How to melt properly

The algorithm of actions looks like this:

- It is required to place sheets of dry paper at the bottom of the firebox. Then, a small layer of wood chips, logs, preferably fruit varieties. To accelerate ignition, it is required to arrange them in a pyramid.

- Set fire to the paper. Then close the door, but leave the vent open. Due to which you can regulate the rate of combustion of firewood. Moreover, depending on the amount of oxygen, the fuel will burn faster or slower.

- After complete combustion of firewood, you need to place a layer of small coal, up to 15 cm, on the resulting pile of ash.

- When it burns sufficiently, you can pour a larger mineral on top in the form of a pillow. The height can reach 60 cm. Before that, be sure to move the hot stones apart so that the coal does not sinter.

If fuel of insufficient quality is used, coking may occur. Therefore, if you are not sure about the quality of the purchased raw materials, put it in the form of a sandwich, mixing it with firewood. Several layers of logs, successively mixed with stone, make it possible to heat up the installation sufficiently and release heat into the premises.

Advantages

The strengths of some models may be weaknesses of others. Therefore, here will be considered general, deserving flattering reviews:

1. Attractive design. They can be built into any interior without compromising its appearance.

2. With excellent quality, prices are not prohibitive at all.

3. There is no difficulty in maintenance: the main care is to throw fuel into the furnace and remove the ashes.

4. Profitability. You can use any solid fuels and firewood, at the same time removing all the trash in the country.

5. The range of models is wide: now their range consists of two dozen, and modifications - from about a hundred items.

6. Reliability and durability. The stoves are made from 4mm steel. The warranty period of 3 years is somewhat incorrect: the use of the product is inconsistent. Another number is more correct - 2000 hours.

7. Various sizes and taking into account the possibility of installation in the right place.

8. Use at a convenient time for the consumer.

9. Slow burning and high heat transfer, that is, you need to throw up fuel infrequently, but at the same time heat is kept in the room.

Features of the Kuban oven

The temperature of the stones in the furnace reaches 650 degrees. The stones themselves are closed, the heater is inside the heating chamber and flames burn from all its sides. As a result, the water that enters the heater with the help of a special dispenser begins to evaporate very quickly and as a result, weightless steam is formed. The oven can also be open, in which you can select the soaring modes to your taste.

- The oven is equipped with a door with which you can adjust the temperature.

- The presence of a dispenser allows you to evenly distribute water inside a closed oven

- The heater can be open, which allows you to combine evaporation modes

- The heating chamber is super-rigid, has a special shape

The Kuban Teplodar furnace has the best performance and is a very reliable device. With this oven, the process of soaring will turn into a real pleasure and will please even the most demanding vapers.

How to fire up a boiler

How to clean a coal boiler from soot

The composition of soot includes a non-combustible residue, which turns into slag during combustion. An additional problem is that under the influence of high temperatures, low-quality coal leads to increased formation of condensate, an acid that can corrode the metal of the heat exchanger.

Boiler cleaning is carried out in several stages:

- It is necessary to remove the ash from the ash pan, a chamber located immediately under the firebox and representing a capacious box closed with a sealed door. The ash pan is taken out, the ashes are poured out.

- Slag removal is carried out with a special tool, the appearance of which resembles a curved awl. Influxes are removed along the perimeter of the heat exchanger and from the grate.

In addition to regular cleaning of the boiler, measures are taken to prevent increased soot formation. The main reason why the heat exchanger becomes clogged with soot is the insufficient combustion temperature of the fuel. Layered stacking of firewood mixed with coal can solve the problem of increased soot formation.

How to clean the chimney of a coal-fired boiler

Proper operation of heating equipment includes measures to reduce the formation of soot in the chimney during operation of the boiler, as well as regular maintenance and cleaning of pipes. The SNiP stipulates the need for routine maintenance, at least, Twice a year.

