Discussions

Frame baths and accessories.

3 posts

If you have already read that frame baths (they are also frame-panel ones) are worse than a beam or a log cabin in terms of thermal insulation, we will please you - this is not so.

Proper warming Frame bath frame bath strife. We have no magic with the facade - we build the base from a bar, the inner frame - from a board and sheathe it with an imitation of a bar. Such a frame is lightweight, does not shrink and can be placed on simple piles. But then we conjure with insulation - we have it only from basalt slabs from Paroc (Finland) and Rockwool (Denmark).

These are the highest quality materials we have ever worked with. It is from the heater that the time of warming up and cooling down of the bath depends. Our materials will keep heat in the steam room for 2-4 hours more than simpler and more inexpensive ones.

Service lifeBasalt slabs are, in fact, stone wool. She is not afraid of fungus, mold, rodents and insects. It does not deform and does not burn. A bath with such a heater will last up to 100 years.

CostYou can buy a turnkey frame bath inexpensively - from 175,000 rubles. Our price for building a bathhouse with Rockwool and Paroc is 5,000 - 7,000 rubles higher than analogues, but you know what you are overpaying for. Often, builders save on your heat in order to win the price of a finished bath over competitors. In fact, a frame bath, insulated to the conscience, retains heat better than timber and logs.

Each project that is on the site or that you come up with can be built in wireframe technology - there are no restrictions. Such a bath is built from 5-7 days. If you don't want to waste your time and listen to the sound of hammers under the windows, order a mobile sauna. We'll bring a ready-made building and install it in a couple of hours.

Roof decking, color of your choice Metal tile, color of your choice

Foundation plinth finish profiled sheet. Color to be agreed Finishing the basement of the foundation facade panel "DOCKE" Treatment of the lower crown and the floor log with an antiseptic Floor logs from a bar 150x100 Increase of the floor board from 28mm to 36mm Larch sheet pile in the sink 27mm Set of material for chamber drying Finishing the walls of the bath Blockhouse 28mm Finishing the walls of the bath Blockhouse 36mm

Floor and ceiling insulation up to 150mm Izover Replacement of insulation Izover 100mm for Rockwool 100mm Replacement of insulation Izover 100mm for Rockwool 150mm

Furnace accessories

Chimney wall thickness 0.8mm Sauna stones Kabrodiabase 20kg Sauna stones raspberry quartzite 20kg

Replace a wooden window 60x60 with a PVC window 60x60 single-chamber Replace a wooden window 80x80 with a PVC window 80x80 single-chamber Replace a wooden window 1100x90 with a PVC window 1100x900 single-chamber Replace a wedge bath door with a frame one, aspen finish with glass Replace a wedge bath door with a frame one, linden finish Replace a bath door wedge on glass matt Entrance door China metal Entrance door Russia metal Entrance door Russia metal, with a thermal break Portable bench in the sink 0.4x1.0m Portable bench in the sink 0.4x1.5m Portable table 0.6x1.0m

Install a shower tray 90x90 Finishing the corner of the tray 90x90, PVC lining Finishing a steam room Lining Linden "Extra" for a steam room 2.1x2m Shelves linden 25x90x2.4m, grade "Extra" Shelves abash 27x90x2.4m, grade "Extra" Plinth linden for a steam room Finishing interior walls timber imitation 20mm

Do-it-yourself veranda Foundation binding

Wooden strapping is suitable for structures of small and medium weight. When building with your own hands a low-rise house of an outbuilding or a bathhouse made of building materials using frame technology, an excellent solution for tying screw piles is tying with a wooden bar. To give the structure strength and reliability, free-standing supports are combined into a single rigid system using a grillage. This is the binding of the foundation, designed to evenly distribute the load from the building to the ground.

The binding of the pile-screw foundation with a beam begins with the impregnation of the tree with antiseptic agents. This operation will help further protect it from mold and fungi.The ends of the beams intended for tying the pile-screw foundation are made in the form of grooves for connecting them “in a paw” or “half a tree”.

Condensation will form on the metal surface. In order to protect the wood from contact with moisture when tying screw piles with a beam, the surface of the heads is covered with roofing material.

The beams for tying the pile foundation are fastened with nails or self-tapping screws. It is desirable to strengthen the corner joints of the grillage with metal brackets.

