Characteristics of boilers Oasis

The Oasis boiler is gas, but at the same time it will not be able to work on liquefied gas. All models are designed only for natural gas - conversion to liquefied gas is not provided and is impossible. In view of this, the boiler can only be used for buildings connected to the gas supply system.

With regard to the "average" structure, the Oasis boiler of various modifications is able to heat the area (m 2):

- NZR 13 - up to 100;

- NZR 16 - up to 120;

- NZR 20 - up to 160 - 180;

- NZR 24 - up to 200 - 220.

The volume of the membrane (expansion) tank of the gas "Oasis" is 6 liters. This must be taken into account if the boiler is selected for a private house. You may have to install an additional tank (with a large volume of coolant).

All Oasis gas boilers are double-circuit, therefore, in addition to heating, they also provide hot water supply. Depending on the automation setting, the water temperature can be from 36 to 60 0 C. The capacity of the DHW circuit is 10 l / min (for the NZR 24 model - 12 l / min) - it is quite sufficient to meet all the household needs of a family of 5 - 7 people.

The nuances of cleaning a gas boiler

When starting to cleanse, you need to know that:

Flushing of boilers should be carried out when they are completely disconnected from electricity, gas and water.

When dismantling the heat exchanger, you should try not to damage the sealing elements, sealing failure will lead to leaks and damage to the unit.

Care must be taken when cleaning the heat exchanger, the thin tubes on the inner surface may be damaged.

A control check for the tightness of the joints can be carried out by coating the joints with soapy water.

When washing in aggressive solutions, it is recommended to add substances - stabilizers that reduce the acid effect on the metal and form a protective film on the surface of the element.

It is best to wash the heat exchanger of a gas boiler with special reagents that will be gentle on the material of the unit and will qualitatively remove all contaminants.

Master Boiler Power removes iron-oxide and carbonate-calcium deposits, does not affect gaskets and seals, the process is accompanied by active foaming, operates at a temperature of 20-40°C. Cleaning is considered completed when the release of foam stops.

Zinconex Powder - removes almost all deposits, contains a color indicator that allows you to control the degree of washing. Compatible with aluminum, galvanized, copper, steel and cast iron surfaces.

Fauch 200, Fauch 610 - spray (aerosol) designed to remove soot from the walls of boilers and heat exchangers.

Effective soot remover HANSA - is a mixture of crystals that burn in the firebox during ignition. It is designed to clean the elements of the boiler and chimneys from soot and tar deposits, reacts with them, destroying the structure of deposits.

https://youtube.com/watch?v=ccEAX_yoExc

WATCH VIDEO

Periodic flushing of the gas boiler heat exchanger with your own hands will save the cost of electricity, fuel and the replacement of expensive parts, as well as extend the life of the unit.

do-it-yourself gas boiler heat exchanger repair

sulfamic acid

do-it-yourself cleaning of the heat exchanger of a double-circuit boiler

secondary heat exchanger

gas column cleaning

thermocouple device

check thermocouple on gas boiler

do-it-yourself gas column cleaning

fluid for flushing heat exchangers of gas boilers

do-it-yourself flushing of the gas boiler heat exchanger

cleaning the heat exchanger

flush the heat exchanger at home

soot

scale

soot

process

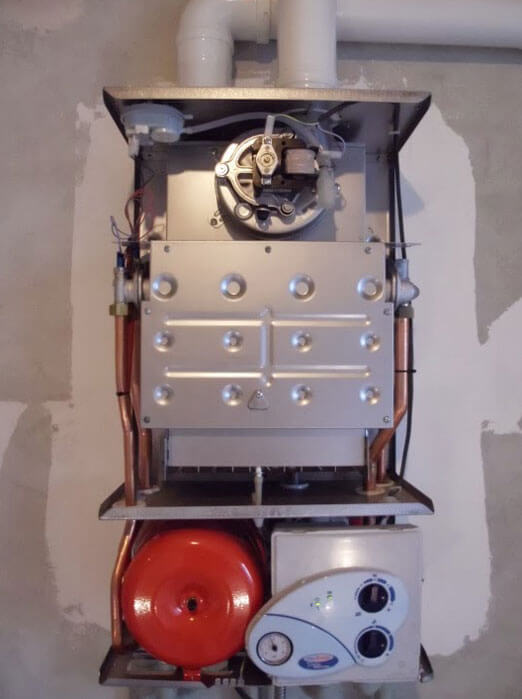

Internal arrangement of boilers Oasis

One of the characteristic features of the modifications is the presence of a closed combustion chamber. Air intake is carried out from the street, using a coaxial chimney. The products of combustion are also discharged through the pipe. This makes the operation of the boilers as safe as possible. In addition, due to the closed furnace, gas consumption is significantly reduced.