Pipe cleaning is carried out in the following ways:

Mechanical cleaning method - proper cleaning of chimneys is carried out using a special brush. Flexible plastic rods are attached to the rod. If necessary, the brush can be extended by attachable flexible bars. Cleaning is carried out from the roof. Soot is removed through special revision wells. The heaviest layers of soot accumulate at corners and chimney adapters

During cleaning, they are given the most attention.

Chemical preparations for cleaning - are available in the form of additives to the fuel. It is enough to place the bag in burning coal to effectively clean the chimney.

Chemicals are used as preventive measures and cannot completely replace the need for mechanical cleaning.

Reducing soot emissions from coal combustion. Soot prevention is the best measure to control deposits on the chimney walls. As a preventive measure, several methods are used. They install a soot trap, provide the required temperature for burning coal, change the design of the chimney and install a deflector to improve traction characteristics.

All of these measures are aimed at maintaining the health of both the boiler itself and the chimney. Acid condensate leads to a rapid burnout of the heat exchanger and chimney.

Proper operation of a coal-fired boiler includes: a competent choice of fuel, kindling and maintaining combustion in the chamber, preventing increased soot formation and regular maintenance of the heating unit and chimney.

Owner opinions

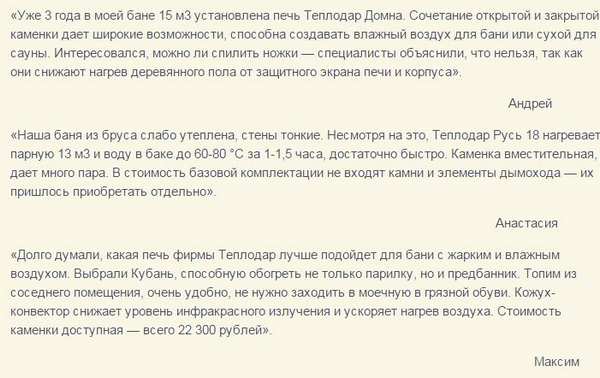

The following are some reviews from furnace users.

“We bought a Russian sauna stove with a fireplace door. Looks great and very presentable. And it works even better - a couple of clutches, and in the steam room it is already 110 ° C. Comfortable warmth without feeling suffocating. Economical fuel consumption, coupled with a stylish design and reasonable price - with both hands for Teplodar!

Zarina Radina, Sverdlovsk region.

“The most affordable option for our house was the opportunity to buy a Teplodar gas stove. It was doubted for a long time whether this would be an effective solution. But in fact, everything turned out to be very simple and functional. The latest design of the stove allows you to steam comfortably after 30 minutes of intense heating. Nothing better than wood burning. Thanks to the manufacturer, we are satisfied.

Sergei, Moscow.

“According to the reviews of friends, I decided to purchase a Rus stove from the manufacturer Teplodar. Outwardly, it is presentable, attracted by an increased manufacturer's warranty of up to five years. Well constructed - thick solid steel. It’s a pity I didn’t immediately buy a tank for heating water, then I had to run around in search of a suitable one. So far I have not found any complaints in operation.

Mikhail Badin, St. Petersburg.

“We have a small bathhouse, we had enough money for it, so an electric stove is enough for us. A very inexpensive and practical option was purchased from Teplodar. We steam with pleasure, just like in a real Russian bath. Installation is simple, consumes electricity in moderation.Considering that we use the bath once a week, the operating costs are quite bearable. In general, the result exceeded all expectations.”

Peter, Yekaterinburg.

Price

It is available to buy sauna stoves in a variety of dealer stores, as well as on the website of the manufacturer Teplodar. The table shows the price of equipment without taking into account the cost of additional installation of a gas burner.

