Material preparation and welding of parts

The process of argon metal welding.

For the installation of heating devices in the form of registers, it is necessary to prepare pipe, consumable material:

- smooth steel pipes with a diameter of 76 to 159 mm;

- branch pipes with a diameter of 32 mm for jumpers;

- inlet and outlet pipes for welding, threaded or flanged type with a diameter of 35 mm or more;

- threaded fitting for connecting an air vent (Maevsky tap);

- plugs according to the diameter of the pipes;

- floor supports from corners or brackets for mounting to the wall.

For the manufacture of such heat exchangers, pipes with diameters of 76, 89, 108 and 159 mm are more often used. Products of profile, rectangular or square section are also used.

From the tools you will need:

- welding machine;

- gas key;

- grinder (grinder);

- hammer, electrodes;

- roulette, level;

- welder's protective equipment.

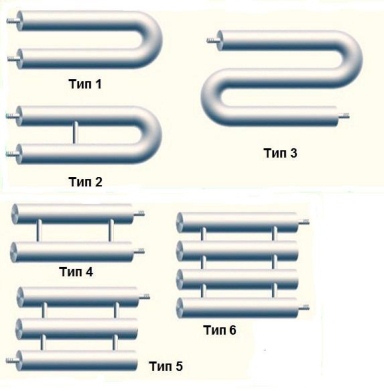

Heating register device.

The joined surfaces of the parts are cleaned and degreased before welding to avoid defects in the seams. The ends of the pipes must be perpendicular to their axes. Processing of pipes of large diameter is carried out on milling machines or gas-acid cutting.

The pipes are cut into segments of calculated dimensions, the ends are cleaned with a grinder. On horizontal pipes, marking and cutting holes for jumpers are made, the nozzles must go into the hole.

Jumpers inserted into the holes are welded to horizontally laid pipes in compliance with the dimensions. Plugs are welded to the ends of the register elements. Inlet and outlet pipes are welded into two ends (diagonally) into pre-cut holes.

A threaded branch pipe is welded in one of the upper ends for installing a Mayevsky crane. All seams are cleaned with a grinder to give an aesthetic appearance. Racks are welded to the structure (when the device is located on the floor).

To check the register for tightness, the lower outlet for the coolant outlet is closed with a plug. The structure is filled with water and inspected for leaks. When they are found, the water is drained, and the problem areas are boiled again. The seams are cleaned again, and the register is painted with paint.

Basic principles of work

The design of a hot water heating system can undoubtedly be called one of the most significant developments of the nineteenth century. What is the principle of its work. When rising up the pipes, with the help of hot water, a continuous stream is formed. and the vacated space is filled with cold water. Water is constantly moving and constantly heated. Thus, the maintenance of a comfortable temperature in all rooms of the house is ensured for a long time. After all, the water will independently circulate through the pipes.

Types of heating systems:

- Gravity-flowing. The water itself moves through the pipeline

- With forced movement. Water moves under the action of a pump

Systems using forced movement are much more efficient than the first ones, since in gravity systems, passing through the radiator, the water slows down and cools down, ceasing to heat the premises. The flow of water is accelerated by a circulation pump, which is built in to ensure a constant movement of water.

Such designs require an electrical connection. Perhaps this is their only drawback, but in all other respects they are the most efficient and economical compared to other types of heating systems.

Requirements for a room for gas boilers

Gas boilers can be installed in a closet, kitchen or basement, a special annex. Certain requirements are imposed on the room in which gas boilers are installed in a private house.They are the same for any room and are as follows:

- The room must be well ventilated, with the obligatory equipment of an exhaust hood.

- The windows should be provided with vents, at the bottom of the door - a small gap.

- Ceiling height - from 250 cm. Room volume - from 15 m2. Each power unit of a gas boiler requires an additional volume (0.2 m2) so that you can freely approach the boiler for maintenance.

- Walls. separating the room with the installed boiler from others, must be made of fire-resistant materials that do not support combustion.

