Why do you need a heat exchanger in the heating system

A heat exchanger is a device that transfers heat from one heat source to another, while excluding direct contact of heat carriers. Therefore, theoretically, a heat exchanger can be installed in any heating system, the main thing is that this would be useful, since the cost of the heating system itself increases in direct proportion to the load, or simply the cost of the installed heat exchanger itself with regulating measuring and control equipment.

The main field of application of heat exchangers in the heating system is an independent heat supply system. To understand why we need this, we need to make a short digression into the nature of the heating networks available in our country.

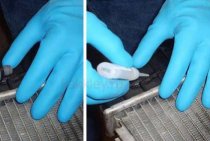

Dependent heating system operating without a heat exchanger.

Individual substation designed to operate in a dependent heat supply system without a heat exchanger

There are two heating schemes or how to say heat supply correctly. The dependent heating system, with which we are all well acquainted, is when the boiler, heating water, supplies it through pipelines directly to the heating devices - heating radiators in the apartment, bypassing the heat exchanger. Of course, in such a scheme there is a heating point, regulating and measuring instruments, sometimes weather-dependent automation is installed. Only without a heat exchanger, we can influence the temperature in the batteries, which means that in general in apartments we can only decrease the temperature.

For boilers in a boiler room, such a scheme is also not convenient, it requires large pumps, boilers and pipes of the heating network work like an accordion, which is why they are constantly torn, and it’s better not to remember about heat leaks and heat losses lost at the same time. But at the initial stage, without installing a heat exchanger in the heating system, it turns out to be quite cheap, but not efficient, the boiler room does not know how much heat everyone needs, and the consumer is not able to influence the production of heat for heating, hence the overheating and low energy efficiency of such a heating system without separation heat exchanger.

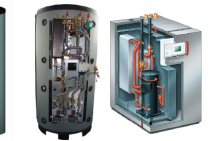

Independent heating system with heat exchanger.

Individual heating substation designed to work in an independent heat supply system with a heat exchanger

The heat exchanger in such a heating system is the main device that allows you to save. Of course, it is not he who saves, he only separates the media from each other, automation saves. How does it save? Here is an example of an independent heating system - a modern centralized heating system, it has one main heating point that distributes heat and additional heat exchangers for each consumer already installed in the ITP of residential buildings.

From the boiler house to the central heating point, where the main heat exchanger is installed, heat is supplied in a rigid, fixed thermal regime - for example, 95 degrees on the supply and theoretically 70 degrees on the return. The boiler house does not need automation and operators, the power of the pumps and the diameter of the pipes of the heating network can be much smaller, there are no leaks in the boiler circuit by nature. Sometimes a high-power heat exchanger is installed directly in the heating system of the boiler room, then the circuit is double and in boilers, due to the small volume of coolant in the internal circuit, there is no scale, the boilers last forever.

Block heat substation designed to operate in an independent heat supply and hot water supply system with heat exchangers

By installing a heat exchanger in the heating system, the consumer gets the opportunity to influence the temperature in the apartment, as much as everyone needs and will take, of course, if control devices are also installed in the apartment on batteries. There is a benefit for everyone.

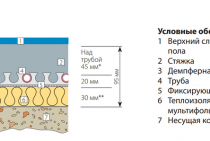

How to connect a warm floor to the heating system through a heat exchanger.

You need a heat exchanger for underfloor heating.If, for example, you want to make a warm floor, by inserting it into the heating system without a heat exchanger, you will leave the whole house without heat, there will be little heat on the floors, but the water - the coolant will circulate only through your floor and will not go to the neighbors, she is "lazy and takes the shortest route.

There is only one drawback of installing a heat exchanger in a heating system, an increase in costs at the initial stage of installation, but it is more than offset by all its advantages.

It is easy to upgrade a dependent heating system into an independent system by installing an additional heat exchanger with control equipment. True, this will have to be done simultaneously in the entire area connected to your boiler room. But in this way you can save up to 40 percent on heating costs, compared to your current costs without installing such a necessary heat exchanger in the heating system.

Heat exchangers in hot water supply. Hot water supply of a private house

Some people actually suggest doing so. Usually this coefficient is calculated that the water temperature is 60gr. But in fact it can be 65 and 70 gr. So, in my opinion, it is not entirely correct to subtract any normative from the actual testimony. But regardless of my opinion, the formula must be approved by the government of the Russian Federation. All other invented formulas are debatable. You will also subtract from the readings of the heat meter the calculated Qhvs according to the cold water flow meter and you will have a difference that you can no longer write off for heating.

