Heat consumption for ventilation

According to its purpose, ventilation is divided into general, local supply and local exhaust.

General ventilation of industrial premises is carried out with the supply of supply air, which absorbs harmful emissions in the working area, acquiring its temperature and humidity, and is removed using an exhaust system.

Local supply ventilation is used directly at workplaces or in small rooms.

Local exhaust ventilation (local suction) should be provided when designing process equipment to prevent air pollution in the working area.

In addition to ventilation in industrial premises, air conditioning is used, the purpose of which is to maintain a constant temperature and humidity (in accordance with sanitary and hygienic and technological requirements), regardless of changes in external atmospheric conditions.

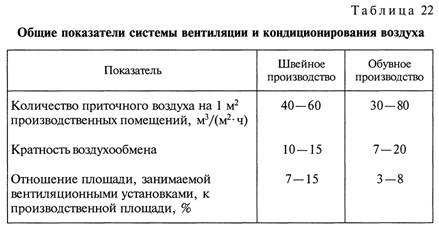

Ventilation and air conditioning systems are characterized by a number of general indicators (Table 22).

The heat consumption for ventilation, to a much greater extent than the heat consumption for heating, depends on the type of technological process and the intensity of production and is determined in accordance with the current building codes and regulations and sanitary standards.

The hourly heat consumption for ventilation QI (MJ / h) is determined either by the specific ventilation thermal characteristics of buildings (for auxiliary premises), or by

At light industry enterprises, various types of ventilation devices are used, including general exchange devices, for local exhausts, air conditioning systems, etc.

The specific ventilation thermal characteristic depends on the purpose of the premises and is 0.42 - 0.84 • 10~3 MJ / (m3 • h • K).

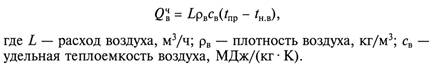

According to the performance of supply ventilation, the hourly heat consumption for ventilation is determined by the formula

the duration of the existing supply ventilation units (for industrial premises).

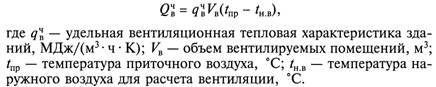

According to the specific characteristics, the hourly heat consumption is determined as follows:

In the event that the ventilation unit is designed to compensate for air losses during local exhausts, when determining QI, it is not the outside air temperature that is taken into account to calculate ventilation tHv, and the outside air temperature for heating calculation /n.

In air conditioning systems, the heat consumption is calculated depending on the air supply scheme.

Thus, the annual heat consumption in once-through air conditioners operating using outdoor air is determined by the formula

If the air conditioner operates with air recirculation, then in the formula by definition Q£con instead of supply temperature

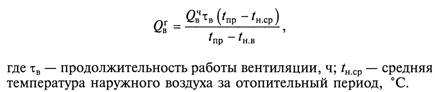

The annual heat consumption for ventilation QI (MJ / year) is calculated by the equation

Feasibility study of the project

Choice

one or another design solution -

the task is usually multifactorial. In

In all cases, there are a large number

possible solutions to the problem

tasks, since any system of TG and V

characterizes a set of variables

(a set of system equipment, various

its parameters, sections of pipelines,

the materials from which they are made

etc.).

V

In this section, we compare 2 types of radiators:

Rifar

Monolit

350 and Sira

RS

300.

To

determine the cost of the radiator,

Let's make their thermal calculation for the purpose

specification of the number of sections. Payment

Rifar radiator

Monolit

350 is given in section 5.2.

102. CALCULATION OF AIR HEATING

|

Permanent systems The most appropriate heating of industrial If permanent workplaces are located at a distance of 2 m or less from the outer walls and windows, then it is recommended to arrange an additional central water On weekends or at night when work is not The question of what type of heating should be used, Calculation of air heating of industrial buildings with |

Air heating

has much in common with other types of centralized heating. AND air

and water heating are based on the principle of heat transfer by heated…

Local air heating

provided for in industrial, civil and agricultural buildings in

the following cases

Air heating.

