Types of PPE insulation materials

At the moment, a huge range of products is being produced, which can be called thermal insulation from foamed polyethylene.

One of the differences between such products, which may not be noticeable externally, but is significant in operation, is the type of polyethylene foam from which they are made. It can be a "cross-linked" or "non-cross-linked" polymer, the first of which has higher physical and chemical properties (strength, operating temperature range, etc.). However, the design of the product usually plays an important role in the selection of an insulating product for a particular purpose.

Characteristics, properties and scope

To determine the harm of polystyrene as a heater, it is necessary to consider its properties, composition and method of manufacture

Special attention should be paid to the scope, since it is it that is the decisive factor in identifying the impact on a person.

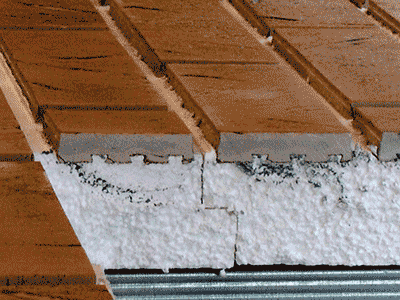

The structure of the material on the cut

insulation

As a material for protection from the cold, foam is almost indispensable.

- Its porous structure can significantly reduce thermal conductivity.

- Styrofoam perfectly holds its shape, which none of the heaters in this price category can boast of.

- It is more than 90% air, so it does not burn and does not support this process.

- In its manufacture, the minimum amount of styrene-containing substances is used, which is considered a decisive factor in determining environmental friendliness.

- The maximum service life of foam plastic exceeds 50 years. This is evidenced by the installation instructions and the quality certificate attached to most products made from this material.

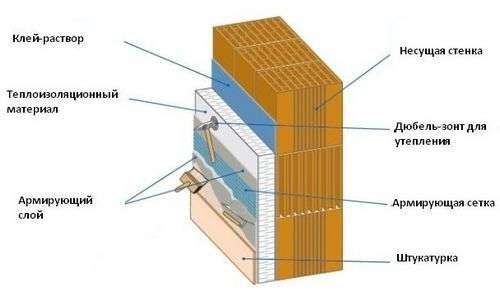

Use as external insulation of houses, amateur photo

Isolation of toxic substances

It is believed that the foam, when burned or strongly heated, releases styrene, which is very harmful to the body and in its pure form can become a real poison. However, the harmfulness of basalt insulation is sometimes much higher, especially if violations were made during its manufacture, which leads to the decision to use a less dangerous material, although it emits unnecessary substances.

The use of this material was approved back in the Soviet Union, taking into account the relevant GOST

Thus, it becomes clear that it is quite safe to insulate a loggia or other premises with foam. In cases where it will release harmful substances, there are many other materials, in the form of vinyl wallpaper and plastic interior items, that can cause more damage.

This material is very popular with rodents. What can indicate the absence of toxicity

Application area

Determining the degree of harmfulness of this material, it is necessary to consider the places of its use.

First of all, it is worth understanding that indoor foam is used only when plastic windows or entrance doors are insulated. In all other cases, cheaper materials are used. Therefore, its impact on humans is minimal.

Separately, it is worth noting the insulation of the walls in contact with the street. The fact is that it must be produced only from the outside (see also the article Insulation of facades with foam plastic: we make external thermal insulation with minimal time and money)

Otherwise, condensation will appear between the insulation and the wall, mold and fungus will form.

When drywall partitions are erected, it does not matter at all whether the basalt insulation is harmful or whether the styrene foam is released.In this case, both of these materials are placed in such conditions that their use is not only the most optimal solution, but also environmentally friendly.

The only unsafe place to use this insulation is a metal roof.

However, taking into account the fact that the foam plastic separates the waterproofing layer from the immediate incandescent area, and the vapor barrier film separates it from the living room, then its use for these purposes is quite acceptable.

Houses in Japan made entirely of Styrofoam

Research and practice

Many novice masters, doing installation work with their own hands, seek advice from specialists or the Internet. However, on the issue of the dangers of this material, there is no unequivocal opinion of the masters and reliable research by specialists.

