Tying a gas boiler in the heating system

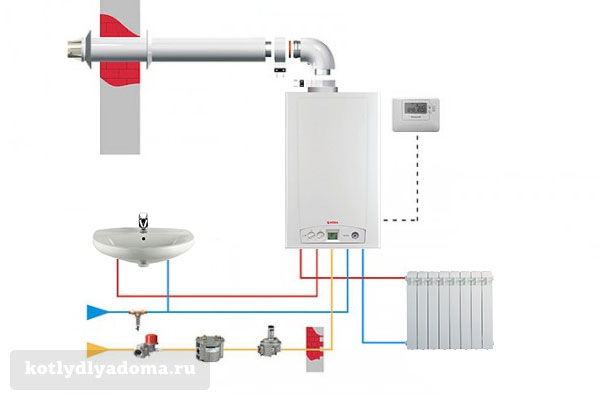

After the installation of the wall-mounted gas boiler is completed and the heater is placed on the wall, the first step is to connect it to the heating system. Depending on which model is installed single-circuit or double-circuit, there are various strapping schemes. We will consider the connection process using the example of a wall-mounted double-circuit gas boiler.

As you know, a double-circuit boiler, in addition to heating, is capable of producing hot water for household needs. Structurally, this is realized by installing one bithermic or two separate heat exchangers. A double-circuit boiler does not produce very much hot water, but it is enough for 1-2 distribution points (for example, a kitchen faucet and a shower).

A modern mounted gas boiler is very compact and already contains within itself the main elements necessary for the operation of a forced circulation heating system, such as: a circulation pump, an expansion tank, a safety group. In the heating systems of small private country houses, this is more than enough, but if necessary, you can install an additional expansion tank or another pump.

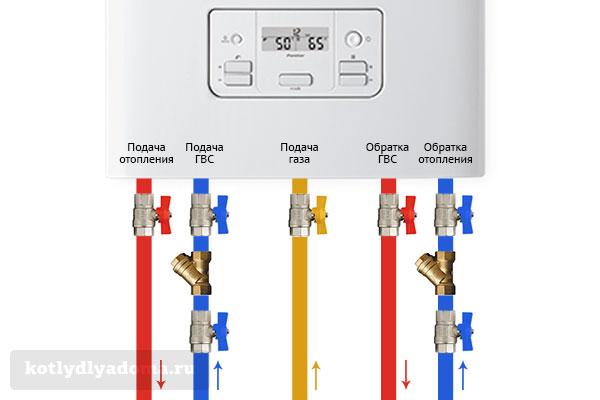

At the bottom of any mounted double-circuit boiler there are 5 nozzles. They are connected to: supply and return lines of the heating system, supply and return of hot water supply, main gas. The gas inlet is usually centrally located and colored yellow. All other lines can be arranged in any order, depending on the model of the gas boiler. Therefore, before starting the strapping, it is required to clarify the purpose of each of them in the instruction manual.

The piping of the wall-mounted gas boiler is carried out with polypropylene or metal pipes. The cross section of heating pipes is usually larger than DHW pipes 3/4 and 1/2 inches, respectively. The heating system is connected to the boiler through the American nuts. Ball valves are installed on each line, for the convenience of dismantling the gas boiler without draining the coolant and for isolating the boiler from the heating system, if necessary. To ensure tightness, all connections must be made using plumbing FUM tape or linen.

Coarse filters must be installed in the heating return line and in the DHW supply line. For the convenience of their washing and cleaning, they are also cut off with shutoff valves. Often, in order to increase the service life of the secondary heat exchanger of a double-circuit boiler, a magnetic fine filter is additionally installed at the DHW supply.

Electrical connection of the gas appliance

Modern gas boilers exist with 2 options for connecting to the mains: a three-core insulated cable and with a plug for connecting to a socket. In both cases, you should follow the rule: the gas device is connected through an individual circuit breaker to the shield and you will definitely need to take care of grounding. It is recommended to use voltage stabilizers as well as backup power supplies to prepare for a power outage.