As a starting material, you can use a beam with a section of 150x150 mm or boards 50x150 mm assembled into a composite beam. With a distance between supports not exceeding 2.5 meters, such a structure can easily withstand the weight of a two-story frame-type building.

The lower trim of the frame house on screw piles simultaneously plays the role of an intermediate link in attaching the walls to the foundation. Therefore, the responsibility for the uniform distribution of the load lies with it.

Bath house project Drawings for construction

Foundation Binding Overlapping in a frame house bath

Bath house frame Walls and roof

How much does it cost to build a house

How to insulate the ceiling with mineral wool

Installation of lining Method of fastening to the facade

Installing a window sill

Hemming the cornice overhang

Hemming the gable overhang

Plastic slopes for windows

Drain in the bath Insulation of the floor and walls Installation of a window

DIY tool rack

Do-it-yourself warm door

Gypsum board for tiled floor

Vapor barrier in the steam room

Furnace lining with brick or brick portal

Shelf above the fireplace

Do-it-yourself door to the steam room and installation of a remote tank

Connecting a remote tank to the register of a sauna stove

Shelves in the bath with their own hands

The back of the shelf in the steam room in the bath

Processing shelves in the steam room in the bath

Steam heating time Temperature in the steam room

Draining from the bath Laying the outer pipe

How and how to insulate the floors of the bath

Warming the floor surface is a rather complicated process, which has many nuances. It all depends on what the floor will be made of. If it is wooden, then some materials are used, and if it is concrete, then it is preferable to use completely different ones. Although, for example, expanded clay, you can insulate all types of floors. It is necessary not to forget about the waterproofing work. This is due to the fact that usually the insulation does not tolerate contact with water. For example, mineral wool loses its quality characteristics.

Choosing thermal insulation materials

Choosing the right heater is not easy at all. Many experts, not without reason, believe that this process is an art. After all, the market for thermal insulation materials is quite diverse. Therefore, for many beginners, as they say, “eyes run wide”. They usually purchase the most expensive material. But, this does not guarantee its quality at all. Experienced bath attendants are not at all satisfied with the heaters that are sold in stores. Therefore, they experiment, trying to insulate the bath with completely unexpected objects, for example, bottles.

You can also use ceramic tiles. It is used only where there is a concrete floor. This method has already been tested by many attendants, who are simply delighted with it. The advantage of tiles is that they eliminate the use of expensive systems and materials. It must be of high quality. It is better to purchase one that can withstand the maximum load.

Thermal insulation of the bath on screw piles

Today, a bath on screw piles is becoming increasingly popular. This is due to the fact that many attendants do not want to bother with foundation work. The warming of such a bath has its own specifics. Insulation work should be carried out after shrinkage of the house on stilts. This will be enough. Because baths on stilts are so popular.

Wood or tiles can be used to finish the floor surface, they have good thermal conductivity.You can also walk barefoot indoors. But it is better not to lay the concrete floor in the bath on piles.

Wooden floor insulation

For better stability of the floor structure, floor beams should be used that are in direct contact with the brick foundation. A cranial beam should also be placed on top of the beams. After that, a draft floor is constructed, on which heat-insulating material will be attached. You can use expanded clay, polystyrene foam, slag, mineral wool.

After carrying out thermal insulation work, you can proceed to vapor barrier work. Usually glassine is used to protect the insulation from steam and moisture.

It is important to take care of the drainage system. However, some wood floor lovers use its removable type.

This means that it is not fastened with nails, it can be removed.

concrete floor insulation

It is best to insulate this floor with expanded clay. But you can use perlite, mineral wool. Typically, thermal insulation materials are laid between two layers of concrete. Another technology for warming the steam room with expanded clay. It can be mixed directly into concrete. Difficulties can also be encountered when insulating with perlite. The thing is that it can easily scatter in different directions. Therefore, doors should be tightly closed during thermal insulation work. Another disadvantage is that it can cause pulmonary diseases. Always wear a respirator.

Conclusion

Warming the floors of the bath is simply necessary. Indeed, after its implementation, its effectiveness is significantly increased. The choice of insulation materials depends on the type of floor. However, insulation will be ineffective if a drainage system is not built and appropriate waterproofing work is carried out.

