The main criteria for choosing a solid fuel boiler

The choice of a solid fuel boiler for space heating is based on several basic criteria.

- Type of fuel - if coal is the main type of fuel, then in this case it is better to purchase boilers made of high-alloy steel. If wood is used as fuel, then cast iron will be an ideal option.

- Boiler power / useful volume of the loading chamber - this criterion indicates how much fuel can be loaded into the furnace at a time, and how often this will need to be done. This also takes into account the weight of the heating equipment. For example, a steel boiler with the same power as a cast iron boiler will require less free space for installation from the entire area of \u200b\u200bthe room, by 19% on average.

- The weight of the boiler and its cost - a steel boiler is less in weight than a cast-iron one, by about 17%, therefore the price of installation and delivery is much less.

- Profitability - the coefficient of performance (COP) of a cast-iron boiler is less than that of a steel one, although the cast-iron boiler cools down much more slowly.

- Maintenance costs and ease of use are equally important criteria that affect not only the heat output of heating equipment, but also the physical and energy costs of loading and cleaning combustion chambers.

- Durability - the conditional figure for the service life of a heating solid fuel boiler is about ten years. But this figure is more related to the obsolescence of heating equipment. than with the period of its operation. In fact, any boiler with proper maintenance can last much longer.

We must not forget about such an important factor in choosing a solid fuel boiler as the risk of injury or burns. and degree of security. In most cases, steel heating boilers are produced only by companies that occupy a leading position in the heating equipment market. All steel boilers of these companies have more than one level of protection against burns and injuries during operation. The equipment used in the production of steel boilers is very expensive. therefore, they are produced in small volumes, while there are more than enough offers for cast-iron solid fuel boilers. But their level of security is much lower.

The fact that a solid fuel boiler can be used as the main source of heat. there is no doubt. Despite the fact that such heating equipment requires constant maintenance during operation, until recently it has been and remains the most alternative source of heat for residents of remote areas. And the availability and relatively inexpensive price of solid fuels make it possible to successfully use such heating equipment in country houses.

Varieties of boilers

Wood burning heaters are a great alternative to gas appliances. They are characterized by multiple advantages:

1. High efficiency - due to slow combustion of fuel, the efficiency reaches 90%.

2. Long-term activity - a volumetric furnace with a powerful blowing fan is able to provide continuous operation for up to 7 days.

3. Environmental friendliness - when fossil fuels are burned, a small amount of carbon dioxide is released into the atmosphere.

4. Profitability - built-in electronics helps to set the optimal boiler loading mode.

Slow burning heating units are presented on the modern market in three varieties.

They work on coal, wood or wood briquettes. Due to the small firebox, the combustion period of one bookmark is reduced. To ensure continuous operation during the day, the fuel has to fall asleep 4-6 times.The advantage of classic boilers is the low price.

Design with a large hopper and a wide loading opening. Dry bulk materials are used. Automatic control optimizes the combustion process. Depending on the load, a powerful boiler operates from 6 to 24 hours. The efficiency is no more 75 %.

They operate on the principle of burning wood gases released during a slow smoldering process. The design ensures high efficiency of heat transfer and fast heating of the coolant. At one load, the furnace operates until the fuel burns out completely, the efficiency factor is 85%.

Scheme of a wood-burning stove with a water circuit

Boilers according to the drawings of Vasily Pustovoichenko are simple and affordable installations that you can do yourself. As a basis, an all-welded pipe, a steel barrel or a used gas cylinder is used. The thickness of the metal walls should be at least 3-4 mm. This reduces metal burnout and ensures long-term trouble-free operation of the equipment. The height of the base varies from 800 to 1000 mm. The volume of a single fuel load depends on the value of this parameter.

