Maintainability of the heat exchanger

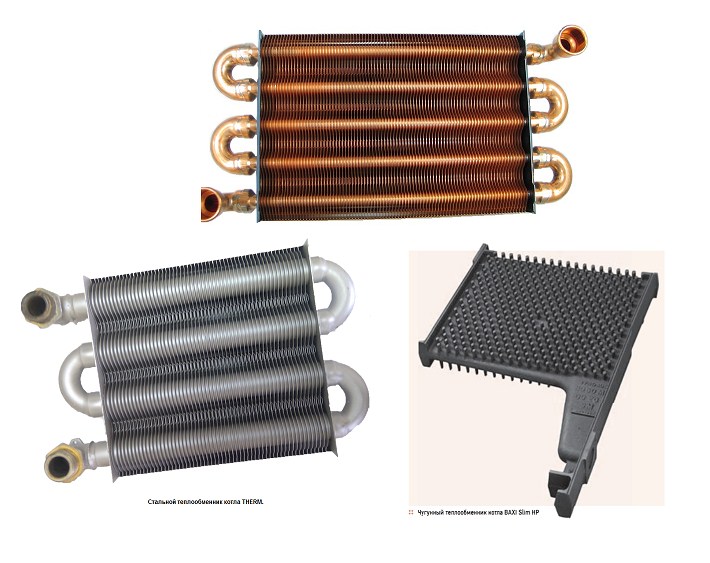

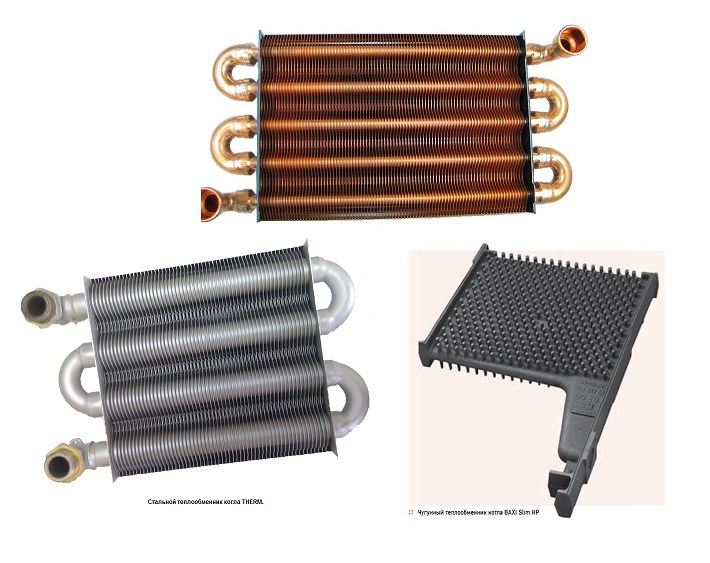

As noted above, the heat exchangers of modern gas boilers are made of: copper, stainless steel, cast iron. According to reviews, under the right operating conditions life time

steel heat exchanger in a gas boiler

is 15-20 years, and cast iron up to 30 years. The life of a copper coil is limited to 5-10 years.