- In the basement or basement, a separate exit to the street should be provided.

- The annex should be placed only against a blank wall of a residential building. The minimum distance to the nearest window is 4 m. The height from the ceiling to the window is 8 m.

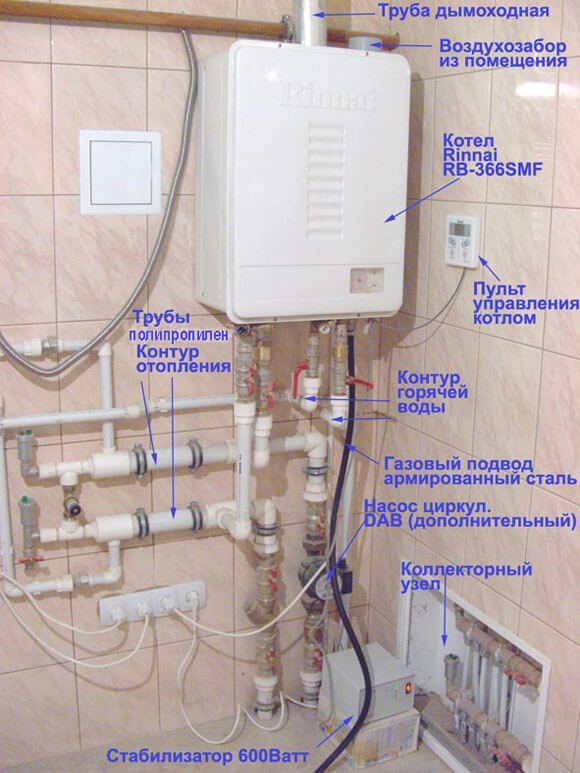

Features of piping gas boilers

There are several ways to tie a gas boiler. The most popular option was tying the heating boiler with polypropylene. Working with pipes made of this material is characterized by low cost and simplicity. Plaque and solid particles do not collect on the walls of polypropylene products. When such pipes are used, do-it-yourself piping of a gas boiler is not difficult; any property owner can handle such work.

The lining is paronite. It is forbidden to use tow, fum-tape or accessories made of rubber. The fact is that rubber gaskets under the influence of high temperatures can narrow and, as a result, practically block the passage in the pipeline, and the tow is flammable.

A pipeline tied with polypropylene pipes, such as in the photo, is able to withstand pressures up to 25 bar, and high temperatures reaching 95 degrees Celsius are also not dangerous to it.

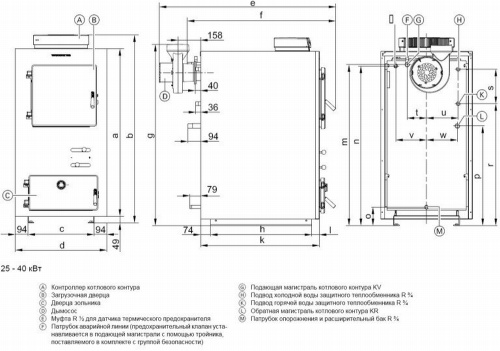

How to install a wood burning boiler

Let's start installation

Please note that inside the volume of the device should be the same, but the heat exchanger jacket should be increased in volume to improve the efficiency of the wood-burning boiler. When you install it in a place prepared in advance for it, you will need to connect it to the water circuit, and then check the work by sealing all the joints

The best energy return occurs in the gas-generating mode; to heat up the room, the wood-fired boiler heats up for about half an hour.

After installation, it can be painted to make it as fire resistant as possible, in addition, thanks to painting, the boiler will have a more attractive appearance.

If you did everything right, made the calculations and made the correct assembly, then wood-fired water boilers will become more efficient than gas ones. Also, a wood-burning boiler allows you to more evenly distribute heat in the room.