| Name | Dimensions (WxHxD), mm | Steam room volume, m3 | Price, rubles |

| Domna 25 LK | 615x995x705 | 10-25 | 26000 |

| Cascade 18 LP Panorama | 380x920x770 | 10-18 | 20500 |

| Kuban 20 L | 500x865x700 | 10-20 | 19900 |

| Laguna 12 TK | 855x330x690 | 6-12 | 15000 |

| Teplodar Rus 18 LNZP Profi | 335x810x790 | 10-18 | 22600 |

| Rus Panorama 27 LNZP | 440x930x800 | 18-27 | 30800 |

| New Russia 18 L (2004) | 395x815x805 | 10-18 | 13800 |

| Sahara 16 LRK | 785x380x755 | 8-16 | 17500 |

| Siberian cliff 20 LPU | 835x565x730 | 10-20 | 26500 |

| Siberia 20 LRK Panorama | 785x375x750 | 10-20 | 23200 |

| Taiginka 10 TU | 405x330x705 | 4-10 | 8500 |

| Electric heater SteamFit 3 | 560x400x240 | 12 | 16700 |

| Oven SteamGross 3 | 580x530x643 | 26 | 41000 |

The best fuel for the boiler

Each type of fuel has its pros and cons. The most expensive type are briquettes and pellets. It is convenient and safe to use them, but not everyone can afford the cost of raw materials. The most economical and efficient type of coal is anthracite, which is the most expensive of all coal grades.

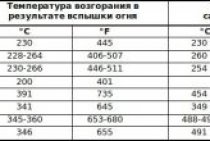

Anthracite should be used with caution, as the fuel gives a high temperature, and the boiler elements may not withstand it.

Optimal for standard boilers will be hard coal of the "DPK" brand - it has good efficiency indicators and a lower price. Firewood is less efficient than coal, but in areas where there is no access to other types of fuel, it will be a good alternative. Such species as birch, ash, beech and oak have the maximum calorie content. But in any case, firewood will cost consumers more.

Every owner of autonomous heating should know how to heat the boiler correctly. This will allow efficient use of solid fuel and extend the life of the heating system.

When installing an individual solid fuel heating system in houses, there may be problems with proper operation. Design features, the sequence of actions during kindling, as well as the selection of solid fuel elements can cause difficulties for owners.

Moreover, stoves and boilers operating on coal are quite dangerous, so you should be careful and not violate fire safety standards.

Also, it is important to study all the parameters and features of the purchased equipment.

What kind of coal is better to heat the boiler

The manufacturer initially carries out heat engineering calculations, and adapts the design of the combustion chamber and heat exchanger to a specific type of fuel. Therefore, in order to increase the efficiency of a domestic boiler, it is enough to use coal of the grade and fraction indicated in the operating instructions.

What brand of coal to heat

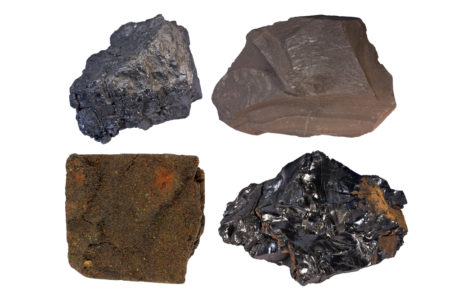

The composition of coal includes carbon and non-combustible impurities, which form ash and slag after combustion. The ratio between carbon and impurities depends on the selected fuel grade. Coal has (depending on the brand) a different degree of moisture, loose or solid structure, age of formation.

In order to effectively heat a coal boiler, it is necessary to understand well what characteristics distinguish one or another type of fuel:

- Lingit - this type of fuel has a loose structure and a large percentage of ash residue. Lingit is used in industrial power plants. For heating the house, this type of fuel is not suitable.

Coal - has a calorific value of 5500 kcal / kg. The percentage of carbon is not less than 75%. Ash content from 2 to 4%. Most household boilers of the classical type are heated with coal. For gas generator type equipment, not suitable due to humidity above 20%.

Brown coal - calorific value is in the range of only 3000 kcal / hour. When burned, a large amount of ash residue and coking substances are formed. Humidity is at 50%.Brown coal is not recommended for heating household boilers, due to the rapid clogging of the chimney and heat exchanger.

Anthracite - the moisture threshold is within 7%. It has high rates of specific heat, equal to 9000 kcal/hour. The share of ash carried away by gases from the coal boiler is not more than 7%. Anthracite, manufacturers of heating equipment, recommend heating gas-generating boilers. Coal is divided into several grades by size: fist, nut, seed.

