How to replace the heating element in the boiler

The need to replace the heating element arises when it malfunctions. When it stops heating the water, an electrical safety device is activated. The average service life is 4 years. Then it fails due to increased water hardness. This event can be delayed if the boiler is serviced annually: the heating element and the magnesium anode are descaled. This operation will increase the duration of operation and improve the quality of water, the rate of its heating. Before purchasing a new element, it is worth checking the condition of the old heating element using a test lamp or a multimeter. In the first case, a simple electrical circuit is assembled, including a lamp and a heater. If the light is on, it's not the problem. In the second case, the resistance is measured with a special device. A zero value indicates a malfunction of the heater.

The designs of different models of boilers have minor differences, but the very principle of replacing a heating element in a water heater is the same for all types of devices.

To begin with, the water supply is turned off, and the remaining liquid is drained from the boiler. The water heater must be de-energized by pulling the plug out of the socket. At the bottom of the boiler there is a cover that is fastened with screws. They need to be unscrewed with a screwdriver, and the cover will be removed. For safety reasons, before proceeding with the replacement of the heating element in the boiler, it is necessary to check the presence of voltage at the terminals, for example, using an indicator screwdriver. Then the wires are disconnected and the nuts holding the heater in place are unscrewed. They replace the heating element on the water heater, after checking that the contacts are dry. If an anode is installed in the boiler, it is also replaced. Check the seal for leaks and screw the cover into place. After these manipulations, it is necessary to fill the boiler with cold water and bleed air from it by opening a hot water tap. Only now can you turn it on.

Criterias of choice

When choosing a heating element for a boiler, it is necessary to build on the characteristics of the previously installed element.

Varieties of devices

In addition to the type of heating element in contact with the liquid, a lot of other parameters must be taken into account:

Mounting method - nut or flange. The latter is cast or stamped. Flange mounting is typical for open-type heating elements;

The possibility of installing an anode - this element is designed to protect metal surfaces from corrosion and scale, thereby increasing the overall life of the boiler. Gradually, the anode "melts", so periodically you need to install a new one. If a hole for the anode is provided in the base of the heating element, then a new heater with the same hole is required.

The shape depends on the type of storage tank. The heating element can be straight or bent. They choose a heater similar to the previously installed heating element, taking into account not only the shape, but also the size, as well as the bending angle.

Production material - the outer surface of the heating element can be made of copper or stainless steel

It is important that the material of the tank and the heating element match, otherwise, due to the potential difference, the service life of the heating element and the tank itself will be reduced. A closed-type copper heater can be placed inside an enamelled steel bulb, in which case you don't have to worry about creating a galvanic couple.

Features and amount of heated liquid

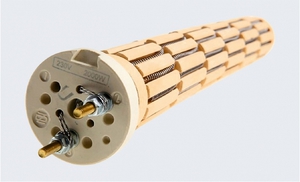

Heating element with magnesium anode for hard water

Heating element with magnesium anode for hard water

If the water is hard, a heating element under the anode is needed, which will partially eliminate the scale problem and extend the life of the boiler. Power must correspond to the volume of the heated liquid. It is recommended to purchase a part of the same power as the failed one. The heater parameters are specified in the technical data sheet of the device.

Operating conditions

Power must match the capabilities of the wiring. But this already applies more to the choice of a boiler, and not a heating element, since the old element is replaced with a new one of similar power. The power of the boiler as a whole also affects the rate of heating of a given volume of water. If the heating element is low-power, for example, 1000 W, and the capacity is 80 or even 100 liters, the water will heat up to the maximum temperature for a very long time, several hours, so you need to turn on the boiler in advance. This power is optimal for small boilers, up to a maximum of 50 liters.

If you plan a large consumption of hot water, it is recommended to buy a model with two heating elements. They heat water faster. In economy mode, one element will work, and the second will be connected thanks to the thermostat when it is necessary to heat a new portion of cold water.