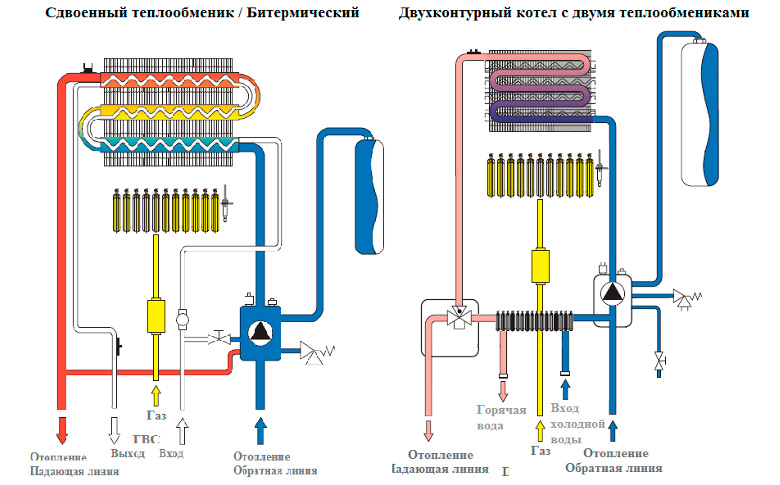

In single-circuit heating heat generators, one coil is installed, which transfers the thermal energy obtained during the combustion of fuel to the coolant. Depending on the design, two heat exchangers (primary and secondary) or one bithermic one can be installed in double-circuit boilers.

- In the first option, the primary coil is responsible for heating the coolant and is installed in the upper part of the boiler plant (above the burner). The secondary is responsible for creating a hot water supply.

- Bithermic has a “tube in a tube” design. A coolant for the heating system moves in the space between the outer and inner tubes; water flows through the inner tube of the heat exchanger to provide hot water.

Any heat exchanger is prone to scale formation. This is especially true for devices through which hard tap water circulates. A separate coil is enough to simply rinse or replace the failed section.

In a bimetric heat exchanger, scale forms much faster than its separate counterpart. Deposits that have appeared in the inner tube of such a device are almost impossible to eliminate. Heat transfer will gradually decrease, which means that in order to maintain the desired temperature regime of water, it will be necessary to increase the amount of fuel burned. Continuous operation of the boiler in this mode will significantly reduce its service life.

The specifics of gas boilers that do not depend on the consumption of external energy

A prerequisite for the operation of floor gas heating boilers is the presence of a gas main.

The presence of other sources of energy or electricity is not necessary. Indeed, today, along with improved models (equipped with pumps that circulate water forcibly, automatic control of safe operation, regulators of the temperature regime of the coolant and burner modulation), that is, volatile, there are non-volatile gas floor boilers. They are bought in those regions where there are interruptions in the supply of electricity.

Features of equipment that works without electricity

These boilers are economical in terms of fuel consumption.

In order for the boiler to work only on gas, modern manufacturers went two ways. In the first case, they completely simplified the design of the unit. That is, they made it more powerful, but without the automatic and electronic parts for managing work. With the help of such a device, the owner of the house can maintain the temperature in the house only at a certain level, that is, there is no automatic adjustment. The modulation of this parameter depending on the environmental conditions occurs only after intervention in the operation of the boiler from the outside.

The second way is a heat generator, which is able to independently generate energy for the functioning of the control system. In this case, there is a thermocouple in the flame of the gas burner. When it warms up, it generates enough voltage for the control system to work above the valve. When the gas supply suddenly stops, the voltage drops, then the valve closes.

Important! Since non-volatile boilers do not provide for the presence of circulating sediment, the movement of the coolant is carried out due to natural circulation (expansion / compression of the liquid), therefore, such heating systems should be organized with a slight pipe slope.

Overview of gas boilers

"Prometheus" is a well-known domestic brand of energy-independent floor-standing boilers with a steel heat exchanger. Prometheus models are used to heat rooms with a large area of up to 750 square meters. meters. The efficiency is 92%.Microflare burner with automatic ignition, steel plate heat exchanger ensures efficient and safe operation of the heating system. This company produces not only high-quality models that can successfully heat areas from the size of one apartment to large buildings of various functions, but also affordable. Gas boiler "Prometheus" - the best combination of quality and price.

Neva gas boilers is a St. Petersburg brand of Gazapparat OJSC, which specializes in the production of gas boilers and water heaters. The company carefully checks and tests all equipment for performance, electrical safety and tightness. The range of gas boilers is represented by 3 classes suitable for any wallet: “economy class” (Neva brand), “comfort class” and “premium class” (Neva Lux brand ). Since 2005, the company has been assembling wall-mounted gas boilers from ready-made purchased European kits. Since 2007, she has been manufacturing Neva Lux equipment, which has parts manufactured by the company itself. All boilers are made in a modern design, the consumer can purchase equipment at an affordable cost.