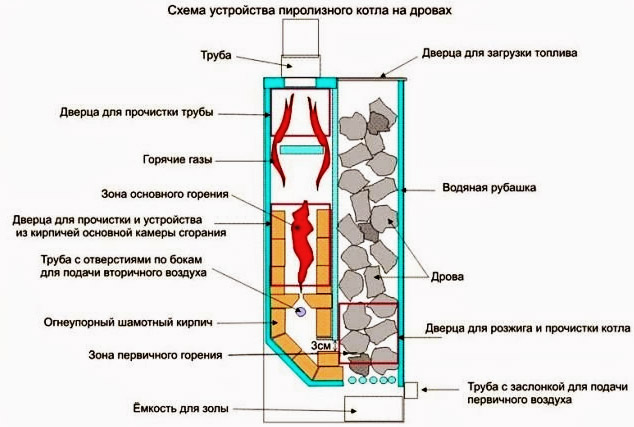

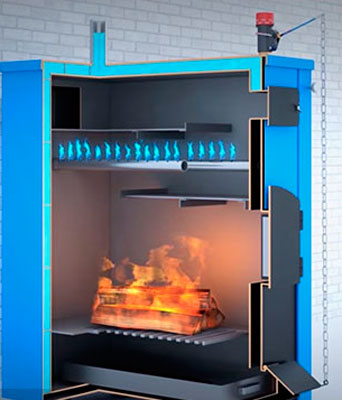

The scheme of a wood-fired heating boiler consists of three parts:

- loading hopper - a container for laying fuel, the height of which changes as it burns out;

- combustion chamber - the area where the slow smoldering of firewood and the generation of gases occur;

- complete combustion zone - a closed pan where wood gases are burned, ash accumulates and smoke is removed.

The combustion chamber is limited by an air distributor. This is a metal circle 4-6 mm thick with a hole in the center. A telescopic (or solid) pipe passes through it, supplying oxygen to the combustion zone. The distributor disk is in motion, so its diameter is slightly smaller than the boiler body. Air enters the discharge pipe from the atmosphere, penetrating through the upper damper.

Exhaust gases are discharged through a chimney fixed at the top. At the bottom of the wall is a door through which ash and ashes are removed. In long-burning boilers, solid fuel is burned almost completely, so waste is removed infrequently. In addition, the design provides points for connecting the supply and return water. Also determine the place of fixing the thermometer and the draft regulator.

Plumbers: You'll pay up to 50% LESS for water with this faucet attachment

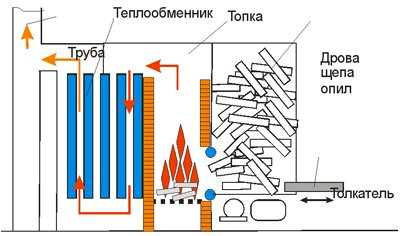

There are two ways to heat the coolant in the water circuit:

1. Make an external storage tank, inside which pass a pipe. Exhaust gases move along the chimney and at the same time heat the water.

2. Pass the heat exchanger tube through the combustion chamber. Connect a coil to it, which is located in the storage tank.

The efficiency of the second method is higher. However, the execution technology looks much more complicated.

Making a long-burning boiler with your own hands video

Popular queries

automation swimming pools and fountains household appliances bathroom fans air ducts country toilet shower cabin chimneys shutoff valves tools sewerage well convectors air conditioning boiler equipment taps and mixers outdoor plumbing pumping equipment heaters lighting water purification air purification furnaces design work with pipes radiators do-it-yourself welding septic tanks well solar panels heating circuits coolant warm floor air humidification insulation filters electrical wiring

Editor's Choice

Warm electric baseboard: price and installation

Ceiling infrared heaters with thermostat

Dimmers for LED lamps 220v

Supply ventilation in the apartment with filtration

Sockets & Switches - Top Brands

Case Features

In order for the cylinder-shaped housing to contribute to high efficiency, the following recommendations must be observed:

- The height to inside diameter ratio should be between 3:1 and 5:1.In this case, the diameter value should fluctuate within 30-80 cm. If the solid fuel boiler has an inner diameter that is too small, then the air will not be able to react with the fuel properly, since it will be quickly expelled through the chimney. The efficiency drops a lot. When the wood-burning boiler has a very large diameter, the central part of the fuel will burn quickly, and the edges slowly. Because of this, a hole will appear in the center, into which the air distributor will sit, and the combustion of firewood will stop.

- The body wall should be 4-6 mm. This rule applies to those cases when solid fuel boilers are made of structural steel. If heat-resistant steel is used for production, then its optimal thickness is 2.5 mm.

