How to rinse the boiler heat exchanger from scale

- Increased gas consumption.

- The burner works almost without switching off.

- Buzzing during the operation of the circulation pump.

- Reducing the pressure of hot water.

Equipment for flushing heat exchangers

The device is charged with a chemical reagent and connected to the heating circuit through the outlets on the boiler body. The method of flushing a double-circuit gas boiler includes an in-line connection to each heat exchanger in turn.

The essence of the method is as follows: the booster pressurizes and forces the reagent to circulate in one direction. After a while, recirculation automatically turns on. So, the heat exchanger is washed in different directions, which leads to a complete cleaning of the cavities from scale.

To clean the heat exchanger of a gas boiler from scale at home and achieve a high-quality result, you will have to purchase a household booster. Products are manufactured under the following brands:

- Pump Eliminate

- Alfa Laval

- Teploservis

- Pipal Chemistry

- Aquamax

Means for flushing the heat exchanger

- Hand tools.

- Chemical reagents for cleaning and washing.

In order for flushing the gas boiler heat exchanger with citric acid or vinegar to be beneficial, you will need to soak the heat exchanger in the solution, after removing it and filling it with the composition. It will take about a day to soak the contour. This method is effective only when cleaning a small layer of scale.

Chemicals are an effective way to descale at home. For flushing, a removable and non-removable method is used. It is possible to completely clean the circuit of moderate deposits only by means of a booster. The device is filled with liquid for washing the heat exchangers of gas boilers. Chemical reagents are made on the basis of hydrochloric, sulfamic, phosphoric acid and reagents (Antinakipin, etc.).

Chemical cleaning has its drawbacks. After the procedure, often, sealing gum and welds leak. Therefore, the technical condition for acid washing is a mandatory check of the tightness of the joints after maintenance.

Flushing the gas boiler heat exchanger with hydrochloric acid can cause a circuit leak. This method is not recommended for thermal units after five years of operation.

If none of the above methods is suitable, hydrodynamic cleaning is applied. The liquid for washing the heat exchangers of gas boilers is made on the basis of a conventional aqueous solution with the addition of abrasive substances. Hydrodynamic cleaning is used exclusively in specialized service centers.

For self-cleaning using a booster or a collapsible method, the following tools are used:

- Detex

- Zincotex

- Alfa Laval

- steeltex

- Aquamax

- B.W.T. Cillit

How to protect the heat exchanger in the boiler from scale

- A high-quality coolant is poured - distilled water is optimal. The liquid from the heating system is not drained unnecessarily. After several heating seasons, the composition of the coolant becomes optimal.

- A water treatment and filtration system is being installed.

- In some boilers, manufacturers build in special cathodic protection. The electrode connected to the mains prevents the formation of scale.

Why scale forms

The main reason for the appearance of scale on the walls of gas boiler heat exchangers is the use of hard lime water. As a rule, the water supplied to the heating system is not well purified and contains calcium and magnesium salts, as well as ferric iron, in dissolved form. Under the influence of high temperature, these impurities crystallize on the walls of the heat exchanger, forming a layer of deposits and rust.

If the coolant used in the heating system undergoes at least some filtration, then water sometimes enters the hot water circuits of double-circuit boilers and bithermic heat exchangers without any purification. That is why these elements are especially susceptible to scale formation.

What is the danger of scale on the walls of the heat exchanger? There are several factors of the detrimental effect of deposits on the operation of the heating system as a whole and its individual devices in particular:

Increase in gas consumption

The mineral deposits included in the scale have a much lower thermal conductivity in comparison with the metal from which the heat exchanger is made. Based on this, more energy will be spent on heating the coolant, and, consequently, the volume of burned gas will increase. Just 1 mm of deposits increases heating costs by 10%.

Heat exchanger overheating

The principle of operation of a gas boiler is based on the fact that the coolant coming from the return line cools the heat exchanger, removing heat into the heating system. Scale prevents normal heat exchange and the boiler automation gives the command to heat up more in order to reach the required temperature in the supply line. Working for a long time in the mode of extreme temperatures, the heat exchanger quickly wears out and fails.