The Korean company Daesung is a leading manufacturer of heating boilers. The company's boilers are economical, of excellent quality and safe in operation. The first heat exchanger is made of copper, therefore it has a high efficiency and, accordingly, a long service life. The second heat exchanger is made of steel plates, so there will always be hot water in any quantity and instantly. The boiler is usually used to supply hot water.

Mimax LLC is a domestic company whose main focus is the manufacture of automatic gas equipment. Mimax gas heating boilers have a 3 mm thick steel heat exchanger, thanks to which they have excellent heat dissipation. When assembling the equipment, heat-resistant materials are used, which can significantly reduce the temperature of the outer case to 40 -50 °C. The efficiency of the company's boilers is 87%. The service life of heating equipment is more than 15 years. The Mimax company has developed a series of universal boilers that operate on both gas and solid fuels. Wood, coal, peat are used as fuel. The average time of transition from one fuel to another does not exceed 1 hour.

Gastroy LLC is engaged in the production of gas boilers of the Ochag trademark, which successfully sells 40 types of heating boilers. Among them are gas boilers for heating the hearth, designed to provide heat to small rooms with an area of about 1000 m². All Ochag devices are easy to use, have an excellent level of quality combined with reasonable prices.

Protherm's Medved gas boiler has a heat exchanger constructed from several links. This design allows the combustion of fuel to give maximum heat to the heating water. Advantages of heating equipment of the Medved series: compact dimensions of the boiler, easy installation, simple control, efficiency is 92%, maximum heat transfer with minimal losses, two-stage regulation.

Both in the domestic and in the European market of heating equipment, worthy models are presented, from which you can choose a boiler that suits you in terms of functionality and price.

Any heating equipment has its own lifespan.

Therefore, when choosing equipment, we pay attention to the quality of materials, strength and place of production. Every customer wants their heater to last as long as possible.

To do this, it is important to understand what the standard service life of gas boilers depends on. On average, he works 7-12 years

What factors negatively affect performance and contribute to wear? How to prevent breakage? This article will help you understand how to choose and operate a gas boiler correctly in order to avoid rapid wear and tear.

What factors should be considered

In addition to the class and price segment, other aspects also affect the duration of operation of gas equipment.

Heat exchanger material

Why is the service life of a wall-mounted appliance shorter than a floor-standing one? Perhaps the type of placement matters? No, just floor units are equipped with cast-iron or steel heat exchangers. For the same period of operation, their percentage of wear is significantly lower than that of copper radiators, which are installed in mounted boilers.

Copper is thinner than steel, and during operation it lends itself to oxidation and corrosion. Backlash in the heat exchanger can be soldered, but the unit will not last long. The average term of work is from 5 to 10 years maximum. Practice shows that copper radiators serve no more than 7 years, after which they must be repaired or replaced. They are more sensitive to the quality of tap water.

The type of heat exchanger also matters. An ordinary coil can be descaled on its own, and the boiler will continue to work. Bithermic radiators are not subject to cleaning, and the replacement of the node is almost equal to the cost of a new device.