Separately, we can note the presence of two heat exchangers. This solution increases the rate of heating water for hot water supply, and also allows the device to be started in summer mode, which increases its efficiency.

All wall-mounted double-circuit gas heating boilers Oasis have a high degree of autonomy, achieved thanks to the internal device, including:

- Burner

- a blower type device is used. The connected burner is automatically controlled. Electric ignition provided. The burner is equipped with photo sensors that monitor the presence of gas. After a power outage, the gas supply to the burner is blocked. A coaxial chimney is used for the boiler. It simultaneously takes in air and removes combustion products. Not included in the basic package. -

Security group

— 2-circuit hinged gas heating boiler Oasis has a multi-level protection that prevents spontaneous combustion and the occurrence of explosive situations. Provided: water flow sensor - controls the pressure of water supply and heating systems, blocks operation in case of a drop to critical levels. Relief valves are installed to help in case of overheating of the coolant. When the room temperature drops, the anti-freeze system is activated, maintaining the minimum heating of the heating system.

Oasis boilers have been certified and received a permit for operation by Rostekhnadzor. This made it possible to operate equipment from a Chinese manufacturer throughout the Russian Federation.

What to focus on the operation

Boiler piping

- in the internal structure of the boiler there is a circulation pump and an expansion tank. During installation, you will need to additionally install a filtration system. Automation is sensitive to voltage drops, which is one of the main disadvantages of the Oasis boiler. To eliminate a possible failure of the control board, you must connect the UPS.

big noise

— The forced draft burner is very noisy. Noisiness requires the installation of the boiler in a separate room. The specifications declared by the manufacturer are somewhat different in this respect from what actually happens.

Especially noisy when turning on the hot water supply.

coaxial chimney

- it is extremely important to comply with the requirements associated with installation, strictly adhere to the maximum height, angle of inclination and other parameters. Productivity and work efficiency ultimately depend on a quality installation.

Chinese doesn't mean bad

All components from the closed combustion chamber to the temperature sensor are checked for quality and compliance with standards. The only condition for trouble-free operation is the installation and operation of the boiler in accordance with all the rules and in accordance with the manufacturer's recommendations.

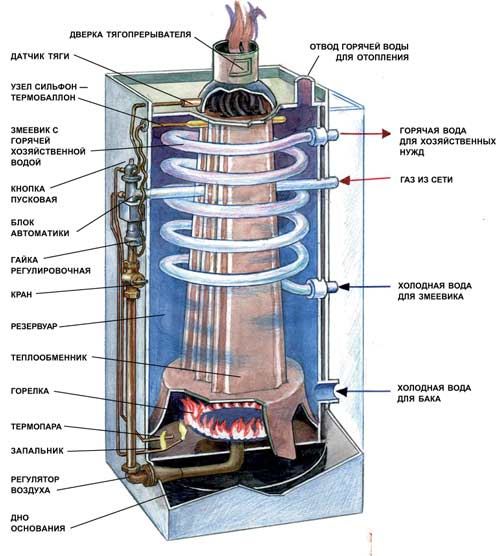

The principle of operation of the AGV

The main element of the AGV is the tank. Through it, the heated coolant (water) is supplied to the heating network of the apartment. When burning, the gas heats the flame tube-heat exchanger, which is located inside the tank itself.

The flame tube is narrower and gives off heat to the water in the tank. It is connected to the chimney, into which all combustion products are discharged. The automatic device is connected to a valve that is turned on to supply gas. This maintains the required temperature of the coolant in the heating tank.