How to weld a heating boiler with your own hands

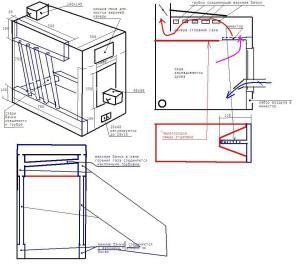

Scheme for the manufacture of a long-burning boiler with a heat exchanger

Before you weld the heating boiler yourself, you need to decide on its design. It is preferable that it meet modern requirements for safety and efficiency. Therefore, as an example, a pyrolysis-type boiler made independently will be considered.

How to weld a heating boiler of this type? In addition to the welding machine, this will require the following materials and tools:

- Sheet steel, the grades of which are selected from the data in the table shown above. For the combustion chamber, the thickness of the metal should be 3-4 mm. The case can be made of steel of smaller thickness - 2-2.5 mm;

- Pipes for the manufacture of a heat exchanger. Their optimal diameter is 40 mm. This size will allow you to quickly heat the coolant. Number of registers - from 3 to 6;

- How to weld a heating boiler without a cutting tool? It is best to use a "grinder" with special discs for metal for cutting sheets;

- Doors for the combustion chamber and blower.You also need to purchase cast iron grates. This must be done in advance, since openings and fixing parts of the boiler will be made according to the dimensions of the components;

- Level, tape measure and pencil (marker) for marking;

- Protective equipment - gloves, a welder's mask, transparent work glasses and long-sleeved clothing made of dense material.

For clarity, you can see how to cook heating in a private house. Video or photographic materials will help in the work, as they clearly show all the stages and features of their implementation. However, this should be done only after drawing up the drawing and preparing all the tools and components. This applies to all stages of the manufacture of components, since it is impossible to weld heating with your own hands, including boilers, registers, combs, without the correct scheme.

It is also important to prepare the place of work before welding the heating in the garage. Most often, the manufacturing process takes place in it

First you need to provide maximum free space by removing unnecessary items.

For safety reasons, flammable liquids - gasoline, oil, etc. - should also be taken out of the garage. And only after that you can get to work - to weld the heating in the garage. Proper welding of a heating boiler consists in the manufacture of two components - the boiler body and the heat exchanger itself.

heat exchanger

Heat exchanger for heating boiler

This element is made before the heating boiler is welded. Subsequently, it will be installed in a structure that will directly depend on its actual dimensions.

Structurally, it consists of 2 rectangular tanks interconnected by pipelines. The optimal thickness of the material should be 3-3.5 mm. This is due to the high temperatures that will affect the surface. The specifics of its manufacture can be viewed on the video - how to weld heating in a private house.

On steel sheets, the structure is marked according to the drawings. First, the back panel is cut out and a partition is welded to it to remove wood (coal) gases. At this stage, you need to be very careful, as the weld may not always provide proper fastening. Then the side and bottom are welded to the partition and the back wall.

It should be noted that it is rather problematic to weld a heating boiler yourself. Therefore, this work is recommended to be done by two people. In particular, this applies to the stage of installation of the finished heat exchanger. Its nozzles are placed in pre-prepared holes, and the pipes are spot-welded to the inner walls of the boiler.

The question often arises - how to weld the heating inside the garage without forced ventilation. To do this, work must only be carried out with the gates open to ensure a normal supply of fresh air.

The main problem of home-made structures is low work efficiency. To increase the efficiency, it is recommended to make double walls, between which a basalt refractory heat insulator is installed. It is possible to weld such a boiler with your own hands for water heating, but for this you need to provide for additional material consumption. First, double walls are made, which are filled with insulation. Then the further welding technology of the structure is fully consistent with that described above.

Gas boiler piping schemes

If the gas boiler is piping in the classical way, the coolant moves up the supply pipe. Further, the water is directed to the risers, in which there are special devices that do not allow them to open.

When the piping of a double-circuit gas boiler is performed by the owner of the house on his own, you need to prepare the following tools and accessories for the work:

- circulation pump;

- thermal head or distribution valve;

- expansion tank;

- drain and ball valves;

- inline filter;

- balancing crane;

- check and air valves;

- corners and tee.