Additional load on heating equipment

The formation of scale on the walls of the heat exchanger reduces the effective diameter of the channels and prevents the normal circulation of the coolant. As a result, the load on the circulation pump increases, which leads to its premature wear and failure.

The problem of scale formation in gas boilers is quite serious and can hurt the owner's pocket if it is not eliminated in time.

Measures to prevent scale in steam boilers

The amount of scale in boilers can be reduced by using measures to prevent its formation:

- install aluminum heating elements with heating power up to 2400 W;

- carry out regular maintenance;

- check the condition of protective coatings on internal parts;

- follow the manufacturer's recommendations regarding the quality of the water used;

- use water softeners: chemical compositions, magnetic converters, etc.

Before descaling the boiler, it is necessary to evaluate the thickness and composition of the layer, the technical conditions for the work, and then choose the appropriate method. Not only the efficiency of removing deposits will depend on this, but also the safety of the protective inner coating of the walls and surface of the heat exchanger. Only a competent approach to solving the problem will ensure the maximum service life of the boiler without breakdowns and with high efficiency.

The service life of a gas boiler depends not only on careful operation, but also on the timely cleaning of its components and assemblies. A heat exchanger that is constantly in contact with a hot coolant is most susceptible to the formation of scale and various deposits. In this article, we will talk about the causes of plaque formation, symptoms of the need for cleaning, how the gas boiler heat exchanger is flushed and what reagents are used.

Flushing is necessary for all types of heat exchangers: tubular and plate, primary and secondary, shell-and-tube and bithermic. Copper and steel, aluminum and cast iron - all of them are more or less susceptible to the formation of deposits and scale.

Chemical cleaning Boiler flushing

The main condition for high performance and full-fledged functioning of boiler equipment is regular flushing of deposits. Both domestic and industrial boilers are usually subjected to chemical washing.Minimization of the corrosive effect on metal parts is possible only with proper monitoring of the condition of the boiler unit. If you neglect regular cleaning of the system, the heating capacity of the boiler will decrease, and scale will form on its inner surface.

Scope of work during chemical washing of the boiler:

- Preliminary diagnostics of water circuits of heat-exchange equipment by hydraulic method with excess pressure. (for the tightness of the circuits)

- Chemical cleaning in place of industrial boilers, monitoring the progress of the reaction by measuring the pH level throughout the cleaning.

- Alkalinization of the boiler.

- Neutralization of the washing solution, repeated washing with water.

- Hydraulic tests (pressurization) of the boiler.

What do you get as a result of flushing or cleaning the boiler:

- Reduce fuel consumption by up to 25%;

- The probability of emergency situations (local overheating, cracks at individual nodes, etc.) will decrease by 60%;

- Increased service life after washing.

Prevention is the best way to avoid unscheduled, and therefore costly repairs or, even worse, complete replacement of equipment.

Our staff employs qualified and experienced employees who know their business, so flushing the boiler will not be difficult for them. We are always ready to help you, so if you have any questions, you can contact our managers who will answer your questions 24/7. Entrust the cleaning of the boiler to experienced professionals. Contact a reliable engineering service company.

Flushing boilers must be carried out carefully and systematically. The use of hard water leads to the formation of scale and sediment. If the cleaning procedure is neglected, the boiler may fail prematurely. To understand how pollution occurs, you can imagine an ordinary kettle that heats water several times every day. After some time, scale forms on the walls of the kettle, which leads to a slower heating of the water. The same goes for the boiler.

Causes of scale formation in the boiler and why it is dangerous

To protect the primary heat exchanger, a system is installed that somewhat reduces the degree and intensity of deposits. It is quite difficult to protect the secondary circuit or the DHW coil from scale and requires significant material costs.

In practice, in the domestic realities of operation, scale protection is used extremely rarely. Lack of water treatment is the main cause of clogging of heat exchangers.

