Distinctive properties of PVC and polypropylene pipes

The main differences between PVC pipes are increased rigidity and the impossibility of using them when transporting hot (more than + 60 ° C) liquids. Polypropylene pipes are more resistant to high temperatures, and therefore are suitable for transporting both cold and hot water.

These qualitative characteristics cause differences in their areas of application.

Application of PVC pipes

| Scope of application | Qualitative characteristics of PVC pipes used |

| Cold water supply system in multi-apartment and private houses. | Pressure pipes made of unplasticized gray PVC are used, as they are strong, rigid and durable, withstand strong water pressure. The wall thickness is up to 3.2 mm, and the diameter is from 50 to 160 mm. |

| Separate sections of cold water supply or internal sewerage. | Gray plasticized PVC pipes are used, they are less durable with a wall thickness of 1 to 2 mm and a diameter of 30 to 50 mm. |

| Drainage system for dishwasher or washing machine. | Gray corrugated PVC pipes are used - the simplest and cheapest, not durable, but they can be easily replaced. |

| Protection of electrical wires in the internal and external electrical network. | Corrugated PVC pipes are used, in their production a self-extinguishing additive (antiperene) is added, which ensures fire safety. They are very flexible and durable, which makes it possible to lay an electrical cable in them inside wooden or concrete walls, in wet rooms or in swimming pools. |

| External sewer system. | Rigid orange PVC pipes with a wall thickness of 3 mm and a diameter of 100 to 500 mm are used. These pipes easily withstand weather temperature fluctuations and soil load at shallow depths. |

| External sewerage system at a depth of up to 15 m. | Corrugated multilayer PVC pipes of orange color are used. Due to the large number of stiffening ribs, they withstand the load of the soil at a depth of up to 15m. |

| Septic tanks and drainage wells. | PVC pipes of the largest diameter in orange color are used. |

The use of polypropylene pipes

| Scope of application | Qualitative characteristics of the applied polypropylene pipes (PP pipes) |

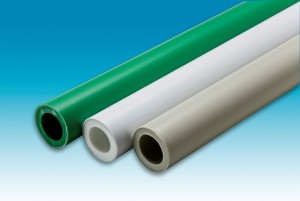

| The system of internal cold and hot water supply in apartments and houses. | White PP pipes are used, they are easily connected by welding or through fittings, withstand high pressure and are the cheapest of PP pipes. |

| Centralized and individual heating system. | Gray PP pipes are used, they have chemical and thermal resistance and tightness. |

| Drainage and watering system on the street. | Black PP pipes are used, which have the highest resistance to ultraviolet radiation, drying out and exposure to aggressive weather conditions. |

| Summer irrigation system in the garden. | Green PP pipes are used - the most unstable to internal water pressure, but the cheapest. |

| Internal floor heating system. | For resistance to high temperature and water pressure, three-layer PP pipes reinforced with aluminum or glass fiber are used. |

In the production of plastic pipes, an information line with technical characteristics is necessarily applied to them using a laser for ease of use and installation.

The choice between PVC and polypropylene pipes depends entirely on the scope of their application and may be based on the quality characteristics given above.

Scope of application

On an industrial scale, XLPE pipes find little use because their diameter is limited to a maximum of 250 mm and their limited ability to operate under heavy loads. In individual construction, the use of cross-linked polyethylene is widely used in installation:

- heating communications;

- in cold and hot water supply.

Cross-linked polyethylene pipes for underfloor heating are popular. This material is easy to install, does not require special skills or sophisticated equipment, durable and reliable. For heating systems, only pipe materials with a protective layer are used.

When choosing pipes and fittings for the installation of water supply communications or heating systems, one should be guided by the recommendations of the manufacturers, since the documentation always indicates the direction of use and permissible operating parameters.

Note! All pipe products are marked in detail on the outside. The label indicates:

The label indicates:

- mode of production;

- release date (up to a week);

- wall thickness and diameter;

- permissible operating parameters;

- quality check mark.