And in fairness, it should be noted that even in winter, the difference between the heat actually spent on heating water and received by calculation according to Vgvs will be distributed in proportion to the area of apartments, even in the form of heating. A resident who, for example, was on vacation for a month and did not use hot water, will pay for the fact that the neighbors underpaid using water not 60g, but 70, but already as part of the heating fee.

Thus, the rights of this person will be infringed. There should be no influence of one resource on another. There are also technical solutions to this problem, but they should also be spelled out in the rules. For example, you can install 2 heat meters, one for heating and one for a water heater, and TCO is calculated as the sum of these indicators. But this option does not fit in with the rules for accounting for thermal energy and TSO most likely will not accept such a metering unit. It is possible to reconnect the water heater to the heat meter, then the heat meter will count only heating, and the water heating will be calculated by the volume of heated water.

Again, TCO will not accept this, as it is not provided for by the rules for accounting for thermal energy. This issue of accruals is still open and painful.

Causes stress among residents. From time to time, courts make decisions taking one side or the other. In our city this month there was a similar court in one of the Criminal Codes. The court decided to recalculate the owner of the apartment for heating according to the readings of the OD PU heat, but did not say how. Accepted the calculations made by the plaintiff from his personal guesses.

DIY manufacturing

Homemade copper heat exchanger coil

Making a decision about self-production, as a rule, indicates the presence of some kind of tool and skills in working with it. Ideally, you need a full-fledged workshop with a vice, welding (two types), a workbench, an anvil, etc. If the equipment leaves much to be desired, it is possible to assemble the simplest modification - a copper spiral coil.

Pros of this option:

- Copper is relatively easy to bend and solder.

- The serpentine does not contain connections exposed to strong heat.

- The spiral shape is simple, versatile, and does not require complex equipment to give it.

- The installation of such a heat exchange device will not require a major modernization of the furnace structure.

A sauna stove with such a heat exchanger will cope with everything that can be expected from it: it will ensure the operation of 2-3 heating radiators, it will heat water in a small tank. Nevertheless, the heater is responsible for the microclimate in the steam room.

Consumables

Of the special tools for working with copper, only a gas burner is needed. A professional will need a pipe cutter, a beveler, a metal brush of the right size. However, all this is replaced by a grinder, a file (rasp), a soft abrasive sponge. Consumables will also need a minimum:

- annealed copper pipe in a coil d32, 3.5 - 4.5 m long (depending on the d of the chimney);

- transitional water sockets (thread-soldering) d32 * 1.25” - 2 pcs;

- conventional low temperature and hard copper solder for medium temperature soldering (650 - 750°C);

- paste "flux";

- soft abrasive sponge;

- propane-butane gas for medium temperature soldering - 1 cylinder (0.5 l);

- washed sifted fine sand - 5 - 6 kg;

- pipeline, taps, Mayevsky valves, radiators.

You need a "pipe bender" - a smooth round log. With it, the heat exchanger for the sauna stove will take the form of a spiral coil. The length of the log is not less than 1 m, and the diameter is equal to the dimensions of the chimney at the outlet of the stove. As a rule, the parameter depends on the size of the furnace and is never less than 10 cm.

Assembly algorithm

The most difficult part of the assembly is giving a spiral shape. To do this, the pipe will have to be bent using a rigidly installed log. Unannealed copper cannot be bent, so you need to buy exactly the one in the bays. The easiest way to install a "serpentine" heat exchanger in a brick oven (for heating) is to mount it on a chimney. Action algorithm:

- Plug one end of the pipe securely, for example with a soldered factory plug.

- Fill the pipe with sand, spilling water, tapping with a hammer, compacting with a “ramrod”. It can be a metal-plastic pipe or a plugged rubber hose.

- When the pipe is full, compact the filler as much as possible, then plug the other end. Try to keep the sand from "decompacting".

- Screw a U-shaped or round clamp to the log, which will hold the pipe tightly. The base "P" is perpendicular to the pipe bender closer to the end, and the location around the circumference does not play a role.

- Insert the end of the bay into the clamp, start slowly winding the pipe onto the log.

- If a hall has appeared somewhere, it means that the sand is not dense enough in this place. It is advisable to start all over again, but, theoretically, you can try to tap the hall with a hammer.

- If the d of the chimney is 150, and the length of the bay is 4.5, you should get 8 - 9 turns of the spiral (no more than 35 - 40 cm high), as well as two "tails" of 30 - 40 cm each.

