Common causes of breakdown

If during the diagnosis of the borehole pump it turns out that everything is in order with the cable, then the cause of the malfunction lies in the electric motor. In this case, the product will have to be disassembled to the very engine compartment, remove the stator or rotor and rewind the winding

As for the Vodomet pumps or units of other brands, the causes of failure can often be:

- silting of the impeller;

- power cable break;

- failure of the rotor or stator.

To diagnose the problem with your own hands, you should adhere to the following rules:

- To begin with, the unit must be removed from the well and perform a test run. If the shaft rotates, then the problem lies in the impeller. It must be cleaned of silt and the unit can be assembled and operated further.

- If the “Vodomet” pump does not even turn on during the test run, then first you need to check the power cable with a tester. To do this, check the voltage at the terminals of the engine compartment. If it is, then the cable is intact. Otherwise, you will have to replace it with a new cable.

- If during the diagnosis of the borehole pump it turns out that everything is in order with the cable, then the cause of the malfunction lies in the electric motor. In this case, the product will have to be disassembled to the very engine compartment, remove the stator or rotor and rewind the winding.

The pump is not working

The reasons may be as follows: depressurization of the case, the motor winding burned out, the blades are broken after the ingress of solid large particles. Check for leaks by immersing the pump in a bucket, also check the voltage at the sockets. Then unscrew the bolts and remove the housing. Rotate the motor shaft for large particles. If the engine is stuck due to large inclusions, they should be removed and, if possible, the destroyed working rings should be replaced. If the impeller and vanes are damaged, they must be replaced.

Next, check the electrical. Disconnect the power cord from the motor and if melted parts are found, replace the entire cord and plug. You should also check if there is a break in the motor winding. If this is found, it is better to entrust the repair to a specialist.

How to disassemble the pump for repair

To repair any pumping equipment with your own hands, you need to learn how to disassemble it

To repair any pumping equipment with your own hands, you need to learn how to disassemble it. How to do this, we will look at the example of the Water Cannon pump. We perform disassembly in the following sequence:

- At the inlet pipe, it is necessary to unscrew the cylinder with a perforated bottom. This is a coarse filter that protects the product from sand and silting.

- Further, with their own hands, all washers, disks and “glasses” are dismantled from the shaft on the engine of the pumping unit. To make it easier for you to install the removed products in the correct order back, lay them out side by side in the order in which you remove them.

- After that, it is necessary to dismantle the engine retaining ring from the Vodomet borehole pump. This part closes the engine compartment cover. To do this, you need to use a mallet. With a blow of this tool, we shift the engine down, then pull the cord and return it back. After such manipulations, the sealing ring will move. After that, the retaining ring is shifted with a screwdriver towards the housing. As a result of this, the stopper will warp and it will be easy to remove it.

- Next, disconnect the wiring, open the engine compartment lid. After that, using a mallet and a screwdriver, you can remove the motor from the housing.

As a result of such disassembly, it is easy to rinse and clean the impeller and all its constituent elements. The engine can be taken to a specialized workshop for diagnostics and repair.After cleaning and repair, reassembly takes place in the reverse order.

Drain pump selection criteria

Let's summarize how to choose a drainage pump. When purchasing the necessary unit, be guided by the following points:

- Operating conditions of the equipment. Although drainage pumps can easily handle wastewater pumping, the technical characteristics are limited by the degree of contamination (it should not exceed the permissible parameters). In other words, large stones, a high percentage of sand in the liquid, silt and dirt can adversely affect the operation of the unit. That is, to eliminate the flooding of basements, you can use a conventional drainage pump. But if you need to drain the reservoir, a solid platform with a flat surface is placed under the bottom of the pump. And if the front of the work is a construction site, then it is optimal to resort to the help of a powerful fecal pump with a grinder.

Drainage pump can drain even a pond

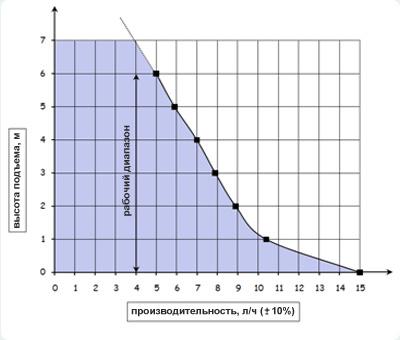

- Arithmetic calculations. When calculating the required capacity of the equipment, please note that 1 meter of vertical length is equal to 10 horizontal meters. This means that if you have a sewage pit depth of 5 m, then the length of the hose should not exceed 50 m. In this case, the sewage discharge rate will be low, although the drainage pumps operate in conditions of constantly arriving water. In order for the pump to cope with its task flawlessly, add to the height of the drains the length by which the discharge pipe will be laid on the surface of the earth in a horizontal direction. If even then the pressure is not optimal, you should add a "allowance" of length - about 3 m.