Characteristic air heating. CENTRAL AIR

HEATING with full recirculation, with…

During business hours central air heating

subject to the conditions of ventilation of the premises.

Air heating

includes: air heater, in which the air can be heated with

hot water, steam (in heaters), heat ...

air-thermal

the curtain is created by the recirculation unit of the local or central air

heating.

When aerial Sirtema heating

is also a ventilation system, the amount of air introduced

set under the following conditions.

Central air heating

can become even more perfect if individual water or

electrical heaters...

central system air heating

- canal. The air is heated to the required temperature /g in the thermal center

buildings where…

Local air heating With

heating or heating and ventilation units are used in the industrial.

tse.

Specifications and cost of Calorex Delta

| Model Calorex Delta | 1 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | |

|---|---|---|---|---|---|---|---|---|---|---|

| The cost of model A 230 V | Euro | on request | on request | on request | on request | |||||

| Model cost 400V | Euro | on request | on request | on request | on request | on request | on request | on request | on request | on request |

| Compressor | ||||||||||

| Rated power consumption | kW | 2 | 2,6 | 2,6 | 3,4 | 4,1 | 5,2 | 6,3 | 7,8 | 13,3 |

| Launch: 1 phase | A | 56 | 76 | 76 | 100 | N/A | N/A | N/A | N/A | N/A |

| Work: 1 phase | A | 8,1 | 12,4 | 12,4 | 16,6 | N/A | N/A | N/A | N/A | N/A |

| Soft start: 1 phase | A | 27 | 31 | 31 | 34 | N/A | N/A | N/A | N/A | N/A |

| Launch: 3 phase | A | 38 | 42 | 42 | 48 | 64 | 75 | 101 | 167 | 198 |

| Work: 3 phase | A | 3,9 | 4,7 | 4,7 | 7,3 | 6,3 | 7,4 | 11,5 | 20,7 | 24,9 |

| Soft start: 3 phase | A | 15 | 16 | 16 | 17 | 28 | 30 | 34 | 39 | 41 |

| Main fan | ||||||||||

| Airflow | m³/hour | 2 500 | 2 600 | 3 000 | 4 000 | 5 000 | 6 000 | 7 000 | 10 000 | 12 000 |

| Maximum external

static pressure |

Pa | 147 | 147 | 196 | 196 | 196 | 245 | 245 | 245 | 294 |

| FLA: 1 phase | A | 4,6 | 4,6 | 3,9 | 6,4 | N/A | N/A | N/A | N/A | N/A |

| FLA: 3 phase | A | N/A | N/A | 1,6 | 2,6 | 3,7 | 3,7 | 3,7 | 7,4 | 11 |

| Exhaust fan | ||||||||||

| Air flow (summer) | m³/hour | 1 200 | 1 300 | 1 500 | 2 000 | 2 500 | 3 000 | 3 500 | 6 700 | 8 000 |

| Air flow (winter) | m³/hour | 600 | 650 | 750 | 1 000 | 1 250 | 1 500 | 1 750 | 3 350 | 4 000 |

| Airflow

(during the period of non-use) |

m³/hour | 120 | 130 | 150 | 200 | 250 | 300 | 350 | 670 | 850 |

| Maximum external

static pressure |

Pa | 49 | 49 | 98 | 98 | 98 | 147 | 147 | 147 | 147 |

| FLA: 1 phase | A | 1,6 | 1,6 | 2,9 | 4,8 | N/A | N/A | N/A | N/A | N/A |

| FLA: 3 phase | A | N/A | N/A | 1,2 | 2,1 | 2,1 | 2,6 | 2,6 | 4,2 | 7,4 |

| Dehumidification performance | ||||||||||

| With heat pump | l/hour | 4,5 | 5,5 | 6 | 8 | 10 | 12 | 14 | 28 | 30 |

| Total @ 18°C dew point (summer) | l/hour | 6,5 | 7,3 | 9 | 12 | 15 | 18 | 21 | 41 | 48 |