Incorrect wall thickness will result in the following consequences:

- if domestic coal-fired boilers have too thin a wall, then heat will quickly pass through it. That is, too much heat will be released through it. As a result, the exhaust gases after passing through the gap between the housing and the air distributor will become colder than 400 ° C, and their combustion will be incomplete. Because of this, the walls of the combustion chamber will begin to become covered with dense soot, and very strong condensate will form on the walls of the chimney;

- if the solid fuel boiler has too thick walls, then its thermal inertia will greatly increase. The water in the shirt will start to boil. The situation will not be saved even by blocking the pipe supplying air.

According to different videos and drawings, the best materials to make the case are:

- Gas cylinder for industrial use. It has walls with the required thickness. It does not need to make a bottom. In addition, the rounded top contributes to better afterburning of flue gases. Solid fuel boilers of long burning from a cylinder have a power equal to 12-15 kW.

- Pipe with large diameter. In this case, you do not need to bend a sheet of metal with your own hands. However, it is almost impossible to bend metal 4-6 mm thick at home.

Very often, a wood-fired boiler is made from a pipe with a diameter of 30 cm and a height of 90 cm.

Choosing a long-burning boiler

When choosing any heating device, there are many factors to consider. First of all, this concerns power, so it is necessary to calculate in advance what indicator the boiler should have in order to effectively heat a room of a specific area. The efficiency of the device is also of great importance.

Then you need to decide on the material from which the boiler should be made. Most often choose steel and cast iron appliances. The weight, the principle of heating and the power of the device depend on the material.

Before buying an appliance, you need to make sure that there is enough free space in order to position it and store fuel supplies. The installation of a wood-fired boiler differs depending on the design and manufacturer. After choosing a device, you should carefully examine it so that if there are defects, you can identify them immediately, and not during operation. In order for the boiler to serve for a long time and work efficiently, all operating recommendations must be followed. In addition, only dry fuel should be used, since moisture not only reduces the amount of heat generated, but also reduces the life of the heater.

Technical characteristics of solid fuel boilers

Boilers with top combustion are produced with different capacities from 8 to 95 kW. Some models can reach 1200 kW. The higher the indicator, the more efficient the operation of the unit and the larger the area can be heated. Boilers with a minimum power are designed for installation in small houses. Ukrainian "Burans" with 40 kW are designed for heating large houses or warehouses.

Solid fuel boiler BURAN-EXTRA 1200

Solid fuel boiler BURAN-EXTRA 1200

Materials for the manufacture of boilers - cast iron or steel. The cast iron heat exchanger is more durable, but due to its large weight, it can be difficult to install. Steel heat exchangers are made of steel of various qualities from low-grade to high-quality, resistant to high temperatures. In addition, steel boilers are often protected by fireclay bricks.

Most often, top-burning boilers run on wood, but there are models in which coal, peat briquettes, shavings and other fuels can be placed.

The efficiency of boilers is 85-93%. According to the manufacturers, the operating time of the device after one load of firewood is from 8 to 31 hours, and on coals up to 5 days. An average inexpensive boiler produces heat within 5-8 hours.

Water heating temperature 70 0 C on wood and 85 0 C on coal. The recommended inlet temperature is from 60 0 C. The heating system can be either with natural or forced circulation.

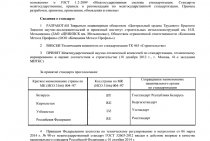

The principle of operation of long-burning wood-burning boilers

The operation of the device begins with the smoldering of fuel (wood, peat, coal) in the furnace. Since the oxygen supply is minimal, the smoldering time is significantly increased, due to which the fuel lasts for about 12 hours. One bookmark is enough for 80% longer than in a conventional boiler, which allows you to save wood. In addition, this makes it possible to reduce the time required to control the operation of the device. A wood-burning boiler is suitable for giving, a private house, industrial premises - the heating will be of high quality, and at the same time, fuel will not require a lot of money.

Since smoldering occurs for a long time, a gas with a high calorific value is formed in the bunker. It, having entered the combustion chamber through a refractory nozzle, ignites under the influence of oxygen. During the operation of the boiler, a lot of heavy and dangerous compounds are burned, including soot. Thus, toxic substances do not enter the chimney and do not pollute the environment, but burn out, giving off heat. Only non-flammable, non-toxic smoke enters the chimney.

Types and characteristics of long-burning boilers, detailed video:

Water jacket

includes two corners: one at the bottom, the other at the top

Features of the water jacket of a household appliance for the heating system of a private country house or cottage are as follows:

- The internal distance from the body to its wall should be 4-6 cm.