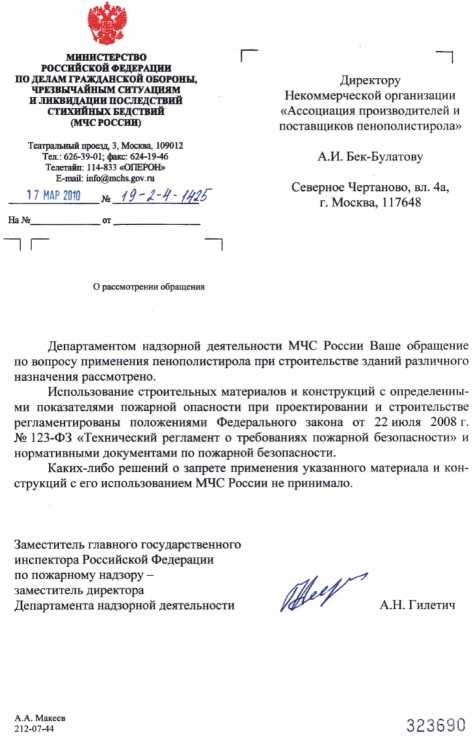

The response of employees of the Ministry of Emergency Situations to a request about the dangers of this material and its fire safety in the construction of residential buildings

At the same time, practice has shown that the location of the insulation and external influences on it cannot completely exclude the release of harmful substances. True, the probability of such cases is so small and requires certain conditions that it is not worth taking it seriously.

It is also necessary to remember that the price of other environmentally friendly heaters is very high, and their natural components also emit harmful substances during combustion or strong heating.

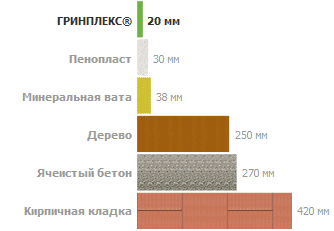

Thickness of different kinds of material to achieve the same thermal insulation effect

Styrofoam classification

regular foam

The main advantage of the material is the lack of ability to absorb moisture. In addition, it does not rot or biodegrade. Durable material, light weight and easy to use. It can be glued to any building material.

Expanded polystyrene is easily combustible, but it contains a substance such as a fire retardant. It is this that gives the foam the ability to self-extinguish. In addition, expanded polystyrene cannot be used for facade insulation. This is due to its low vapor permeability. And in order to carry out work with polystyrene under the roof, you should think carefully about the ventilation system.

Usage depending on material grade

- PSB-S 15. Styrofoam marking indicates that they can insulate structures that are not subjected to mechanical stress. For example, insulation of the roof, the space between the lines and the ceiling.

- PSB-S 25 and 25F. Common marking of expanded polystyrene. It says that you can insulate any surface. Walls, facades, ceilings or flooring, roofing.

- PSB-S 35 and 50. Such material can be used to insulate objects that are under constantly high load.

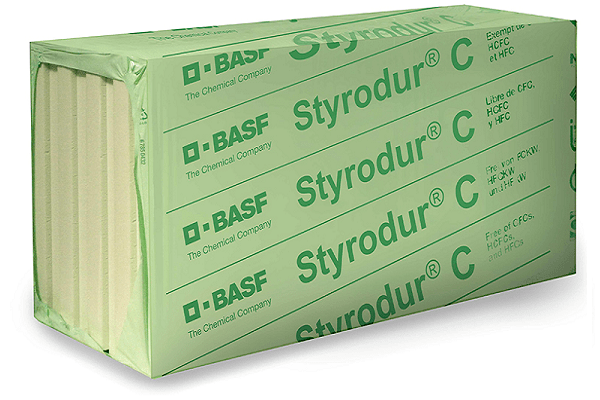

Extruded polystyrene foam

The structure of the material is cellular. And the complete closure of each cell provides absolute protection against water penetration. Therefore, such material is recommended to be used where the humidity is high or where the material can come into contact with water. This is the insulation of the basement or the foundation of the cottage. Even in conditions of insufficient waterproofing, extruded polystyrene foam will retain its thermal insulation qualities.

In addition, this material is highly resistant to various deformations. This feature allows you to use it as a heater for surfaces that carry heavy loads.For example, extruded polystyrene foam can be used to insulate facades. Especially if the lining material is very heavy.

As for the temperature. Expanded polystyrene is able to withstand sharp jumps, from -120 to +175 degrees. At the same time, its structure remains intact and unharmed.

The disadvantages of this material is combustibility, but, like foam, its constituent elements can cause it to fade. Contact of Styrofoam with complex carbohydrates can lead to destruction.

Properties and technical characteristics of EPP

Water absorption tending to zero. If the plate is completely immersed in water, then its sealed surface will not be able to absorb moisture.

The end parts are open, and therefore water can penetrate into the intercellular space, but its amount will be scanty.