Categories of heating elements by type of contact with liquid

Inside the heating element for heating water, a nichrome spiral is hermetically sealed, and the space between it and the outer walls is filled with quartz sand. The outer tube can be made of copper, carbon steel or stainless steel.

Open heating elements are in direct contact with water. Their main advantage is the high rate of liquid heating and low cost, but there are also significant disadvantages:

- limited service life;

- rapid formation of limescale;

- high electricity consumption;

- insecurity.

Closed do not come into contact with water. TEN is protected by a strong flask. Its advantages:

- the probability of electrical short circuit is reduced;

- easy to repair and maintain;

- long service life - three times longer than open heating elements;

- consume significantly less electricity than open-type heating elements.

There are two important disadvantages: high price and slow heating of water.

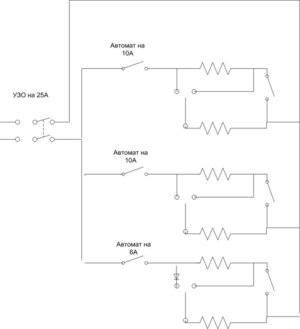

How to connect a heating element with a thermostat

Now you know how and by what parameters heaters are selected. But how is the connection made? In order to connect a heating element with a thermostat, you must select a wire with reliable insulation

We also pay attention to the cross section - it should be such that the wire can provide full power to the heater and not melt.

For example, for a heater with a power of 3 kW, the wire cross section must be at least 2.5 mm. We recommend choosing cables with copper conductors for connection.

Do not forget to pay attention to the presence of an RCD - it will instantly turn off the power in the event of an unexpected failure of the heating element or a short circuit. The RCD must be placed as close as possible to the heater itself.

It is also necessary to ensure a reliable connection of the conductors to the contacts of the heating element (without "snot" and flimsy contacts that can spark).

Temperature regulators for domestic purposes are used quite widely, and they regulate the temperature literally everywhere: from a banal soldering iron to the microclimate in the house.

Advantages of dry heater

If we compare the dry construction from the submersible one, the first one will have a lot of advantages:

- lack of scale;

- compact dimensions;

- ease of maintenance;

- excellent performance;

- long service life;

- no air pockets.

The dry design is reliably protected from such troubles, since there is no contact with water, which means that scale cannot form.

Since most developers allocate catastrophically little space to the toilet and bathroom, the second important criterion for choosing a boiler is its size. The dry heating element is rather small in size compared to its "wet" counterpart. Since the size of the water heater itself is significantly reduced, the manufacturer can reasonably install two or even three heating elements, which allows the consumer, if desired, to heat the water in just a few minutes. Moreover, the consumer is not afraid of interruptions in the operation of one of the heaters, since he can always use the remaining ones.

High performance and easy maintenance

Another important feature of the tubular element is the ease of repair. Despite the fact that such an element is durable, it can still fail. In order to repair the device, it is not necessary to completely dismantle the tank. It is enough just to unscrew the protection and remove the element. After inspection and repair, the heating element is put back. According to a similar scheme, every six months the tank is cleaned of scale. The heating element is not affected, but only the inner wall of the tank is cleaned.

Water heater durability

Manufacturers also made sure that the boiler does not turn on if there is no water in it at the moment. Dry start protection is installed in absolutely all water heaters with a dry element. This feature allows the unit not to burn out and last longer.

If the element still needs to be repaired, the variability of such a water heater will be a pleasant surprise. Tubular heating elements are not much different from each other, so finding the right part is not difficult.

Purpose of heating elements

Why do we need heating elements with thermostats? On their basis, autonomous heating systems are designed, boilers and instantaneous water heaters are created.

For example, heating elements are mounted directly into batteries, as a result of which sections are born that can work independently, without a heating boiler. Separate models are focused on the creation of anti-freeze systems - they maintain a low positive temperature, preventing freezing and subsequent rupture of pipes and batteries.

A heating element with a thermostat is built into this battery, with its help the house is heated.

