Instructions for cold pipe welding

First you need to qualitatively prepare the base. To do this, all areas on which the resin will be applied are cleaned of rust, dirt, old paint. You can process them with sandpaper to immediately remove all contamination. You should not try too hard, otherwise deep scratches will remain on the surface. But small abrasions will come in handy - they will enhance adhesion. Immediately before welding, the parts must be degreased with a solvent (usually acetone) or washed with detergent. If possible, you need to dry the joints with a hair dryer - heating will improve adhesion.

Glue is prepared depending on the instructions. For the manufacture of a liquid adhesive, a strictly measured amount of hardener is added to the resin. The lifetime of the composition is also indicated in the instructions, then its polymerization begins. Usually the period is 10-15 minutes or a little more. You can slightly extend this time by cooling the product.

Repair is carried out in this way:

- apply glue to the place of the future joint, right into the hole, to ensure the penetration of the mass deep into;

- the second option is to wind glass fiber, fiberglass, cover with a liquid composition that has already begun to thicken a little;

- smooth the product on the outside with a small spatula or other flat device, moistening it a little in water;

- within a few minutes, you can change the position of the mixture;

- if the hole is too large, a metal patch will have to be put on it (directly on cold welding);

- fix the area for 15-60 minutes, depending on the instructions, using a clamp;

- if possible, the joint should not be subjected to intensive loads for 1-24 hours, although 1-1.5 hours is sufficient for most welds.

If the repair is carried out in a room with a low temperature, the glue must be rolled into a ball and the mass inside should be allowed to warm up to +40 ... +50 degrees. The holding time of the ball should not be longer than the pot life of the mixture (usually it is not held for more than 4 minutes). For effective heating of the ball, it must be made with a mass of at least 50 g. It must be remembered that in order to repair complex joints and assemblies, it is better to immediately use hot welding or replace parts, a cold joint may turn out to be unreliable.

Security measures

After drying, the material is safe for humans, but care must be taken when working with it. All work is carried out with gloves, avoiding direct contact of the epoxy with the skin.

Do not use a food grade knife to cut resin. Upon contact with the mass, the skin is washed with soap and water.

Cooling system device

The cooling system of a car consists of:

- radiator;

- water pump;

- expansion tank;

- branch pipes and hoses;

- thermostat.

Radiator - a lattice of pipes and plates made of light metal: aluminum, brass or copper. Numerous tubes allow to reduce the volume for cooling, and the plates increase the area of the heat exchanger.

All components are connected to each other by pipes and hoses. The water pump (pump) drives the coolant through one of the circuits. The thermostat is responsible for the circulation of the refrigerant in a long or small circle. We know from a physics textbook that a liquid increases in volume when heated. The expansion tank helps offset this physical property of the antifreeze.

Solutions

How to fix a leak in a water pipe? It is possible to carry out work, knowing certain methods, without the help of specialists.

Elimination of leaks on the body of the pipe

To eliminate the leakage of the pipe body under pressure, you can use:

self-tapping screw with rubber gasket. A self-tapping screw is screwed into the leak and prevents the penetration of water.This method has a significant disadvantage - a foreign object appears in the pipe, which prevents the free passage of liquid and over time can lead to increased formation of corrosive plaque;

Self-tapping screw, supplemented with a rubber gasket for sealing

For normal sealing, the diameter of the self-tapping screw used should be slightly larger than the diameter of the hole on the pipe.

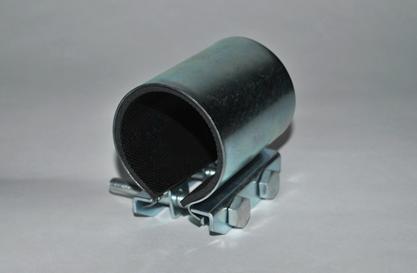

- clamp, which is installed on the pipe at the point of leakage. The clamp is equipped with a rubber gasket and is fixed to the pipe using fasteners;

- emergency adhesive.

Do-it-yourself clamp to eliminate leaks:

purchase in the store;

Ready-made clamp to eliminate leaks

make it yourself.

To make your own collar, you will need:

- a piece of rubber. You can use, for example, a cut from a bicycle camera. The size of the rubber cut depends on the size of the leak. The rubber seal should be 5–7 cm larger in width than the hole formed, and in length wrap the pipe in 2–3 layers;

- wire or any other elements for fixing.

To eliminate the leak, you must:

- wrap the place of water leakage with rubber;

- secure the rubber with wire. Pliers can be used to tighten the wire more.