| Total @ 7°C dew point (winter) | l/hour | 9,5 | 10,7 | 12,1 | 16,1 | 20,1 | 24,2 | 28,2 | 55 | 60,5 |

| VDI 2089 | l/hour | 7,6 | 8,2 | 9,5 | 12,6 | 15,8 | 19 | 22,2 | 42,5 | 51,4 |

| Total DH + VDI 2089 @ 12.5°C

dew point (summer) |

l/hour | 9,8 | 10,9 | 12,5 | 16,6 | 20,8 | 25 | 29,2 | 56,5 | 62,4 |

| Air heating | ||||||||||

| Via heat pump (mode A) | kW | 1,3 | 1,5 | 1,4 | 1,5 | 1,6 | 2 | 2,5 | 6 | 7 |

| Via heat pump (mode B) | kW | 3,8 | 4,9 | 5,1 | 6,6 | 8 | 10 | 12,1 | 30 | 35 |

| Via LPHW @ 80°C (water heater) | kW | 20 | 22 | 25 | 30 | 35 | 38 | 42 | 85 | 90 |

| Total | kW | 21,3/23,8 | 23,5/26,9 | 26,4/30,1 | 31,5/36,6 | 36,6/43 | 40/48 | 44,5/54,1 | 91/115 | 97/125 |

| Water heating | ||||||||||

| Via heat pump (mode A) | kW | 4 | 5,5 | 5,8 | 8 | 10 | 12,5 | 15 | 35 | 43 |

| Via heat pump (mode B) | kW | 1,7 | 2,2 | 2,3 | 3 | 3,7 | 4,6 | 5,5 | 12 | 14 |

| Via LPHW @ 80°C (water heater) | kW | 10 | 10 | 10 | 15 | 15 | 30 | 30 | 65 | 65 |

| Total: | kW | 14/11,7 | 15,5/12,2 | 15,8/12,3 | 23/18 | 25/18,7 | 42,5/34,6 | 45/35,5 | 100/77 | 108/79 |

| Flow rate | l/min | 68 | 68 | 68 | 110 | 110 | 140 | 140 | 100 | 100 |

| Max Working Pressure Delta | bar | 3,5 | 3,5 | 3,5 | 3,5 | 3,5 | 3,5 | 3,5 | 3,5 | 3,5 |

| Cooling | A/B mode | A/B mode | A/B mode | A/B mode | A/B mode | A/B mode | A/B mode | A/B mode | A/B mode | |

| Cooling performance (sensible) | kW | -2 / N/A | -2.5/N/A | -2,94 | -3,85 | -4,7 | -5,9 | -7,1 | -13 | -15 |

| Performance (total) | kW | -3/N/A | -4 / N/A | -4,2 | -5,5 | -6,7 | -8,4 | -10,1 | -23 | -28 |

| Recommended power for coolant | kW | 30 | 32 | 35 | 45 | 50 | 65 | 70 | 1 50 | 150 |

| Flow rate | l/min | 25 | 25 | 30 | 37 | 42 | 64 | 64 | 115 | 115 |

| Max Working Pressure Delta | bar | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Pressure drop @ rated flow | bar | 0,2 | 0,2 | 0,25 | 0,25 | 0,3 | 0,32 | 0,32 | 0,35 | 0,4 |

| Electrical data | ||||||||||

| Total Power Consumption (nominal) | kW | 3,18 | 3,84 | 3,94 | 5,12 | 6,25 | 7,8 | 9,35 | 15 | 18 |

| Min. current (max. at FLA ) 1 phase | A | 16 | 20 | 20 | 31 | N/A | N/A | N/A | N/A | N/A |

