Penoplex installation

Lay foam sheets side by side. Try to avoid large cracks. A standard cutter will come in handy, allowing you to fit the sheets close to each other.

When insulating the scaffold, it is necessary to ensure that cracks do not appear. They need to be filled with the remaining pieces of foam. Formed suture connections require processing. You need to create a uniform structure. Mounting foam will do.

Recommended:

- Cover the resulting thermal insulation with geotextile.

- Install drainage pipes. The connection is made by "corners".

- Pull the pipeline to remove water into the ditch.

- Lay another ball of crushed stone, coarse-grained sand on top of the pipeline.

Cushion cushion device for penoplex

All types of blind areas require depreciation cushions according to a single principle:

- rigid type of construction requires the use of clay, sand, gravel;

- soft repeats the previous version, but with an additional ball of rubble;

- semi-rigid needs additional use of crushed stone and sand.

The optimal width of one layer is 10-15 mm. Each ball is carefully rammed. Sand is additionally watered with water, rammed.

Reinforcement, concreting

The reinforcement process involves the use of a finished reinforcing mesh. You can make a metal frame from rods at the installation site. The standard cell size is 150x150 mm. Connect individual elements by welding. You can use knitting wire, plastic clamps.

The reinforcing mesh is mounted on supports. Made from stones and bricks. Before the end of the formwork, a gap of 10 mm is made.

Pouring concrete mortar into the formwork is done carefully. Gaps are carefully filled. Internal vibrators are used to remove air bubbles from the concrete composition. You can use conventional fittings, often piercing the mass. The holes that appear are filled with concrete.

Compliance with the technological process of isolating the blind area with foam will provide reliable protection for the foundation. If you do the work yourself, you can save. But you will have to work hard. It is necessary to take into account the depth of groundwater, the level of soil freezing, and the type of soil. Better to leave it to the experts. After receiving the project, you can take on its direct implementation yourself.

Hand-made blind area insulation

The process of self-insulation of the blind area is simple. It is recommended to strictly follow the recommendations of experts. Penoplex will not be difficult. It is easy to work with him.

Scheme of thermal insulation of the blind area

Schematic thermal insulation of the blind area with foam:

- The territory is being prepared. A place is being vacated, a trench is being dug. The upper ball of fertile soil is removed.

- Sand is poured into the bottom of the pit. Watered with water. Carefully rammed.

- A layer of rubble falls asleep. Compacted.

- Foam sheets are laid.

- Reinforcement in progress.

- The gap between the wall and the sheets is blown with mounting foam.

- Formwork from boards is being arranged.

- The surface is concreted, asphalted. It is necessary to control the slope of 10 degrees.

Marking, earthworks

Marking is done with a metal bar, several wooden pegs. Corners are marked. Marking material is driven in. A cord is stretched around the perimeter of the building. Additional pegs are being installed. The resulting straight line is the main reference point.

It is possible to seal the foundation with a high edge of the blind area. It is recommended to use polyurethane sealant, damper insulation tape.

In the process of excavation, you need to correctly set the slope of the future trench. The bottom of the pit is carefully compacted.The usual rammer, log is used.

Formwork installation

Structurally, the formwork is boards, 4-5 mm thick. They are assembled in a height equal to the thickness of the blind area, with the addition of 5 cm. In the corners, individual elements are fixed with bolts. This will make it easy to disassemble the structure after the concrete mortar has hardened. Additionally, retaining elements are used to prevent bursting of concrete. Mounted on the outside of the formwork.

Self-created formwork must be carried out so that expansion joints are equipped along the perimeter of the concrete surface. If you do not follow the recommendations, over time, cracks will go along the foundation. The reason is the influence of the soil on the structure due to temperature changes. Distance between individual temperature seams should reach two meters. Boards are installed across the blind area, 2 cm thick. If the concrete screed is not to be poured, it is not necessary to make seams.

Possible variations of thermal insulation material

The market for building materials that perform a thermal insulation function is wide. Popular:

- expanded polystyrene;

- Styrofoam;

- penoizol;

- expanded clay.

Let's consider their characteristics in more detail.

Extruded polystyrene foam

Differs in high density, low thermal conductivity. Sufficiently durable material that allows the use of sheets of small thickness. Ecologically pure. Does not harm the body, the environment. Does not absorb water. Resistant to sudden changes in temperature. Building materials are easy to work with. Processing does not require a specialized set of tools.

The main disadvantage is the fire hazard. It does not flare up on contact with fire, but burns well. A leveling coating is required to eliminate the possibility of mechanical influence.

Styrofoam

Shows good thermal insulation properties. Easy to install, affordable. It is subjected to cutting into elements of any shape, performance.

Styrofoam

Styrofoam

Of the negative properties:

- short service life, in comparison with other heaters;

- sheets of low density actively absorb liquid;

- produced in sheets. Butt joints require additional processing;

- instability to mechanical influence. Reinforcing mesh required;

- combustibility.

Penoizol

Shows a low level of thermal conductivity. Note the durability of operation. Shows fire resistance. It is applied by spraying, forming a continuous, seamless layer of material. Requires equipment, professional help. The cost of insulation is high.

Minus - destruction from excessive moisture levels. The presence of toxic compounds in the composition.