Is it possible to heat with coal briquettes

Coal briquettes are made by pressing small fractions (dust). As a binding element, special organic or mineral compounds are used. The latter greatly increase the ash content of the fuel, but are cheaper. The most popular are coal briquettes, in which coal tar acts as a binder.

Heating with pressed coal has the following advantages:

- Ease of installation in the combustion chamber.

- Good flammability.

- High calorific value, identical to anthracite.

- Ease of storage and transportation - briquettes have the correct geometric shape, so they are easier to store and take up less space.

The only drawback of pressed coal is considered to be a high cost, which exceeds the price of lumpy raw materials by about a third. The advantage is the ability to heat the boiler on coal, without pollution by combustion products.

How to fire with coal dust

The safest and most efficient method of dust incineration is considered to be a method using a special burner device.

Can you burn charcoal

With all these advantages, charcoal has one serious drawback. The cost of a kilogram of purchased charcoal will cost almost 2 times more than coal. You can reduce the cost of raw materials somewhat by setting up its independent production. To obtain 1 ton of charcoal, you will need to burn about 10 m³ of wood.

Domestic heating boilers Siberia Hephaestus

The boiler "Siberia" Hephaestus is a novelty in the domestic market of heating equipment. It has been produced since 2014, but it can already compete with devices that have been on the market for a long time, such as the combined Dakon solid fuel boiler. In total, three sizes are available for 15, 20 and 30 kW.

Like any other classic solid fuel boiler, "Siberia" Hephaestus has a firebox surrounded by a water jacket. Under the grate there is a capacious ash box for collecting solid waste. Flue gases are discharged through a pipe at the rear of the boiler into the chimney. In addition to these, in general, standard nodes, there are also some features:

- As a backup source of heating, it is possible to install a heating element for 4 kW. It can be used to stabilize the operation between loads and to heat the heating system in the absence of the owner.

- On the left and right walls of the boiler there are supply and return pipes for ease of installation and piping. The unused branch pipe of the supply line is closed with a plug, and a 4 kW heater block can be installed in the free return pipe.

- To control the combustion process, an optional mechanical draft regulator can be installed. A separate output is provided for its installation on the front panel. The sensor measures the temperature of the water in the boiler and, if necessary, opens or closes the ash pan damper using a long chain.

- To improve efficiency, the grate is filled with water. For the same purpose, beams with a coolant inside the loading chamber are used.

- Under the top cover of the boiler there is a round hole leading to the furnace.It can also be used to load the boiler with fuel, as well as to install a pot or other kitchen container.

- The casing of the boiler is covered with wear-resistant paint, and on the front panel there is a thermometer for visual control of the temperature regime of the solid fuel boiler.

"Siberia" Hephaestus works in the same way as a conventional wood-fired water heating boiler. Let's take a closer look at its characteristics:

| Model | KVO 15 TE Hephaestus | KVO 20 TE Hephaestus | KVO 30 TE Hephaestus |

|---|---|---|---|

| power, kWt | 15 | 20 | 30 |

| Efficiency, % | 75 | 80 | |

| Heating area, m² | 150 | 200 | 300 |

| Chimney diameter, mm | 150 | ||

| Heat exchanger capacity, l | 43 | 50 | 80 |

| Price, rub | 20 540 | 22 620 | 28 860 |

On the thematic forum, we found a thread with discussions of the Siberia Hephaestus line, and this is what people say about them:

Anatoly Vladimirovich, Rostov

In terms of price-quality ratio, "Siberia" Hephaestus is a pretty good model, and is suitable where a budget heating system is needed that does not involve serious loads. In other cases, it is better to buy a more serious boiler.

As a video review, watch a short YouTube video about the Siberia KVO boiler:

The NMK company produces mainly budget modifications of household solid fuel boilers. If you do not need an expensive multifunctional device, but you need a cheap heating device with a minimum set of functions, then we advise you to pay attention to the Siberia boiler range.