| Min. current (max. at FLA ) 3 phase | A | 11 | 12 | 9 | 13 | 13 | 15 | 20 | 35 | 48 |

| Max. power fuse 1 phase | A | 25 | 32 | 33 | 48 | N/A | N/A | N/A | N/A | N/A |

| Max. power fuse 3 phase | A | 17 | 19 | 14 | 18 | 21 | 24 | 30 | 50 | 60 |

| common data | ||||||||||

| Height | 1 735 | 1 910 | 1 955 | 2 120 | ||||||

| Size Width | mm | 1 530 | 1 620 | 1 620 | 2 638 | |||||

| Depth | 655 | 705 | 855 | 1 122 | ||||||

| Approximate unit weight (without packaging) | kg | 300 | 310 | 350 | 360 | 370 | 410 | 460 | 954 | 1 020 |

| To select equipment, please contact Eurostroy Management | ||||||||||

| Maximum recommended pool size | ||||||||||

| Swimming pool in an individual house | m² | 50 | 65 | 70 | 90 | 110 | 130 | 160 | 300 | 360 |

| Swimming pool of a small holiday home | m² | 45 | 55 | 60 | 80 | 100 | 120 | 140 | 220 | 265 |

| Public pool | m² | 40 | 50 | 55 | 70 | 90 | 110 | 130 | 200 | 240 |

Application of thermal air curtains

To reduce the volume of air entering the room when opening external gates or doors, in the cold season, special thermal air curtains are used.

At other times of the year they can be used as recirculation units. Such thermal curtains are recommended for use:

- for external doors or openings in rooms with a wet regime;

- at constantly opening openings in the outer walls of structures that are not equipped with vestibules and can be opened more than five times in 40 minutes, or in areas with an estimated air temperature below 15 degrees;

- for external doors of buildings, if they are adjacent to premises without a vestibule, which are equipped with air conditioning systems;

- at openings in internal walls or in partitions of industrial premises in order to avoid the transfer of coolant from one room to another;

- at the gate or door of an air-conditioned room with special process requirements.

An example of calculating air heating for each of the above purposes can serve as an addition to the feasibility study for installing this type of equipment.

In the heat and air balance of the building, the heat supplied by the intermittent air curtains is not taken into account.

The temperature of the air that is supplied to the room by thermal curtains is taken not higher than 50 degrees at external doors, and not more than 70 degrees - at external gates or openings.

When calculating the air heating system, the following values of the temperature of the mixture entering through the external doors or openings (in degrees) are taken:

5 - for industrial premises during heavy work and the location of workplaces no closer than 3 meters to the outer walls or 6 meters from the doors;

8 - for heavy types of work for industrial premises;

12 - during moderate work in industrial premises, or in the lobbies of public or administrative buildings.

14 - for light work for industrial premises.

Calculation of air heating systems with thermal curtains is made for various external conditions.

Air curtains at external doors, openings or gates are calculated taking into account wind pressure.

The coolant flow rate in such units is determined from the wind speed and the outside air temperature at parameters B (at a speed of not more than 5 m per second).

In cases where the wind speed at parameters A is greater than at parameters B, then the air heaters should be checked when exposed to parameters A.

The speed of air outflow from slots or external openings of thermal curtains is assumed to be no more than 8 m per second at external doors and 25 m per second at technological openings or gates.

When calculating heating systems with air units, parameters B are taken as the design parameters of the outside air.

One of the systems during non-working hours can operate in standby mode.

The advantages of air heating systems are:

- Reducing the initial investment by reducing the cost of purchasing heating appliances and laying pipelines.

- Ensuring sanitary and hygienic requirements for environmental conditions in industrial premises due to the uniform distribution of air temperature in large premises, as well as preliminary dedusting and humidification of the coolant.

The disadvantages of air heating systems include significant dimensions of air ducts, high heat losses during the movement of air masses through such pipelines.