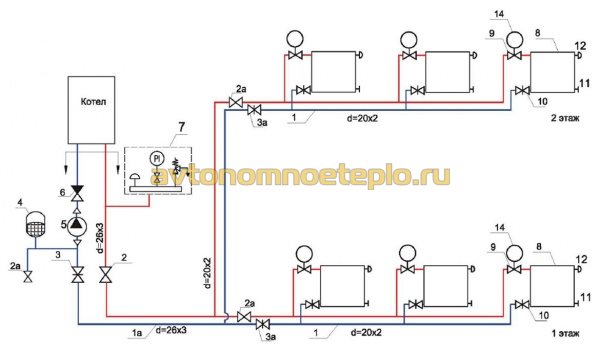

General view of the connected AGV

The heating network consists of the following elements:

- expansion tank;

- pipeline (ascending);

- radiators;

- distribution line (upper);

- return highway.

Heated water, which is lighter than cold water, rises through the pipeline, enters the radiators, cools down, enters the return line and again ends up in the heating tank.The movement of water in the system is created due to the difference in height between the heating tank and the radiators, where heat transfer occurs.

Scheme of work of AGV

Such a heating system is called thermosiphon (gravity-flowing). Water is moved by natural circulation. During operation of the system, the coolant (water) heats up and increases in volume. The excess volume of water enters the expansion tank, which is installed at the highest point of the line.

Through the overflow pipe, excess water from this tank is drained back into the line. Due to the water that is in the tank, the loss of water that is in the system is compensated, and the pressure in it is equalized due to the fact that the expansion tank communicates with the atmosphere.

Important! A pump can be installed in the heating system with AGW, which will circulate water in the system. But in this case, it is necessary to have an available power grid.

Automatic AGV provides for stopping the gas supply if the chimney draft is disturbed, the pressure of the gas itself drops, or if the igniter flame goes out.

Types of gas boilers

- By appointment: only for heating (single-circuit) and for heating with water heating in boilers (double-circuit).

- By power output:

- low-power - with one-stage power adjustment,

- medium productivity - with two-stage power adjustment,

- high-performance - with modulated power control.

- By type of draft: for ventilation (closed type) and with natural draft (atmospheric, open type).

-

By installation type:

- wall-mounted, with heat exchangers made of copper,

- floor - with a heat exchanger made of cast iron or steel.

Advantages their uses are as follows:

- They are environmentally friendly;

- Compact and silent in operation;

- Easy to operate;

- They can be installed in a residential area.

But they have a significant drawback - explosiveness.

How to clean the heat exchanger

Cleaning of the heat exchanger is carried out at the end of the heating season. To carry out the work, it is enough to have a standard set of tools available. Before starting work, it is necessary to disconnect the boiler unit from the gas network (main or local) and electricity.

Consider, how to clean a floor standing gas boiler :

- first of all, the burner is dismantled;

- it is required to disconnect all wires from the gas valve;

- a thermocouple is removed from the combustion chamber, which is connected to the gas valve by a capillary tube;

- the fuel supply pipe is disconnected;

- the bolts or nuts (4 pcs) are unscrewed, fixing the stove with the burner, the assembly assembly is taken out.

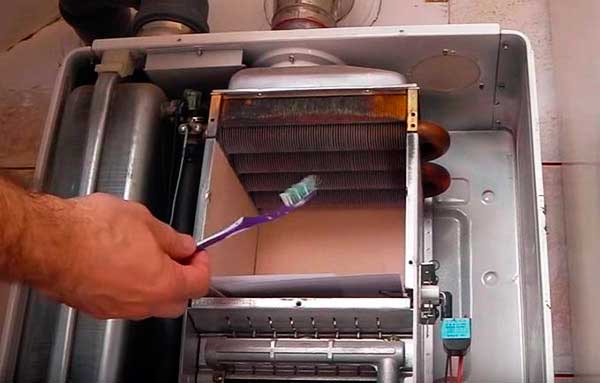

It is convenient to clean the burner of a gas boiler with an old toothbrush. Soot must also be removed from the flame control sensor, igniter, piezoelectric device for automatic ignition.