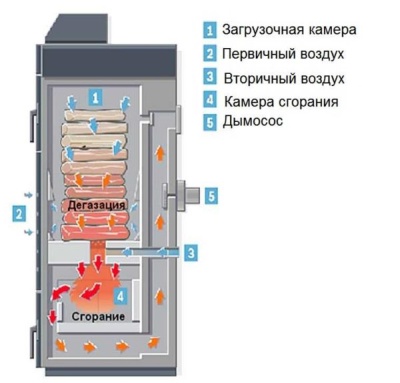

Pyrolysis heating boilers

In order to save on materials and energy spent on the operation of the boiler, this type of unit should be used. The principle of operation of the boiler is a mixture of air and pyrolysis gas, which ignites and gives more heat. The cost of materials for the manufacture of a pyrolysis boiler is an order of magnitude higher than that of a wood-burning boiler, but after a couple of heating seasons, the device pays off.

The design of the pyrolysis water unit will consist of several sectors: power supply regulators, an opening, smoke channels, a fan, a combustion chamber and pipes. In its manufacture, it is necessary to adhere to an exact drawing due to the complexity in assembling the structure. High heating capacity and efficiency allow to reduce energy consumption and set the power to 25-30 kW, unlike other boilers (40-50 kW).

To assemble it, we need an electric drill, a temperature sensor, a 230 mm cutting wheel, a grinder, electrodes and a welding machine, as well as 2 mm thick steel strips and a fan.

- Cut the fuel hole slightly higher than the combustion tank.

- Install a restrictor that controls the air supply.

- Cut a special hole in the boiler for the limiter.

- Weld a limiter from a pipe 65-70 mm thick.

- Make a rectangular opening for loading and securely close it with a steel plate.

- Cut a hole to remove the ash.

- It is desirable to make a branch pipe with a bend in order to increase the amount of heat generated.

- Install a valve outside the structure to adjust the amount of coolant.

- Carry out a leak test and install.

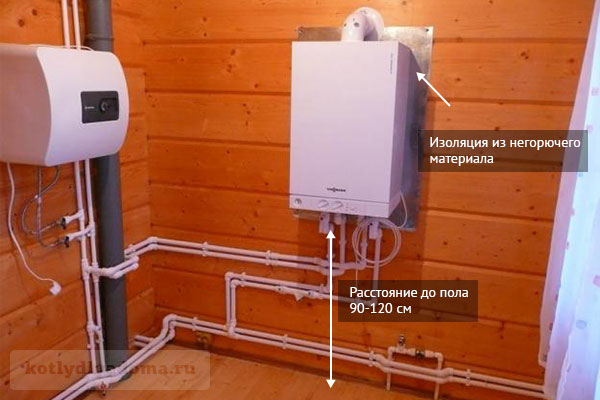

How to place a gas boiler on the wall

Having correctly selected and prepared the room for installation, it is necessary to determine the position of the wall-mounted gas boiler on the wall and prepare the surface for installation accordingly:

- Installation is recommended to be done on a solid wall that can support the weight of the device. If the wall is made of combustible material (for example, a wooden house), then between the boiler and the wall there must be a gasket made of non-combustible material protruding along the perimeter of the appliance to a distance of 200 mm. Usually, a layer of asbestos cardboard is used as a layer, and a sheet of galvanized steel is attached on top of it.

- The hinged boiler is recommended to be installed at a height of 90-120 cm from the floor and at a distance of at least 10 cm from adjacent walls. This space is necessary for convenient piping and maintenance of the boiler.

- The socket for connection to the mains must be located next to the wall-mounted boiler and in no case under it. This will prevent a short circuit in the event of a leak. Nearby, a place should be provided for installing an uninterruptible power supply (UPS) for a gas boiler.