Self-made leak clamp

Emergency adhesive is a two-component mixture consisting of:

- epoxy resin;

- metal dust.

An addition to the adhesive is a hardener that promotes the fastest polymerization of the chemical compound.

Emergency glue kit

Instructions for using emergency glue:

- the surface of the pipe is carefully cleaned. Remove paint and rust;

- using sandpaper, roughness is applied to the pipe;

- glue is being prepared;

- the finished composition is applied to the place of crack formation and left to dry completely. To speed up polymerization, you can use a building hair dryer.

Fixing a leak with a chemical

All work is recommended to be carried out with rubber gloves, as the chemical composition of the adhesive can damage the skin.

You can learn more about how to fix a leak using emergency glue by watching the video.

https://youtube.com/watch?v=N8q7haSut7M

Fitting Leak Repair

If a cold water (hot water) pipe flows at the fitting installation site, then the malfunction can be eliminated in the following ways:

- tighten the threaded connection. To do this, you can use a wrench of a suitable diameter or an adjustable wrench. Fixation must be done very carefully so as not to spoil the thread. In most cases, the described method allows you to get rid of the leak;

Fixing a threaded fitting to eliminate leakage

When performing work, it is recommended to keep the pipe in its original position so as not to damage it or an adjacent fitting.

- if fixing the thread does not help, then it is necessary to add a sealing material to the thread. To do this, you need to prepare an adjustable wrench and linen thread in advance, since all the work needs to be done as quickly as possible. The process of adding linen thread:

- the fitting turns off approximately 1/2;

- sealing material is wound on the thread. It is recommended to wind in the direction of movement of the connecting fitting along the thread;

- thread is tightened.

Adding linen thread to thread

If none of these actions helps, then the fitting must be replaced, which is carried out only after the water supply is turned off.

Weld leak repair

To eliminate the leak formed in the weld, you can use emergency glue or a homemade clamp. How to use these tools, described earlier.

Any of the described methods for eliminating a pressure pipe leak is only a temporary measure.To eliminate the problem completely, it is necessary to replace the damaged section of the pipe, replace the fitting, or repair the weld. All these operations can be carried out only with the water supply turned off.

Cold welding for pipes

Cold welding for batteries and heating pipes mastix is a modern technology for connecting pipeline systems without the use of welding equipment, which works on the principle of exposing the parts to be joined to high temperatures. In this case, the connection is carried out due to the deformation of the welded mixture, its tight fit to the surface of the workpieces.

What is technology

Cold welding is an adhesive composition specially made for joining metal elements. Glue in composition is one-, two-component:

- epoxy resins serve as the base, which perform the tasks of plasticity, homogeneity of the mixture;

- additional fillers - sulfur, metal elements.

By consistency - a polymer mixture with adhesive properties in the process of slight heating, deformation.

If you strictly follow the cold welding technique, ideally, the welded area, for example, a riser, will be much stronger than the base metal of the product, but the seam is inferior in reliability to the connection made using electric arc welding. Therefore, it is recommended that this method of joining metals be used only when performing minor repairs, for example, if a leak is detected in a pipe, a crack can be welded.

Varieties of glue for cold welding of metals

Many are interested in the following question: is it possible to glue a radiator with hot water using this method, and how effective and durable is such a repair? Experts say that it is possible, but the quality and period of operation of the connection will depend entirely on the correct choice of adhesive and its application.

Classification by physical characteristics

The composition may be liquid or plasticine-like.

When purchasing a liquid product, it is recommended to pay attention to the two tubes that are in the package. In one, the main composition is an elastic agent made from epoxy resins, in the other, a hardener

Before use, they are mixed together. The finished mixture must be used up within 2-20 minutes.

Solid cold welding for pipes, radiators of the heating system is a plastic bar (similar to plasticine). Inside there is a plastic agent, the top coating of the timber is a hardener. Before use, it must be well kneaded.

If a small part of the plastic bar is enough for the repair, you can cut it (recommended across).

- Glue for metals. With the help of such welding, it is possible to obtain sufficiently strong joints even between workpieces made of different metals.

- Special formulations for extreme conditions. Such welding can work at high pressure, under water.

- Adhesive mixtures for automotive parts.

- General purpose welding adhesive. Such compounds provide the ability to connect polymer, metal, wood products, but they are less durable.

Flaws

- Cold-type welding for a riser, batteries involves extremely small loads; it is not suitable for more serious repairs.