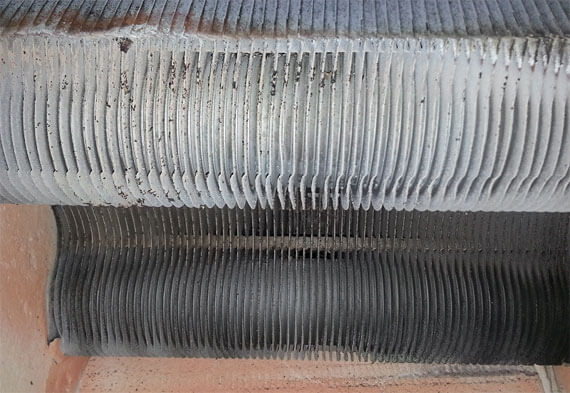

To get to the boiler heat exchanger, remove the top cover of the unit, disconnect the draft sensor and the chimney, remove the insulation, dismantle the casing fasteners and the casing itself. Having gained access to the heat exchanger, it is necessary to remove the turbulators from it.

A soft metal brush is suitable for cleaning the turbulators, and the heat exchanger itself is freed from soot deposits with a miniature scraper made of thin metal. A brush with a long handle is also used. First of all, the smoke pipes are cleaned and swept, then the soot that has fallen on the bottom should be removed.

Cleaning the wall-mounted heat generator. After turning off the gas supply, it is necessary to dismantle the front panel of the boiler. Then the front cover is unscrewed, which closes the combustion chamber. It is recommended to cover the nozzles with a sheet of thick paper so that the burner does not become clogged with falling soot.Do-it-yourself cleaning of the heat exchanger of a double-circuit boiler is carried out using an old toothbrush or a brush with metal bristles. After the cleaning is completed, it is necessary to sweep the heat exchanger with a brush and carefully remove the paper with the collected soot. How the procedure is performed, see the video below.

Flushing of a single-circuit and double-circuit gas boiler

Flushing the gas boiler heat exchanger is necessary to remove internal deposits that can disrupt the normal circulation of the coolant in the heating system and cause problems with the supply of hot water to the local DHW system. Substances that destroy the metal may also be present in the deposits.

How often this measure is required depends on the type of coolant. If purified water circulates in the system, it is enough to do prophylaxis every four years, removing deposits. The system with antifreeze should be flushed every two years and the coolant should be changed regularly - under the influence of high temperatures, it changes properties over time and can become dangerous for the metal elements of the system.

Installation of a floor boiler

- Floor-standing boilers, especially cast iron ones, are of considerable weight, therefore, to install it, it is necessary to build a pedestal (a solid foundation). In the annex, a concrete screed is poured for this. In other rooms, with sufficiently strong wooden floors, a piece of galvanized sheet iron is placed under the boiler.

- The installation is carried out by controlling its position with the help of a level.

- After direct installation, it is connected to the chimney and the draft is checked.

- Connect the boiler to the heating system inside the house. By doing this, in order to protect the heat exchanger from clogging, a coarse filter is installed before the return line enters the boiler, immediately after the outlet line that fills the system with water.

- For double-circuit boilers, a connection to the water supply is required. In this case, the insert is best done before the branching, closer to home.

- They are connected to the gas pipeline by means of a metal pipe.

Rules for the operation of gas boilers

- The first and one of the most important rules: the room for installing gas boilers in a private house must be dry.

- It is necessary to protect the heat exchanger from dust and dirt, which reduce its performance.

- Use filters to improve water quality.

- Perform maintenance regularly. It is advisable to do this before the start of the heating season or when it ends.

Maintenance

During maintenance, the following is done:

- Checking the ventilation system and the condition of the chimney.

- Cleaning and washing filters.

- Flushing the entire system with special detergents that effectively remove various deposits.

- Check the tightness of all connections and replace worn parts.

- Burner cleaning.

Compliance with the operating rules and regular maintenance of the boilers will reduce fuel consumption and significantly increase the life of the unit.

Recent publications

What is steam heating in a private house How to make the right sewer slope in a private house What is needed in order to pressurize the heating system in a house

Do-it-yourself cleaning of the boiler heat exchanger getting started

Before starting work, firstly, you should disconnect the heating boiler itself from the power source.

In order to access the system heat exchanger, you will need the following tools:

- Phillips screwdriver

- Flat screwdriver

- Wrench.