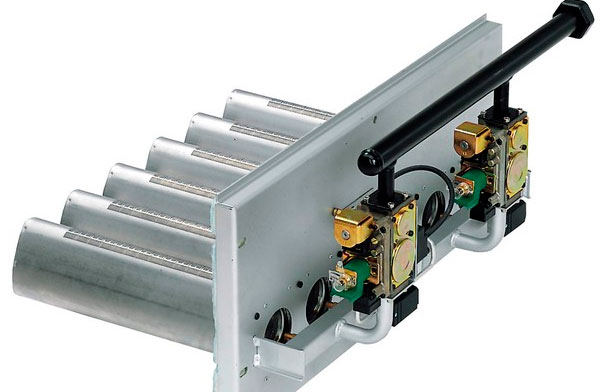

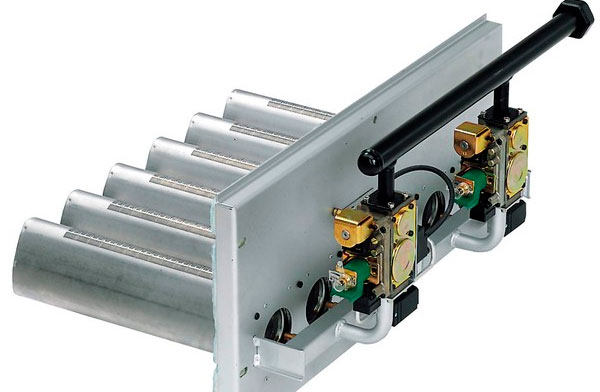

Burner type

Gas appliances have two types of burners:

- Atmospheric - take air from the room to maintain the flame. Combustion products are discharged naturally with the help of traction.

- Supercharged or forced (turbo chambers) - clean air is taken from the street through a coaxial chimney. The power of the flame can be adjusted, the smoke is removed by a fan.

What about operating time? Forced removal of combustion products is more efficient. The boiler works with greater efficiency, which increases the efficiency and reduces the load on its units.

In devices with an atmospheric combustion chamber, a lot of soot accumulates in the holes and on the elements. As a result, the equipment spends more power to maintain operation, heating temperature, so the nodes fail faster.

Electronics and automation

Electronic models are equipped with control sensors, self-diagnostics and require connection to the network. Instability in the network, power surges lead to damage to the elements. We recommend installing a voltage stabilizer.

Operation features

The service life of heating equipment initially depends on the right choice. To do this, it is necessary to select the boiler, taking into account the characteristics of the room in which it will work, and the planned peak loads. It is recommended to choose a boiler with a power reserve of 15–20%.

Choose a room for the installation of equipment in accordance with the regulations. It shouldn't be damp inside. Corrosion quickly destroys the heat exchanger, so install an air vent to bleed excess air.

Also, the pressure affects the life span of the unit. To keep the performance stable, include in the expansion tank.

- Devices with steel and cast iron radiators have the maximum service life.

- Devices with forced draft burner are more efficient.

- With a voltage stabilizer, the equipment will last a longer time.

It does not depend on the manufacturer's forecasts how many years the boiler will work. Its maintainability is of great importance. Therefore, it is better to choose so that, if necessary, it is easier to find service centers and spare parts.

Running on gas fuel, it is available to customers in a wide range. Modern models have many differences among themselves both in design and in functional content. The introduction of new technological solutions, as well as the use of materials with improved performance indicators, makes it possible to regularly improve the level of technical characteristics of such units.This is confirmed by gas industrial boilers of domestic production. Russian enterprises produce high-quality equipment in this segment, focusing not only on the experience of foreign colleagues, but also on their own developments. It is worth noting the economic attractiveness of mass production This is facilitated by two factors. First, the payback of products that are not cheap. Secondly, the demand for high-quality and efficient units.

Modern manufacturer of gas boilers Protherm. What are its advantages

Protherm products (Slovakia) are popular in the domestic market for a reason. All this is achieved due to the high performance characteristics of the equipment, its reliability and durability.

A wide range of floor standing, a variety of models both in terms of pricing and configuration, a huge number of service centers - all this had a positive effect on the demand for this company's equipment.

Protherm product range

Today, the following lines of gas boilers manufactured by this company are on sale:

- bear PLO are floor models with piezo ignition. They are volatile, that is, they have an electronic control system over the work;

- bear KLMO - these models have electric ignition and operate autonomously, that is, without human control, as they are equipped with power modulation;

- the KLZ bear is a floor unit, it has two circuits, therefore, in addition to heating the room, it is also designed for preparing hot water;

- TLO bear - floor-standing boilers with an electronic work control system are designed for heating small areas, as they have a power of 44.5 kW;

- Grizzly KLO - a floor unit, in addition to heating large (up to 1.5 thousand square meters) areas, they will prepare hot water for home and office.