- Cut off the plugs, clean the sand, rinse the coil.

- Solder transitional water sockets to the ends of the spiral.

- Remove the cover covering the heater or dismantle the slide damper (remove part of the chimney).

- Put the "serpentine" on the pipe as close as possible to the stove.

- Reassemble the chimney, taking into account the necessary sealants, windings (if any).

Now you can install and connect the remaining elements of the heating system, including an open samovar-type expansion tank, pipeline, taps, radiators, air valves. To improve natural circulation, the diameter of the pipeline should not be much smaller than the dimensions of the coil. Ideally, it will also be copper, of the same diameter.

Norms and schemes of hot water supply in apartment buildings

Advantages of heat exchangers for hot water from heating Using heat exchangers to produce hot water has several significant advantages: High performance - if you need to supply water to several points at the same time, the device will perfectly cope with this task. Savings - you do not need additional energy sources. So, unlike boilers and instantaneous heaters, such a device does not consume gas and electricity. Compact dimensions - the heat exchanger does not take up much space. Easy installation and maintenance - the device is easy to connect, and it will take only a few hours for preventive cleaning and disassembly. The disadvantages include the need for cleaning - the device will have to be periodically cleaned of scale. Sometimes this requires disassembly and mechanical cleaning, sometimes rinsing with a special compound is enough.How is the heat exchanger calculated? In order for the device to work effectively, it is necessary to choose its parameters correctly: the material of manufacture, the number of plates, the heat exchange area, the connection diameter, etc.

Heat exchanger installation options

Installing a heat exchange device of any kind involves a considerable amount of work, especially if its efficiency is of great importance. For example, the simplest spiral on the chimney can warm up slightly, and there can be no circulation at all without a pump. Then you have to take measures, up to the rejection of such a design. In practice, one heat exchanger for a furnace installed in different places produces different efficiencies. It is conditionally possible to compile such a TOP, starting with the most effective variety:

- cast iron or steel U-shaped register in the furnace;

- a water jacket around the firebox or at any of its surfaces;

- U-shaped diplomat in the firebox;

- diplomat directly above or behind the firebox, with maximum contact;

- water jacket around the heater;

- register, diplomat or serpentine heater;

- diplomat or serpentine behind the stove;

- water jacket on the chimney.

A chimney coil is conditionally the least efficient option. However, the simplicity of the device often offsets the shortcomings. In addition, efficiency is increased in various ways. Among them is lining the coil with a thermally insulated casing with filling voids with sand or installing the structure directly into the heater.

Correct connection

- the higher the run-up of the pipes of the heat exchanger in height, the better;

- the expansion tank is placed as high as possible, next to the stove;

- a pipe goes to the tank from the upper pipe;

- the pipe from the expansion tank goes to the lower radiator inlet;

- all horizontal sections are made at an angle (at least 3 mm per 1 m);

- exit from the radiator only from the opposite side or diagonally.

Another important point is the permeability of the pipeline. The higher it is, the better. Therefore, you should not narrow the diameter, build in extra elbows, fittings, or use rusty or plastic pipes from the inside.

Annex a Example of calculation of a single-stage parallel scheme for connecting hot water heaters

Initial

data:

1.Temperature

coolant (heating water) is accepted

(at design outdoor temperature

air for heating designt=

- 31ºС):

—

in the supply pipeline

=

100ºС;

—

in the opposite

=

70ºС.

2.

Cold tap temperature

water tWith=

5ºС.

3.

Hot water inlet temperature

in SGV th=

60ºС.

4.

Estimated thermal output

water heaters,

Qsph=Qhm=QhT\u003d 12180.9 W.

5.

We accept the density of water =

1000 kg/m3.

6.

Maximum Estimated Flow Rate

hot water qh=

0.65l/s.

Order

calculation:

Estimated

heating water consumption, kg/h, calculated by

formula:

(A.1)

whereQhm

- calculated thermal performance

water heater, W;

With

– heat capacity of water, equal to 4.187 kJ/kg g;

τ1

- the temperature of the heat carrier in the supply

pipeline, ºС;

τ2

- the temperature of the heat carrier in the reverse

pipeline, ºС.

=

349 kg/h;

Consumption

heated water for hot water supply, kg / h, we calculate

according to the formula:

(A.2)

whereth-temperature

hot water entering the SGW, ºС;

tWith

- cold water temperature

water, ºС.