Perhaps, in your case, to flush the gas boiler heat exchanger, you will not need the entire set of tools from the list above, however, we recommend that you still provide for the presence of each of them as a “reserve”.

For example, to access the heat exchanger of a double-circuit turbocharged boiler with a Hermann SuperMaster 24SE boiler, you will need to do the following:

- remove the front cover from it, after which you will get access to the "insides" of the boiler,

- then remove the cover from the tightly closed combustion chamber, for which you will have to unscrew six bolts.

In turbocharged boilers, as in the case under consideration, the combustion chamber cover must have a rubber seal on all sides. Under the cover is the combustion chamber of the heating boiler. In order to gain access to it, at least a few walls covered with refractory material should be removed. To do this, once again unscrew the next five screws and open the combustion chamber.

At the bottom of a turbocharged boiler, you will most likely find a bunch of air-drawn debris. It will be most convenient to remove it with the help of an ordinary household vacuum cleaner.

The lower part of the combustion chamber is occupied by a number of nozzles that pass gas into the system. All nozzles should be thoroughly cleaned - the holes through which gas is supplied should become transparent.

Next, you need to remove the heat exchanger itself. In the model under consideration, there are no threaded connections; the tube through which water is supplied and removed is connected using an adapter. On one side of the heat exchanger is a temperature sensor, from which the wires should be carefully disconnected.

How to clean the heat exchanger

Cleaning the heat exchanger depends on its design and on what kind of water is used in the system: prepared - with special additives - or unprepared.

By design, the heat exchanger can be one of three types:

Lamellar are further subdivided into two types - primary and secondary (for heating water). The fire tube heat exchanger is installed in floor-standing boilers, and the bithermic heat exchanger is installed in compact wall-mounted or floor-standing models.

Cleaning can be done in the following ways:

- mechanical;

- chemical;

- electric discharge;

- hydrodynamic,

Maintenance of gas equipment, including boilers, must be carried out by specialists with appropriate education. If you do not have enough technical skills, it is better to invite the master.

Independent repair of gas boilers

Before you start repairing a gas boiler with your own hands, it is necessary to identify the cause of the breakdown. Various elements of heating equipment can fail. Most often, the causes of breakdowns are: violation of operating requirements, poor quality of parts, shocks.

Volatile boilers often fail due to reset. Therefore, the repair of the heat unit must begin with checking the settings and the presence of open contacts. Performing troubleshooting, the device is turned on at full power in the "Winter" mode. Repair of heating gas boilers begins with this step.

Repairing gas heating on your own is far from always possible, and only if the malfunctions are simple and noticeable. Only specialists can deal with complex breakdowns

Also, do not forget that gas boilers are dangerous equipment, so you need to handle them carefully, and in no case try to repair the gas pipe and safety elements yourself.

Video about repairing a gas boiler with your own hands:

The modern market for heating equipment is saturated with a very wide range of boilers of various types. But a special place in this assortment is occupied by gas boilers, which are gaining more and more popularity every day.

This trend is due to the fact that units of this type are very efficient and economical devices for heating a country house and even an apartment. In order for the gas boiler to function smoothly and stably, it is necessary to properly care for it.

One of the types of such maintenance is cleaning the gas boiler from soot and other contaminants. Let's talk in more detail about why to clean the gas unit, as well as in what ways this can be done.

Modernization of AGV boilers by the manufacturer

The manufacturer of AGV boilers was in no hurry to withdraw them from production due to obvious advantages.

However, taking into account that this equipment needed a thorough modernization, the following changes were made to the design:

- Fragile glass thermometers have been replaced with more reliable Italian-made instruments;

- The new systems were equipped with automation from the American company Honeywell;

- To turn on the device with a handle, a piezo ignition system began to be used;

- The new coating technology made it possible to make the appearance of the unit more aesthetic.

Scheme of the boiler AOGV - 23

Rules for handling the heating system

Install the unit in a separate room. It is desirable that this room be soundproofed, since when the boiler burner is turned on, a rather loud bang occurs.

In some new modifications (AOGV-23.2-1-U), this disadvantage is largely eliminated, since when the water overheats, the automation does not turn off the burner completely, but switches it to a mode in which the flame is minimal.

