Digital pump timer CAVR.ru

Tell in:

The process is fully automated, and there is no need to constantly monitor the water level in the tank - the device controls and maintains the specified water level in the tank. The use of a microcontroller made it possible to increase its reliability, as well as to build a small-sized and easily repeatable design.

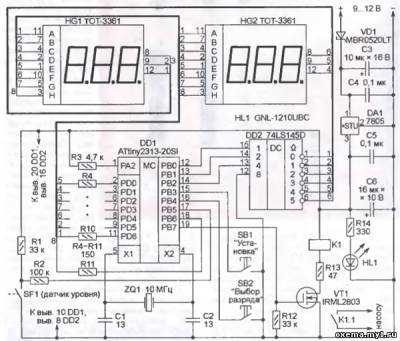

Rice. one

The timer circuit is shown in fig. 1. The clock frequency of the ATtiny2313 microcontroller (DD1) is set by an external crystal ZQ1. The duration of continuous operation of the pump and the duration of the pause from turning it off to turning it back on are set using two buttons (SB1 and SB2)

These values are stored in the non-volatile memory of the microcontroller, so there is no need to re-set them after each power off and then on, which is especially important in rural areas. When the power is restored, the timer starts its work with the formation of a pause, which protects the pump from failure as a result of repeated switching on and off in a short period of time

On two three-digit seven-element LED indicators with common cathodes (HG1, HG2), during the timer operation, the time remaining until the pump is turned on (while maintaining a pause) or until it is turned off (during water supply) is displayed. The indication is dynamic. The decoder DD2 with outputs made according to the "open collector" scheme converts the three-digit binary code of the familiarity number generated by the microcontroller into signals applied to the cathodes of the indicators for switching them on one by one. The pump also stops when the maximum level sensor SF1 is triggered. This is accompanied by the display of the inscription FULL on the indicator. The sensor can be any microswitch equipped with a lever with a float. For greater reliability, you can install another microswitch that breaks the timer power circuit if the SF1 sensor does not work for any reason.

Rice. 2

All parts of the device, except for the SF1 sensor, are mounted on a printed circuit board made of fiberglass foiled on both sides, shown in Fig. 2. In its author's version, unused sections of the foil on both sides of the board are connected to the - (9 ... 12) V circuit and serve as an additional common wire. The board is designed for surface mounting parts (except for the ZQ1 quartz resonator, DA1 stabilizer, HG1, HG2 indicators, SB1, SB2 buttons and K1 relay). Relay type - JRC-23F. The resistance of its coil is 167 Ohm, the operating voltage is 5 V. The contacts are designed for switching alternating voltage up to 125 V with a load power of not more than 62.5 VA. A pump or other actuating device, the power of which exceeds the capabilities of this relay, can be turned on using another relay or contactor rated for the appropriate current and voltage. Relay K1 in this case will serve as an intermediate relay.

Rice. 3

The board also has a pin connector XP1, the contacts of which are connected to the microcontroller pins according to the diagram in Fig. 3. It is designed to connect the programmer to the microcontroller already installed on the board. The table shows how the microcontroller configuration bits should be programmed. They set its operation with a quartz resonator with a frequency of more than 8 MHz and delay the start of the program by 16000 cycles. To protect the information in the EEPROM of the microcontroller from accidental damage in the process of increasing the supply voltage, the response threshold of the internal voltage detector (BODLEVEL) is set to 1.8 V.

When loading codes into the program memory of the microcontroller from the Pump-Control.hex file available in the application, the duration of the pump and the duration of the pause can be independently changed from 0 to 60 minutes in increments of 1 s. The timer consumes a current of no more than 500 mA from a voltage source of 9 ... 12 V.

The timer microcontroller program can be downloaded here

Leave your comment or question:

Functions and characteristics of lighting control timers.

The main thing you should pay attention to when buying is the maximum allowable switching load.

Which is easy to calculate by simply adding up the powers that you plan to connect to the timer

To convert to Amps, divide Watts by the operating voltage of 220 Volts.

It is very important when buying to pay attention to the type of attachment. which can be under the Din rail of the electrical panel, as well as the timer can be designed for built-in installation inside the wall or overhead.

The third is the operating temperature range

which is important when installing in unheated places.

According to the type of control, they are divided into: mechanical (Figure 1) and more accurate and functional electronic (Figure 2 and 3).