On the basis of heating elements, storage and instantaneous water heaters are created. The purchase of a boiler is far from available for every person, so many assemble them on their own using separate components. By inserting a heating element with a thermostat into a suitable container, we will get an excellent storage-type water heater - the consumer will only need to equip it with good thermal insulation and connect it to the water supply.

Also, on the basis of heating elements, storage water heaters of bulk type are created. In fact, this is a container of water filled by hand. Heating elements are also built into the tanks of the summer shower, providing heating of water to a predetermined temperature in bad weather.

Heating elements for heating water with a thermostat are necessary not only for the creation of water heating equipment, but also for its repair - if the heater is out of order, we buy a new one and change it. But before that, you need to understand the issues of choice.

Popular manufacturers

You should choose a heating element from a trusted manufacturer. This is not the item to skimp on. The best firms include:

- Termeks (Thermex). Produces boilers for almost 50 years. This manufacturer manufactures heating elements from copper and stainless steel. They are well protected and therefore have a long service life. On the market, Termex has established itself as a manufacturer of boilers of the largest volume, so powerful electric heaters can be found in the assortment.

- Ariston. Heating elements from an Italian manufacturer are made of an alloy containing copper and are equipped with a chromium-nickel tube. The flange is made of brass, which increases heat transfer. They are well protected from scale, easy to install. And at the same time they are relatively inexpensive. Ariston offers water-heating heating elements with a thread and a thermostat from 1.2 to 4.5 kW.

- Electrolux. You can choose a heating element from this manufacturer for almost any heater model. At the same time, they are guaranteed to last a long time, since they are especially resistant to scale and are not demanding on water quality. The water heater with a heating element from Electrolux does not require frequent maintenance. In some devices of this manufacturer, two closed heating elements are installed, so it is possible to increase the rate of heating of the liquid.

- Timberk. Another manufacturer that offers its products at an affordable price. In the assortment there are heating elements designed for boilers of 80 or more liters of water. They are well protected from corrosion and other destructive factors.

- The firm Atlantic is also known. It produces a wide range of high-quality and reliable heating elements for boilers, including copper water heating elements, dry steatite and others, suitable for vertical and horizontal installation.

Each manufacturer produces electric heaters designed for installation in boilers of their own production. However, universal heating elements can also be found. They are less popular due to dubious quality, but their use is possible.

Types of heating elements according to the principle of operation

Features of open and closed heating elements are clear from the name. The former are not protected from water, the latter are closed with a flask. In another way they are called wet and dry. The principle of their work should be considered in more detail.

Wet

Wet-type heating elements are tubular, they are in direct contact with water and heat the water with their surface. Their service life depends on the quality of water, its hardness, the percentage of salts. Due to the influence of these factors, the metal corrodes, and lime deposits form on the surface. By installing a magnesium anode, the process can be slowed down, since the element attracts salts. Vitreous enamel is also used to protect water heating pipes.

Dry

A dry heating element is a heater that is placed in a flask filled with a second layer of ceramic backfill (the first layer fills the space between the nichrome coil and the tube in which it is placed). The waterproof shell is made from magnesium silicate or steatite. Steatite heats up quickly and cools slowly, has increased strength and high thermal stability. There are more advantages to using a dry heating element in a water heater than disadvantages, and in particular, to replace such a heating element, it is not necessary to drain water from the boiler.