Heating for houses and apartments is inevitably associated with material costs. Consumers know that the price range for gas boilers, installation and service assistance is quite high. For this reason, many seek to minimize the cost of acquiring, installing and operating boiler plants.

List of works

To understand what exactly should be cleaned, checked and adjusted in the boiler, with what frequency, it is enough to look at the instructions and technical documentation, which must be attached to the boiler upon purchase. These documents provide a complete list of components and elements involved in the equipment, maintenance requirements and the frequency with which to check the status, perform service and update settings if necessary.

It is absolutely impossible to focus on this information for self-cleaning of a gas boiler. This information gives a clear idea of what to expect from a service company with which to conclude a contract for the maintenance of gas equipment.

Works are conditionally divided into three groups:

- Regular work carried out before the start of the heating season and after it, preparing the boiler for summer inactivity.

- Capital service. Works carried out every few years and aimed at servicing elements with an initially long service life (flushing the heat exchanger, replacing seals and valves, maintenance of fans, etc.).

- Repair in case of breakage. The procedure for actions and mandatory work in the event of an emergency, breakdown or consequences of external factors.

Seasonal maintenance schedule

Before the start of the heating season, the boiler should be brought into proper working condition, the operation of the sensors responsible for safety should be checked. Only after that the boiler is switched on for operation.

If the manufacturer is allowed to carry out routine maintenance only once a year before starting, then in addition to commissioning, the main elements of the boiler are cleaned, with the exception of flushing the heat exchanger and a complete overhaul of the control units. If maintenance (maintenance) is carried out after the season, then cleaning is assigned to this stage.

Required list of works:

- General inspection, removal of dirt from internal and external surfaces.

- Cleaning filters (air, gas, coarse cleaning for water).

- Cleaning and checking the burner.

- Cleaning the fire section of the combustion chamber.

- Checking the tightness of the internal gas channels.

- Checking the ignition electrodes (piezoelectric element and burner).

- Test and diagnostics of the electronic control unit.

- Test and diagnostics of sensors and automation responsible for safety.

- Boiler parameters adjustment, combustion adjustment. The process is accompanied by the analysis of off-gases. According to the composition and concentration, the master judges the accuracy of setting the boiler.

- Checking the condition of the shut-off valve.

- Checking the gas supply pipeline in the section from the main to gas equipment.

- Checking and adjusting the pressure in the expansion tank.

Overhaul

In addition to routine maintenance carried out every season, during the overhaul of a gas boiler, elements with a limited warranty period are replaced, the internal surface of the heat exchanger is cleaned, seals and valves are flagged. The main task is to replace elements that are not subject to maintenance during routine maintenance, but still have a service life.

In the event of a breakdown

In an emergency situation, when a breakdown occurs during operation, it is very important to react to the problem as soon as possible and return the boiler to working condition. Breakdowns, if they appear, then just during the heating season, for example, if the boiler operates for a long time at maximum power in the coldest period of the year

At this time, it is extremely difficult to find a specialist for a quick repair, but with a service contract, all you need is to leave a request so that the repair team arrives in a short time to fix the problem. Since the service center keeps records of boilers, a specialist already arrives at the customer with a set of necessary tools and spare parts for a specific model of a gas boiler.

What factors should be considered

In addition to the class and price segment, other aspects also affect the duration of operation of gas equipment.

Heat exchanger material

Why is the service life of a wall-mounted appliance shorter than a floor-standing one? Perhaps the type of placement matters? No, just floor units are equipped with cast-iron or steel heat exchangers. For the same period of operation, their percentage of wear is significantly lower than that of copper radiators, which are installed in mounted boilers.

Copper is thinner than steel, and during operation it lends itself to oxidation and corrosion. Backlash in the heat exchanger can be soldered, but the unit will not last long. The average term of work is from 5 to 10 years maximum. Practice shows that copper radiators serve no more than 7 years, after which they must be repaired or replaced. They are more sensitive to the quality of tap water.