Each manufacturer offers fittings for mounting their products. The use of native materials is the key to a reliable connection and long-term operation, since a single process is used in the production of pipes and fittings.

What is considered when choosing pipes for plumbing

The cold and hot water supply systems used in residential premises must meet certain requirements:

- Reliability. Materials and design nuances allow in the event of an accident to quickly stop the water supply and carry out repairs.

- Functionality. Materials and components selected in accordance with the scope of application, professional installation ensure the full operation of the system, reduce the likelihood of accidents and leaks.

- Ease of maintenance. The reduction of preventive and repair measures is achieved due to the presence in the system of an insignificant number of working nodes and joints.

- Compliance with the specifics of the interior. The pipeline is assembled in such a way and from such materials that fit into the interior design.

- Protection of plumbing fixtures. For hot water, pipes that can withstand high temperatures are selected. Devices are protected from pressure surges, temperature, low-quality water to extend the life of the system as a whole.

- Reasonable quality for the price. The cost of materials, installation works correspond to the degree of reliability of the system.

For plumbing systems, most often the choice is between metal-plastic and polypropylene pipes.

Polypropylene pipes for water supply and heating

Products are offered in a range of brands. German, Czech and Chinese products are on sale. Pipes made in the Czech Republic are the most suitable in terms of cost, and also have a quality that is not inferior to German polypropylene with strict pressure testing. When buying products, we recommend checking the manufacturer's certificates. In the case of the purchase of a large batch, it does not interfere with making a test pressure test, in this case, the positive and negative features of the pipe will appear.

Pipes for water supply

Guaranteed reliable option for internal communications - these are gray polypropylene pipes and type 3 fittings that can withstand the full range of workloads. If you installed them in a country house and accidentally did not turn on the heating in cold weather, you don’t have to worry at all, the pipes will survive freezing without breaks and cracks. What other benefits do they have?

For water supply

Polypropylene pipes provide better plumbing performance than metal. There are no growths on the walls, the pipes do not conduct stray currents. On average, they allow transporting liquids with temperatures up to 70 C.This is quite enough to solve most problems.

For heating - gray PPR

Many users will object that any polypropylene pipes are not applicable for piping solid fuel boilers. Indeed, their use even in the gray version is not desirable, since operating temperatures can reach 130 C for a short time, which will lead to material melting. What are the exit options? In this case, corrugated stainless steel or metal is used in a section with high thermal loads, then a hydraulic arrow with a temperature sensor is installed, and only after that it is fed into a circuit with a strong reinforced PPR.

We recommend using commercially available specialized products manufactured in the Czech Republic and Italy for heating.

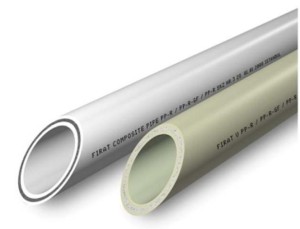

Its main features are given (see photo):

- reinforced with basalt fiber (WAVIN Ekoplastik), up to 90 C, wall thickness 2.8 mm;

- reinforced with fiberglass (WAVIN Ekoplastik), up to 90 C, wall thickness 3.5 mm;

- the most durable with internal metal reinforcement (Italy, Turkey), up to 95 C, wall thickness 4.2-4.9 mm;

- without reinforcement (Turkey, Italy, Czech Republic) - operating temperature of 70C is allowed.

These pipes are characterized by increased operational reliability due to internal reinforcement. Depending on the parameters of the heating system, you can choose one of the appropriate rulers. For systems with solid fuel boilers with a hydraulic arrow, durable gray PPR pipes with internal metal reinforcement and reliable fittings are used, which allow significant temperature fluctuations. Options determine which views to choose for your case.

Marking of polymer pipes

Polymer pipes are marked according to the type of polymer (RE

,

RE-X

, RR

etc.), according to the outer diameter and nominal

pressure (PN).