Low thermal conductivity

(much lower than that of other materials), therefore representatives of construction specialties, manufacturers of refrigeration equipment and even road builders have long paid attention to extruded polystyrene foam.

Inability to rot, which is easily explained, because EPP does not come into contact with moisture.

Poor UV tolerance.

Expanded polystyrene extruded has outstanding characteristics due to the ordered cell structure, because it perfectly tolerates bending and contact loads.

High resistance to chemicals

, including saline solutions, alkalis, alcohols, acetylene, fluorinated hydrocarbons, etc. The material does not come into contact with oils, lime, cement, natural gases and their mixtures, but is afraid of dichloroethane and acetone.

Insignificant light transmission ability (for unpainted EPP).

The plates have a small thickness (15–20 mm), which in some cases is highly appreciated by people who are forced to use it for a wide range of tasks.

The melting point is 2500 C, and some grades of extruded polystyrene foam can melt at a temperature of 3000 C.

Temperature range at which the material can be used: from +750 C to -500 C

Sharp drops are undesirable, since it has been noticed that because of this, the EPP can be covered with cracks.

Useful video polystyrene foam and its characteristics

April 06, 2018

A person who buys a thing is always interested in its quality. Good quality usually determines the longevity of a purchase. Buying clothes, for example, he sensibly assesses the period of wear - from one season to several years. Then it will simply go out of fashion, dilapidated, or it will need to be repaired. When choosing finishing materials for repairs, a person also assumes that they are not eternal, and someday they just want to change. But there are things when buying which, we are only interested in their durability. I don't think anyone would want to buy a new drill or lawn mower for their house just because the old ones are out of fashion. Or, guided by the same principle, change the pump in your own boiler room. Moreover, we want such things to work forever! Unfortunately this is not possible. At the same time, even a complete breakdown of such mechanisms is not associated with great difficulties in replacing them. But there are materials that are quite difficult to change, if they lose their properties and, as a rule, this will be associated with high costs.

Here we will talk with you about the durability of insulation. In particular, insulation with non-extruded, foamed polystyrene foam, or as we call it - polystyrene foam. We do not consider extruded polystyrene foam as wall insulation now for a number of reasons that we will not mention in this article. A lot has been written about the service life of a mineral plate, but for polystyrene, it is difficult to find any results of serious research.

When building a house, a person hopes for the reliability of what he builds.He wants his children and grandchildren to use the creation of his hands, and for as long as possible, without any unnecessary repairs.

In Russia, houses are now insulated. And not because it has become accepted, but because it is necessary. On the face and economic benefits and comfort. Warming, as a rule, is inside, in a layer. In monolithic construction for insulation, the foam is placed between various blocks, facing bricks. In private, low-rise housing construction, after appropriate preparation and laying of a special reinforcing mesh, plaster is laid on it, making the so-called "wet" facade. The construction of sip or sandwich panels involves the laying of foam at the stage of their production, when between OSB sheets or painted rolled steel, a layer of expanded polystyrene is fixed by gluing. In general, almost always, any insulation is protected, in a layer. Minplita, for example, is afraid of moisture, and after it gets inside, it becomes useless as a heater, so it must be securely covered from precipitation. They have little effect on the foam, but one of its few drawbacks is that it is afraid of the sun, or more precisely, ultraviolet radiation.

In general, it is clear that given the inaccessibility of the location of the insulation, replacing it if it loses its low thermal conductivity and mechanical strength will not be easy, and sometimes almost impossible. For example, in the case of construction with sip or sandwich panels, this will essentially be tantamount to new construction.

What sizes of foam to choose for you

It all depends on your needs.

For example, if you decide to insulate the walls of the house with foam, then sheets of 1000 × 1000 mm and 1000 × 500 mm are suitable for solving this problem. The optimal thickness is mm.

Usually they buy sheets of 1000 × 1000 mm. And to fill the remaining areas, the existing sheets are cut into two parts:

You can also buy the required number of sheets of 1000 × 500 mm in size for these purposes. But this is in cases where the walls are even, without numerous elements that will prevent the laying of whole sheets. Otherwise, you will still have to adjust the width of the sheets frequently.

That is why many people buy polystyrene foam with dimensions of 1000 × 1000 mm to insulate the walls of the house. And in the process of laying, they are adjusted to the desired dimensions (the sheets are cut into pieces). This material is easy to cut, so everything is simple here.