The type of heat exchanger also matters. An ordinary coil can be descaled on its own, and the boiler will continue to work. Bithermic radiators are not subject to cleaning, and the replacement of the node is almost equal to the cost of a new device.

Burner type

Gas appliances have two types of burners:

- Atmospheric - take air from the room to maintain the flame. Combustion products are discharged naturally with the help of traction.

- Supercharged or forced (turbo chambers) - clean air is taken from the street through a coaxial chimney. The power of the flame can be adjusted, the smoke is removed by a fan.

What about operating time? Forced removal of combustion products is more efficient. The boiler works with greater efficiency, which increases the efficiency and reduces the load on its units.

In devices with an atmospheric combustion chamber, a lot of soot accumulates in the holes and on the elements. As a result, the equipment spends more power to maintain operation, heating temperature, so the nodes fail faster.

Electronics and automation

Electronic models are equipped with control sensors, self-diagnostics and require connection to the network. Instability in the network, power surges lead to damage to the elements. We recommend installing a voltage stabilizer.

Operation features

The service life of heating equipment initially depends on the right choice. To do this, it is necessary to select the boiler, taking into account the characteristics of the room in which it will work, and the planned peak loads. It is recommended to choose a boiler with a power reserve of 15–20%.

Choose a room for the installation of equipment in accordance with the regulations. It shouldn't be damp inside. Corrosion quickly destroys the heat exchanger, so install an air vent to bleed excess air.

Also, the pressure affects the life span of the unit. To keep the performance stable, include in the expansion tank.

- Devices with steel and cast iron radiators have the maximum service life.

- Devices with forced draft burner are more efficient.

- With a voltage stabilizer, the equipment will last a longer time.

It does not depend on the manufacturer's forecasts how many years the boiler will work. Its maintainability is of great importance. Therefore, it is better to choose so that, if necessary, it is easier to find service centers and spare parts.

In the matter of economical use of equipment, it is important to take into account the service life of a gas boiler, because the more often it is changed, the more expensive the final operation of the entire system will be. The modern market for such units is able to offer many options for various designs.

All of them show their effectiveness in certain conditions. At the same time, in order to identify the most economical gas boiler for specific circumstances, you will need to familiarize yourself with their diversity.

Additional information about the device information about heat exchangers

Water-tube and fire-tube heat exchangers have their pros and cons, but they are used equally successfully in industrial thermal equipment. It is impossible to answer the question of which type of heat exchanger is better. Everything depends on the specific case.

For example, a boiler from the manufacturer Ferroli with a capacity of 8 MW has a coolant pressure of up to 10 bar. The design in this case is fire-tube and has three gas passages. The devices of this company have proven themselves as reliable and efficient units that are operated at various enterprises around the world.

But other Italian manufacturers offer steam-generating industrial gas boilers with water-tube heat exchangers for sale, which have high performance. Economizers are used to increase the efficiency of thermal installations. They are needed so that the device has the ability to take thermal energy from the exhaust gases. These nodes are optional devices. They are supplied complete with the boiler. Sometimes economizers are built into the unit, as is the case with Viessmann Vitomax 200HS equipment.

If you look, this is another fire-tube device, which is located at the end of the tract and lowers the temperature of the flue gases. This makes it possible to achieve an increase in efficiency by 6%, which, given the impressive volume of fuel consumption, is a good economy.

Steam models

This category of boilers is designed to generate steam.Most plants that use steam in their process require high pressure. Therefore, the performance of such equipment is made up of temperature and pressure indicators. For the most part, gas-fired industrial steam boilers are units that, through fire-tube structures, generate steam with a capacity of at least 0.25 t / h. Depending on the requirements of the enterprise, you can choose models with more power. As a rule, the maximum reaches 55 t/h. Pressure indicators, in turn, can be up to 30 bar, and temperature conditions - up to 300 ºС. Modern models are distinguished by the ability to work on various types of liquid and gaseous fuels. When choosing, it will not be superfluous to take into account the additional provision of equipment in the form of deaeration devices, dispensers and bubblers.