External pipe diameters (in mm) for internal wiring are presented

next row: 10; 12; sixteen; 25; 32; 40; 50 etc.

In addition to diameter, pipes are marked by wall thickness.

Nominal pressure is usually expressed in bar: 1 bar = 0.1

MPa. Rated pressure means constant

internal water pressure at 20°C, which the pipe can reliably

withstand for 50 years (for example, PN=10, PN=12.5 or

PM=20).

To assess the level of these parameters, we can recall that the working

water pressure in the plumbing system is not more than 0.6 MPa (6

bar). The maximum pressure that the pipe can withstand

short time, several times higher than the nominal. At a temperature

above 20°С the period of non-failure operation of polymer pipes at a constant

pressure decreases or may remain the same - 50 years,

but subject to lower operating pressure.

Characteristics of polypropylene products

Modification allows to increase the mechanical properties of the material - to improve the viscosity, elasticity, high-temperature strength. This copolymer belongs to the category of thermoplastics.

When deciding which pipes are better - polypropylene or metal-plastic, the following properties of polypropylene products should be taken into account:

- chemical resistance to alkaline and acid solvents;

- due to the plasticity of the material, water in polypropylene pipelines can freeze without destroying them;

- high strength and durability during operation in high-temperature systems, combined with low thermal conductivity, determines their widespread use in engineering networks;

- production, use and disposal of polypropylene do not harm the environment and health.

A wide range of polypropylene products allows you to choose the right type of pipes for work: in internal systems of cold and hot water supply, distribution of central heating pipelines, in underfloor heating, for internal sewer systems, drainage of soil water.

The operating temperature of polypropylene pipes is 75C, pipes reinforced with aluminum foil or fiberglass can operate at higher temperatures.

Reinforced polypropylene pipes can operate at elevated temperatures

Plastic or metal-plastic pipes: selection criteria

Making a choice - plastic pipes or metal-plastic, are also guided by considerations of diameter.

Metal-plastic products are produced in a rather narrow range of diameters - 16-63 mm, polypropylene in a wider range - 16-125 mm or more.

Polypropylene pipes of large diameters - more than 63 mm, are most often used for industrial needs. For the installation of such pipes, a butt welding method is used. Choosing pipes, metal-plastic or polypropylene, take into account that the coefficient of thermal expansion of polypropylene pipes is much higher than that of metal-plastic products. When installing polypropylene pipes, it is necessary to install compensators - compensation loops, L- or U-shaped sections.

https://youtube.com/watch?v=BwbPk94eSz0

To choose metal-plastic or plastic pipes, you need to pay attention to the fact that the installation of a metal-plastic pipeline is carried out without the use of expensive tools, does not require special knowledge and experience, and takes a little time. It should be remembered that fittings must be purchased in strict accordance with the type of communications chosen.

Polypropylene packaging advantages and disadvantages

Polypropylene bags have many significant advantages, which we will discuss next.

- First of all, it is worth highlighting the excellent indicators of reliability and strength, which allows you to create high-quality and reliable packaging.

- In addition, high-density polypropylene allows you to protect food from the negative effects of environmental factors. Therefore, most manufacturers choose polypropylene for packaging food products with a long shelf life.

- The strength of polypropylene allows you to protect products from deformation when dropped.

- Excellent strength indicators allow you to efficiently and compactly store goods in a car and transport them over long distances. Therefore, polypropylene packaging is used by most product manufacturers and warehouse owners to move them to the final consumer.

- Polypropylene allows you to print various inscriptions on its surface, namely information about a specific type of product. In other words, it is possible to create ready-made packaging from polypropylene, ready for sale.

- It is also worth highlighting the transparency of polypropylene, which allows you to evaluate the quality of food products and at the same time preserve their useful properties.

- An excellent level of elasticity is another significant advantage of polypropylene. In other words, such packaging is not deformed under mechanical influence. Polypropylene bags are difficult to break without the use of sharp objects.