The lower the height of the effluent, the more efficient the pump works.

Pro tip:

When choosing a drainage pump, mainly pay attention to its power. Only this parameter determines the optimal use of a particular equipment.

- The selection of the drainage pump model is made depending on the condition of the surface where the drainage pump will be mounted. It is best to install a drainage pump in a pit, the depth of which is from 40 to 60 cm. This will protect against water from entering the basement floor. Then the pump can be equipped with a vertical float mechanism, which will turn on the equipment as the recess fills, leaving the floor dry. If it is possible to organize a pit with a width and length of 50 cm or more, any type of float will do.

Float pump will not allow maximum dehumidification

When it is required to drain the tank as much as possible, a special drainage pump is needed, which is mounted on a hard surface. In this case, the float is not needed, since it will only start working at a sewage level of at least a few cm. In all other cases, conventional models will also cope with the task.

Faults and repairs

Most pump products of different brands often face the same problems

Most pump products from different brands often face the same problems. We list the most common of them and indicate what needs to be done to fix the problem:

- The hum of the motor is heard, but the unit does not pump water. This means that the device works “dry” (without water). If you are sure that the equipment is installed correctly and the problem is not related to the debit of the hydraulic structure, then the probable cause of the malfunction may be loosening of the nuts securing the shock absorber, wear of the rubber parts (valve) or stem breakage. To troubleshoot, do the following:

- Locate the shock absorber of the pumping equipment. There are two nuts on the stem that fix it. They must be tightened to the stop, and for greater reliability, it is better to lock the topmost nut.

- If the valve is worn out, it must be replaced with a new product. Such a malfunction occurs if the unit pumps heavily polluted water.To prevent this from happening, use a coarse filter on the inlet pipe.

- In the event of a stem break, it will not be possible to repair the device, so you will have to buy a new pump.

- During start-up, the device knocks out plugs. This may occur due to the burning of the winding or a malfunction of the electrical cable. You should start looking for a problem by testing the cable. If it fails, the cable must be replaced. If it is in order, then the problem lies in the burnt winding. You can try to replace the old coil with a new product or take the unit to a service center to rewind the winding.

- During operation, the pump gets very hot and vibrates. Both problems are related to the operation of the device "dry". The thing is that water cools the body of the device well, but if it works outside this environment, it quickly overheats, which causes the magnet to detach and the piston to stop. To repair the device, do the following:

- The unit is dismantled and, by tapping on the body, they find the place where the magnet is to be installed.

- Then all the parts are removed from the body, and on the inner surface with the help of a grinder a notch is made of vertical and horizontal stripes 2 mm deep.

- After that, the notched place is lubricated with a good moisture-resistant adhesive or sealant.

- The magnet must be well pressed into this glue.

- When the adhesive is dry, the device can be assembled.

- Low pressure may be due to the fact that too little clearance is left in the vibrator. To adjust it, do the following:

- First you need to check the tightness of the nuts on the stem, the integrity of the rubber valve, and also make sure that there is no break in the thrust.

- If everything is normal, then you need to increase the gap for water penetration. To do this, the required number of washers is screwed onto the vibrator. Their number can be different and depends on the required pressure and stroke of the pumping equipment.

Video instructions for repairing the Whirlwind borehole pump:

The principle of operation of the drainage pump

The drainage pump, pumping out the drains, diverts them from the building to an external sewer or treatment plant located away from the house. Often, a recess becomes a place for installing pumps, from where it is necessary to pump out water.

For high-quality operation of the pump, the content of fibrous inclusions should be minimal, and the largest size of solid particles should not exceed 5 mm. As for the installation depth, the smaller it is, the better, because in emergency cases it is easier to organize quick access to the equipment.

It is worth focusing on the fact that the operation of drainage pumps in wastewater, which are characterized by elevated temperatures, is limited to a certain time, since the motor is cooled by heat transfer to the pumped liquid. Many manufacturers of units indicate a temperature of 50 C maximum

Naturally, there is qualified equipment designed to operate in special, non-standard conditions, but we will not dwell on it in detail.

The principle of the movement of wastewater inside the drainage pump

What distinguishes a drainage pump from a fecal pump

Drain pump capable of working in solids environment

The purpose of drainage pumps is to pump out and discharge water and sewage with foreign impurities from various reservoirs: pits, mines, drain pits, domestic sewer pipelines, industrial systems and other treatment plants. With their help, you can pump out and divert fecal effluents, serving multi-storey buildings, as well as use the equipment in case of basement flooding.