What factors should be considered

In addition to the class and price segment, other aspects also affect the duration of operation of gas equipment.

Heat exchanger material

Why is the service life of a wall-mounted appliance shorter than a floor-standing one? Perhaps the type of placement matters? No, just floor units are equipped with cast-iron or steel heat exchangers. For the same period of operation, their percentage of wear is significantly lower than that of copper radiators, which are installed in mounted boilers.

Copper is thinner than steel, and during operation it lends itself to oxidation and corrosion. Backlash in the heat exchanger can be soldered, but the unit will not last long. The average term of work is from 5 to 10 years maximum. Practice shows that copper radiators serve no more than 7 years, after which they must be repaired or replaced. They are more sensitive to the quality of tap water.

The type of heat exchanger also matters. An ordinary coil can be descaled on its own, and the boiler will continue to work. Bithermic radiators are not subject to cleaning, and the replacement of the node is almost equal to the cost of a new device.

Burner type

Gas appliances have two types of burners:

- Atmospheric - take air from the room to maintain the flame. Combustion products are discharged naturally with the help of traction.

- Supercharged or forced (turbo chambers) - clean air is taken from the street through a coaxial chimney. The power of the flame can be adjusted, the smoke is removed by a fan.

What about operating time? Forced removal of combustion products is more efficient. The boiler works with greater efficiency, which increases the efficiency and reduces the load on its units.

In devices with an atmospheric combustion chamber, a lot of soot accumulates in the holes and on the elements. As a result, the equipment spends more power to maintain operation, heating temperature, so the nodes fail faster.

Electronics and automation

Electronic models are equipped with control sensors, self-diagnostics and require connection to the network. Instability in the network, power surges lead to damage to the elements. We recommend installing a voltage stabilizer.

Operation features

The service life of heating equipment initially depends on the right choice. To do this, it is necessary to select the boiler, taking into account the characteristics of the room in which it will work, and the planned peak loads. It is recommended to choose a boiler with a power reserve of 15–20%.

Choose a room for the installation of equipment in accordance with the regulations. It shouldn't be damp inside. Corrosion quickly destroys the heat exchanger, so install an air vent to bleed excess air.

Also, the pressure affects the life span of the unit. To keep the performance stable, include an expansion tank in the piping.

Recommendations for choosing heating equipment:

- Devices with steel and cast iron radiators have the maximum service life.

- Devices with forced draft burner are more efficient.

- With a voltage stabilizer, the equipment will last a longer time.

It does not depend on the manufacturer's forecasts how many years the boiler will work. Its maintainability is of great importance. Therefore, it is better to choose brands of domestic production, so that if necessary it would be easier to find service centers and spare parts.

Any equipment has its own service life. Depending on the operating conditions, this period may vary to a greater or lesser extent, but there is always a calculated indicator that is guided by when choosing.

The intensity of work and the nuances of operation

Before purchasing, the necessary calculations regarding the power of the boiler installation are necessarily carried out. As a rule, in a design organization, specialists "throw" 15-20% of the power to reduce the load on the boiler at the time of peak loads. If the choice of the boiler unit is made independently, then often, in order to save money, a model is purchased, the power of which “back to back” corresponds to the calculated one. Continuous operation at maximum load significantly reduces gas boiler life

Therefore, when purchasing a device, you should ensure a power margin of at least 20%.

Corrosion can destroy a copper heat exchanger in a few years. To increase its service life, you need to get rid of the presence of air in the heating system, since oxygen is a powerful oxidizing agent. To do this, use air vents, regularly identify and bleed air from radiators through Mayevsky taps. We recommend that you watch the video.

In it, a specialist talks about the relationship between the service life of a boiler installation and corrosion in various types of heating systems.

The service life of the boiler is affected by the pressure in the heating and water circuits. The stability of this parameter in the heating system is carried out by a competent selection of the volume of the expansion tank. Due to the low pressure of the water, its volume may not be enough for the continuous operation of the burner. Having reached the required temperature, the burner will periodically turn off, and when the temperature drops, it will turn on. With prolonged operation in this mode, the resource of the device is developed much faster, which affects the life of the entire boiler unit.