- The use of polypropylene in the packaging of products allows you to make high-quality and tight seams. In other words, food products retain freshness and useful properties for a long time.

- It is also worth highlighting the excellent resistance of polypropylene to high temperatures.

Features of the use of polypropylene

Polypropylene film, as well as polypropylene duplex laminates in the form of a web, are commonly used for automatic filling of the product on vertical or horizontal type packaging machines; at the same time, the seams of the package are formed by welding thermoelements at a constant temperature.

Transparent biaxially oriented polypropylene film 20, 25, 30, 35 and 40 micrometers thick; used for packaging bulk products of groceries (cereals, sugar, salt, tea and other products), bakery products and pastries, biscuits, crackers, group packaging of sweets and other confectionery products, industrial goods (box wrapping, packaging for textiles and knitwear) and in many other cases.

Pearl polypropylene, 30 and 35 micrometers thick; has all the same properties as transparent polypropylene, but in addition, thanks to the foamed microstructure, it also perfectly reflects light and has a reduced specific gravity, which makes it very economical to use; also, pearl polypropylene perfectly withstands low temperatures without becoming brittle during polymer crystallization; that is why it is successfully used for packaging ice cream, glazed curds and other products that require storage at low temperatures.

The choice of pipes for organizing water supply

To date, the main scope of their application is the supply of water to objects. Reinforced pipes are used for hot water supply, and non-reinforced - for cold. The material from which they are made can withstand temperatures of 90 degrees. Such pipes have proven themselves well when laying internal systems.

Watch the video, selection criteria:

https://youtube.com/watch?v=_-3CjfQuj8k

This is also facilitated by their durability, the service life can reach 50 years or more. In addition, even the best polypropylene pipeschosen for home water supply are much lower in cost than their counterparts made of copper or steel.

Preference is given to them taking into account such important advantages as:

- Low cost;

- Strength and durability;

- Easy installation;

- Reliable tightness of connections;

- Possibility of application in the arrangement of heating and hot water supply.

Overview of popular manufacturers

Plastic is gradually replacing metal pipes from plumbing and heating systems. He is not afraid of corrosion, he does not collapse under the influence of aggressive environments, is able to withstand low and high temperatures, is lightweight and has a low cost.

Therefore, it has become very popular in the market. Today, the main question that interests consumers is: which company is better for polypropylene pipes? Let's try to determine which of the manufacturers has the most favorable ratio of quality and cost.

We watch a video about Rehau products, expert opinions:

https://youtube.com/watch?v=QB-6XwSB2R8

Judging by the numerous reviews of specialists and homeowners, the leading positions are occupied by products from Germany, where they produce the best and highest quality polypropylene pipes today. The most famous brands are:

The second place is confidently occupied by Czech products of such companies as:

- ECOPLASTIC;

- FV plastic.

At the next level are pipes produced in Turkey. The most famous brands are Valtek and Kalde.

Polypropylene pipes from China in the list of which of them are better in fourth place. There are two brands:

The most budget option is considered domestic products:

- Politek;

- PRO AQUA;

- Heisskraft;

- RVC;

- Santrade.

Let's take a closer look at what are and how polypropylene pipes of Russian manufacturers differ.

Watch a video about PRO AQUA products:

PRO AQUA products are used both in water supply systems of industrial, administrative and residential buildings, as well as in technological pipelines. The permissible temperature in them is +95 degrees. They are not afraid of corrosion, resistant to aggressive substances, easy to install, absolutely harmless. Able to withstand high pressure of 79.5 atm, which significantly increases their service life.

Pipes with the RVC trademark are produced by the Russian company Plastic from Orenburg. Made of polypropylene PN 25, they are used in heating and hot water systems. They have internal aluminum reinforcement. One of the shortcomings of the products of this company, buyers call "walking sizes."

In the Moscow region there is a plant where Heisskraft pipes are produced. Their quality is quite high, especially reinforced products, which are produced using German technology.It is possible that some of the products are brought ready-made from Germany.