A cut-off switch must be installed near the boiler so that it can be switched off quickly and easily. Do not ground the device to a heating pipe or gas pipeline. In order to ensure high-quality grounding, it is necessary to equip a ground loop or point grounding.

Connecting the wall-mounted boiler to the mains

Most modern wall-mounted gas boilers are equipped with sophisticated automation. It controls many processes, turning the heating boiler into an autonomous mini-boiler room, the operation of which practically does not require the intervention of the owner.Obviously, the control unit and various sensors require an electrical connection.

Double-circuit wall-mounted boilers are available in two versions: with a familiar socket and with a cable for connecting directly to the machine. In any case, they must be powered from the mains through an individual machine. If you purchased a model with a plug, then an individual socket for a gas boiler should be placed next to it, but in no case under it. This is one of the safety requirements so that in the event of a coolant leakage, a short circuit does not occur.

The gas boiler requires mandatory grounding. For these purposes, you can purchase a point grounding kit. It is installed in the basement or next to the house and occupies a small area of about 0.25 m².

Attention! It is strictly forbidden to ground a wall-mounted gas boiler to a heating radiator or gas supply pipe. This is a gross violation of the rules for operating gas equipment and is extremely dangerous.

Boiler automation is very sensitive to the quality of the supply voltage. With an insufficient level or non-ideal shape of the sinusoid at the input, the devices quickly fail. To prevent frequent breakdowns and extend the life of the unit, it is required to connect voltage stabilizers for gas boilers. To avoid stopping the heating equipment in the event of power outages, you should additionally purchase an uninterruptible power supply.

How to connect a gas double-circuit boiler

A double-circuit device differs from a single-circuit one in that it has 2 heat exchangers: one is the main one, which heats water for heating, and the other is an additional one, which will heat water for hot water supply. In most cases, such boilers are wall-mounted and represent a high-tech boiler room, where everything is automated and provided.

Connection of a double-circuit gas boiler.

You should pay attention to the figure, which depicts the insides of a two-circuit device. 5 pipes will be connected to it: 1 - a pipe with a coolant from the heating system, which goes to reheating; 2 - a pipe with cold water going to the heat exchanger in order to heat water for hot water supply; 3 - gas pipe; 4 - pipe for hot water supply; 5 - pipe with hot coolant for the heating system

All automation of double-circuit boilers is arranged inside. The default heat carrier, which is heated by the main burner in the boiler, is sent to the heating system and returned to the boiler cooled down. Thus, the boiler-heating-boiler circulation occurs. However, as soon as someone opens a tap on one of the consumers with hot water, cold water will begin to flow into the boiler through the pipe. The three-way valve will immediately redirect the coolant, which will not go beyond the boiler, but the main heat exchanger circulates. The coolant will heat the water for hot water until it is no longer used. As soon as the tap is closed, the coolant begins to circulate through the heating system.

Scheme of connecting a gas double-circuit boiler directly.

In practice, a double-circuit gas apparatus is not capable of providing a large amount of water for hot water. The boiler does not have time to heat it in the required volume. That is why they are used exclusively in families of small sizes, and in order to heat a larger volume of water, a water heater is additionally used.

According to this scheme, the coolant only heats the water in the boiler, and the system itself, the water supply to the 2nd circuit will be closed. This allows you to significantly increase the durability of a two-circuit device, which suffers greatly from hard water taps.

Scheme of connecting a gas double-circuit boiler with an indirect heating water heater.

After about a year, the additional DHW heat exchanger will clog and fail. In this regard, the circulation of pure coolant in the 2nd circuit is a more economical solution. However, it makes no sense to use a two-circuit design. In this case, it is much more profitable and more practical to install a single-circuit boiler of greater power.