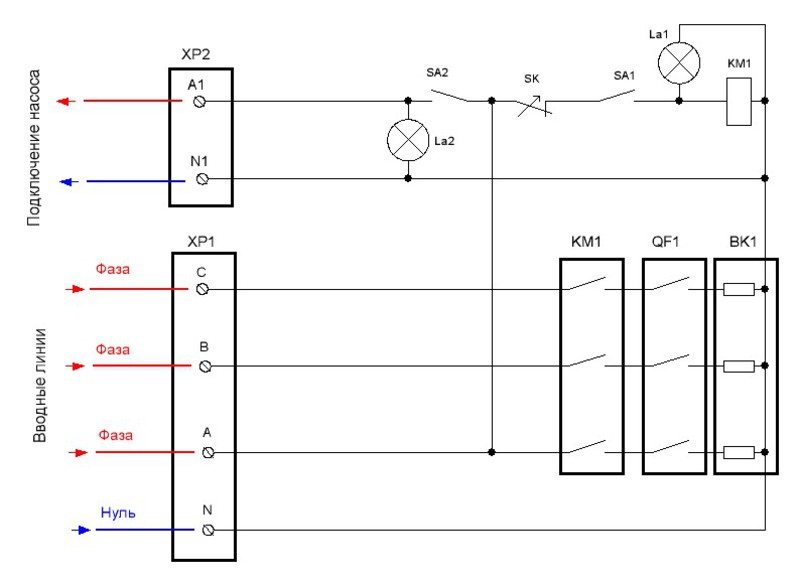

Connection methods

It should be noted that heating elements for boilers can be mounted in the device either one at a time or several at once.

Parallel connection

This connection option must meet certain requirements.

- The voltage both in the electrical network and in each individual element must be the same.

- To determine the total power of the boiler, you need to sum up the power of all installed elements.

- If for some reason one of the heating elements breaks, the circuit will continue to work. In this case, the only thing that needs to be done is to change the broken element.

Series connection

The second option is to connect in series. In this case, it is necessary to observe the principles of work:

- If one of the heating elements breaks down, the operation of the entire network will be interrupted.

- To find out the total resistance, it is necessary to sum all the resistances in the network.

- The total voltage cannot be greater than the total voltage of all heating elements.

Combined method

Given this scheme, different connection options must be used in several sections of the electrical circuit. Quite often, the combined method is advisable if it is impossible to purchase heating elements of the required power. In this case, available heating elements are installed, and the required value is achieved using various connection methods.

The choice of heating element

When choosing a heating element, it is necessary to pay attention to some details. Only in this case, you can count on a successful purchase, high-quality heating, service life and compatibility of the selected model with a tank for heating water, a boiler or a heating battery

Shape and size

Dozens of models of heating elements are presented at the choice of buyers. They have a different shape - straight, round, in the form of "eight" or "ears", double, triple and many others. When buying, you should focus on the use of a heater. Narrow and straight models are used for embedding in sections of radiators, since there is not enough space inside

When assembling a storage water heater, you should pay attention to the volume and shape of the tank, and on the basis of this, choose a suitable heating element. In principle, almost any model will fit here.

If you need to replace the heating element in an existing water heater, you must purchase an identical model - only in this case you can count on the fact that it will fit in the tank itself.

Power

If not everything, then a lot depends on power. For example, it could be the heating rate. If you are assembling a small volume water heater, then the recommended power will be 1.5 kW. The same heating element can also heat disproportionately large volumes, only it will do this for a very long time - with a power of 2 kW, it can take 3.5 - 4 hours to heat 100-150 liters of water (not to boil, but on average by 40 degrees).

If you equip a water heater or water tank with a powerful heating element of 5-7 kW, then the water will heat up very quickly. But another problem will arise - the house electrical network will not withstand. When the power of the connected equipment is higher than 2 kW, it is necessary to lay a separate line from the electrical panel.

Protection against corrosion and scale

When choosing heating elements for heating water with a thermostat, we recommend paying attention to modern models equipped with anti-scale protection. Recently, models with enamel coating have begun to appear on the market.

It is she who protects the heaters from salt deposits. The guarantee for such heating elements is 15 years. If there are no similar models in the store, then we recommend buying stainless steel electric heaters - they are more durable and reliable.

The presence of a thermostat

If you assemble or repair a boiler or want to equip a heating battery with a heating element, choose a model with a built-in thermostat. It will allow you to save on electricity, turning on only when the water temperature drops below a predetermined mark.If there is no regulator, you will have to monitor the temperature yourself, turning the heating on or off - this is inconvenient, uneconomical and unsafe.