Products from Heisskraft

Heisscraft pipes, judging by the numerous positive reviews, are also of good quality. Consumers are a little confused by the gray color of the products, which is caused by the addition of technical soot to polypropylene. But such an addition to the composition is fully justified, since soot acts as a good stabilizer. This gives the pipes additional strength and elasticity, which should please, not upset, consumers.

It is still difficult to say what kind of quality polypropylene pipes of the Santrade brand are, since there are practically no reviews about them. This is most quickly explained by the still not very popular brand.

What length and wall thickness to choose polypropylene pipes of the Politek brand depends on the scope of their application. According to installers, their installation does not cause big problems, despite the susceptibility to deformation during compression.

Conclusion

When purchasing products from Russian manufacturers, you should also purchase polypropylene fittings from the same companies along with pipes so that the pipeline systems being created are homogeneous. Domestic products in many cases have the same technical characteristics as foreign counterparts, but at a lower cost.

Polyethylene packaging advantages and disadvantages

The properties of the polyethylene film will depend on the feedstock. In addition, density also affects the strength of plastic bags. In most cases, such bags are characterized by a low level of strength, therefore they are used for temporary storage and transportation of food. The low price is the main advantage of polyethylene packaging, which makes it affordable in our time. However, this type of packaging has many disadvantages compared to polypropylene.

Among the disadvantages of polyethylene are the following:

- The lack of the desired level of elasticity is the main drawback. In other words, such packaging is easy to tear, so it is used for products that do not require a long shelf life.

- Under the action of mechanical action, such packages lose their attractive appearance.

- Low level of strength even for bags created under a high level of pressure.

Polyethylene in the refrigerator

Many people think that any food can be stored in polyethylene in the refrigerator. This is far from the case: products can be stored in polyethylene, but you need to use special bags that are resistant to low temperatures. Ordinary plastic bags at low temperatures can release toxic substances in the same way as when heated. If you freeze vegetables or fruits for the winter, even clean and high-quality ones, in such a package, it can cause food poisoning.

Features of the installation of polyethylene pipes

Various types of connections are used.

1. Bell-shaped.

Stages of work:

selection of pipes and fittings according to the project and taking into account the dimensions (when choosing the length, you need to take into account those sections that will be inserted into the socket);

remove the outer chamfer from the pipes; cleaning the inside (no burrs, burrs, or other irregularities should remain);

inserting the pipe into the socket manually (you need to leave a compensation gap of 1 cm);

when drawing up a project, it is important to provide for the laying of a pipeline under a slope.

2. Welded.

For these types of connections, a special apparatus for welding polyethylene pipes is needed. Main structural elements:

- bushings on which pipes are put on;

- heating plates.

The essence of welding is to melt the ends of the pipes and connect them.

3. Coupling.

Type of connections used in the installation of corrugated pipes. Sliding couplings are used to assemble the pipeline, and rubber seals are used to seal the joints.

Thus, polyethylene pipes are perfect for arranging both internal and external sewage. For internal work - smooth pipes, for external - corrugated.

Polyethylene and polypropylene. What is the difference

Polyethylene (PE) and polypropylene (PP) are common polymeric materials in demand in the industry. They are used for the manufacture of plastics, containers, pipes, packaging and thermal insulation fibers, etc.

There are many similar properties between polymers:

- Durability - retain their appearance when exposed.

- Versatility - soften when heated, which makes it possible to use them in different areas.

- Ease of use - low weight.

- Practicality - not exposed to water, oxygen and salts.

- Electrical insulation - do not conduct electricity.

The difference between polypropylene and polyethylene

Polypropylene and polyethylene are widely used in industry and often seem the same to the consumer. But, polymers have many differences.

What is the difference between polypropylene and polyethylene:

- Lightweight - PP weighs 0.04 g/cu. see less.

- Melting point - polypropylene melts at 180 degrees C, and polyethylene - at 140 degrees C.