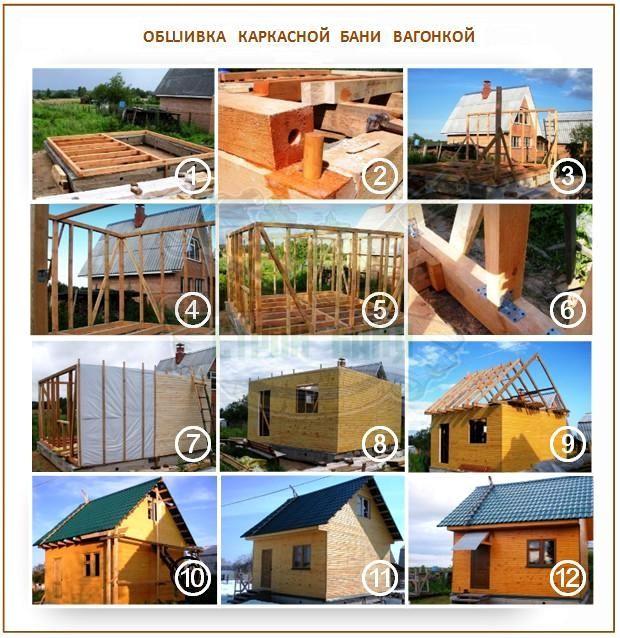

Stage VI. We decorate the walls with modern materials

And now - to the most interesting part of the construction of a frame bath. We're not leaving her in the RSD, are we? Of course, it's time to pick up a "fur coat" for her.

But painting with paint and plastering are not the only options for exterior decoration that a frame bath can have: reviews of experienced summer residents say that it doesn’t matter, its design is so simple - from the outside it is quite possible to give it an expensive and chic look. And the modern construction market offers a sea of finishes for such buildings, the most successful of them for the bath will be the following

clapboard

Decorative and imitation wall paneling is the simplest and most affordable way to upholster frame baths on the outside: such structures turn out to be very solid, and it’s not a shame to show them to acquaintances and friends, inviting them to a bath broom and a barbecue in nature.

It is necessary to place the lining on the outer wall horizontally, and after putting waterproofing from glassine under the upholstery

At the same time, fasten the whole sheets with an overlap, gluing all the edges with adhesive tape - it is important to do this operation carefully so that unnecessary moisture does not occur in the bath

Thermal panels

The traditional construction of a frame bath still provides for mandatory wall insulation, so why not do this with the help of thermal panels? At their core, they are a three-layer structure with insulation - mineral wool or foam, enclosed between two PVC layers. Their outer surface is usually made in the form of masonry and sprinkled with compressed stone chips.

At the same time, the panels themselves have mutual grooves, and therefore form a monolithic pattern of a stone or brick wall. And you can make such a finish in the bath with the most common self-tapping screws that will fix the panels to the profiles on the facades.

Vinyl siding

Siding is the lightest and most popular material for sheathing frame baths. It's not expensive and it's surprisingly easy to install. And the variety of colors, textures and thickness cannot but rejoice.

Block house

For those owners who have dreamed of a beautiful log bath all their lives, but have built only a frame sauna on the site so far, there is good news - with the help of the latest material for finishing the block house, it will now be impossible to distinguish a steam room from a real log house from the outside:

Features of the construction of a frame bath with their own hands

Before proceeding with the construction work on the construction of a frame bath, you need to know some features of the work

Experts recommend paying attention to three important points - vapor barrier, thermal insulation and the choice of wood species.

vapor barrier

Please note: it is better not to use roofing material as a vapor barrier material during the construction of a frame bath - when heated, it releases a rather specific, unpleasant odor into the air. A vapor barrier layer is laid between the inner lining of the bath and the insulation layer

A vapor barrier layer is laid between the inner lining of the bath and the insulation layer.

thermal insulation

Experts say that mineral wool and / or fiberglass can be safely used as a heat-insulating material for a frame bath.

Wood for a frame bath

The main requirements for the choice of wood for the construction of a frame bath with your own hands are:

- the material must be well, fully dried;

- the best choice would be larch, aspen or linden - they have a low thermal conductivity threshold;

- for external walls you will need boards with a thickness of 30 mm;

- the outer skin of the building can be made of pine or larch;

- the inner lining is made of wood of any species, but it is better to give preference to linden.