due to the thick walls, cast iron models are more resistant to burnout even at very high temperatures.

Price. Steel models are 1.5-2 times cheaper than cast iron ones.

Inexpensive models popular with summer residents are usually combined. The surfaces that are highly heated and subject to corrosion are made of cast iron, the rest of the structural elements are made of steel, which makes it possible to combine durability and low weight.The price of such devices is in the middle range.

Additional functions

The main task of heating stoves is to quickly warm up the house.

- . Depending on the model, they may be equipped with additional useful features:

hob, solid or with burners;

the ability to connect a heating circuit, water or air;

decorative elements that allow you to create a cozy atmosphere in the country - panoramic glass in the furnace door, decorative inserts, forged grates.

Whether these features are needed or not is a matter of personal preference, but it should be borne in mind that their presence affects the price of the stove.

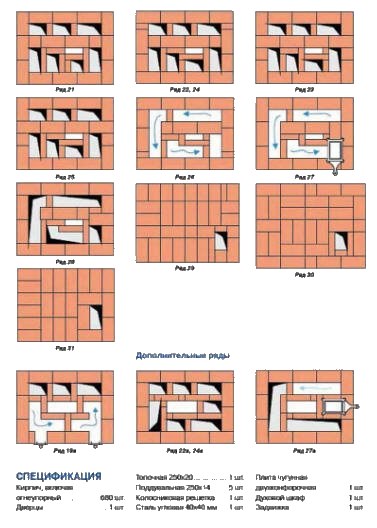

Furnace ordering

Before proceeding with the self-laying of the furnace, perform a few simple preparatory steps.

Soak the brick first. To do this, the bricks need to be dipped in clean water and left there for about a day. Water will fill the pores in the brick structure. Due to this, in the future, the building material will not absorb water from the clay solution.

Prepare clay solution. It will consist of ground clay, some sand and clean water. The specific ratio of components is selected in accordance with the characteristics of the clay.

It is important that the finished solution has normal plasticity and a uniform structure. On average, it takes about 20 liters of mortar to lay hundreds of bricks.

1 row. It was previously noted that this row should be laid out exclusively on the building level with additional verification using a square. Lay out this row with a solid masonry. Inside, the use of halves of bricks is allowed.

2 row. Lay out in the same way as the 1st row. Be careful and do everything in strict accordance with the technology, because. the first two rows serve as the base of the furnace, which should be as reliable as possible.

3-4 rows. Continue laying, gradually forming an ash chamber. At the same stage of masonry, the door of the said chamber is installed. Additionally, 3 doors for cleaning hatches and a door for a blower are mounted. On the reverse side of the Swede, lay out the smoke turns. They are placed in a vertical position and communicate with the combustion chamber through a hole, which is equipped during the laying out of the furnace.

5 row. Install the finished oven and place a suitable grate in it. Form an overlap for the cleaning hatches and the blower door.

6-10 row. Lay out the walls of the chamber of the firebox and oven. Between the furnace compartment and the oven, a partition made of fire-resistant bricks is laid out. The brick must be laid out on the edge. The partition should be a row lower than the cameras themselves. After the tenth row is ready, lay a standard steel corner and an additional cast iron plate from the front of the structure. To fix the corner, use steel wire and a 2-centimeter layer of clay mortar.

11 row. Complete to the end the overlap of the channel, through which the cast iron plate and the right wall of the furnace are separated.

12-16 row. Lay out the brewing compartment and 3 vertical flues. Lay out the chimney openings from refractory bricks.

17-18 row. Form an overlap over the brewing compartment. To form the floor, use the sheet steel laid in the previous steps and a corner of the same material.

19-20 row. Fix 2 hatches on the front of the door structure for cleaning the gas outlet channels.

21-28 row. Lay out the chimneys. Do not forget about dressing the seams. In the process of laying out the 27th row, install a convenient valve. Above the installed smoke damper, leave a technological hole through which the gas ducts will interface with the air ducts.

29-30 row. Lay out the overlap of the chimney channels. At this stage, the width of the masonry along the perimeter must be increased by 50 mm. Thanks to this expansion, a cornice will be formed.

31 row.Bring the dimensions of the overlap of the design dimensions of the 27th row.

32 row. Start laying out the chimney. The standard design of the chimney has dimensions equal to 130x250 mm.

On this, the layout of the furnace can be considered complete. In the end, it remains only to complete the chimney device, as well as, if desired, finish the stove, for example, with paint or ceramic tiles. In addition, you can buy a variety of accessories, for example, for fuel storage.

Swede oven (front view)

The construction of stairs in the house is not an easy process, but doable. The main difficulty lies in calculating the angle of inclination and span parameters, because not only ease of use, but also the durability of the structure depends on this. Durable and beautiful ladder…

Advantages and disadvantages

Modern long-burning stoves have a lot of advantages that can play a decisive role in the initial choice of heating equipment. However, the shortcomings of existing designs require you to weigh the pros and cons before deciding to replace a working heating unit with a newfangled pyrolysis boiler.