- The quality and reliability of the seam connection primarily depend on the correct application of the working composition.

- In the course of work, it is necessary to adapt to the established operating temperatures of the adhesive composition.

- The resulting seams have a shorter service life than, for example, those made by arc welding.

Choice

When choosing an adhesive for pipe welding, you should not base your choice on the cost of the product, since in this case the price is absolutely not a determining factor.It is recommended to purchase material only from well-known, trusted manufacturers who have long established themselves in the market.

Sergei Odintsov

How to identify a leak

If the engine began to overheat frequently, and even more recently the coolant poured into the tank quickly left somewhere, it is urgent to diagnose the radiator for holes. To find out where the hole is, you need to dismantle the radiator and carefully inspect it.

But it is not always possible to find a hole visually. Then you should use other diagnostic methods. So, how to check the radiator for a leak:

- To do this, all openings of the device are closed with plugs.

- Then the part is lowered into a suitable container with water.

- Next, you need to observe - if bubbles appear, then there is a breakdown in those places on the radiator.

Diagnosing leaks from pipes or from the heat exchanger itself will not be a problem. But if there are no fluid leaks, and the temperature of the antifreeze or antifreeze during the movement quickly rises to critical values, then it is much more difficult to find out the cause. Usually this situation occurs if there is not enough coolant or the radiator is not working efficiently. If traces of coolant are found under the hood, it is urgent to repair the radiator.

Causes and remedies for leakage

It is important to monitor the level of refrigerant in the system. There are special marks in the expansion tank for this.

If the level constantly drops and you have to add fluid, then the system is leaking. We need to find the cause and fix it as soon as possible. Consider the main causes of leakage and ways to solve the problem:

-

If the radiator has a neck, then you need to check the cap. The coolant heats up to 120 degrees Celsius and circulates in the system under high pressure. If the cap is not able to hold pressure, then the antifreeze evaporates from the heat exchanger and the level drops. This problem is solved by replacing the cover with a new one.

- The second reason for the leakage of antifreeze is the wear of rubber pipes. Check the connections to the radiator. If there are traces of coolant leakage, then replace the pipes and clamps.

- The most unpleasant breakdown is the appearance of a leak in the radiator itself. It occurs as a result of mechanical shock, physical wear and tear, or due to the use of poor quality antifreeze.

Finding a large hole is not difficult - hot steam will pour out of it. It is difficult to fix such a defect on the road. Get to the nearest service station as soon as possible and have the heat exchanger repaired or replaced. In any case, the old radiator will have to be dismantled and inspected. Some craftsmen know how to weld holes. If the radiator is made of copper or brass, then it can be soldered. Aluminum is repaired using argon welding.

As experience shows, such repairs are rarely carried out with high quality, and after a few months the car owner is forced to change the radiator to a new one.

Finding a small leak is more difficult, but antifreeze itself will help in the search. Its chemical composition contains a dye that is highlighted in ultraviolet light. It is enough to shine a special lamp on the radiator and you will see the places where the coolant flows.

The detected defect in the garage is eliminated by cold welding. This is a two part epoxy resin. The prepared composition is similar to plasticine and is applied to the detected defect. Pre-clean the surface: remove dirt, oil and dust. After 15-30 minutes, the weld hardens and the leak is eliminated.

It is believed that a small leak can be eliminated by folk methods, for example, using dry mustard. This product is added to the radiator, under the influence of temperature, the particles increase in size, spread through the system and close the hole where there is a leak.Remember that with the elimination of the defect, foreign substances clog the entire system: engine channels, radiator cells. Do not use folk methods. Find another way to get to a service station or use radiator sealant.

Instructions for using cold welding for metal

Cold welding for metal can be useful not only for auto repair. In addition, it is widely used in everyday life (gluing ceramics and so on).

As for cars, it is used for gluing torn off or broken metal parts, repairing damage to radiators, fuel tanks, mufflers, crankcases, pallets and other elements. Most often, it is plastic compounds that are used for this, but sometimes liquid ones are also used, because their strength is higher than that of putties.

The main advantage of such repair kits is that to repair damage in the tank, radiator and similar parts, it is not necessary to drain gasoline, diesel fuel or oil. Cold welding does not react with them, is convenient to use and quickly hardens. In addition, the consumption of this material is relatively small, and it will serve you more than once.

To seal cracks or holes in tanks, mufflers, pans, etc. using cold welding, the same scheme is used, so there is no need to paint each case separately. It is only necessary to follow the general recommendations.