If the scale is not removed in time, the following consequences will appear:

Chemical washing of boilers and process equipment.

In order to ensure efficient heat exchange, the internal surfaces of boilers and process equipment in direct contact with water and steam must be kept clean and free from deposits. The surface of the boiler pipes directly in contact with the fire (boiler furnace) usually consists of magnetic iron ore (magnetite) and copper. Chemical flushing of boilers and process equipment must be carefully planned. The criteria that determine the success of chemical procedures and the effectiveness of reagents for dissolving certain deposits are determined on the basis of a detailed analysis.

The appearance of deposits and scale in boilers and process equipment is an inevitable, progressive process.Even with good water treatment and strict control of condensate with chemical additives, scale and deposits will occur.

Deposits cause the following main problems:

- Increase in pipe wall temperature;

- Reduced heat transfer, resulting in an increase in energy costs and loss of reliability.

- The increase in the temperature of the pipe walls occurs as a result of the low thermal conductivity of deposits compared to metal.

- Reduced heat transfer can cause the design temperature of the pipe walls to be exceeded, which can eventually lead to pipe failure due to creep failure. Heat transfer efficiency is defined as the ratio of boiler output to fuel consumption, once deposits begin to reduce heat transfer, more fuel will be required to produce the design temperature, thus there is an overall loss of efficiency and wasted energy. Ultimately, the removal of deposits and scale from the boiler or process equipment becomes essential to prevent damage to it. One of the ways to remove deposits and scale is chemical washing of equipment. Chemical flushing of equipment is a multi-stage process aimed at removing all existing types of deposits from the internal heating surfaces of boilers and process equipment. As a result, the hydraulic system must remain clean and decontaminated.

How to descale the boiler flushing methods

Impurities definitely negatively affect the working condition of the boiler. Too hard water always leads to the formation of scale, which can disable the entire system. Usually, users install a strainer, which should protect the boiler from scale formation.

Particles formed from the water as a result of its heating move through the pipes, causing noise. Usually, equipment is installed in houses and apartments, which is relatively small. Drainage of particles that pollute the system does not occur, which ultimately leads to poor performance of the equipment or its breakdown.

Descale options:

- Use of reagent acids. Using strong acids is an effective way to get rid of scale. They easily remove iron deposits and carbonate scale.

- To remove silicate scale, it is necessary to use substances that contain a lot of alkali.

- To flush the boiler from scale, you can use a collapsible or non-collapsible cleaning method.

The non-separable method of cleaning involves the use of reagents, the use of which does not require the process of dismantling the boiler. Most often, the method of this cleaning involves the use of three-component boosters, which perfectly clean boiler equipment. The booster consists of three blocks: a reagent tank, a heating tank and a pump.

Popular cleaning methods

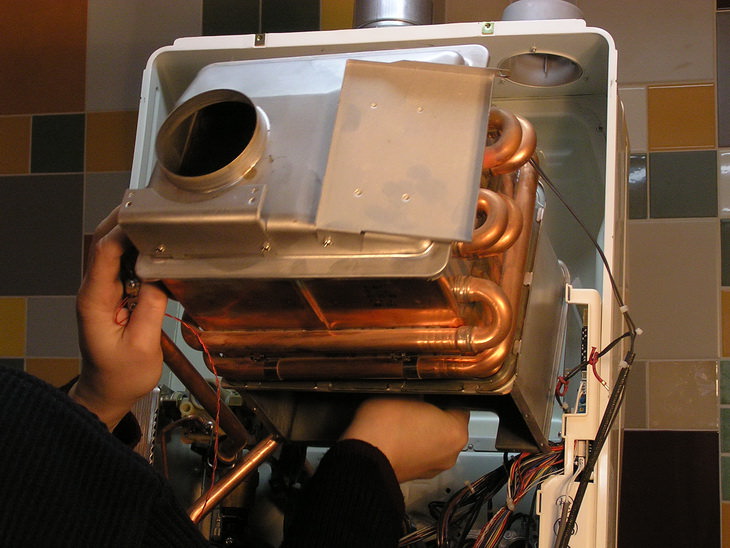

There are several technologies for flushing heat exchangers, which can be divided into two groups: collapsible and non-collapsible. The collapsible flushing technique consists in the fact that the heat exchanger is removed from the gas boiler and washed separately. When using CIP technology, nothing needs to be removed, and the cleaning process is carried out using special equipment. Let's take a closer look at the main flushing methods:

Manual cleaning

Manual flushing is a collapsible type and requires the heat exchanger to be disconnected from the gas boiler. Its body is cleaned of external contaminants with metal brushes and soaked for several hours in an acid solution or a special flushing liquid. The main disadvantages of this technology are the lack of reagent circulation during the flushing process and the detrimental effect of reagents on gaskets and other sealing joints.When starting the washed gas boiler, make sure that all connections are tight and that there are no leaks under pressure.

Chemical flush

Chemical (hydrochemical) flushing can be performed without dismantling the heat exchanger from the gas boiler. To remove rust, scale and other deposits, the heater is connected to a special device called a booster. This special device, equipped with a pump, pumps the chemical reagent through the heat exchanger in various directions for several hours. During this time, the chemistry that is part of the washing liquid completely removes the most difficult contaminants without damaging the metal.

Hydrodynamic cleaning

This cleaning method also applies to in-place methods. Its essence lies in the fact that by connecting a special installation, water is driven through the heat exchanger under high pressure. Sometimes, to achieve a better result, the aqueous solution contains an abrasive filler. The increased speed of the flushing liquid promotes effective removal of deposits from the walls of the heat exchanger.

Most often, owners of gas boilers use chemical flushing of the heat exchanger with a booster. To do this, they conclude an agreement with a company that performs this type of work, or purchase special equipment and do the cleaning with their own hands.

Fluids for flushing heat exchangers

Regardless of the cleaning method you choose, you will need a flush reagent. The choice of flushing fluid should be approached wisely, as some of them can damage and even disable the heat exchanger of your gas boiler. Let's consider in what cases certain solutions are suitable:

Hydrochloric acid

To clean heat exchangers made of copper or stainless steel, an aqueous solution of hydrochloric acid with a concentration of 2-5% is successfully used. Special additives, inhibitors, help protect the metal without preventing the dissolution of oxides and carbonates. Washing with hydrochloric acid is the lot of professionals who are aware of their actions when working with this aggressive reagent. Independently, at home, it is highly not recommended to clean the gas boiler heat exchanger with this tool without a clear understanding of the ongoing processes.

Sulfamic acid

Washing the heat exchanger with sulfamic acid is particularly effective in removing deposits containing metal oxides. This cleaner is safe for all materials and can be used successfully at home. The composition for washing the heat exchanger includes a 2-3% aqueous solution of sulfamic acid and corrosion inhibitors.

Orthophosphoric acid

Flushing with phosphoric acid is effective for heat exchangers of gas boilers of all types. This cleaning agent not only perfectly removes scale and dirt, but also does not cause any harm to the metal and even creates a protective film. To obtain an effective regent, it is necessary to dilute phosphoric acid in water to obtain a 13% solution.

Lemon acid

A solution of citric acid at 60°C perfectly removes scale and oxidation without affecting the metal of the heat exchanger. This product is great for cleaning copper, brass and stainless steel devices. Depending on the degree of contamination, the recommended concentration is from 0.5 to 1.5%.

Flushing liquid "Detex"

Detex flushing agent is used to remove scale, oxides, salts and various biological deposits from the walls of cast iron, steel and copper heat exchangers.Due to the content of surfactants and corrosion inhibitor additives, it protects the metal, thereby increasing the service life of heating equipment. Depending on the degree of contamination, the Detex concentrate is diluted with water in a ratio of 1/6 - 1/10 and poured into the washing machine.