Connecting a gas wall-mounted boiler paired with an ordinary electric boiler as a storage tank for hot water is also acceptable. In this case, hot water will enter the boiler from the boiler, and when its amount decreases to a critical point, the boiler will start heating water again in order to fill the boiler. A variant is possible in which the boiler is filled with hot water from the boiler, and its further temperature will be maintained using a heating element.

Requirements for the use of RCD

Requirements for the use of RCDs for the purpose of electrical safety are regulated by the PUE, chapters 1.7, 6.1, 7.1. The tripping current of an RCD installed for electrical safety purposes should not exceed 30 mA (use RCDs with a tripping current of 10 mA and 30 mA).

The rating of the RCD for the tripping current is selected in accordance with the requirements of clause 7.1.83 of the PUE. The total leakage current of the network in normal mode should not exceed 1/3 of the rated current of the RCD. Since there are no data on leakage currents, the calculation of leakage currents is carried out in accordance with the requirements of this paragraph. When calculating, the leakage current of the electrical receiver is 0.4 mA for every 1 A of load current, and the network leakage current is 10 μA per meter of cable length.

Requirements for the installation of RCDs in order to protect against fire are regulated by the following documents:

- PUE, p. 7.1.84 “To increase the level of fire protection in case of short circuits to grounded parts, when the current is insufficient to operate the overcurrent protection, at the input to an apartment, individual house, etc. it is recommended to install an RCD with a tripping current of up to 300 mA”;

- Federal Law of July 22, 2008 N 123-FZ "Technical Regulations on Fire Safety Requirements". Article 82, part 4 “The power supply lines of the premises of buildings and structures must have protective shutdown devices that prevent the occurrence of a fire. Installation rules and parameters of residual current devices must take into account the fire safety requirements established in accordance with this Federal Law.

In accordance with these requirements, an RCD with a trip current of 100 mA or 300 mA is installed at the entrance to the apartment. Such an RCD is called fire-fighting.

If the calculation shows that the total leakage current of the apartment shield does not exceed 10 mA, then you can save money and you can install an RCD with a trip current of 30 mA at the entrance to the apartment. This RCD will serve as a "fire" RCD and RCD used for electrical safety purposes.

Otherwise, a “fire-fighting” RCD with a trip current of 100 mA or 300 mA is installed at the entrance to the apartment, and an RCD with a trip current of 10 mA or 30 mA is installed on the outgoing lines (where the installation of an RCD is required for electrical safety).

Connecting a gas boiler to a chimney

The diameter of the chimney must be equal to or greater than the diameter of the outlet in the device.

In most cases, the diameter of the chimney depends on the power:

- 100 kW - 230 mm;

- 80 kW - 220 mm;

- 60 kW - 190 mm;

- 40 kW - 170 mm;

- 30 kW - 130 mm;

- 24 kW - 120 mm.

Ordinary chimneys are brought up, 0.5 m above the ridge of the house. They are arranged both inside the wall of the house, and inside the house or behind its wall. No more than 3 bends are allowed on the pipe. The first section of the pipe that connects the boiler to the main chimney must be no larger than 25 cm. The pipe must have a closable opening for cleaning. For boilers with ordinary chimneys and an open combustion chamber, a large air supply is required. It can be provided either with an open window or a separate supply pipe.

The chimney must be made of sheet metal or other material that is resistant to acids. Do not connect the boiler with a corrugation to the main chimney. A brick chimney cannot be used either.

The coaxial chimney must be mounted horizontally and led into the wall. This type of chimney is a pipe in a pipe. It should move away from the wall by at least 0.5 m. If the boiler is ordinary, then the chimney should have a slight slope towards the street. If the device is condensing, then the slope should be towards the device itself. Thus, the condensate will be able to drain into a special pipe, which will need to be diverted to the sewer. The maximum length of coaxial chimneys is 5 m.