Also, when choosing, consider the cost of sheets. For example, it may turn out that buying 1 sheet of 1000 × 1000 mm will be more profitable than two sheets of 1000 × 500 mm.

If you decide to buy polystyrene foam 2000 × 1000 mm, then keep in mind that such sheets can be more difficult to install. It is often easier to stack two sheets of 1000x1000 than one sheet of 2000x1000mm. Of course, much depends on the purpose for which you need this material.

In general, now you know what sizes of foam plastic exist. We hope you have already made your choice.

Application area

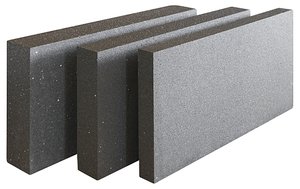

Extruded gray polystyrene foam has a wide range of applications. Mainly used for insulation work. The scope of use is limited only by temperature indicators (not higher than 75 ° C). The material can be laid in damp places, in the ground.

Usually the scope of use is limited only by financial possibilities. The high cost makes it impractical to use in many places. In places where there is no need for high technical characteristics, ordinary foam is used instead of PPS, reviews of which are also positive in order to save money.

Used for insulation:

- concrete or wooden floors;

- walls inside or outside the building. Compatible with any material;

- wells. It is not uncommon for concrete rings to be coated with a material for added protection;

- blind areas;

- the surface of the earth.To prevent destruction of the structure, paint is applied. Even a thin layer will not allow damage to the composition.

In addition to these areas, the material is used in road construction. Included in many refrigeration units as an extrusion heater. Used in agriculture. Expanded polystyrene insulates roofs, underground floors. One of the promising areas is the production of sandwich panels.

Specifications of extruded polystyrene foam

The material has one of the highest technical characteristics on the market for insulation products. Any gas has a much lower thermal conductivity than solids. For air, the indicator is 0.026 W / m * ° C. Extruded polystyrene foam is approximately 90% air-blended. It has a thermal conductivity of 0.03 W / m * ° C. Almost like air, which means that heat is retained perfectly.

The material is produced with different densities. Manufacturers offer from 25 to 47 kg / m3. The higher the number, the greater the strength. As density increases, strength increases from 20,000 to 50,000 kg/m2.

Water is poorly absorbed by polystyrene foam. In about a month, one tile is able to absorb about 0.4% of its own volume if it is completely immersed in water. Further, the percentage of absorbed fluid does not increase, but stops. Vapor permeability is minimal. It is 0.0128 Mg / (m * h * Pa). Often companies specializing in repair work suggest not to use a vapor barrier, limiting themselves to using only polystyrene.

The insulation is able to withstand temperatures ranging from -50 to + 75 ° C. Its use is possible in almost any climate. Flammability is high, the class varies depending on the addition of additional substances, from G1 to G4.

Some models have a special notch along the edges. Made to increase the density of the boards by insulating the seams. This innovation prevents the formation of layers of cold between the elements, ensuring complete preservation of heat.

Tests have been carried out with expanded polystyrene. Their meaning is repeated freezing, thawing of wet tiles. It was determined empirically that without changing the technical characteristics, the material can withstand 80 cycles. For users, this information is useful: for about so many years the composition can withstand operation.

Application area

Styrofoam as a heater can be used not only in civil engineering, but also in industrial.

Expanded polystyrene is used for insulation of the following places:

- walls, floors, ceilings;

- mansards, balconies, attics;

- roofs;

- foundations, plinths, cellars, blind area;

- fences;

- pipelines;

- for installation of heated parking lots;

- for the construction of drainage outlets;

- when creating sandwich panels and much more.

Styrofoam boards are lightweight and have convenient dimensions, as a result, they can be installed by one person, and in any position. For their installation, adhesive mixtures are used and, if necessary, special plastic dowel umbrellas. Metal fasteners are not used for insulation, as they conduct cold.

Reviews

“For a long time I could not decide what to buy to insulate the warehouse - mineral wool or polystyrene. But, after reading the reviews of buyers and builders, I decided that it was better to take expanded polystyrene plates, since they do not absorb moisture. Mineral wool, of course, will also not absorb and insulate well if covered with membranes, but its installation method did not suit me. Insulated with foam plastic 50 mm thick walls. Working with him is a pleasure, it couldn't be better. The plates are light, they are well attached to the adhesive solution and do not emit dust, which means that there is no harm to health from it.

Maxim, St. Petersburg.