The requirements for the location of gas boilers on the wall and the distances to various structural elements are different for many models. We have given the most typical values, but still, before performing the installation, it is necessary to clarify them in the passport for a specific device.

How to weld a heating register with your own hands

How to weld the heating register correctly and in what cases is it recommended to install them? First you need to correctly understand their purpose. In fact, these are heating devices that should ensure maximum heat transfer from the hot water of the heating system to the room.

Before welding heating registers, it is necessary to prepare the main material for manufacturing:

- Main pipes. They should be relatively large in diameter - up to 100 mm.For forced systems with a high temperature regime, it is recommended to use just such. It is better that the pipe section be round, since the profile structures will create a large hydraulic resistance, which is undesirable;

- In order to properly weld the heating register, pipes of smaller diameter will be needed, which will serve as nozzles for the circulation of the coolant between the main horizontal ones. Their cross section should be in the range of 24-30 mm.

At the first stage of work, all pipes must be cut according to the previously prepared drawing. Then, before welding the heating registers, it is required to make plugs for the ends of large pipes. They are divided into two types - deaf and with inlet pipes. With the help of the latter, the coolant will move along the contour of the register.

The order of work is as follows.

- In order to properly weld the register of the heating system, you must first cut all the pipes according to the drawing. For this, the "Bulgarian" is used. At the end of the work, the end parts are cleaned;

- Silencer manufacturing. For them, you need to use metal of the same thickness as the pipes. The diameter of the plugs must be greater than the pipe section per metal thickness. This is necessary for welding the mounting edging. After their manufacture, installation is carried out by a welded method;

- Before welding the registers of the heating system with the help of adapter pipes, it is necessary to make holes in the pipes. It is best to do this with a welding machine, since it is impossible to cut a round hole with a grinder.

The final stage of work is the connection of large pipes into a single heating device - a register.

Safety regulations

When using wood burning stoves, always follow the safety rules

Never leave long-burning stoves for a long time without control, do not forget to clean the ash chamber in time and put firewood in the firebox

Pay attention to the chimney flue valves. keep them open until you start lighting the stove

Use only in the cold season, its use in the summer is impractical. Significant overheating can lead to breakdown, and then you have to repair the oven

and seriously. High temperatures can cause the oven walls to collapse. That is why excessively high temperatures and the use of the unit in the warm season should be avoided.

Significant overheating can lead to breakdown, and then you have to repair the oven. and seriously. High temperatures can cause the oven walls to collapse. That is why excessively high temperatures and the use of the unit in the warm season should be avoided.

We build with our own hands

If your oven is brick. then for her a water boiler can also be built with your own hands, and the stove itself can be laid out of bricks too. As a water heater for it, you can take a simple cast iron radiator. A similar model can be found when dismantling old five-story "Khrushchev" buildings, if they are being demolished in your city.

Each of the radiators has a capacity of about one and a half liters. When connecting twelve of these radiators to each other, you will end up with a powerful 18-liter heater with an area of three square meters. However, such scales are far from suitable for all rooms, but for heating a volumetric Russian bath, this will be one of the most acceptable options.

Before you install the structure itself, disassemble the radiators. then they should be thoroughly cleaned. To remove any dirt on them, make a hot solution based on six percent hydrochloric acid and rinse the radiators with it, then they should be rinsed with cold water. Now we change the intersection gaskets, since the temperature can be more than six hundred degrees.With such a temperature regime, the cardboard will not be able to withstand the impact, which will provoke a radiator leak. Therefore, as a gasket, take an asbestos cord, after soaking it with drying oil.

You should also chamfer the edges of the pipes, before cooking, make sure that the rings are located about 5 cm apart from each other. Often the boiler in the brick oven can leak heavily, if this happens suddenly, clean the leaks with a grinder and rinse them.