Rules for the operation of hot water boilers

The latter are able to work on any type of fuel. Before operating the device, it is necessary to perform it strictly on the floor surface, it is better if a separate room is allocated for this. The operating instructions for the boilers must also be observed.

The equipment is equipped with all the required automation, so the operation process is simple. While the instrument is in operation, human presence may be required only to perform certain temperature changes and to shut down the equipment in an emergency.

Modern wall-mounted devices are mounted on the surface of the wall. Such equipment has compact dimensions, is convenient in the process of use, it does not require the allocation of a separate room.

Without exception, all hot water boilers purchased from a trusted manufacturer have a fairly long service life, are relatively simple and light, economical and very quickly installed.

How to choose a gas boiler

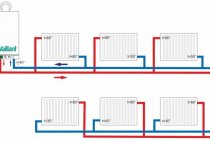

According to the installation method and the basic principles of operation, heating gas boilers are divided into groups:

- Mounted;

- floor;

- Condensing.

Each type has its own advantages and, as usual, disadvantages. To choose a thing that is really necessary in the household, you need to understand what are the differences between different models.

The mounted (wall-mounted) boiler is characterized by the following advantages:

- Profitability;

- The convenience of use;

- Compactness;

- Ease of installation.

If, in addition, we consider double-circuit gas heating boilers, then the advantages of the models include not only heating the house, but also the production of a sufficient volume of hot water for everyday consumption. The design of the device provides all the elements for the excellent operation of a home boiler room. This includes a circulation pump, an expansion tank, a safety valve, the necessary elements of a security system, etc.

The wall-mounted gas boiler is compact and fits perfectly into any interior.

When choosing a gas boiler, it is worth considering such options, the operation of which will be the most convenient and productive for the user.

For mounted models in this aspect, you should pay attention to the following characteristics:

- The presence of forced removal of combustion products;

- Possibility to use different power modes for summer and winter seasons;

- Minimal dependence on power supply, which allows the equipment to work even in the absence of electricity;

- Structural features of the burners, "adjusting" to the change in gas pressure.

Important! If you give preference to a gas boiler that operates strictly from the mains, then during power outages you can be left not only without light, but also without heat and hot water.

The floor heating gas boiler is valued for its reliability, relative cheapness and ease of operation. Its design does not change over time, as well as the materials used in production.

Most often you can find gas boilers with heat exchangers made of steel or cast iron.

Floor standing gas boiler - a traditional solution, characterized by reliability and excellent quality

The main division in this group is carried out according to the types of burners, which are:

- atmospheric;

- Supercharged (replaceable).

The first option is an inseparable part of the boiler design and is taken into account when forming the cost of the product. Atmospheric burners are easy to operate and have a quieter sound during operation. But at the same time, professionals recommend purchasing gas boilers with pressurized burners. There are several reasons:

- Higher efficiency in work;

- Possibility of operation of the boiler on gas or liquid fuel;

- Better functionality;

- High power ratings - up to several thousand kW.

For information! The power of gas boilers with atmospheric burners rarely exceeds 80 kW.

Also, floor-standing boilers are practically independent of electricity, that is, they are autonomous in operation. Previously, outdoor equipment was offered only as non-volatile. Now there are many imported models that are designed to European standards.

Therefore, it is extremely important to know what reviews and recommendations are on gas boilers. A thorough study of the information will help not to make a mistake in the choice.

A significant disadvantage for floor boilers is the need to equip a chimney. This fact complicates the installation of equipment and increases the requirements for the quality of its installation.

The condensing boiler has an efficiency of up to 120%

Condensing gas boilers are a separate group, as they differ in unique operating parameters. According to the installation method, the equipment can be both floor-mounted and mounted. However, the design of the boiler allows you to achieve efficiency from it that exceeds the 100% threshold. This makes the condensing unit the most economical of all models on the market.