=

190.3 kg/h;

Temperature

DHW water heater pressure, ºС, calculate

on

Formula:

(A.3)

ºС;

Necessary

section of water heater tubes, m2,

at speed

water

in tubes

=

1 m/s and

2 MW in single line configuration,

we calculate according to the formula:

(A.4)

whereGhm

- consumption of heated water for hot water supply, kg / h;

—

coolant density, kg/m3.

=

0.00005 m2;

By

the obtained value of the cross section of the tubes

water heater we select the type of section

water heater with characteristics:

=

0.00062m2;

=

57 mm; = 0.00116 m 2;

\u003d 0.013 m; \u003d 0.37 m 2;

= 0.014 m.

Speed

water in the tubes, m / s, we calculate by the formula:

(A.5)

where

— section of water heater tubes, m2.

=

0.09 m/s;

Speed

network water in the annular space,

m/s, calculate

on

formula:

(A.6)

where

- section of the annulus

water heater, m2;

Gd- settlement

heating water consumption, kg/h.

=

0.08 m/s;

Medium

heating water temperature, ºС, calculate

according to the formula:

(A.7)

=

85 ºС;

Medium

heated water temperature, ºС,

we calculate according to the formula:

(A.8)

=

32,5;

Coefficient

heat transfer from heating water to the walls

tubes,

W/m2

ºС, we calculate by the formula:

(A.9)

where

— average temperature of heating water, ºС.

=

1082.4W/m2

ºС;

Coefficient

heat transfer from the tube walls to the heated

water,

W/m2

ºС, we calculate by the formula:

(A.10)

where

is the average temperature of the heated water,

ºС.

=742.6W/m2

ºС;

Coefficient

heat transfer, W/m2

ºС, at

= 0,9;= 1,2;

=

105 W / m ºС, we calculate by the formula:

(A.11)

=

489W/m2

ºС;

Required

heating surface, m2,

we calculate according to the formula:

(A.12)

whereK

– heat transfer coefficient, W/m2

ºС;

∆tWed

- temperature head of the water heater

DHW, ºС.

=

0.5 m2;

Number

sections of the DHW water heater we calculate

according to the formula:

(A.13)

=

1.35pcs;

Accept

two sections, real surface

heating:

Ftr=

0.37 × 2 = 0.74 m2.

V

the result of the calculation turned out 2 sections

in a heater with a heating surface

0.74 m2.

Losses

pressure in water heaters (2

consecutive

sections

2 m long) for water flowing in pipes

with considering

= 2:

(A.14)

whereqh

— maximum calculated second

water consumption for hot water supply, l / s.

=

22 kPa;

Losses

pressure in the DHW tank for

water passing

v

annular space, taking into account B =

25, we calculate by the formula:

∆Рgr

= In ··n,

(A.15)

∆Рgr

= 25 ··

2 = 0.32 kPa.

Accept

designation of this calculated

heat exchanger:

57

× 2 - 1.0 - RG - 2 - U3 GOST 27590-88.

Heat exchanger for hot water from heating

Important: the advantage of the second version of the water supply system for a residential building is the best water quality, which is regulated by GOST R. Also, when hot water is taken from a centralized heating main, the temperature and pressure of the liquid are quite stable and do not deviate from the specified parameters: the pressure in the pipeline of the hot water supply system is maintained at the cold level water supply, and the temperature is stabilized in a common heat generator. Consider the water supply of an apartment building according to the second option in more detail, since it is this scheme that is used most often both in the city and in country houses, including country or garden houses

What elements does the water supply scheme of an apartment building include? The water meter unit, which organizes the supply of water to the house, is responsible for the operation of several functions: It takes into account the consumption of cold water supply, that is, it performs the function of a water meter; It can shut off the supply of cold water to the house in case of emergency or if it is necessary to repair components and parts, as well as to eliminate leaks; It serves as a coarse water filter: any hot water supply scheme of an apartment building should contain such a mud filter.