Although both the drainage and fecal pumps operate in similar environments, there is a fundamental difference between them - for each type, the allowable size of solid impurities in wastewater is determined.For drainage pumps, these are particles with a diameter of 3 ÷ 12 mm (depending on the model of the unit) and up to 120 mm (these pumps are capable of pumping large volumes of sewage).

Fecal pumps operate in liquids where solids are either completely absent or their size is small. In connection with this feature, the equipment is equipped with knives and other cutting mechanisms that play the role of a suspension grinder. The pump impeller can be semi-open, monochannel or vortex.

Design and repair features

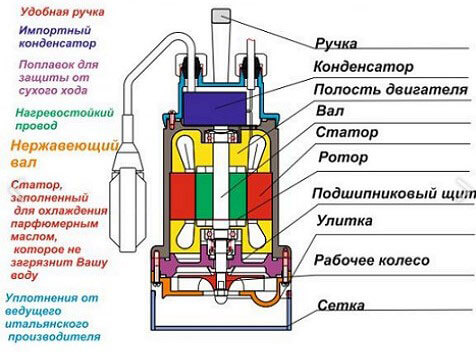

Pumps of the brand "Vodomet" and "Whirlwind" are in great demand due to the simplicity of design and simple repair of the downhole unit. The basis of any submersible pump product is a compact cylindrical body

Pumps of the brand "Vodomet" and "Whirlwind" are in great demand due to the simplicity of design and simple repair of the downhole unit. The basis of any submersible pump product is a compact cylindrical body. It is in this housing that the engine with the impeller is put on its shaft. In this case, the impeller is separated from the compartment with the engine by means of a special insert. The shaft passes through it.

Before proceeding with the repair of downhole deep-well pumps, it is necessary to assess the serviceability of its main components. To do this, do the following:

- First, check the piston for damage and deformation. It should be straight and even.

- Then assess the patency of the suction hole. It is considered serviceable if the air, penetrating from the side of the suction pipe, passes freely from both sides.

- It is also worth measuring the distance between the piston and the coil magnets with your own hands. Normally, it should be in the range of 0.4-0.5 cm. If this value is greater, then the coils in the device may beat. If the clearance is reduced, the engine may overheat.

- In addition, in the Vodomet units and other similar models, it is necessary to measure the distance from the valve that closes the inlet to the device body. Normally, it should be from 0.7 to 0.8 cm. This will allow the liquid to flow freely from the unit in the absence of pressure.

- You also need to make sure that malfunctions in the operation of the downhole downhole unit are not caused by critical power surges. Therefore, using a special device, you need to measure the voltage in the network. It should be within 200-240 V.

Repair of drainage pumps

The malfunctions listed above for the drain pump cannot always be fixed on their own. You can independently fix a weakened shock absorber, release or replace the float, eliminate mechanical damage that caused the impeller to jam, and replace the supply cable.

The simplest of all this will be fixing the shock absorber. To do this, you will need to disassemble the body of the device and tighten the loose nuts on the mounting bolts. Be sure to lock the top nut so that there is no further loosening. It will take some time to replace the power cable. Replacement of the condenser is possible in some models of drains.

The rest of the malfunctions are almost impossible to eliminate without the involvement of service workshops. For example, with a broken stem, it is easier and sometimes cheaper to purchase new equipment than to disassemble and try to repair. Valve replacement is a complicated and unprofitable undertaking to solve the problem on your own. The replacement of a burnt winding must be carried out in specialized workshops.

Dismantling the drainage pump Belamos DWP CS

The most common causes of breakdowns

If it becomes necessary to repair pumping equipment, it is necessary to find out the probable cause of its breakdown, which are often:

- Failure to comply with the terms of periodic inspection and repair of equipment.

- The equipment has been operated incorrectly.During operation of the device, its operating parameters were exceeded.

- The pumped liquid contains solid impurities larger than required.

- Prolonged use of the pump in dry mode.

- Installation of equipment was performed incorrectly or poorly.

- The hydraulic accumulator, the relay are out of order, there is no filter.

When the first hints of a breakdown appear, the following components of the device should be immediately checked: The ideal distance between the electromagnetic coils and the piston must be set from 0.4 to 0.5 cm.

Drainage of the reservoir with a drainage pump

The piston must not have mechanical damage and defects, its condition must be elastic. The valve closing the inlets must have a clearance between the body of 0.7 to 0.8 mm. Air should flow freely when blown in at the intake side. It often happens that the poor performance of the pump is not related to its breakdown. There may be power fluctuations in the network.

Therefore, before disassembling the device, make sure that the mains voltage matches, which should be 220-240 V. It should be noted that for long-term and reliable operation of pumping equipment, it is necessary to carry out technical inspection and maintenance of the device in a timely manner and follow the rules of technical operation.