- Sheet metal thickness can be 2.5 mm. If you want to make a shirt with your own hands more correctly, then you need to take into account that 1 mm should account for 1 bar of operating pressure. This is provided that the shirt is not higher than 2 m.

According to the video, the shirt can be made from sheet metal. and try to find a suitable pipe.

The principle of operation and drawings of a long-burning solid fuel boiler

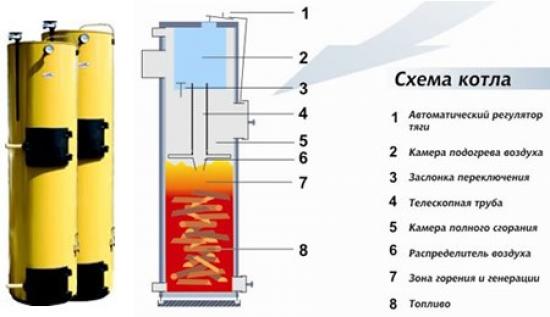

Heaters can work according to several schemes, which is reflected in their design. Boilers based on the principle of upper combustion are somewhat simpler than boilers with a lower hearth, however, their efficiency is almost the same. Upper hearth boilers first went into mass production only in 2000, and since then many have used their design in the manufacture of boilers with their own hands.

The combustion chamber of such a boiler can be quite voluminous, up to 500 cubic decimeters. Therefore, the larger the combustion chamber, the longer the boiler can operate without filling, up to several days. The fuel burns from top to bottom, and the shaft oxygen limiter automatically shrinks the combustion chamber as the fuel runs out. The heat generated during smoldering is transferred to the heat exchanger.

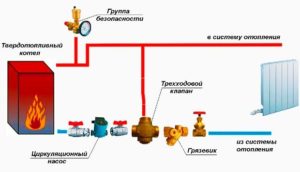

Self-installation of the device

A do-it-yourself long-burning wood-fired water stove must be properly installed.In order to perform all the manipulations correctly, you need to follow certain installation rules:

1. First of all, you need to make a base for the product. Naturally, the place for installation should be suitable. Try to install the boiler in a room where combustible materials are not stored. It must be well ventilated. It is desirable that small children do not have access to this room.

2. For the manufacture of the foundation, you can use bricks and high-quality concrete. The base is necessary in order for the structure to be installed evenly. Moreover, the presented boiler has a fairly large weight.

3. All connecting seams must be pre-checked.

4. After connecting the heating system, the boiler can be checked. If everything is in order, then the installation was successful.

If you are not confident in your abilities, it is better to entrust this work to specialists.

Manufacturing

According to many videos, wood-burning boilers for heating do this:

- Cut off the pipe section necessary for the body.

- Cut holes for doors and chimney. The latter should be near the top at a distance equal to the height of the air distributor with ribs plus 2 cm.

- Cut out the bottom and top. Cut a hole in the center of the top.

- A pancake is cut out and the ribs are welded to it. Make a hole in the center. Weld the air supply pipe. They make a barrier in it.

- The bottom is welded, the air distributor is inserted, the top is welded.

- Fix the corners and the water jacket.

- Weld necks and doors.

A number of useful tips for choosing

Many homeowners are interested in the question of how to choose a double-circuit solid fuel boiler that can work without reloading 8 hours or more. The task is not easy, since the best representatives of the tribe of TT-boilers of long burning are rarely equipped with a second circuit for domestic hot water. So finding a suitable model on the market will not be easy. Hence the advice: it is better to use an indirect heating boiler together with wood-burning heat generators, providing for a one and a half margin in power.

For reference. In the technical passport for a conventional solid fuel unit equipped with a second circuit, the hot water consumption is indicated in liters per 1 hour, and not per minute, as in double-circuit gas boilers. The reason is that in the operating mode of the heater, it will provide passport flow only at a water temperature in the boiler jacket of 90 °C.

Now a number of tips on how to choose a suitable solid fuel heat source:

- When there is a choice between a long-term direct and top combustion boiler, take the first option. A conventional unit with an increased firebox will create much less trouble for you.

- If you need to choose between a cast-iron and steel heat exchanger, then the first option is preferable. Cast iron boiler elements last much longer than steel ones, but they also cost 15-20% more.