In this article, we will consider what a solid fuel boiler Siberia is, we will note its key features and the principle of operation.

Preparing the stove for kindling

In case of infrequent use of the boiler, a visual inspection of the masonry is required before the start of operation in order to exclude the presence of cracks. The penetration of carbon monoxide can be observed through the holes, which in the normal state should leave the furnace through the chimney. If such gaps are found, it is imperative to eliminate them with a heat-resistant sweep of clay and sand. Otherwise, during heating, the opening may expand, with a subsequent increase in the risk of rupture of the furnace or boiler.

When conducting an external inspection, it is imperative to remove from the direct access zone all objects that can ignite when a spark hits. Then, you need to completely remove the ash and slag. Then, wipe the walls of the firebox with a rag to prevent the spread of an unpleasant odor from combustion products.

It is advisable to melt the coal boiler several times a day. The duration of one such process should not exceed 2 hours. Load dry coal in small sizes. If the fuel is wet, steam may form, which subsequently settles on the walls of the chimney, leading to a narrowing of the lumen. As a result, traction will drop significantly.

A couple of reviews

Commenting and posting links is prohibited.

The Teplodar company has been manufacturing stoves for saunas for more than a decade and a half. The range of the company is represented by four series (lines) of stoves, which differ from each other not only in shapes and sizes, but also in design features. All furnaces for the Teplodar bath are of high quality, which thousands of buyers could be convinced of in practice. That is why the company was able to acquire a reputation as a stable, reliable and very solid manufacturer.

The quality of stoves should be understood as structural features and characteristics that allow the model to be classified without exaggeration as a work of stove art.

Each of the stoves below provides a quick heating of the steam room with minimal energy costs. The resulting steam has a beneficial effect on the human body, allowing you to relax well and enjoy relaxing in the bath.

Furnaces for a bath Termofor big choice

Not only in our country, but also abroad, the Siberian company Termofor is widely known for its sauna stoves. The product range of this company is constantly updated. The products are characterized by high functionality, compact size and easy operation. The attractive appearance of the stoves fits into any sauna interior: from classic to the most stylish.

On the forums, reviews about Termofor stoves can be read very different, but most of them are positive. Some of them:

And I like my Angara stove. Have us 2nd year is worth Normal. We heat with peat briquettes, it is very warm and there is little fuss with the stove.

Furnaces for a bath Termofor

We bought a MERANO stove (imported) for the house, and for a GEYSER bath, they are the same price. Both the house and the bath are about the same area (5x5 and 6x4), So, the Termoforovsky GEYSER heats the room twice as fast, I regret that I bought such a stove in the house (I thought if it was imported, it’s better)! Not only the beauty of the stove pluses! Let's see how it shows itself over time!

Decided to share my experience. I have a bath oven "Termofor". Recently bought for a sauna called Vitruvius. Probably, it is already difficult to call it a stove, because it is very sophisticated. However, 21st century #8230 A very large screen is built into it, it is convenient to observe the burning and just beautiful. Diagonal 58 cm! It does not darken, it even practically does not need to be wiped (convenient for lazy people and bachelors). In appearance, it fits perfectly into the sauna. The oven itself is small, as I chose for my cubic meters

Do you have a strange smell when the stove is burning? I myself recently bought, not this one, another manufacturer. Now I'm thinking: will it fade or not?

@Alkard The weird smell is the machine oils that lubricate everything in the factory. I had an odor with the first use only. Then there were no problems.

Reading reviews about Termofor ovens, you understand that for the most part customers are satisfied with their choice.

Types of manufactured sauna stoves

The range of sauna stoves at Termofor is impressive:

- Wasp and Wasp INOX ultra-compact stoves for Russian baths with a volume of steam rooms from 4 to 8 m3.

- Compact and Compact INOX - a wood-burning stove for a Finnish sauna, designed for steam rooms from 8 to 14 m 3.

- Shilka wood-burning stove for a Russian steam room of small volumes - 6-12 m 3.