There are models of switches with a built-in timer for entrances (Figure 4), which, after pressing, turn on and off after a specified number of seconds.

Timers are available for controlling one or two channels, as well as multi-channel ones (Figure 3). Two-channel allows you to separately configure and control the main and auxiliary lighting.

When buying, pay attention to the fact that the timer can only be with a weekly or annual program. More expensive models almost always have all sorts of programs, including weekends.

Pay attention to the astronomical timer. which allows, after setting the location coordinates, to automatically adjust the time of sunset and dawn, taking into account changes in the length of the day during the year.

There are other minor characteristics as well. Such as, for example, the accuracy of the time course, the minimum time setting (usually up to a minute), etc.

Daily weekly timer

A device that operates according to a pre-programmed program. It is used to control processes in automation systems, both at home and in production.

The principle of the timer

Such a programmable timer allows you to control the load in both daily and weekly modes. You can choose suitable time intervals, as well as an arbitrary number of on and off (a good indicator is at least 200). Modern timers "know what weekends and weekdays are."

Well, here, we briefly talked about this device, and now let's move on to the topic of its use in tandem with an electric boiler for heating a room. The thing is that there are day and night tariffs for the use of electricity by citizens of Ukraine. And the night one is a preferential rate (from 23:00-7:00). And if your electric boiler is paired with a timer, then you can easily program it for a different mode of operation during the day, evening and night. For example, if you are not at home during the day (you are at work, the children are at school, kindergarten), the timer program will switch your boiler to the minimum you need. And by the time you return home, the other team will switch the boiler to the maximum that suits you. Again, during the night the apartment (house) will have time to properly heat up. The logic is clear and understandable, and saving your money, so to speak, is obvious. But they can say, and quite rightly, that now there are electric boilers with a built-in timer. Yes, this is true, but ... there are different situations.

situations.

For example, someone already has an electric boiler (without a timer) and the life of the boiler has not yet expired, and in general, the owner is satisfied with everything, “if only we could add a timer.” Or, someone who has an electric boiler plans to switch to gas heating over time, and now wants to take advantage of a preferential tariff. Also an option. Also, an electric boiler can perfectly serve as a backup source of heat, you never know what. All such situations just require such a device as a weekly timer (daily) for their solution.

What else can be mentioned?

Perhaps it would not be superfluous to say where else this device can be used. And it can be used in the control of lighting devices, refrigeration units, ventilation equipment, etc., when their work needs to be regulated by time frames (intervals).And, as we said above, this device can be used in production.

Note.

Good timers have an independent power supply to maintain the program's performance in case of power failure, as well as automatic changeover to summer and winter time. Therefore, if you decide to buy a daily / weekly timer, then you already know what to focus on.

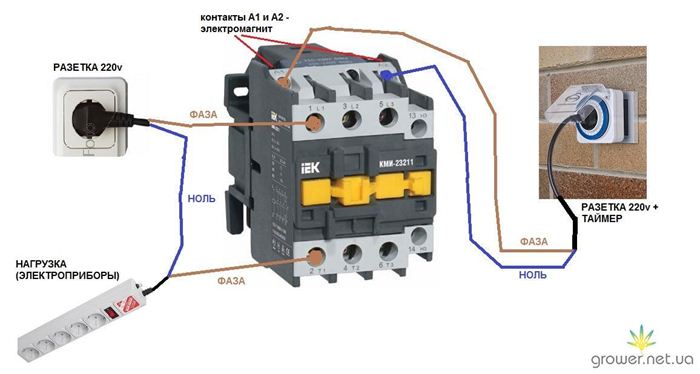

Need advice! How is it more correct and better, from the point of view of ease of use, to connect a 4.5 kW electric boiler, according to 1 or 2 schemes? Contactor - » > VN - load switch for 32A, IEK. Socket with timer Feron TM50 16A, 3500W.

P.S. Everything - automatic machines, RCDs, etc., are in the introductory shield, here we are talking only about connecting the boiler.

I like this one, but I would

The first scheme, but instead of VN-32, put AB 1A contactor coil to protect it.

And such a moment. A 16A socket is connected from the 2x4 cable, and therefore the machine for the 2x4 cable should also be no more than 16A.

HV, because it will be used as a switch, just in order not to pull the plug from the timer every time. And clicking the machine back and forth is not desirable. I’ll probably add an automatic machine in sequence, but on 1A it’s exotic and . price.