Rules for placing pipes and sockets

When laying an electric cable, it must be taken into account that it heats up from currents, and the heater located nearby also heats the surrounding air. Therefore, it is better to avoid laying wires near gas supply and heating pipes altogether. But if it doesn’t work out, it should be remembered that the norms of the PUE (rules for electrical installations) regulate that the air temperature in such cases should not exceed + 25 ° C, therefore, in order to comply with fire safety rules, the distance during parallel laying is the distance from cables and wires to heating pipes must be at least 100 mm, and to gas pipes - 400 mm. When crossing wires with hot pipelines, the distance between them must be at least 50 mm, and with gas pipelines - at least 100 mm.

The switch, socket from the gas pipe must be placed at a distance of at least 0.5 meters. This requirement is due to the fact that there is a flammable gas in the gas pipeline, and in an emergency, the slightest spark from a socket or switch will cause irreparable trouble.

Is it necessary to ground a gas heating boiler and why

- Breakdown of automation - boilers equipped with an electronic microprocessor are sensitive to any power surges in the network. Failure, automation can and from static voltage. A gas boiler without grounding will not work for long. Replacing the automation board will cost approximately half the cost of boiler equipment.

- Explosion Hazard - Static buildup is one of the most common causes of fires in gas appliances. The positive effect of grounding on the operation of the boiler is that it completely prevents the appearance of a spark, leading to an explosion when gas leaks.

PUE 1.7.103 specifies the parameters and requirements for connecting heating equipment. Before issuing an act of checking the grounding of a gas boiler, the inspector will check that the installation of the circuit complies with the specified standards.

Connecting heating to a boiler that runs on gas

Wiring diagram for a double-circuit boiler with storage / water heater.

The location of the pipes may vary. It will depend on manufacturers and models.

If the heating system has already been operated before, and at the moment only the boiler will be replaced. you will need to drain the coolant from the system and be sure to rinse it several times. A large amount of different salts settle on the walls of radiators and pipes, and therefore it is necessary to flush the system.

Both antifreeze and water can circulate in the heating system. In the technical documentation, be sure to read about whether antifreeze can be used in the selected model.

It makes sense to use antifreeze as a coolant in the heating system when the boiler is turned on only periodically. In this case, the water in the pipes may freeze, but not the antifreeze.However, if the user is in the house all the time and the boiler is not turned off for frost, then water can be used as a heat carrier.

- Circulation pump (if needed).

- Ball valve.

- Coarse filter.

- Ball valve.

- Connection "American".

The circulation pump must always be stopped on the return line. Ball valves are needed in order to easily disconnect the system without draining the coolant and quickly remove the filter for cleaning and prevention. A coarse filter in the heating system is needed in order to protect the heat exchanger from clogging with salts. It should be placed directly in front of the boiler, preferably in a horizontal area with the trap down.

DHW connection diagram to a gas double-circuit device:

- Coarse water filter.

- Ball valve.

- Magnetic filter or fine filter.

- Ball valve.

- Connection "American".

In order to maximize the service life of the additional heat exchanger of a 2-circuit boiler and ensure its protection against scale, a magnetic filter and coarse cleaning must be installed on the supply pipe with cold water. If the last filter has already been installed before, then it is not necessary to install it in front of the boiler.

All connections will need to be sealed with tow, special plumbing paste or FUM tape.

Why keep your distance

The kitchen is the busiest area for electrical appliances. Refrigerator, microwave oven, exhaust system, dishwasher - these are a small fraction of household appliances, without which it is impossible to imagine. Therefore, safety in this part of the apartment should be in the first place. Electricity, gas and water supply are useful inventions, but in the hands of a hack or an irresponsible person, they cause fires, injuries, accidents. To avoid such troubles, when developing a kitchen design, you need to carefully consider all the details of the interior, as well as carefully consider the location of outlets in relation to the gas pipe, hob, and heating appliances. Health, well-being, and sometimes life of a person depends on it.