Comparison of single-stage and two-stage DHW connection scheme

Boilers for water heating

Indirect heating boilers

Information

Normative documents

Articles

news

plastic tanks

Products

Drazice

Elbi

Tatramat

Thermal cleaners

Accessories for heat exchangers

Heat exchangers

Plate heat exchangers

Collapsible lamellar STA

Automation, pumps, drainage and submersible pumps Pedrollo

Pedrollo PQ vortex pumps

Drainage pumps Pedrollo MCM

Pump Pedrollo F

JCR pumps

JDW Pedrollo pumps

Pedrollo JSW pumps

Pumps Pedrollo CP

Pedrollo PLURIJET pumps

Pedrollo SR pumps

Pedrollo ZXM pumps

Pedrollo NGA pumps

Pedrollo HF pumps

Surface pumps PK

TOP submersible pumps

Pedrollo circulation pumps DHL

Automation and pumps Grundfos

Storage tanks and tanks

Accumulator tanks for hot and cold water Elbi

Ferroli boilers

Ferroli vertical boilers

Zani water heaters

Water treatment

Hydraulic accumulators and expansion tanks

Other equipment

Shut-off and control valves

gate valves

Shut-off and control valves

Shut-off valves

Protective fittings

steam traps

Instrumentation

Ball valves

Control valves

Sight glasses

Thermal automation

Storage tanks, boilers and water heaters LAM

Pump equipment

Modular pumping stations

Pedrollo pumping stations

Pumps and automation for Wilo pumps

Wilo MHI booster pumps

Wilo MVI booster pumps

Water pumps Wilo IL

Circulation pumps Wilo RS

Circulation pumps Wilo TOP-S

DHW circulation pumps TOP-Z

Shell and tube heat exchangers

Pressure maintenance systems, boilers, Reflex membrane tanks

Control boards

Pedrollo pump control panels

Design

Items in the widget next to the certificates (do not delete)

Service of heat points

Heat meters

Services

Spare parts supply

Accessories for heat exchangers

Types of heat exchangers

A simple device can be effective in different ways - depending on the type. Classification is carried out according to several criteria. Various models of factory or handicraft heat exchangers, for example, in a bath, differ:

- construction,

- installation site,

- material.

These factors influence each other and the characteristics of the heat exchange unit as a whole: its cost, efficiency, performance, system volume, installation complexity, etc.

Design

Design differences largely depend on the purpose of the product. For example, heating water for washing involves a significant volume and intense heat transfer. And the use only for heating requires a gradual transfer of heat to the coolant.

- The coil is a pipe bent at different angles. Warms up quickly, but often does not have sufficient volume. Suitable for installation in a wood-burning firebox, behind the firebox, in a heater, on a chimney (if the coil is spiral).

- The register is an analogue of a pipe radiator, perhaps the most popular, versatile, and energy efficient. As a rule, these are several large-diameter pipes connected by thin tubes. The choice of a specific form and installation location is limited by the author's imagination, as well as by the general scheme.

- Diplomat - one or more interconnected containers with nozzles. This is a common model, easy to assemble and install. A sauna stove with a heat exchanger of this type will provide heat, heat, hot water. Disadvantages - a significant volume reduces the heating rate, limits the choice of location for installation. The primitive form does not contribute to the full heat transfer, interfering with the heating of the parts of the stove itself. Therefore, it is well suited only for installation inside the heater (if we are talking about a bath), behind it or behind the firebox.

- Water jacket - a casing installed on the parts of the heat generator heated from the inside. Often this is a cylinder with nozzles, put on a chimney.Difficult for handicraft assembly, prone to leaks, but does not require disassembly of the stove for installation and is quite effective.

The choice of model is usually associated not so much with efficiency and price, but with the complexity of the installation. For example, some modifications of water "jackets", "coils" and "diplomats" are mounted without dismantling the furnace. The maximum is the modernization of a part of the pipe or the replacement of a cast-iron stove (for cooking) with a “diplomat”.

Material

When designing a stove or fireplace with some kind of heat exchanger, an engineer (or stove maker) takes into account the parameters of the materials. Required properties - fire resistance, elasticity, resistance to corrosion, heat capacity, thermal conductivity. Only metals have these characteristics.

- Steel is excellent in all respects except corrosion resistance. However, if the coolant is always filled, it will not rust.

- Stainless steel has no disadvantages other than high price and difficulty in welding. Galvanized steel is almost never used due to toxic emissions associated with high temperatures.

- Cast iron, the disadvantages of which are the complexity of welding and the high probability of cracking (due to sudden temperature changes during uneven heating).

- Copper, which is good for everything, except for the high price and the connection of parts by soldering. Solder "does not hold" strong heat if the water is drained, so the use of copper is limited.

The choice is usually related to the availability or availability of the material. Often there are bath stoves with a cast-iron heat exchanger, which is a modified battery. Refinement consists in welding the joints of sections and plugs in extra holes. Thus, a heat exchange register is obtained that has all the necessary properties. Its disadvantage is bulkiness, which limits the choice of location.