- Care - products made of PP are practically not subject to contamination and are easy to clean.

- Synthesis methods - polyethylene is produced under any conditions, and polypropylene - at low pressure.

- Costs - the production of products from polypropylene is more expensive than the production of polyethylene due to the high cost of raw materials.

What is the difference between polyethylene and polypropylene:

Elasticity - polyethylene is more flexible, and polypropylene is brittle.

- Frost resistance - PE does not lose its properties at temperatures up to -50 degrees C, and for PP it collapses at -5 degrees C.

- Lightness - due to its low weight, polyethylene is suitable for the manufacture of films, packaging, pipes and insulating products.

- Lack of toxicity - when PE is heated, toxins evaporate.

Film made of polyethylene and polypropylene: differences

PP and PE film is used to protect fragile goods and has several differences:

- Profitability - with equal parameters with analogues, polyethylene packaging is 50% cheaper.

- Presentability - a glossy PP film looks much more attractive than a dull thing made of polyethylene.

- Practicality - polypropylene is less prone to creasing and does not lose its appearance due to handling operations.

- Temperature resistance - polypropylene becomes brittle from cold, and polyethylene tolerates freezing.

Which is stronger: plastic made of polypropylene or polyethylene

Plastic products are inexpensive and durable. Pipes, dishes and other products are obtained by synthesizing PE at low pressure. High density polyethylene is less durable and is applicable in the manufacture of PET and tarpaulins.

Polypropylene is suitable for packaging, bolognese and fiber. PP is not afraid of heat, solvents and bends. It is not toxic, but is afraid of ultraviolet and frost.

Polypropylene or polyethylene: which is better

Both polymers are used in different industries. Depending on the method of synthesis and purpose, polymer manufacturers achieve the maximum benefit from polymers.

The conditions for the synthesis of raw materials affect the technical characteristics of polymers. For example, when pressurizing and choosing a catalyst, products with different chemical and physical characteristics are obtained.

Based on polypropylene, building materials and various containers are created. High-density polyethylene is optimal in the production of pipes, and high-density polyethylene is optimal for the manufacture of packaging.

The difference between PVC and PP pipes

Plastic pipes are widely used, they are used for water and gas supply, installation of sewers, storm drains, etc.On the market you can find pipes of various types, so the consumer may have understandable difficulties in choosing a specific pipe option for the task he is solving.

One of the most popular at present are pipes made of polypropylene (PP) and polyvinyl chloride (PVC). Each of the options has its own advantages, so when choosing pipes, first of all, you should consider for what purposes they are purchased. The main difference between PP and PVC pipes is the materials used in their manufacture, which determined their properties and applications.

PVC pipes

PVC pipes are made from special polyvinyl chloride that does not emit carcinogens. Application areas of these pipes:

- installation of water supply systems,

- creation of irrigation systems,

- laying of non-pressure sewerage,

- arrangement of storm drains.

There are several varieties of PVC, for the production of pipes the most commonly used are unplasticized polyvinyl chloride - nPVC (PVC-U) and chlorinated PVC (PVC-C).

PVC-U exhibits high chemical resistance and pressure pipes made of this material perform well at temperatures from 0 ºC to 60 ºC. They can be used to transport alkalis, acids and other aggressive liquids. In addition, they can be used to supply water, uPVC is absolutely safe for humans.

Chlorinated PVC (PVC-C) has a high melting point - over 480 ºC. In addition, it is characterized by high mechanical strength; pipes from it are widely used to create high-pressure water pipes. The material resists aggressive media well, so pipes made of it can be used for pumping strong acids and other aggressive reagents. In addition, PVC-C pipes can be used to transport water, vegetable oils, juices and any other liquid food products.

When using PVC pipes in pressure systems, they are best connected using a special adhesive and PVC fittings suitable for the size of the pipes. After the glue hardens, a strong reliable connection is formed.