Classification of air heating systems

Such heating systems are divided according to the following features:

By type of energy carriers: systems with steam, water, gas or electric heaters.

By the nature of the flow of the heated coolant: mechanical (with the help of fans or blowers) and natural motivation.

According to the type of ventilation schemes in heated rooms: direct-flow, either with partial or full recycling.

By determining the place of heating of the coolant: local (the air mass is heated by local heating units) and central (heating is carried out in a common centralized unit and subsequently transported to heated buildings and premises).

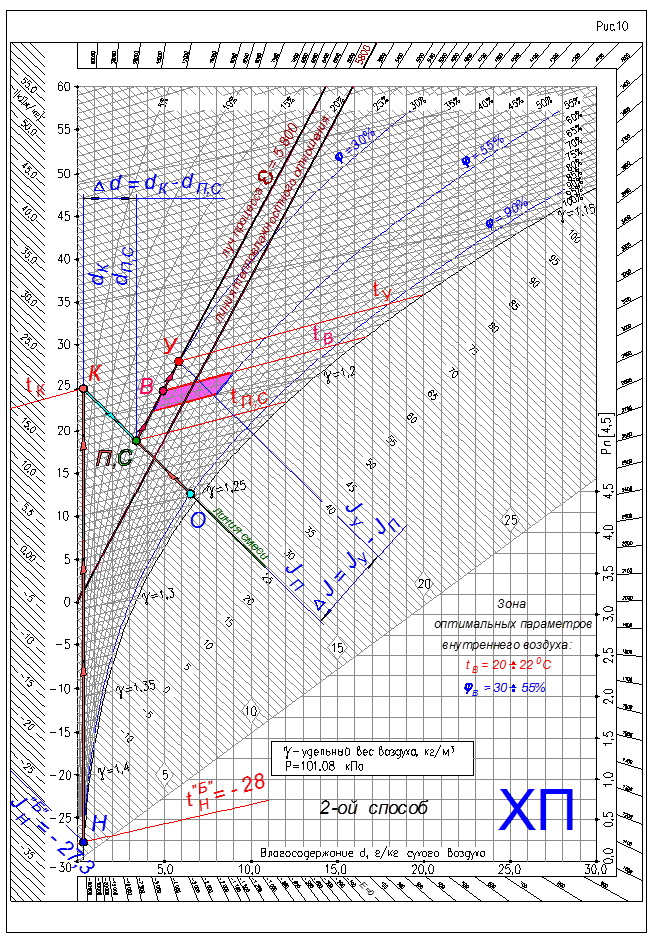

The second way of processing outside air allows you to avoid heating it in the heater of the 2nd heating, see Figure 10.

1. We select the parameters of internal air from the zone of optimal parameters:

- temperature - maximum tV = 22°С;

- relative humidity - minimum φV = 30%.

2. Based on two known parameters of indoor air, we find a point on the J-d diagram - (•) B.

3. The temperature of the supply air is assumed to be 5°C lower than the temperature of the indoor air

tP = tV - 5, ° С.

On the J-d diagram, we draw the supply air isotherm - tP.

4. Through a point with the parameters of internal air - (•) B we draw a process beam with a numerical value of the heat-humidity ratio

ε = 5 800 kJ/kg N2O

to the intersection with the supply air isotherm - tP

We get a point with the supply air parameters - (•) P.

5. From a point with outdoor air parameters - (•) H we draw a line of constant moisture content - dH = const.

6. From a point with supply air parameters - (•) P we draw a line of constant heat content - JP = const before crossing with lines:

relative humidity φ = 90%.

We get a point with the parameters of humidified and cooled supply air - (•) O.

constant moisture content of the outside air - dН = const.

We get a point with the parameters of the supply air heated in the air heater - (•) K.

7.Part of the heated supply air is passed through the spray chamber, the remaining part of the air is passed through the bypass, bypassing the spray chamber.