Well, in principle, yes, I did not pay attention, thanks !! But what about?

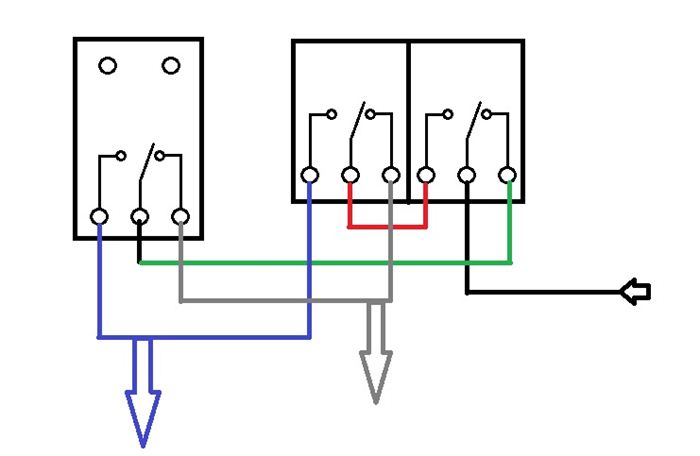

Timer wiring diagram.

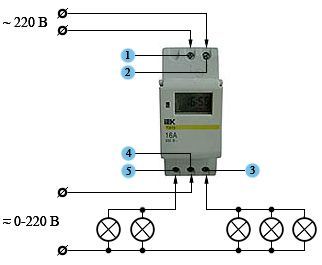

Today, a huge number of different types of timers are sold, which will have their own connection features. I will consider the connection diagram of the popular model of the two-channel timer of the Russian manufacturer IEK.

From above, contacts numbered 1 and 2 are supplied with 220 volts from the home electrical network. As a rule, in all models, the power supply is supplied from above, and switching (on and off control) is performed using the lower contacts. In this case, only the phase conductor breaks, and zero goes directly to the electric lamps. On the middle contact 4, a phase from the electrical panel is connected, which will be separately switched with side connections 5 and 3. If you need to switch only one circuit, then contact No. 5 will remain free.

I recommend to look at our topic on the topic. containing visual instructions for selecting, connecting and configuring the electronic timer menu!

Good afternoon! The question of such a plan. The house is heated by a 12 kW electric boiler. No one lives in the house now. I want to put a relay so that the boiler turns on at night, the night rate is cheaper. What is better to install, a single-phase relay and a starter or a three-phase relay. If not difficult shemku by hand. I'm not an electrician myself, but I have the idea.

Anatoly, hello. I will not draw a diagram, it is on the Internet

there is a working diagram for connecting tenov through a magnetic starter with a block of 2 buttons. there is an IEK timer (exactly the same as you have in the picture). how to connect a timer to turn the shadows on and off by time, but what would the button also be able to turn on and off? thank you in advance.

Alexey, hello. You need to supply power to pins 1 and 2, this will be the power of the timer itself. Further, as according to the scheme, instead of the bulbs, you need to turn on your two heating elements, or rather the control coils of the starters. One coil turns on instead of the left two lamps, and the second coil instead of the right three lamps.The essence of the timer is such that contact four is a control (changeover), and contacts 3 and 5 are receiving (in one position, for example, “on”, it works, again, for example, contact 3, and in another “off” position, contact 5) . Therefore, by setting equal intervals (or the intervals you need) of time, when the timer is turned on, one heating element will work, when the second one is turned off. In parallel with the timer, install the two-gang pass-through switch in exactly the same way. Use the first key to switch the power either to the second key or to the timer, and with the second key you control the first or second starter bypassing the timer.