- Surface preparation - first of all, it involves cleaning the metal, which is carried out with sandpaper. Of course, you can do without it on the road, but with stripping, the glue will last much longer, because small scratches and roughness provide the best adhesion of the composition to the surface.

- Degreasing - for this, anti-silicone is used (at worst, regular gasoline is also suitable), which should wet a piece of cloth and wipe the work surface.

- Preparation of cold welding - it is required to squeeze out the required amount of material from the tube or cut off (break off) from the bar, then knead (stir) to a homogeneous and plastic consistency. As a rule, the mixture warms up a little. Cold welding, the instructions for which are usually included in the kit, will not require any special work skills.

- Application of glue - the resulting composition should carefully repair the damage and level the surface. It is recommended to do this as quickly as possible, as some formulations set in just a few minutes.

After application, you should wait until it dries completely (it can take from an hour to a day). Naturally, it is not always possible to wait so long on the road, so 20 minutes of waiting will be enough for the initial solidification, which is enough to “reach out” to the nearest auto repair shop.

For a detailed video instruction on the use of cold welding for metal, see the end of this article.

Sealant treatment

By the way, motorists from the last century used mustard to eliminate leaks. Mustard powder was poured into the radiator, and so it was possible to get home. But this method has a significant disadvantage. After applying mustard, you will need to flush the radiator.

Today, mustard is no longer relevant. If a radiator leak is found on the road, repairs can be performed using special sealants. What is the principle of action of the composition? It is poured into the expansion tank or into the radiator itself. Then, through cracks and holes, the agent will flow out and solidify. In combination with air, the sealant creates a durable film based on polymers.

How to fix a leak in a DHW pipe using cold welding

To repair the pipe of the water supply system using cold welding, we follow the following sequence of actions:

The section of the pipeline network where damage was detected is blocked.

Water drains out of it as much as possible.

If the pipe is painted or covered with thermal insulation, it is cleaned to the metal at a distance of about 5 cm in the damaged area.

Rust residues are removed, the pipe section is degreased and dried.

A piece is cut off from the cold welding bar, the plastic composition is kneaded by hands until the components visually become one. If a liquid variety is used, the components are mixed in the proportion indicated on the package.

The finished mastic is applied to the site of damage, an even spindle-shaped thickening is formed

It is important to understand that it is desirable to apply the composition to the pipe not in the form of a patch, but to cover it along the entire circumference.

Within 3-4 hours, the composition dries up, forming a rigid, durable mass.

To enhance strength, a bandage of technical fabric, a simple bandage or gauze can be applied over the welding layer. Also, it would be useful to put a layer of paint on this place.

If for one reason or another it is not possible to shut off the water supply, you can try to eliminate the leak on the wet pipe. To do this, you will definitely need a special composition of liquid cold welding that can stop the action of water. It is most convenient to impregnate a tissue tourniquet with such a composition and wrap it around the place of damage. The fabric, even very thin, will provide the material with close contact with the surface and additional strength.

Increasingly, water supply systems based on polymer pipes are found in homes. This material is more reliable than metal, but, unfortunately, it is also not one hundred percent insured against emergencies. Special types of cold welding have been developed for working with plastic products.

The sequence of actions in this case is almost the same, with the exception of a few points:

- The damaged area is treated with sandpaper (this will increase the adhesion of smooth plastic with adhesive), degreased and dried.

- To enhance the effect, after applying cold welding, a clamp is often used.

Features of fixing a radiator leak

If a radiator is leaking in your house, it is akin to a small disaster. Of course, you don’t want to drain the water from the entire system, and, of course, no one will do this if you live in a multi-storey building. So what should be done if a heating radiator is flowing in the apartment and it needs to be quickly repaired without draining the water for this?

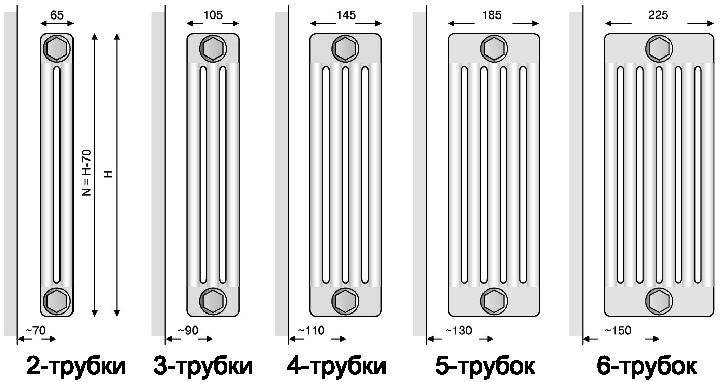

Types of steel radiators.