- With a reliable power supply to the home, it is better to purchase a boiler model with forced air supply by a fan and automation. In standby mode, when the coolant is heated to the desired temperature, and the fan is turned off, air access to the furnace is completely blocked and the wood smolders very slowly.

- Choose a heat generator model where the fan is installed on top of the housing. In products with a fan built into the door or side wall, this assembly fails faster. The reason is dust and debris that the fan captures from the lower zone of the room.

- Avoid buying a boiler with water-tube grates (pipes filled with coolant run instead of the usual grate). Firstly, a small fraction of coals tightly sticks to them. Secondly, the water-tube grate quickly cools the heat in the furnace, forcing the automation to work more often, which starts the full combustion mode.

It looks like a grate made of pipes filled with coolant

When choosing a long-burning wood-burning boiler for home heating, keep in mind that the price of these units is significantly higher. Be careful when communicating with sales representatives of different manufacturers, study the instruction manual for the product. If it says that the volume of the firebox is 45 liters, and the duration of burning is 8 hours or more, feel free to refuse the offer, no matter how attractive the price. In reality, you will have to load such a heater every 4 hours.

Advantages and disadvantages of solid fuel boilers of upper combustion

Top burning boilers have been providing users with heat for more than 15 years. During this time, they have fully confirmed their effectiveness, which is ensured by the following factors:

- when the fuel is loaded, the distributor rises, and after ignition it rests on the firewood and lowers as it burns out;

- at the point of air entry, incomplete oxidation of hydrocarbons occurs. The gas with ash particles is transferred to the upper part of the combustion chamber. There, oxygen is added to it, as a result of which it is burned out and gives off the remaining heat;

- at the beginning of the gas combustion chamber, there is a draft regulator. With its help, the water temperature is automatically determined and the rate of combustion of volatile compounds is regulated.

Boilers have the following advantages:

- long operating time and minimum number of downloads;

- energy independence due to work with natural circulation and natural draft;

- the versatility of some units in terms of fuel: coal, firewood, shavings, peat, etc .;

- a small amount of fuel can provide high efficiency;

- automated continuous operation of the boiler for supplying hot water and heat;

- the absence of complex mechanisms makes the operation of the boiler simple even for beginners;

- high level of security;

- long service life of 10-15 years or more.

The top combustion boiler has a high level of safety

The top combustion boiler has a high level of safety

Disadvantages of solid fuel boilers with top loading:

- high cost compared to other installations;

- sensitivity to changes in heat exchanger temperature. Possible condensation and oxidation of steel elements;

- increased ash content can clog the combustion zone and reduce the level of heat transfer;

- it is necessary to regularly manually clean the chimney and ash pan;

- inconvenient laying of firewood due to design features;

- it is impossible to load fuel of large sizes, for example, not chopped firewood;

- the fuel must be completely dry, so you need to consider the conditions for its storage;

- incomplete loading makes ignition inconvenient, because. the firebox is deep enough;

- it is impossible to carry out additional loading if the process is already running;

- the support beam and disk, which serve as a partition between the zones of combustion of solid fuel and gas, quickly fail.

As you can see, top-burning solid fuel boilers are not without drawbacks, so before purchasing such a device, weigh the pros and cons well.

Overview of models and prices

It is sometimes difficult for a buyer to understand the huge range of heating units, so it makes sense to consider the most popular models of gas-generating boilers.

Buleryan oven with water circuit

Buleryan furnaces have long won the trust and popularity of the buyer due to their compact size and high efficiency. Buleryan according to the type of fuel combustion is a gas-generating furnace. Its barrel-shaped fuel chamber is divided horizontally into two parts: pyrolysis takes place in the lower part, and afterburning of gases in the upper one. The air flow is controlled by a damper on the door.

Video: Buleryan oven operation

The traditional design of the buleryan involves heating one or more rooms with the help of air heated from the walls of the furnace and delivered to different rooms through air ducts. However, in recent years, buleryan-aqua furnaces equipped with a water circuit have appeared.It occupies about 70% of the body surface and effectively removes heat from the chamber walls to the heating system.