- Tunguska - wood-burning sauna stoves of the middle class for space heating from 8-18 m 3 to 12-24 m 3 in the XXL modification.

- Tunguska and Tunguska Vitra - a new version of the popular stove. The furnace has been improved, changes have been made to the design of the heat exchanger for heating water.

- Angara - a stove for a Russian bath, suitable for an average size of steam rooms 8-18 m 3. The entire power of the stove is aimed at heating stones in an open unventilated heater.

- Angara is a powerful stove for a Russian steam room with a closed heater.

- Aurora is a powerful stove for medium-sized Finnish dry-air saunas (8-18 m 3 ) with a chimney offset towards the firebox.

- Geyser - a stove for a Russian bath with a two-stage steam generation system for steam rooms 8-18 m 3.

- Vitruviya - a fireplace stove with a large glass door (58 cm diagonal) for dry-air steam rooms 8-18 m 3.

- Sayany - grid oven for the Finnish sauna 8-18 m 3.

- Biryusa is a vertical sauna stove with a closed heater. Suitable for a Russian steam room with a volume of 8-18 m 3.

- Karasuk is a budget oven made of structural steel 4-6 mm thick.

- Skoroparka - an original design wood-burning stove for a Russian bath, designed for steam rooms 12-20 m 3.

- Kalina - a stove for a large Finnish bath - is designed for a volume of 18-30 m 3.

- Hekla is a sauna stove for commercial use. Suitable for steam rooms 30-50 m3.

"Shilka"

The wood-burning stove is designed for a steam room with a small volume - from 6 to 12 cubic meters. Double-walled, with an open heater at the top and a chimney located in the center. It can be made both with a hot water tank (built-in 24 l or mounted), and without it.Firebox with a volume of 43 liters made of heat-resistant steel. The combustion tunnel is extended for embedding into a wall or a regular door without extension. Provides bath mode "Russian steam room", made of heat-resistant steel with a warranty period of 3 years.

"Biryusa"

The tall and narrow oven for the Russian steam room Biryusa has a closed heater, which can hold up to 30 kg of stones. Made of structural steel, has a built-in stainless steel water tank. The updated layout of the furnace prevents premature boiling of water (the main drawback of the previous design).

Furnace for bath Termofor Biryusa

"Wasp" and "Wasp INOX"

The smallest wood-burning stove, the recommended mode of the steam room is Russian. Designed for a mini-steam room with a volume of 4 cubic meters. up to 8 cubic meters It is made of structural steel with a 1-year warranty period in the Osa modification and heat-resistant chromium steel in the INOX Osa modification (3-year warranty).

KUBAN 20L

- Steam gun effect

- No cooking surface

- The stove is designed for a steam room up to 20 cubic meters.

- Works in the mode of wet soaring, the effect of a Russian bath

- The firebox is made of stainless steel

- Achieved steam by stones+steam gun

- Remote type fuel channel

- Has an additional function - heating water

- Sauna stove Kuban is equipped with a blind door

- Purpose of the device - household

- Stone loading up to 40kg

- Service life up to 10 years

- Ability to use firewood and briquettes

- The chimney of the sauna stove has a diameter of 115mm

- Furnace parameters - 865x500x700

- Weighs 49kg

- Two years warranty given

- The manufacturer is Teplodar

- Price from 22000 rubles

What fuel to choose

Coal is a chemical compound that includes a number of hydrocarbons and impurities with a low degree of combustion. These substances are formed in the lower chamber of the boiler after combustion. This is slag and ash, which must be regularly cleaned from the blower. Moreover, each of the species, depending on the geography and the period of occurrence, contains a certain level of carbon. It is the age, the ratio of combustible and non-combustible components that determines the quality and brand of the solid fuel mineral.

There are several types:

- The youngest of the subspecies is lingit. It is a loose stone structure. Often crumbles and crumbles. Ineffective for home heating. However, it is considered the cheapest, used for energy production in thermal power plants.