http://jelektro.ru

Timer to control the pump Meander entertaining electronics

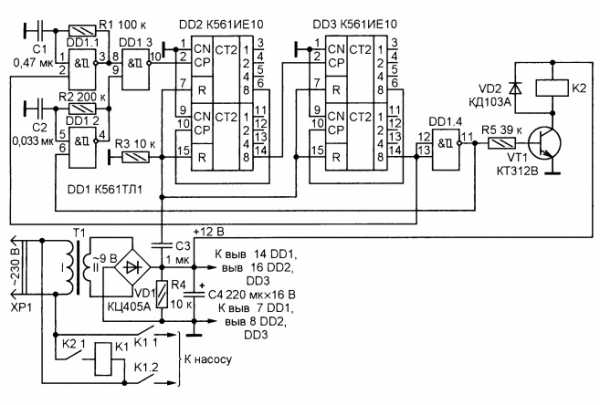

The device, the circuit of which is shown in the figure, periodically generates pulses of positive polarity at the output (at pin 11 of the DD1 microcircuit). It contains two IC generators working in turn (on elements DD1.1 and DD1.2), a switch on element DD1.3, a serial circuit of four counters of microcircuits DD2, DDZ, an inverter on element DD1.4 and an electronic relay on a transistor VT1 and electromagnetic relay K2, which controls the operation of the magnetic starter K1. Pulse duration (Ton) and pauses between them (Toff) depends on the frequency generated by the pulse generators and used counter outputs and can be adjusted over a wide range.

With the device connected to the network, a constant supply voltage appears at the output of the rectifier VD1, and thanks to the R3C3 circuit, the counters of the microcircuits DD2, DD3 are set to zero. In this case, the log level appears at the output of the inverter DD1.4. 1 and the generator on the element DD1.2 is included in the work. At the same time, transistor VT1 opens, relay K2 is activated and, with its contacts K2.1, connects the winding of the magnetic starter K1 to the network, as a result of which it also works and contacts K1.1, K1.2 connects the load to the network. From the output of the DD1.3 element, pulses with a repetition rate of this generator are fed to the CN input (pin 2) of the first counter of the DD2 microcircuit. The countdown begins Ton.

With the advent of the logo. 1 at the output of the counter (pin 14 DD3) log level. 1 at the output of the element DD1.4 is replaced by the log level. 0, the transistor VT1 closes, de-energizing the relay K2, it releases and breaks the power circuit of the magnetic starter K1, which, in turn, turns off the load. At the same time, the generator on the DD1.1 element is turned on, pulses with the frequency of this generator begin to arrive at the CN input of the first counter of the DD2 microcircuit - the time T beginsoff at the end of which everything repeats from the beginning.

In practice, the device has been used for the fourth year to control a water pump with a capacity of 2500 l / h, pumping water from a well with a flow rate of 300 l / h, according to a given cycle. For the ratings of the elements R1, R2, C1 and C2 indicated in the diagram, the pump is turned on for a time Ton \u003d 151 s \u003d 2 min 31 s, pumps out about 130 liters of water into the storage tank, and then turns off for a time Toff = 27 min, during which water accumulates in the well. The need to control the pump with such a cycle is due to the fact that without washing with water, the pump fails. The device is powered by an unstabilized source containing a step-down transformer T1 with a secondary winding of 9 V and a KTs405A rectifier bridge. To control the starter K1, a relay K2 was used with a winding with a resistance of about 700 ohms and a rated voltage of 12 V.

Time relay for turning on the pump as an integral element of the automation system

A time relay is a special electrical device with which you can control the operation of a pump and other electrical equipment. The device is able to close / open el. circuit and form time intervals for turning on / off electrical devices. Due to this, a certain sequence (algorithm) of the work of the elements of email is provided. scheme. Thus, the relay creates a time delay and automatically controls such technological processes as: irrigation, heating, water supply, air conditioning, etc.

For example, in a heating system with pump circulation, using a relay, it is possible to organize the operation of the pump so that it turns on with a certain time delay, and the heating elements of the electric heating boiler would have time to warm up. Thus, the stability and uninterrupted operation of important production and technological processes depend on the reliability of the time relay.

We present to your attention professional devices for automating the operation of the electric pump of the Russian manufacturer NPO Elektroavtomatika - a time relay. Electromechanical devices contain several operation algorithms with wide time intervals and supply voltage tolerances, due to which they demonstrate high quality characteristics in each case of operation.

We produce 2 types of relays:

- time relay to turn off RV-OO to control el. circuits after removing the supply voltage;

- time relay for switching on RV-OV to control el. circuits after the supply voltage is applied.

We will tell you why the relay is an excellent choice for a water supply system. With the help of our devices, you will be able to simultaneously control 2 independent electrical circuits - 2 switching groups of contacts. That is, you can connect 2 different devices and supply different power to them. The principle of operation of the functional device is that the relay does not turn on the pump immediately after the supply voltage is applied, but after a certain time.