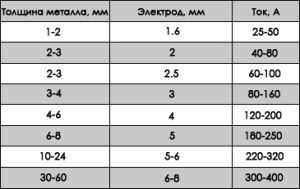

Choosing a welding machine and electrodes

The choice of electrodes and welding mode depending on the thickness of the metal

Currently, manufacturers offer several models of welding machines with which you can make high-quality metal joints of various grades. But before you properly weld the heating, you need to choose the optimal model. Consider the most popular types of devices and their main characteristics.

transformer

The principle of operation is based on increasing the frequency of the incoming current. For this, step-up transformers are used. Despite the relatively large dimensions, this type of welding machine is best adapted to power surges. With it, you can properly weld the heating boiler, observing the manufacturing technology.

inverter

The formation of current according to the set parameters occurs due to the operation of electronic circuits. They are characterized by a stable arc, which ultimately gives a high-quality seam. This must be taken into account before you learn how to weld heating on your own. However, they are extremely sensitive to voltage drops in the network.

As an additional equipment for inverter devices, it is recommended to purchase a voltage stabilizer.

Is it possible to weld a boiler with your own hands for water heating using an inverter apparatus? Yes, but its characteristics must match the parameters of the metal used. For the manufacture of heating elements, carbon steels are most often used.

Table of materials for heating welding

You also need to know the dependence of the diameters of the electrodes on the thickness of the metal being welded.

As for the choice of a welding machine, experts recommend stopping at inverter models operating on alternating current. Their cost is somewhat higher than that of transformers, but they are smaller and can be used to make a high-quality weld.

This is important to consider, since self-welding of the heating boiler must be of high quality

The cost of a device with a power of 7 kW, a welding current of up to 200 A and a maximum electrode diameter of 3.6 mm will be about 16 thousand rubles.

How to weld a heating register yourself

A register is a heat exchanger with parallel-mounted pipes with a diameter of more than 32 mm, connected by jumpers from branch pipes of a smaller diameter. They can also be made in the form of a coil. The devices perform the same functions as radiators, but differ in the possibility of their independent manufacture.

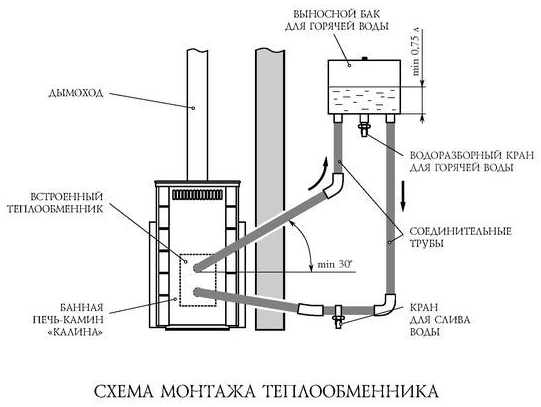

Scheme of installation of the heat exchanger.

As a rule, registers provide heating in warehouses, utility rooms, garages, some low-rise residential buildings, but can be equipped as part of the interior of ordinary rooms. Heat exchangers are used as elements of one- and two-pipe heating systems with increased fire and sanitary standards.

1. Electrodes for manual arc welding

4.1.1.

For manual arc welding of joints

pipelines and boilers made of carbon,

low-alloy and high-alloy

steels, it is necessary to use electrodes,

meeting the requirements of GOST

9466,

9467

and 10052. The brand of electrodes should be chosen

depending on the brand of welded

become. For welding products for which

this RD is subject to

be used domestic

electrodes given in Table 4.1;

chemical composition and mechanical

properties of the deposited metal of these

electrodes are given in the appendix

7.

Stamps

electrodes of foreign companies, which

can be applied, indicated in the appendix

8;

the type of electrodes according to

domestic classification for

determining the scope of a particular

electrode brands.

Opportunity

use of electrodes not listed in

table 4.1

and in applications

7

and 8,

for facilities of the Ministry of Energy of Russia should

be agreed with CJSC "Prochnost

MK", for other objects - from any

specialized research

organization in the field of welding, given

in annexes to the rules of Gosgortekhnadzor

Russia.

4.1.2.