The advantages of the considered structures include:

- multiple increase in operating time on one fuel load;

- the possibility of complete autonomy - when entering the main mode, the operation of the unit does not require operator intervention;

- fuel burns almost without residue;

- increase the interval between downloads;

- use as fuel not only coal and firewood, but also wood chips, sawdust, dry plant waste, pellets, etc.;

- reduced weight and dimensions;

- the possibility of adjusting the combustion process;

- The efficiency of long-burning pyrolysis boilers reaches 90%;

- smoke residues do not contain soot and harmful substances;

- many designs available for DIY.

Be sure to check out the disadvantages of this type of ovens:

- increased requirements for the chimney. It must have sufficient height and thermal insulation;

- only dry fuel can be used in long-burning furnaces. Excess moisture reduces the temperature of the flame, and water vapor blocks the access of oxygen, which makes it impossible for the unit to operate in the gas generator mode;

- low smoke temperature contributes to the layering of soot and other combustion products on the walls of the chimney;

- when burning wet fuel, heavy fractions and hazardous chemical compounds appear in the smoke residues;

- higher cost compared to conventional ovens.

If we weigh all the pros and cons, it is easy to understand that the wide popularity of long-burning stoves is not an accident at all, but the result of accurate calculations and a carefully designed design.

Do-it-yourself step-by-step instructions for making a long-burning stove with your own hands

1. For the manufacture of the body of the stove, a grinder is used, with which the top of a metal barrel is carefully cut off. Of course, in the case of using a container with a thickness of more than 3 mm, the use of a gas cutter will be more justified. Once again, we remind you that the work must be done carefully - the furnace cover will be made from the cut part in the future. If a pipe is used as a body, then a bottom cut from sheet metal 5–6 mm thick must be welded to it.

2. In the lower part, four legs from a channel or corner are mounted to the body using a welding machine. Note that if the body is made of metal and has a rectangular shape, then additional supports can be dispensed with.

3. Using the same grinder or autogen, an air distributor is cut out of sheet steel 5-6 mm thick - a circle that can enter the barrel with a small gap.The edges of the metal pancake must be carefully cleaned to prevent the possibility of touching the furnace walls.

4. A hole with a diameter of 20 mm is cut in the center of the air distribution device and a pipe is welded to supply air to the combustion zone.

5. On the reverse side of the flat piston, four sections of the channel or corner are welded, evenly arranging them in a circle. Note that the blades should not protrude beyond the air distributor. In the future, thanks to these elements, between the metal pancake and the firewood there will be an air gap necessary for fuel combustion.

6. A lid is made from the top of the barrel cut off earlier. To do this, a metal strip is welded from the outside along the entire contour so that its diameter allows you to freely install the top of the stove on the body.

7. A hole is cut in the cover, 3–5 mm larger than the diameter of the duct pipe. In addition, two handles made of metal strips are welded to its top. With their help, it will be easier to open the hatch for loading fuel.

8. A hatch is cut out in the lower part of the body for cleaning the furnace. Try to do this part of the work with a grinder with a thin circle installed. This will ensure a more accurate fit of the door to the body. A thin metal strip is welded along the perimeter of the hatch to eliminate the gap that has formed. Then the hinges are welded, the structure is installed on the body and the valve is mounted.

9. On the other side of the furnace, at a distance of 50–100 mm from its upper cut, a chimney pipe is cut in. A piece of steel pipe is used as it, into which the chimney will enter with a slight interference.

It is better to use a collapsible chimney, consisting of several sections - during operation it will be easier to clean.

On this, the manufacture of a vertical-type solid fuel unit can be considered completed. It remains to install the stove in place and attach the chimney.