It would be great if you could find a way to cover up a damaged radiator or area. In this case, getting rid of the leak would be much easier. It must be assumed that the pressure in the heating system is not as large as in the water supply system, which greatly facilitates repair work.

There is no universal answer to the difficult question of how to fix a heating battery leak. It all depends on the place of the leak and the size of the hole that appeared in the gland as a result of corrosive attack. In most cases, as already mentioned, a leak is formed at the junctions of the battery sections. A small tear can be easily repaired with a clamp. This, as already mentioned, is a metal structure, which consists of 2 plates rubberized from the inside, connected to each other with bolts that are tightened with nuts. With the help of nuts, the structure is tightened to the required density, and the rubber gasket acts as the main element that blocks the leakage of the battery. Pipes and risers come in different sizes, so clamps are also available in different sizes.

Therefore, when choosing a product, it is necessary to pay attention to the coincidence of the dimensions of the clamp and pipes.

If you don't have a clamp handy, you can use a piece of thin rubber instead. To do this, it is enough to wrap the leak tightly with rubber in several layers and fix it from above with an ordinary wire.

The previously mentioned "cold welding" is sold in the form of small strips, similar in appearance to children's plasticine. The cut off piece must be kneaded with your hands until the color of the plastic mass is uniform and the consistency is uniform, after which, with pressing movements, stick the welding to the place of the leak.

Is it possible to use cold welding to repair heating pipes

Have you heard of such a method of welding materials as "cold welding"?

Then it will be interesting for you to read information about this technique and find out how effective this technique is.

Thanks to historical excavations, it became known that a similar technology was used in the old days when creating works of art of the ancient period.

articles:

The National Museum of Ireland exhibits gold caskets made in the Early Bronze Age.

Masters in their work used the technique of cold welding.

In the mid-forties of the last century, the method began to be used in countries with developed industry.

In the Soviet Union, cold welding began to be used in the 50s of the 20th century.

At the moment, this technique has found wide application for welding such metals:

How can welding be cold? Is the process possible without heating, special solutions or electric current?

It turns out it can. And there is no magic in it. The method is based on plastic deformation, which destroys a brittle oxide film, which is the main obstacle to the conjugation of metals.

We all had, at least once in our lives, to experience the problem associated with repairing the pipes of the heating system, the expansion tank and other components of the highway.

About ten or fifteen years ago, any heating circuit with an expansion tank made of aluminum (welding technology) and radiators were repaired only by hot welding.

Do you know how to choose and buy an electrofusion coupling? What is it and how to use them read in a useful article.

About compression couplings for steel pipes is written on this page.

The modern market today offers an almost instantaneous and at the same time a very effective way to eliminate leaks in all devices of the heating system.

There is no need to use welding at high temperatures. A completely new technology has replaced the well-known methods.

Now cook:

- can be using cold welding. In this way, not only metal, but also polymer products are connected.

Very often, manufacturers include a hardening additive in the form of steel powder in its structure.

The substance has good resistance to aggressive environmental influences, and it, in full, retains all its characteristics at temperatures up to +260 degrees.

extraneous noise

Sometimes there may be noise in the heating pipes - it can be either a knock in the heating pipes, or various clicks, and a hum. Why are heating pipes noisy? There are several reasons:

- During operation, the diameter decreases.

- Pipes are leaking.

- A smaller pipe diameter was installed.

It should be remembered that if the heating pipes are buzzing, immediately check for a leak.

You may need to think about how to fix a leaking heating pipe. When you fix the leak, you will also remove such a problem as the heating pipes are noisy.

Why are the heating pipes still buzzing? This may be a reduction in the diameter of the pipes. As heating pipes knock, you can hear right on the spot. You need to go along the pipes and find the reason why the heating pipes click. Usually the source from which the heating pipes click is located in the basement - after all, there is more pressure

It is very important to find in time the reason why the heating pipes shoot, buzz or make noise - after all, this can be a prerequisite for a serious problem.

When performing the installation of engineering communications, it is necessary to foresee the possibility of repairing heating pipes in an apartment without resorting to dismantling the floor covering or wall panels. If a leak has already occurred, then our article will tell you how to fix it.

Heating pipe leak