Types of time relay

The time relay with a delay to turn off - RV-OV is widely used to control a pump or pumping station. The device allows you to fill the hydraulic tank in automatic mode, adjusting the on and off of the pump. Contains two operation diagrams and five time delay ranges: 0.1 s; 1 s; 0.1 m; 1m; 0.1 h. So, for each operation diagram, you can specify one of three time intervals and set a time delay for the relay to operate after power is applied.

Advantages of the NPO Elektroavtomatika time relay:

- Reliable specifications.

- Switching of heavy loads: with a resistive load - 5 A AC.

- Efficiency. Control of two independent electrical circuits - two switching groups of contacts.

- Easy installation. Mounting on DIN rail 35 mm wide.

The second type of time relay to turn off - RV-OO turns on immediately when the supply voltage is applied, and turns off after a certain time delay after turning off the power. The device contains four operation diagrams and three time delay ranges: 0.1 s; 1s; 0.1min In practice, the RV-OO relay allows you to organize an effective automated process control system both in production and in the household.

If you were looking for a reliable device for automating the operation of such equipment as: an engine or a pump, and also want to organize a system for turning on and off electrical appliances, then the NPO Elektroavtomatika time relay will suit you. For more than 10 years, our devices have been in demand in automation systems. When ordering, you can specify the required operation diagram, exposure time range, supply voltage and other characteristics.

Buy a time relay to turn on the pump

On our website you can order a functional time relay to turn on the pump.In addition, in our catalog you will find a comprehensive range of electrical products adapted to your requirements: from basic solutions to manufacturing according to the customer's project and translating your ideas into the finished product.

We invite you to cooperate with our manufacturing company and offer to order reliable electrical products at attractive prices. In the face of NPO Elektroavtomatika, you will find a direct supplier and will be able to order the necessary electrical devices and components with delivery to any region of Russia.

What can an automatic time relay

17.12.2013

Time relay (timer) - provide automatic switching on / off of industrial or household appliances according to a pre-set program.

They are used in a variety of areas: from turning on the heater in the apartment for your arrival, organizing automatic watering of the site when you are away, to controlling the switching on and off of engines and automatic machines in production.

Automatic inclusion of heating.

You can program the heater to turn on at a certain time so that the room or house is already warm when you arrive. Also, in the absence of a weekly timer on the thermostat of your warm floor, floor heating can be programmed using a timer, and then the floor will already be warm by the time you arrive or wake up.

Automatic shutdown of electrical appliances.

For example, you want to limit your child's TV viewing time, or limit the time they spend on the computer. You just need to connect your TV/computer via a time relay and program the time to turn off.

Automatic control in the suburban area.

You can automatically turn on and off the lighting in the area. Using the time relay, you can program the on / off irrigation of the site. For example, watering should be turned on every 12 hours for 15 minutes, the relay is programmed to turn on after 11 hours and 45 minutes and turn off 15 minutes after turning on. Then we program the constant repetition of this cycle.

Automatic control of the electric pump.

One of the options for using the time relay is to install it on electric pumps. If the well is small, then to fill the tank with water, you have to turn the pump on and off several times, that is, practically do not move away from it until the tank is full. If the pump quickly sucks water out of the well and continues to work, then it overheats and may fail, as the water pump is cooled by water. To automate the process of filling the reservoir with water, it is necessary to experimentally determine how long the water is pumped out of the well by the pump (for example, 2 minutes), how long it takes to fill the well (for example, 15 minutes) and how many times the pump needs to be turned on in order for the reservoir to be filled ( e.g. 8 times). After all the measurements taken, we simply program the relay according to the following scheme: turn on for 2 minutes, turn off for 15 minutes and repeat this cycle 8 times. Now you can just turn on the pump and go about your business.

Automation of signboards and outdoor advertising.

It is not economically feasible for a sign to be permanently lit. But it's so inconvenient not to forget to turn it off in the evening, and then not to forget to turn it on in the morning. And this process can be simply automated with the help of a time relay. Thus, you simply program the relay once and forget about the human factor when saving on electricity.

Using a time relay in production.

The time relay, as well as in everyday life, can be used in various areas of production. Lighting automation. Automation of switching on / off engines and equipment.

Thus, there are a lot of scopes for time relays, this list goes on and on.If you need to automate the process of turning on / off a device, you can always consult a specialist, and he will always tell you how to do it and which device to use for this.