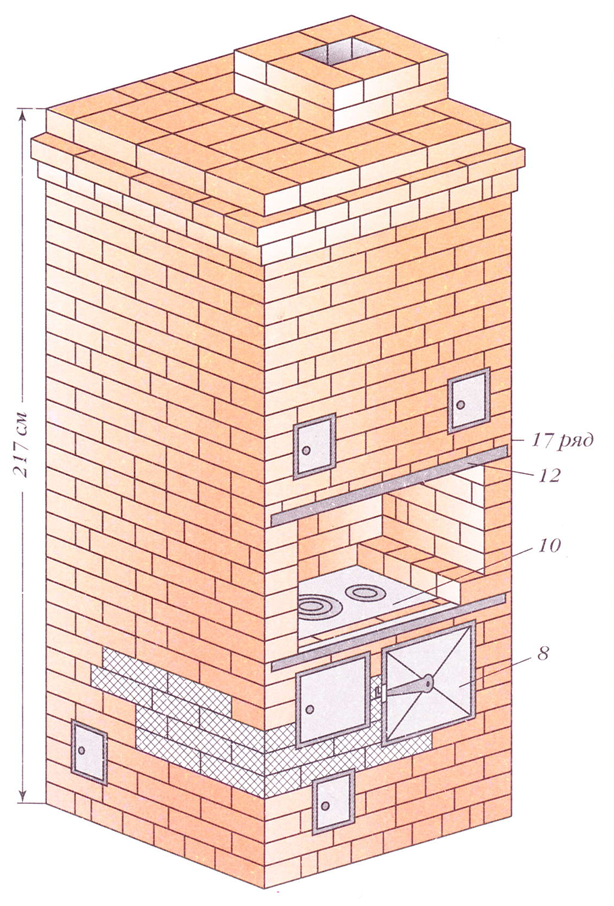

Swede stove with three do-it-yourself firebox modes

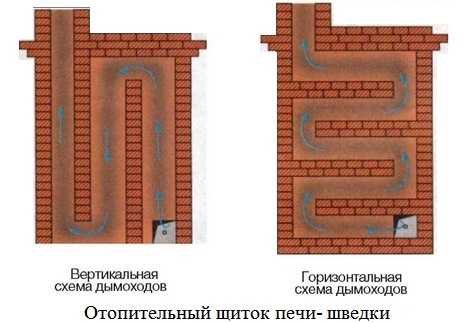

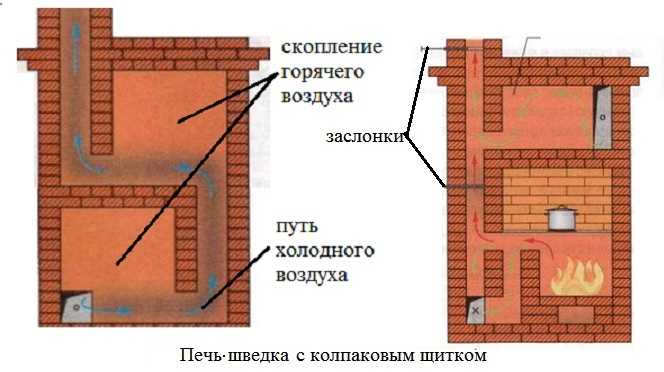

Swede stoves differ from other heating and cooking stoves by the presence of a heating shield in the rear. This brick shield has a system of gas ducts: from vertical or horizontal. The smoke passing through them warms up the structure, and the rooms are already heated from it. The system turns out to be efficient and economical: the heat that went into the chimney in a traditional Russian stove is used for space heating. But both systems for constructing a shield (vertical and horizontal) have disadvantages.

With a horizontal arrangement of gas ducts, the entire shield is heated evenly. But, such a system needs a large number of cleaning holes and, accordingly, doors on them. Given that furnace casting is quite expensive today, these doors significantly affect the final cost.

Heating shield of the Swedish oven with horizontal and vertical gas ducts

With a vertical arrangement of gas ducts in a Swede, there can be one cleaning hatch. But there is another problem: while the stove is heating, in the first channel, on the side where hot gases from the furnace enter, the shield will be noticeably hotter than in the third - at the exit. Since the shield is usually located in two rooms, one of them will be much warmer than the other.

There is also a third type of shield device: bell-shaped. It combines the advantages of both systems: one cleaning window is required, the entire surface is heated evenly, and less brick is required for construction.Moreover, with this construction, the stove cools down more slowly: the warmest air is kept in the tops of the caps for a long time, and the “draft” from the doors passes only in the center.

When using the bell-shaped principle of constructing a shield, heat is retained longer

From all of the above, it follows that the most economical and efficient Swedes with shields built according to the bell principle. They are also easier to manage: it is possible to organize a “summer” and “winter” mode of operation, in which either only a small part of the shield (in summer) or the entire heating power is switched on: in winter. There is even a variant of a Swedish stove with three firing modes: an “autumn” mode is also added, in which a little more than half of the chimney channels participate in the smoke circulation.

Conclusions and useful video on the topic

From the following video you can learn how to choose a small but efficient heating stove:

The following video will discuss how to independently install a potbelly stove in a country house:

Therefore, if the question arose of heating a country house, you should opt for wood-burning stoves or potbelly stoves. The price of the issue will depend only on personal preferences and the area of \u200b\u200bthe country house.

What oven do you use in the country? Does it have enough functionality to meet your needs? If you use one of the models listed in our rating, please share your opinion with other users in the comments block.

Choosing a heating stove for a country house is not an easy task, because special requirements are placed on it. So that the purchase does not become a disappointment, it is necessary to consider the characteristics of the proposed models and choose the most suitable option.