Electrodes for welding fasteners

from high-alloy steels to pipes

superheater and other elements

boiler or to a pipeline made of low-alloy

pearlitic steels, as well as for welding

fasteners must be selected

according to Table 4.2.

For

welding fasteners from steel of any grade

for pipes made of austenitic steel

electrodes EA-395/9 should be used,

ZIO-8, OZL-6, TsL-25, TsT-10, NIAT-5, steel

12X11V2MF - electrodes EA-400/10U and EA-400/10.

4.1.3.

Before welding production joints

and test electrodes should be

calcined according to the regime given in

relevant document (OST, TU) or

label. In the absence of such

data, the calcination mode is selected according to

table 4.3.

Imported

electrodes are calcined in the same mode

as domestic with the same type

coatings.

4.1.4.

Basic coated electrodes,

intended for welding pearlite

steels should be used within

5 days after calcination, electrodes TsT-45

— within 10 days, other electrodes

- within 15 days if they are stored on

warehouse in compliance with the requirements of clause 3.10.

After the specified period, the electrodes

must be reapplied before use.

ignite. When storing electrodes

in an oven at a temperature

80-115°C their shelf life is not limited.

table

4.1

Piping schemes for floor boilers

As the piping diagram of the floor gas boiler suggests, when creating a heating system, the installation of a circular electric pump is required (read: “Connection diagram for a gas heating boiler with examples“).

Forced-type devices are easy to operate and are considered more comfortable to use.

The heating unit is controlled automatically. Among the advantages, it should be noted that for individual rooms it is possible to set a certain temperature, thanks to the presence of sensors that control the heating process.

At the same time, the piping scheme for a wall-mounted gas boiler has negative sides, including:

- high price for components;

- the complexity of the implementation of the strapping, which can only be performed by a professional;

- the need for constant balancing of parts;

- service cost.

If the house has a complex heat supply system, for example, there is a “warm floor” and batteries, then some inconsistency can be noticed when the coolant moves. Therefore, to solve the problem, a hydraulic decoupling is included in the piping scheme, which forms several circuits for the movement of coolants - a common one and a boiler one.

For waterproofing each circuit, an additional heat exchanger is installed.This will be required to combine open and closed systems. Units belonging to the separate type must be equipped with circular pumps, a security system and taps (drain and make-up). How to connect a gas boiler, in detail on the video:

Benefits of Using the Registry

The principle of connecting pipes by welding.

Register heat exchangers have certain advantages over other heating devices:

- Self-made heating registers are large, therefore, they provide more uniform heat transfer, unlike radiators, which are local heat sources.

- The devices are easy to maintain and do not have hard-to-reach places where dust accumulates.

- With high-quality welding of parts, heat exchangers withstand significant pressure and high temperature of the coolant.

- When the device is equipped with a heating element, it can serve as an autonomous source of heating.

- A well-mounted heating register can last at least 25 years without repair.

At the same time, heating registers have worse characteristics than radiators of the same size, in which the heat exchange surface is formed more compactly. The maximum working pressure of the heat-carrying medium, for which the register heat exchanger can be designed, is 10 kgf / cm². The system works more efficiently with the installation of a circulation pump.

Types of heating boilers

Before starting the independent manufacture of the boiler, it is necessary to determine its type, which depends on the type of fuel heated by the coolant. If desired, you can build a boiler that runs on any fuel. You can find the necessary information on the Internet resources. However, before making a choice, it is worth having an idea about the advantages and disadvantages of the most famous of them.

- Gas boilers for heating. You should not try to make this type with your own hands, since they have a lot of requirements that you are unlikely to be able to satisfy. Well, no less important reason is the high probability of an explosion during operation. Installation of a gas boiler is prohibited in the basement of the house.

- To make an electric boiler, you do not need professional skills and the availability of many materials. It should be noted a huge drawback - high prices for electricity. This is ideal for periodically heating a country house, but for permanent use, an electric boiler is very expensive.