A chimney (with a diameter of 140 mm or more) for combustion products is equipped outside the living quarters. Below the junction of the pipe from the heating tank with the chimney, there is a garbage collector - a "pocket" for foreign objects and waste that accidentally fell into the channel.

Version of the chimney for AGV in a private house

Note! Connecting the unit with your own hands should not be done. It must be carried out by employees of the gas service

This will register the device.

For the unit, a room should be allocated in the lower part of the building. The ascending line of the pipeline needs to be insulated. The return line should not be insulated.

The installation instructions for heat transfer devices (radiators, convectors and heating panels) provide for their installation at the highest possible height from the unit itself. To circulate air layers, such devices should be installed under windows. The return pipeline is laid under the floor of the room.

If the return line is laid over the door jambs, the system may be "aired".

General view of a fragment of the piping of the heating system with AGV

Two-inch network pipes do not look very aesthetically pleasing, however, when replacing them with pipes of a smaller diameter, it must be taken into account that with a decrease in pipe diameter, hydrodynamic resistance increases, which weakens the pressure of water in the system. This, of course, can seriously impair the efficiency of such a unit.

AOGV connection: rear view

During installation, pipelines are installed with a slope of 1 cm for each meter of pipe length. This avoids air locks in the system, facilitates water circulation and allows water to be drained from the system.

This addresses some of the practical issues of installing an AGV in a private home:

Some caveats

- When the temperature of the water in the system drops below 55-50°C, condensate begins to be abundantly released. When accumulated, it can extinguish burners;

- Combustion products, mixing with condensate, form nitric and sulfuric acids, which cause equipment corrosion;

- If the temperature of the water in the system drops below 50°, then its circulation in the system almost completely stops;

- If the room is not heated in winter, the water from the system must be drained, but in this case, corrosion is greatly enhanced;

- To get hot water without heating the entire system, you can use a tap that shuts off the circulation in the heating system. And if you connect the direct and return lines, you can save the turnover.

http://otoplenie-gid.ru

Basic error codes

Let's try to consider in more detail the error codes of Oasis boilers, and the possible reasons for their appearance.

Error e1. Indicates a malfunction of the ignition, possible causes:

e2

Error e2. Lights up if the air pressure switch does not close after 8 seconds after the fan is switched on.

The reasons may be:

e6

Error e6.Means there is no flame. What to do if a similar problem occurs?

The following must be excluded:

e7

Error e7. Low pressure or insufficient fluid in the hot water system.

Likely causes:

e9

Error e9. Indicates that the pump has failed, or that the pressure in the system is unacceptable.

Check the following:

Optimal fluid pressure level

in the system varies from 0.1 to 0.15 atm.

Check the operation of the water pump

after having removed it. If necessary, clean the pump, flush, check the integrity of the blades.

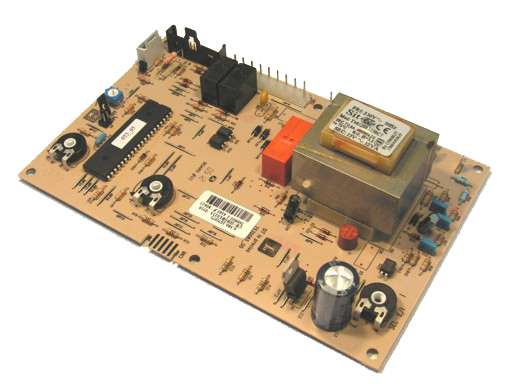

Broken control board

Needs replacement.

You also need to check if the temperature sensor is working.

.

How the Oasis boiler works

The devices of this manufacturer are double-circuit. This means that the water heater can provide not only hot water in the tap, but also heating in the room. The heating temperature is from 35 to 60 degrees, the average productivity is 10 liters per minute.

The boiler is equipped with two heat exchangers. One of them is responsible for providing water for heating batteries, the other for hot water supply (DHW). Accordingly, fuel consumption and heating waiting time are reduced in summer.

Combustion products are forced out. Closed chamber and ensure automatic and safe operation. Flame sensors, gas supply, flow sensors are installed for control. A safety valve is also provided, which is activated when the pressure rises.

Not without fault control. The equipment is equipped with a self-diagnostic system. In the event of a malfunction, the display shows an error, the meaning of which is indicated in the instructions.