“I join all the positive reviews about the foam. He really is one of the best heaters. Previously, there were always problems with the foundation and walls.In winter, the ground around it froze hard, swelled, and as a result, cracks appeared in the walls. Last spring, I insulated the foundation and the blind area near the house with foam plastic. The winter passed, not a single crack appeared, and the house became better, warmer.”

Kirill, Nizhny Novgorod.

“Before choosing a heater, I read a lot of reviews, and after weighing all the pros and cons, I decided to buy foam. Compared to other thermal insulations, it suits me better than others, since there is no need to make a frame. He insulated them with only one wall of the house, from the north side. I did all the work myself, since the plates are light, they are laid on the adhesive mixture. Additionally fastened with umbrellas-dowels. In winter, I immediately noticed that it became much better. The rooms are warming up faster than before.”

Andrey, Moscow.

“I have been insulating facades for many years and I can say for sure that polystyrene foam is an excellent insulation. It is cheaper than mineral wool and is easier and faster to install. At the same time, it has an excellent coefficient of thermal conductivity. It is easy to process and finish. Plus, it can last more than 30 years.”

Mikhail, Moscow region.

Price

The price of insulation depends on the thickness of the material, as well as the presence of additional properties (self-extinguishing). A table with prices at which you can buy foam from different manufacturers, sizes and thicknesses:

| Name | Dimensions, mm (length/width/thickness) | Price, rubles | |

| Knauf term | Roof | 1200x1000x50, 1.2 m3 | 5460 |

| Dacha | 1000x1200x20, 1.176 m3 | 2000 | |

| Wall | 1000x1200x30, 1.188 m3 | 3560 | |

| Dacha | 1000x1200x100, 1.2 m3 | 2190 | |

| Wall | 2000x1200x50, 2.4 m3 | 7200 | |

| PSB-S 15 | 1000x1000x60, 1 m3 | 2100 | |

| PSB-S 25 | 2930 | ||

| PSB-S 35 | 4130 | ||

| PSB-S 50 | 5380 |

In order to determine whether the foam is harmful or not, you should ask the seller for a quality certificate and check its composition. It is better to purchase those brands that do not use phenol-formaldehyde components in the production, and also have the largest number of positive consumer reviews.

Factors affecting thermal conductivity

Styrofoam boards are made in various thicknesses. Therefore, there are numerous factors that affect the thermal conductivity of a material.

- Layer thickness. To achieve high-quality energy saving, it is necessary to make the layer thicker. For example, a 5 cm layer will transmit less heat than a 1 cm layer.

- The structure of the material. Its porosity enhances the insulating qualities. This is because the cells contain air. And it retains the thermal conductivity of the foam well.

- Humidity. During storage, the foam must be protected from moisture. It adversely affects the characteristics of the material, even vice versa.

- Average layer temperature. If the temperature rises, there will be consequences. The efficiency of using the insulator will become worse.

Production technology and scope

The technology for the production of extruded polystyrene foam involves the use of foaming modifiers. In the role of gas-forming agents, light freons or carbon dioxide most often act.

If the pressure is released, the mass begins to expand, and along the way it cools. Ultimately, it hardens, and in order for this process to be not spontaneous, but directed, a plate of the required dimensions is immediately formed from the hot, thickened mass, which has a finely porous structure.

Important!

Freon is a gas that is unsafe for the environment, so modern manufacturers are trying to use freon-free technologies. Extruded polystyrene foam helped solve the problem of basement and foundation insulation

In addition, it is used to insulate the base of the roadway, is used in the construction of greenhouses, and it is also used for thermal insulation of refrigeration chambers.Modern builders construct thermal insulation of underground structures only with the participation of the EPP, as well as communications. Application is possible, both during construction work and in the process of finishing.

Extruded polystyrene foam helped solve the problem of basement and foundation insulation. In addition, it is used to insulate the base of the roadway, is used in the construction of greenhouses, and it is also used for thermal insulation of refrigeration chambers. Modern builders construct thermal insulation of underground structures only with the participation of the EPP, as well as communications. Application is possible, both during construction works, and in the course of finishing.

-

Penoplex

. It is intended for warming of various designs. Distinctive feature: the presence of a "thorn-groove" system that simplifies installation. -

Primaplex.

It has all the properties that extruded polystyrene foam is endowed with. This variety combines all the main technical characteristics. -

stickers

. This brand serves as the basis for the manufacture of sandwich panels. Stickers is also involved in the creation of roads and runways. -

URSA EPPS

. A product endowed with more pronounced heat-insulating properties than penoplex - extruded polystyrene foam. This determines its application: for vapor and waterproofing and insulation of foundations. - Other varieties (technoplex, europlex, etc.) have minor differences in properties and characteristics.