- A liquid fuel boiler is quite suitable for do-it-yourself manufacturing, but the cost of fuel and the features of setting the nozzles can cause considerable difficulties in the course of work.

- Among all the options listed, the most optimal can be called a solid fuel boiler, which can be successfully used as firewood.

Everyone knows that firewood has a high combustion rate, and therefore does not have time to heat the room to the desired temperature at the initial efficiency. In order to optimize this process, it is worth considering two ways to independently build solid fuel boilers.

Advantages and disadvantages

Before undertaking the manufacture of heating registers, it is necessary to evaluate all the pros and cons of these heaters, so as not to be deceived in expectations later. So, first about the advantages:

- low cost and ease of manufacture;

- low hydraulic resistance: thanks to this, the heater can be used in the "tail" of any system;

- reliability and durability: a register welded from ordinary pipes with high quality will easily last at least 20 years;

- resistance to pressure drops and water hammer;

- smooth surface facilitates easy removal of dust when cleaning rooms.

Unfortunately, a do-it-yourself heating register also has a lot of drawbacks. The main one is low heat transfer with a significant mass of the device. That is, in order to ensure a comfortable temperature in a medium-sized room, the register must have a decent size. Here is a simple example taken from the technical literature. If the temperature difference between the coolant and the room is 65 ºС (DT), a register welded from 4 DN32 pipes 1 m long will give out only 453 W, and from 4 DN100 pipes - 855 W. It turns out that, based on heat transfer per 1 m of length, any panel or sectional radiator is at least twice as powerful.

Note. The presented data were determined experimentally at a high coolant flow rate of 300 kg/h.

Other negative aspects of smooth-tube registers are not so critical, although they are significant:

- holds a large volume of water: the disadvantage does not play a big role if there are 1-2 pieces for the entire system of such heating devices;

- during operation, it is very difficult to increase or decrease the power of registers from smooth pipes. You can not do without dismantling and welding machine;

- subject to corrosion and require periodic maintenance with painting;

- have an unpresentable appearance: the defect is reparable, if necessary, the heater is hidden behind a decorative screen.

After analyzing the advantages and disadvantages of smooth-tube devices, we can conclude that their scope in private housing construction is very limited. As already mentioned, the registers can be used for heating various rooms with low requirements for comfort and interior.

Register heat exchanger design

Heating register of four smooth pipes and a flow diagram.

The heat exchanger consists of simple parts, and it will not be difficult to weld the register with your own hands if you have welding skills. With the independent manufacture of the heater, it is possible to accurately maintain its required dimensions and technical parameters necessary for the existing operating conditions. Buying a finished register can cost about 3 times more than the cost of materials for making the structure.

More often, carbon steel pipes are used to manufacture the heating register. The material of stainless low-alloy steel and cast iron is also used. The distance between the sections in the register must be 50 mm greater than their diameter. The registers are installed with a slope along the coolant flow of at least 0.05%.

To increase the heat transfer of the device, the jumpers are mounted as close as possible to the ends of the horizontal parts. The coolant must enter the upper part of the device, flow through the sections and exit from the lower horizontal element.

Welding of steel pipes.

Pipes in the serpentine type of registers are connected by arcs of the same diameter. When using an S-shaped heating device, the heating efficiency is increased by increasing the heat exchange area and reducing the hydraulic resistance.

To install heating registers in residential premises, it is recommended to use pipes with a diameter of 3 to 8 cm to match the load on the domestic boiler. When calculating the number of sections and the parameters of the blanks, the heat transfer of the pipe for each of its running meters is taken into account. For example, 1 m of a pipe with an inner diameter of 60 mm is able to heat about 1 m² of room area.

The design parameters increase by 20-40% with poor thermal insulation of the room and a large number of windows.

The lower section is located 15-20 cm from the floor surface. For autonomous operation of the register heat exchanger, a heating element with a power of 1.6 to 6 kW is installed in them by means of a flange connection.