- Anthracite is a variety that, when deposited, warmed up most deeply. It is a transitional form from coal to graphite. The amount of carbon reaches 95%. The most effective among all varieties.

- Coal is the result of the transformation of bituminous masses. It is divided into several varieties depending on the carbon content, from 75-95%. Humidity reaches 12-15%.

- The brown subspecies, unlike other varieties, is formed from peat and includes up to 70% carbon. It has a characteristic white color. Can be used as fuel or raw material. Also, includes a large number of volatile compounds.

Due to the minimum mass and significant carbon content, it is anthracite that has the maximum specific heat capacity. Indicators can reach 9 thousand Kcal / kg. Due to the lower content of combustible substances and higher humidity, coal has up to 5.5 thousand kilocalories per kilogram. Brown has an even lower rate of 3 kcal / kg. Therefore, it is anthracite that is considered the best choice.

How to remove ash

If the boiler is heated exclusively with wood, then cleaning the combustion products is quite simple. Through the cast-iron grate, after burning out, the ash will crumble down. Then it can be removed from there with a spatula. However, it is advisable to remove flammable objects and liquids.

With the use of coal, the burn-out time is significantly higher. Therefore, it is extremely difficult to clean a slagged niche in a timely manner.To prevent such an effect, it is required to additionally lay layers of coal with layers of wood. Or by significantly increasing the temperature in the boiler. This is easy to achieve by increasing the thrust, so either activate the fan or use boost methods.

The use of solid raw materials as an element for heating has several advantages over firewood. Heating with peat or analogues on carbon Ignition is much easier, and solid fuel minerals will burn at a higher temperature. The use of combined materials helps a lot. Using firewood in combination with coal is the best option for a private house.

Sahara

A steam room equipped with a Sahara stove can easily turn into a traditional Russian bath or a classic Finnish sauna. The stoves have a unique ergonomic design, they embody the principle of the "golden section" without violating the proportions and smoothing the corners. This form allows you to successfully fit into almost any interior.

When developing the design of the Sahara oven, the principles of maximum comfort in operation with aesthetic appearance and work efficiency were embodied. Heating of stones is provided from five sides, the fastest heating is achieved due to the successful placement of the chimney parallel to the axis.

The creation of a microclimate similar to a Russian bath and a Finnish sauna is ensured by installing an additional converter.

Heater stoves for saunas "Teplodar" without a shadow of exaggeration can be called a work of stove art, all products are characterized by stylish design, high functionality, reliable operation and ease of operation.

" What

How to reduce coal consumption

An increase in the coal consumption rate, after several years of operation of the boiler, is quite common. The increase in costs is primarily due to the clogging of the heat exchanger and the chimney with soot. It is recommended to completely clean the chimney and internal components of the boiler at least 2 times a year.

To reduce coal consumption, it is required to heat the boiler correctly. To reduce the amount of soot, carry out the laying of fuel in layers - firewood-charcoal. Such styling will provide maximum heat transfer. The change in coal consumption occurs, depending on the efficiency of the boiler. Therefore, the greater the efficiency, the lower the fuel consumption.

Another way to reduce coal consumption is to burn with exceptionally high-quality fuel. Cheap raw materials, brown coal, have a high percentage of underburning, quickly clog the chimney and heat exchanger and, as a result, are more expensive than anthracite.

Features of the boiler furnace in winter

Winter is the period of the most active operation of the heating system. So that vital devices do not fail in severe frosts, care should be taken in advance to prepare the boiler for winter. To do this, the system is preliminarily cleaned of soot - chimneys, channels, grates. This will allow the heating to work at maximum efficiency and extend its service life.

In winter, it is very important to maintain a stable temperature in the home, which means that you will periodically have to fill the firebox with raw materials. You can increase the efficiency of one bookmark by installing a heat accumulator

It is able to accumulate the heat produced by the system, quickly warm up the radiators and the water supply. As a result, even after the fuel has completely burned out, the coolant in the system will remain hot for several hours. This is especially true for night hours, when it is not possible to regularly feed the boiler.