Advantages for warming balconies and loggias

Considering the above, polystyrene foam, the properties of which allow this material to be used in different weather conditions, is well suited for the performance of work on the insulation of various premises, including balconies and loggias of urban-type apartments.

For external and internal insulation of walls, floors and ceilings in these rooms, sheets of expanded polystyrene grade PSB-S 25 with dimensions of 1000x1000 and 1000x500 mm are most often used. It is convenient to work with them due to the minimum number of joints during installation.

The advantages of foam:

- Low cost. The use of this material allows you to reduce the cost of landscaping a balcony or loggia, without losing the quality of the thermal insulation.

- High thermal insulation characteristics. In terms of thermal conductivity, an 80 mm thick foam plastic sheet corresponds to 100 mm of mineral wool, 274 mm of wood, 760 mm of brickwork and 1720 mm of concrete. Thus, with its minimum weight, it provides a sufficient level of thermal insulation of the balcony, without creating additional load on the load-bearing parts of the structure.

- Ease of use. Styrofoam is easy to carry, cut and install, so it is well suited for insulating various surfaces of balconies and loggias, including their outer part.

- Safety in use. Polyfoam has excellent antistatic characteristics and does not absorb moisture, which distinguishes it from another popular insulation - mineral wool. It is also environmentally friendly and non-toxic material.

And below is a short video showing the foam production process.

Material selection rules

Demand for expanded polystyrene is high, increasing annually. In order for the insulation to last as long as possible, to perform all the required functions without failures, it is necessary to make the right purchase. Each manufacturer claims that his product is the best on the market, but this is not always true.

Selection rules:

- Polystyrene is designated by two numbers. If the marking is below index 28, you should refuse to buy. Checking is required, some brands of the product are not suitable for facade work, they will not cope with the insulation of the house. Choose material with an index of 40 or higher.The PSB-S-40 brand, a self-extinguishing composition, has proven itself well.

- Before buying, look at the standards on the basis of which production was carried out. Many manufacturers make plates not according to GOSTs, but to their own specifications. Possibly defective product. Usually the density is reduced, thereby reducing the cost. You should not focus on the number of the brand, be sure to familiarize yourself with the characteristics.

- To ensure the high quality of the product, you can break off a small piece from the edge. If small balls are visible at the fracture site, the styrofoam is probably low grade. At the break, there should be polyhedrons of regular shape. The broken piece is flat. The test shows the method of production: extrusion performed on professional equipment, or an artisanal method, like a simple foam.

- Purchase goods from reputable manufacturers. These are Penoplex URSA, Knauf and TechnoNIKOL - Russians. Basf or Novachemicals are foreign.

Do not forget that the production of expanded polystyrene is a complex technological process. Production methods differ among many manufacturers. Some are safe, others can be harmful to human health.

1 Material features

The use of foam as a heat-insulating material is widespread, both in industrial and private construction.

The main reason for this is the cost of this material with foam adhesive, which, with technical characteristics comparable to other heaters, is an order of magnitude less. After analyzing all the features of the use of foam as a heater, we can draw the following conclusions:

- The technology allows to reduce the financial costs of insulation. For example, even if we take into account that the cost of mineral wool and polystyrene foam is identical (in reality, a cubic meter of foam plastic costs about 2 tr, mineral wool - 4-6 tr), then for thermal insulation of the same surface, mineral wool will be needed in on average, one and a half times more than polystyrene;

- Simplification of installation - there is no need to create an additional supporting structure, the sheet is mounted on the walls with an adhesive solution.

By means of this material, it is possible to carry out the insulation of any surfaces - walls, ceilings, floors, facades, roofs, interfloor ceilings.

Styrofoam is also often used as the main insulation inside the walls of houses built using frame technology, and free space inside hollow brick walls.

house insulated with styrofoam

to the menu

Variety and indicators of foam

The construction market offers a large selection of insulation materials. Styrofoam has low thermal conductivity. But this figure may vary, depending on the type of polystyrene. When compared with other heaters, certain conclusions can be drawn. For example, a foam sheet with a density of 50-60 mm can be replaced with a large volume of mineral wool. Material with a density of 100 mm can be replaced with foamed polystyrene with indicators of 123 mm. The characteristics of these types of heaters are somewhat similar. Therefore, the difference is small. The performance of polystyrene exceeds the characteristics of basalt wool.