Advantages of the Buleryan furnace with a water circuit:

- high heating rate of the heating system;

- uniform heat transfer, sudden changes in water temperature and boiling are excluded, buleryan can be used in systems with natural circulation;

- the furnace itself is compact and easy to install;

- the price of buleryan is lower than that of pyrolysis boilers;

- A wide range of models of different power allows you to choose a heater for any room.

The operation of the furnace implies the fulfillment of certain requirements:

- firewood must be dry, the use of pellets and briquettes is allowed;

- The furnace chimney must create good draft and have cleaning elements, since the flue gases in the furnace often do not burn out completely, and soot settles on the walls of the pipe.

The price of Buleryan-aqua furnaces, depending on the capacity, ranges from 16 to 46 thousand rubles.

Pyrolysis boilers "Trajan"

The boilers of the Trayan company, with the light hand of the buyers, received the unofficial name of the Trojan. They are gas generators with bottom loading and power from 10 to 30 kW, depending on the modification. The case is made of steel, in its frontal part there is a loading door, as well as an ash pan damper and a cleaning door of the afterburner chamber.

Advantages of the boiler:

- high productivity with low consumption of firewood;

- non-volatility - there are no fans in the boiler;

- the unit is equipped with a built-in emergency circuit to avoid boiling and water hammer in the system;

- Trojan can be equipped with an additional electric heating element to maintain the temperature in the system during breaks in the furnace.

Below is a detailed video: boiler "Troyan"

The price of Troyan boilers, depending on the model, is from 45 to 70 thousand rubles.

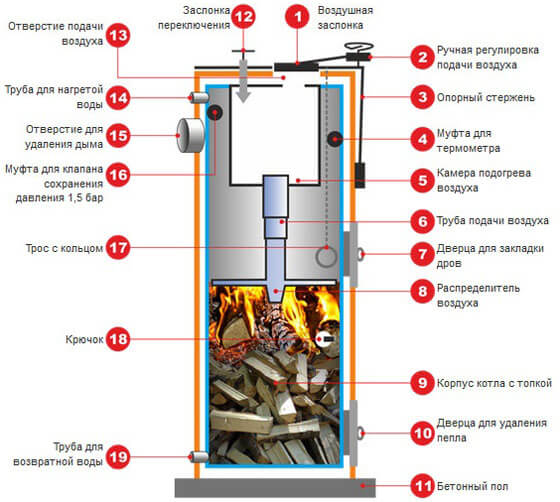

Stropuwa mining boiler

The air necessary for combustion is supplied through a telescopic pipe directly to the top layer of firewood. The damper is regulated by a bimetallic element. When burning and lowering firewood, the pipe gradually increases. After the end of the firebox, the pipe is lifted by a special cable.

Advantages of Stropuva boilers:

- long burning mode without loading - up to 5 days when using coal;

- high efficiency - up to 90%;

- safety - in case of overheating, the boiler will not explode, possible deformation of the walls occurs inside the boiler, which will avoid leakage and burns;

- independence from power supply - adjustment is carried out mechanically;

- compact dimensions even for high power boilers.

Video: Stropuva mine-type boilers

Long-burning boilers are a new word in the production of heating units. Their design is constantly being improved, while increasing efficiency, increasing safety and ease of use, and the price becomes more affordable. Installing a pyrolysis boiler in a private house is a step towards comfort and savings.

How a solid fuel boiler works

The use of dampers, which the unit is equipped with, allows you to regulate the combustion process. When the boiler is ignited, all gates are opened, thereby providing access and removal of a large amount of air necessary for the operation of the boiler. As firewood or coal flares up, they first cover the ash pan damper, and after stabilization of combustion, the heat exchanger, ensuring the required movement of hot air masses through the internal cavity of the equipment. The damper on the chimney pipe is covered only when the closed ash pan damper cannot contain the increase in the temperature of the coolant.

To maintain a constant combustion temperature, thermostats are used, which, depending on the change in the parameters of the coolant, control the lower damper of the boiler. Install the regulator at the top of the water jacket. Due to the rigid connection, with the help of a lever and a chain, the position of the gate changes when the thermal head is turned, which reacts to fluctuations in the temperature of the coolant.

The device of most solid fuel units involves manual loading with wood or coal. Manufacturers of modern equipment offer the consumer models with automatic fuel supply. This technique is popular when using granular briquettes, specially made for combustion in the preparation of the coolant.