PP pipes

Polypropylene pipes are more expensive than PVC pipes, but they also have their own advantages, including:

- high strength,

- heat resistance,

- frost resistance,

- environmental friendliness,

- durability.

PP-pipes have high strength, they restore their shape well after loads. Reinforced pipes have the greatest strength, their strength is provided by a special reinforcing layer of aluminum foil or fiberglass fibers.

Polypropylene pipes can withstand temperatures up to 140 ºC, which allows them to be used in heating and hot water systems (usually the operating temperature is not higher than 95 ºC). Polypropylene pipes withstand frosts down to -20 ºC, they can be installed even in winter. Finally, PP pipes are very environmentally friendly and durable, their service life is tens of years.

Installation of PP pipes is most often done by welding; a variety of fittings are used to ensure the desired configuration of the system. Most often, polypropylene pipes are used in the laying of water pipes, heating systems and hot water supply.

Materials for sewer pipes

Now that the requirements are presented, it is necessary to consider each of the materials and evaluate how it corresponds to them. And although a fairly wide range of products made from different raw materials are used for sewer pipes, only three options are most common: cast iron, polyvinyl chloride and polypropylene. In addition to them, you can see ceramic, steel, asbestos-cement pipes, but they come across much less frequently.

Ceramic sewer pipes

Cast iron

Without a doubt, if cast iron is not the best sewer pipes, then it is certainly the most durable and durable.Their service life is measured in almost centuries, and this is supported by well-known practice, and not by theoretical calculations. As for the rest of the properties, the resistance to all factors is high, with installation there may be difficulties associated with connections and heavy weight, which is extremely inconvenient during work. The surface has irregularities, sooner or later leading to clogging. Another disadvantage is the high cost.

Cast iron pipes for sewerage

Polyvinyl chloride (PVC)

The strength and durability of these pipes is at the level, at least according to experts, since they have been used relatively recently.

Let's take a look at the rest of the features:

- Temperature resistance - with an increase above 70 degrees - deformation, at negative temperatures - brittleness.

- Fire resistance is absent, moreover, during combustion, it releases phosgene gas, which is officially classified as a chemical weapon.

- Immune to ultraviolet and aggressive reagents.

- Installation is simple, the inner surface is smooth.

- The cost is affordable.

Summarizing all of the above, we can say that it is better to use PVC for internal sewage, and for the external one, choose another material that is more suitable for this role.

PVC sewer pipes

Polypropylene (PP)

Fittings for PP pipes

Looking ahead, we can say that at the moment, the best sewer pipes are still polypropylene. Such a conclusion can be drawn by evaluating them according to all the above parameters, where for each of them they are rated at five. Strength and durability are high, the pipes are resistant to a complex of influences, the only thing is that with constant heating a slight linear expansion is possible. Installation of PP pipes is easy and without the use of any particularly expensive and complex devices, the inner surface is not something that does not retain deposits - it repels them, and after a few years, it will be almost as clean as when installed. The cost is quite acceptable.

Other materials

Going through the rest of the materials, we can say the following:

- Steel. Strong and resistant to most factors, easy to process, but suffers from corrosion and has a large weight that can create serious installation difficulties.

- Ceramics. It is resistant to chemicals, fire, corrosion, strength and durability. Installation is difficult, if the grooves are clogged, it cannot be carried out. Also, ceramics are fragile and cannot withstand mechanical shock loads, and all protective properties depend on the presence of glaze. Today, ceramics can be found, perhaps, in old reclamation structures; it has already been replaced by more modern and practical materials from other areas.

- Asbestos cement. The material has almost disappeared, and has many more minuses than pluses: fragility, fragility, inconvenience during installation, and many others.

Sewerage from PP pipes

When choosing a material for the construction of a sewer, it is necessary to carefully and seriously evaluate and calculate all the minuses and pluses of any option, without bypassing the final cost of the project. To date, sewerage from plastic pipes made of polypropylene is probably the best option, both in terms of practicality and economy.