Subtleties of repair of units of different brands

Since there are models of pumping equipment from different manufacturers on sale, which are distinguished by their strength and design features, the repair and operation of such devices should be carried out taking into account the model

Since there are models of pumping equipment from different manufacturers on sale, which are distinguished by their strength and design features, the repair and operation of such devices must be carried out taking into account the model. Since you could choose not “Vodojet” or “Whirlwind” as a downhole unit, but a model of another brand, we decided to list the weaknesses of the most common pumping products, as well as the features of their repair:

- Most Grundfos models have special motor insulation and built-in valves. Therefore, sometimes it is necessary to change the thermal insulation seals of the motor. This work can only be done by a professional.

- Gilex brand pumps often encounter fluid leakage from the electric motor. For repair, it is necessary to replace the fluid with a similar product. This can be done only in a special service center.

- The domestic pump "Kid" is the most popular. Although the price of service repairs is quite acceptable, it is easy to repair this device with your own hands. A common problem is that the unit makes a lot of noise after turning on, but does not pump water. Usually this happens due to a rupture of the central axis on which the membrane and anchor are installed. Usually, disassembling the unit allows you to quickly identify the problem. The axle needs to be replaced. You can learn more about repairing the Baby pump from the proposed video:

- The Aquarius well pump overheats quite often during operation. This is especially true for units installed in shallow wells. However, since the repair of such equipment can be about half of its cost, it is easier to buy a new device if an inexpensive pump breaks down.

- Pumps "Vodomet" and "Whirlwind" are quite reliable equipment, which, if used correctly, can last a long time without breakdowns. If used incorrectly, the units can become clogged with silt and sand. For repair, you will need to change the pumping part.

- Pumping equipment "Rucheyok" is also famous for its ability to overheat. And this despite the design in compliance with European standards.According to the manufacturer's instructions, the device can work without stopping for 7 hours, but in practice this will cause overheating. Therefore, the pump is recommended to give a break after 2-3 hours of operation.

Selection criteria for drainage pumps

There are several rules that should be observed when choosing a device: It is necessary to take into account the type of liquid being pumped - here they pay attention to the size of the fractions in dirty water. You need to carefully read the main parameters of the drainage unit in order to opt for a particular model

- pressure - this value for equipment of medium productivity is 7-10 meters. In some models, it reaches more than 30 meters. The data regarding the pump head depends on the distance over which the liquid is planned to be supplied;

- performance - the choice depends on the volume of the tank. For example, for a capacity of 40 "cubes" a device with 10 cubic meters per hour is enough. For industrial purposes, more efficient pumps are needed - about 100 m³ / hour or more;

- immersion depth of the device - the maximum value reaches 5 -15 meters, and the minimum - 0.3 - 0.9 meters.

It should be remembered: when the unit is operating, its pumping part must be under water.

In addition, you need to know on what points the duration of the pump life depends:

- the quality of the materials from which the equipment elements are made;

- temperature of pumped dirty water, it should not exceed +50°C;

- drain passage diameter;

- protection against possible overheating. Usually, a thermal switch is built into the pump (it will turn off the power if the liquid temperature becomes critical) and a float switch.

Types of drainage pumps

Such units for pumping out dirty water and wastewater are surface and submersible according to their purpose (read: “Dirty water drainage pump - which is better, surface or submersible“).

The drain pump has two pipes:

- input - for the intake of dirty water from the waste tank;

- output - necessary to drain the liquid outside the tank.

During the operation of the device, it is necessary to ensure that water does not get into it (read: “How does the drainage pump work, what is the principle of its operation for”). Otherwise, the unit may fail and then it will be necessary to repair the drainage pump with your own hands or with the help of a specialist. Effluent must be pumped out faster than their level in the well rises. The pumps are connected to the sewer system by means of nozzles. To do this, measure the diameter of the sewer pipe with an accuracy of one millimeter.

The advantage of surface pumps is mobility - they can be easily and quickly moved to another location.

Submersible drainage pumps. This type of apparatus is used when it is necessary to clean deep tanks and in case of large-scale flooding to pump out excess water. The unit is lowered into a well or container, from where liquid is to be pumped out (for more details: “Drainage pump for a well: how to choose“). Suction is carried out through the holes in the bottom of the device, and not through the inlet hoses. To prevent large inclusions from entering the impeller of the apparatus, the pump has mesh filters.

The use of float switches allows you to automatically turn on the device with a large number of drains. It is possible to avoid the possibility of a short circuit when the device is immersed in a liquid due to the presence of high-quality electrical insulation. If it is necessary to pump out or pump over liquid with large fractions, experts recommend using fecal (sewer) pumps with special cutting and chopping elements. They are capable of pumping and processing effluents containing large wastes.The most optimal solution would be to purchase an automatic sewer station, which will allow you to operate bathrooms that do not have a connection to centralized sewage systems.