Do-it-yourself heating from PPT

To equip heating in private houses from polypropylene pipes with your own hands, you will first need to prepare consumables and tools, including a soldering iron and connecting fittings. To obtain a reliable system in operation, a number of conditions will need to be met before its installation:

the main attention during the work is paid to laying the thermal circuit;

previously prepared fittings and a set of tees should be selected according to size;

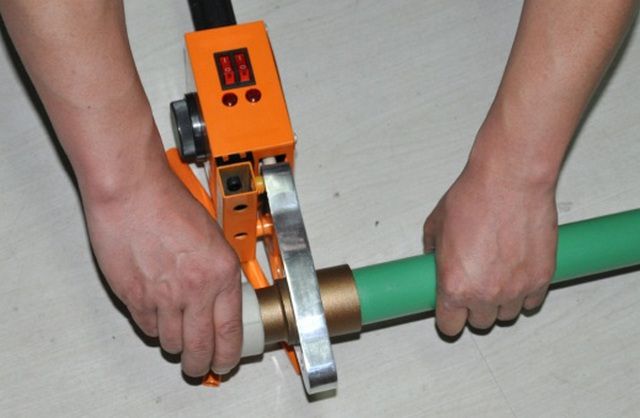

the welding machine must have a nozzle that matches the diameter of the working pipes and fittings.

In a one-story private house, it is recommended to install heating based on polypropylene pipes in the following sequence:

- A diagram or drawing of the pipeline layout is being prepared.

- The footage is calculated with a single-pipe or two-pipe wiring, and then fittings of the required size are selected.

- Pipes selected in accordance with the parameters and scheme are cut using special scissors.

- The soldering iron is placed on a horizontal plane, after which its working head is heated to 260 degrees.

The working parts of the fitting and pipe are degreased with white spirit, and then put on the heating element of the soldering iron, followed by melting of the tips. After some exposure, the parts are removed from the heater head, two articulated elements are inserted one into the other. After about 10-15 seconds, the welding site turns into a solid and completely sealed monolith.

The heating time of pipe blanks and fittings depends on their thickness, as well as on the presence or absence of a metal and fiberglass protective coating, and a number of other factors. All the necessary data on the procedure for soldering products from PP are given in the instructions for use of the soldering machine

Here you can find the heating time of the products. To do this, you need to pay attention to branding. In order for the resulting joint to turn out to be of high quality, you need to familiarize yourself with the technical characteristics

Wiring diagram

Before proceeding with the arrangement of a polypropylene heating system in a house with your own hands, you will need to decide on a wiring diagram, which can be single-circuit or double-circuit. Since there are no conditions for the natural movement of the carrier in a private building, a pressure pump will have to be included in the system. In this case, it will be necessary to select the appropriate type of PP pipes that can withstand the increased pressure in the two-circuit forced circulation wiring.

In the diagram, you must indicate the position of the individual elements of the control and measuring equipment serving heating.

What are the advantages of using a heating system made of polypropylene

advantages of polypropylene heating

Many users doubt whether it is possible to use polypropylene pipes for heating. In fact, the overwhelming majority of modern world experts say that it is precisely polypropylene pipes are by far the most practical material in the field of plumbing systems, and in particular this is due to the following advantages:

- extremely long service life of polypropylene heating pipes, which reaches 50 years or more. This is achieved, first of all, due to the complete absence of corrosion during the operation of the pipeline system, as well as the use of extremely reliable and durable connections compared to standard collet ones;

- environmental friendliness of the material (does not emit any odors and toxic substances);

- complete invulnerability to corrosion, as well as a high degree of resistance to various external influences;

- over a long period of time, a polypropylene pipe completely retains the quality and smoothness of its internal structure, which makes it possible to completely eliminate any interference in the circulation of water, even if the pipe has been in operation for a sufficiently long time;

- extremely high speed and simplicity of the procedure for installing such pipes, which, in particular, is facilitated by the small mass and size of polypropylene pipes for heating;

- significant financial savings, as well as a significant reduction in labor costs;

- minimum thermal conductivity, which minimizes heat loss. Thus, such pipes can be carried out without additional insulation in almost any conditions.

In addition to the fact that the installation of such pipes is characterized by the extremely high efficiency of heating systems, it is also quite economical both in terms of the money spent, and in terms of labor costs and the total time required for the full installation of such systems.

To see the benefits of using such pipes in heating, look at the reviews left by users on polypropylene pipes for heating.

Varieties of PPT

They were the first to use PPT for heating, reinforced with special aluminum foil, which caused a rise in the price of the finished product. Over time, pipes reinforced with fiberglass appeared, gradually replacing analogues with aluminum.

aluminum reinforcement

Aluminum foil in tubular products is used as an expansion compensator during heating, and also acts as a diffusion barrier. Usually it is placed closer to the surface, but in some models the protective layer is arranged deep in the walls. Before proceeding with the formation of the joint in the joint zone, it will be necessary to clean the pipe blank well.

In products where the aluminum foil is located closer to the middle of the wall, after stripping it becomes so thin that the connection is of poor quality. Therefore, when choosing PPR pipes for heating a house, equipped with aluminum foil, a sample with a reinforcing layer located closer to the front surface is preferable.

fiberglass reinforcement

When using polypropylene pipe blanks reinforced with fiberglass, it is important to take into account some of the nuances. Fiberglass, as a fairly unstable material, has the property to collapse under load.

Sometimes it is enough to drop the workpiece on the concrete floor to permanently damage its protective layer.

It is not recommended to use such pipes in places where the temperature drops to very low values. Under such conditions, the fiber becomes brittle and breaks easily with slight deformations.

What to consider when installing such pipes

installation of polypropylene pipes

The most relevant use of such pipes will be if there are no sudden temperature changes during the operation of the heating system. Thus, polypropylene pipes are an ideal option for those facilities that use a heating boiler equipped with a maximum temperature limitation system.

How can such pipes be installed?

To date, specialists use only a few basic autonomous heating schemes, however, systems with lower and upper spills are the most widely used among all existing ones. In particular, due to the use of polypropylene pipes with such a system installation scheme, you can achieve certain advantages.

- The complete absence of the need for additional purchase and installation of a specialized circulation pump when using systems with a top spill, since the basic principle underlying the operation of such systems is a completely gravity-flowing water circulation, which is especially relevant for those facilities that may have frequent interruptions in the central power supply system.

- The contour of the system with a bottom spill is formed using a metal-plastic or plastic pipeline, with the help of which it becomes possible to make absolutely any connections and bends, which is especially relevant for those who want to minimize the presence of pipes in the interior or live in a room with various unusual features in construction.

It is worth noting the fact that today it is systems with a bottom spill that are more widely used, and in particular this is due to the advantages that this method of installation has.

- Sufficiently high efficiency of the system.

- The use of a specialized pump allows you to minimize the diameter of the polypropylene pipe for heating.

- The ability to make the pipeline system completely invisible to others by hiding it in the floor and wall coverings.

Special attention should be paid to the fact that in order to increase the efficiency of such a system, the manufacture of circuits is often carried out from rather expensive copper pipes, which are characterized by extremely high heat transfer and corrosion resistance.

In order to choose the best pipes for your conditions, it is important to consider such a factor as the marking of polypropylene pipes for heating.

In order to choose the best pipes for your conditions, it is important to consider such a factor as the marking of polypropylene pipes for heating.