8. We mix the humidified and cooled air with the parameters at the point - (•) O with the air passing through the bypass, with the parameters at the point - (•) K in such proportions that the mixture point - (•) C is aligned with the supply air point - (•) P:

- line KO - total supply air - GP;

- line KS - the amount of humidified and cooled air - GO;

- CO line - the amount of air passing through the bypass - GP — GO.

9. Outdoor air treatment processes on the J-d diagram will be represented by the following lines:

- line NK - the process of heating the supply air in the heater;

- line KS - the process of humidification and cooling of part of the heated air in the irrigation chamber;

- CO line - bypassing heated air bypassing the irrigation chamber;

- KO line - mixing of humidified and cooled air with heated air.

10. Treated outdoor supply air with parameters at the point - (•) P enters the room and assimilates excess heat and moisture along the process beam - the PV line. Due to the increase in air temperature along the height of the room - grad t. Air parameters change. The process of changing parameters occurs along the process beam to the point of outgoing air - (•) U.

11. The amount of air passing through the spray chamber can be determined by the ratio of the segments

12. The required amount of moisture to humidify the supply air in the irrigation chamber

W=GO(dP - dH), g/h

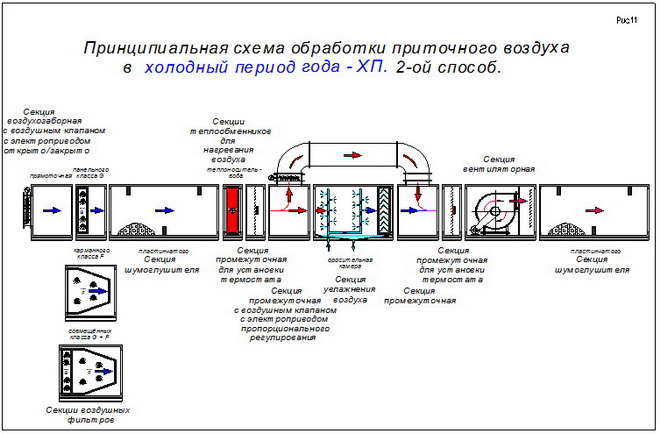

Schematic diagram of the supply air treatment in the cold season - HP, for the 2nd method, see Figure 11.

Advantages and disadvantages of air heating

Undoubtedly, air heating of the house has a number of undeniable advantages. So, installers of such systems claim that the efficiency reaches 93%.

Also, due to the low inertia of the system, it is possible to warm up the room as soon as possible.

In addition, such a system allows you to independently integrate a heating and climate device, which allows you to maintain the optimum room temperature. In addition, there are no intermediate links in the process of heat transfer through the system.

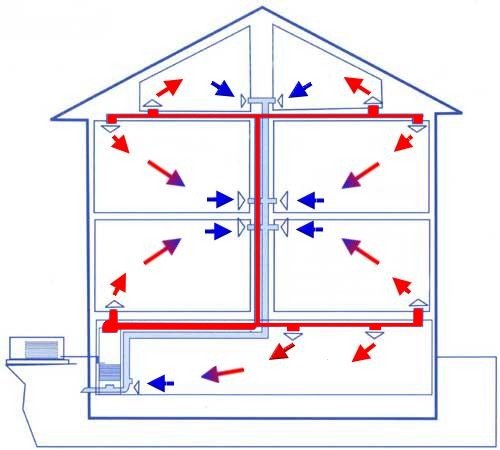

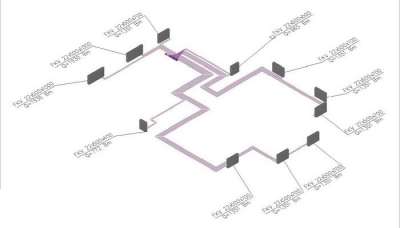

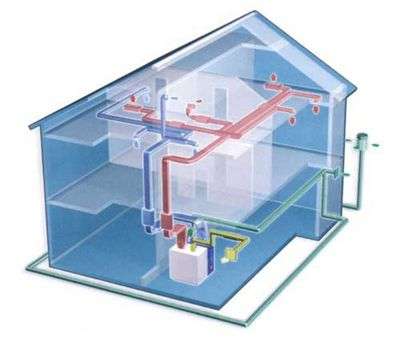

Scheme of air heating. Click to enlarge.