The process of circulation of the flushing liquid through the heat exchanger of the gas boiler is accompanied by gas evolution, the stop of which indicates the end of the action of the reagent. If the required flushing quality is not achieved, increase the Detex concentration until the gas formation process resumes and continue the cleaning procedure. At the final stage, it is necessary to flush the heat exchanger with a neutralizing liquid, and then with water.

In addition to the above reagents, sulfosalicylic, acetic and oxalic acids are used to flush the heat exchangers of gas boilers, as well as industrial chemicals of various brands, such as Steeltex, Alfa Laval, ERP-1 in the form of a concentrate, which should be diluted with water in the required proportion.

For more information about chemical flushing of heat exchangers at home, see the following video:

How often should the heat exchanger be cleaned?

Maybe they are all right, but the most realistic option would be that flushing of the heat exchanger should be carried out when the following symptoms begin to appear:

- the burner in the gas boiler is on all the time;

- the circulation pump works with a characteristic hum, which indicates an overload;

- heating radiators heating occurs much longer than usual;

- significantly increased gas consumption with the same operation of the boiler;

- weak pressure of hot water in the tap (this feature is applicable for double-circuit boilers).

All these points strongly indicate that there are problems in the functioning of the heat exchanger, and this, in turn, means that it is necessary to start flushing.

Specialist's note:

irregular cleaning of the device will reduce the efficiency of the gas boiler.

Varieties of chemicals for descaling

The range of all kinds of chemicals suitable for descaling domestic boilers is very diverse.

The most common reagents are:

- hydrochloric acid;

- adipic acid;

- sulfamic acid.

According to the recommendations of experts, the effective concentration of the solution for flushing the boiler is 1% for every 1 mm of scale layer.

We hope this article will be useful for you, and you will be able to independently cope with such work as flushing the boiler from limescale. Most importantly, do not forget about safety measures and monitor the condition of heating equipment in time.

Scale in a steam boiler is the main negative factor that reduces the efficiency of water heating, increases fuel consumption, and stimulates the occurrence of corrosion processes.

That is why it is important to know how to remove it and prevent its occurrence in the future. Is it possible to remove scale on your own and what methods are most effective for this?

How to detect

The presence of scale when heated by a heating boiler can be visualized by dismantling and partially disassembling it. However, this will void the warranty and service. In addition, it is necessary to involve specialists in order to prevent damage to the structure.

Another method of detection can be called indirect, since it can be implemented without disassembling the boiler itself.To do this, turn off the boiler, wait until it cools down, and then unscrew the nut on the heating circuit pipe, drain the water and examine the condition of the inner surface. If scale is present, a white coating or salt flakes will be visible.

How often flushing is required

Many popular manufacturers of gas boilers such as Navien, Baxi, Ariston, Vaillant indicate in the instruction manual the frequency of flushing the heat exchanger. However, real operating conditions often make their own adjustments. The practice of connecting gas boilers to a hard water heating system shows that the heat exchanger should be flushed every season. In order not to encounter this problem in the middle of a cold winter, it is recommended to flush immediately after or before the start of the heating season. The following are the characteristic signs by which you can judge that the heat exchanger of your gas boiler needs to be cleaned:

Increased gas consumption

The resulting scale reduces the thermal conductivity of the heat exchanger, thereby forcing the gas boiler to burn more fuel to reach the set temperature.

Permanent burner

An increase in the burner operating time may also indicate the presence of scale that prevents the normal heating of the coolant.

Hum and interruptions in the operation of the circulation pump

Reducing the effective diameter of the heat exchanger channels makes it difficult to pump the coolant to the circulation pump. Its operation in the limit mode may be accompanied by a hum and interruptions in operation.

Pressure reduction in the DHW circuit

A sign of the presence of a layer of scale in the secondary circuit of a double-circuit boiler can be a decrease in pressure in the hot water supply line.

If one or more of the above signs can be traced in the operation of your gas boiler, it is urgent to flush in order to avoid breakdowns of expensive heating system components and high costs for their repair or replacement.