Indeed, a number of positive aspects are very attractive, due to which the air heating system is very popular today.

Flaws

But among such a number of advantages, it is necessary to highlight some of the disadvantages of air heating.

So, air heating systems of a country house can only be installed during the construction of the house itself, that is, if you did not immediately take care of the heating system, then upon completion of construction work you will not be able to do this.

It should be noted that the air heating device needs regular service, as sooner or later some malfunctions may occur that can lead to a complete breakdown of the equipment.

The disadvantage of such a system is that you will not be able to upgrade it.

If you, nevertheless, decide to install this particular system, you should take care of an additional source of power supply, since the device for an air heating system has a considerable need for electricity.

With all, as they say, the pros and cons of the air heating system of a private house, it is widely used throughout Europe, especially in those countries where the climate is colder.

Studies also show that about eighty percent of dachas, cottages and country houses use the air heating system, as this allows you to simultaneously heat the rooms of the entire room.

Experts strongly do not recommend making hasty decisions in this matter, which can subsequently lead to a number of negative points.

In order to equip the heating system with your own hands, you will need to have a certain amount of knowledge, as well as to have skills and abilities.

In addition, you should stock up on patience, because this process, as practice shows, takes a lot of time. Of course, specialists will cope with this task much more quickly than a non-professional developer, but you will have to pay for it.

Therefore, many, nevertheless, prefer to take care of the heating system on their own, although, nevertheless, in the process of work, you may still need help.

Remember, a properly installed heating system is the key to a cozy home, the warmth of which will warm you even in the most terrible frosts.

Answer

It is better to entrust the exact calculation of heating systems that take into account all modern requirements and provide all conditions to professionals, but the customer must also represent at least the level of required capacities and be able to perform an approximate calculation of heating. Such a customer, in order to work out all the details, will definitely contact the specialists of design organizations, and they will present him with examples of calculating heating.

For those who still want to do it on their own, or simply do not have the opportunity to turn to specialists, any program for calculating heating will do. with which this market is now filled.

As a rule, only knowledgeable people are able to understand most of these examples, and for those who are far from technology, even the most detailed example of the hydraulic calculation of heating will not give anything in understanding this issue. All methods of such calculations are time-consuming, oversaturated with formulas and have complex algorithms for performing actions. The hydraulic calculation of the heating system is an example of the fact that everyone needs to mind their own business, and not take away work from others. Of course, you can take formulas and substitute the necessary values into them, if you can arm yourself with all the necessary data. But an unprepared person, most likely, will quickly get confused in numerous quantities that are incomprehensible to him. Difficulties will also arise in choosing the necessary coefficients for possible, completely different, conditions.

It would seem that a simple example of calculating air heating will require knowledge - the size of the room, its height, thermal insulation indicators, heat loss, average daily temperatures during the heating season, ventilation characteristics and many more parameters.

Only the simplest example of calculating a heating system, in which only basic data is taken into account, and additional ones are ignored, will be understandable to those who wish to calculate, for example, the required radiator power and the number of required sections.

For other issues, it is still better to immediately contact specialized organizations involved in such calculations.

Article title:

Air heating systems are used to ensure acceptable norms and parameters of air in working areas. Outdoor air acts as the main coolant for such heating systems.

This allows such a system to perform two main tasks: heating and ventilation. The calculation of the efficiency of air heating proves that its use can significantly save fuel and energy resources.

If possible, such equipment is mounted together with recirculation units, which allow air to be taken not from the outside, but directly from the heated premises.