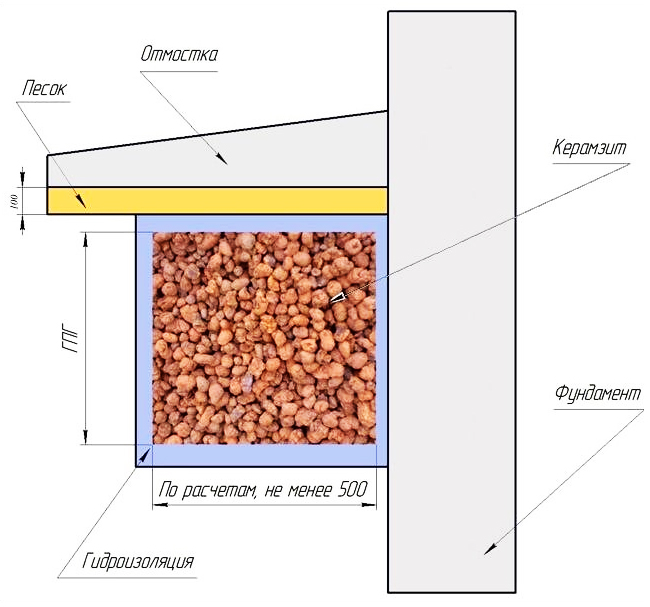

Expanded clay

Differs in durability, fire resistance, moisture resistance. Harmless. Has no toxic component. Made from clay and slate. Accessible. Working with building materials is easy. It is necessary to fill the expanded clay in the trench.

Sand, crushed stone, gravel are suitable. The last type is optimal for the blind area. Less absorbs liquid, frost-resistant.

The best choice is penoplex

Penoplex surpasses analogues in operational and technical parameters. The structure is porous. But unlike polystyrene, the cells do not disintegrate into granules. Each is filled with gas, insulated, providing a high degree of thermal insulation. The building material is dense and durable.

Has a small mass. Easily cut. Doesn't crumble. Sheets are connected by the tenon-groove method, which simplifies the work with the material. Produced in several variations.

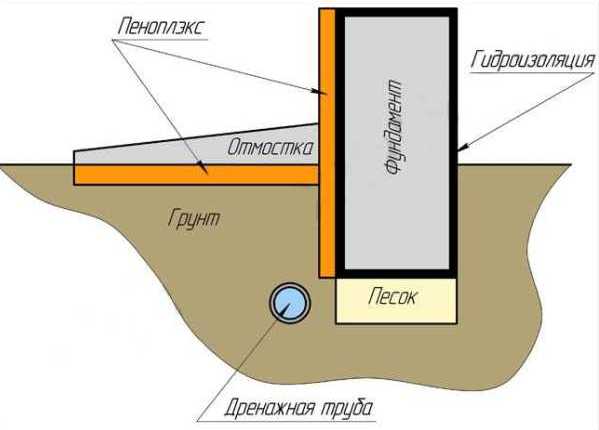

Warming of the strip foundation, algorithm of work

The sequence of work is as follows:

- The foundation is being dug around the entire perimeter. The width of the trench should be at least 1/3 of the overhang of the roof slope. The depth should reach the base of the foundation.

- The foundation is thoroughly cleaned of dirt and soil residues.

- The work is carried out step by step:

- Waterproofing the foundation in one of the ways;

- Drainage, for the removal of groundwater;

- Foundation insulation works;

- Blind area insulation.

- After installing the insulation, the trench is covered with rubble.

When making insulation of the strip foundation, it should be remembered that:

- Insulation sheets are mounted on the walls of the foundation using construction adhesive mixtures.

- In no case do additional fasteners with dowels be carried out, since drilling in concrete violates the integrity of the structure.

- The coating must be continuous; for this, all joints between the sheets are additionally filled with mounting foam.

- Types of waterproofing are selected in accordance with the specific situation on the site. Coating, pasting, plastering and others can be used.

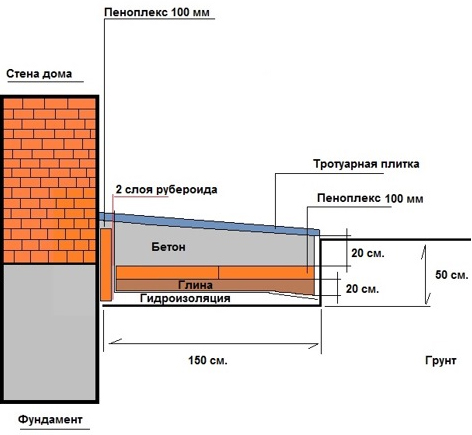

Purpose

Blind area - a wide strip adjacent to the building along the perimeter. It is performed at an angle of 5-10 degrees to the base of the house. Provides drainage of precipitation into the drainage system, soil. The protective functions of the foundation do not end with the surface coating. The structure of the structure assumes a layered design. It deepens into the earth's cavity by 0.25-0.5 m. The quantity, thickness, and type of the spherical layer completely depend on the climatic conditions of the region.

The blind area of the house is a multifunctional part of the building that simultaneously solves a number of tasks:

- Keeping the foundation, adjacent soil dry. It prevents the stagnation of water that destroys the concrete base, the appearance of microcracks, and the violation of the integrity of the building.

- Eliminates freezing of the soil near the foundation of the house. As the air temperature drops, the water in the ground freezes. An increase in its volume is observed. The soil presses on the foundation, destroying it. The blind area keeps the building dry. Separates the values of positive, negative temperature marks. In addition to the outer covering, pillows, equip drainage, use waterproofing, insulating materials.

- Symbolizes the completeness, harmony of the architectural ensemble. Facing materials give style to the building. The blind area is a concise addition to the style. Echoes with individual elements of landscape style.

- sidewalk function. Combining the pedestrian zone with the blind area, the usable space of the local area is saved.

What is the need for insulation?

The blind area keeps the land adjacent to the building dry. Minimizes the possible consequences of the influence of low air temperature on the structure.

Warming is needed if:

- The building is erected on heaving type soil.

- The depth of the base is less than the depth of soil freezing.

Types of external insulation

The nature of external insulation depends on the type of soil and the foundation itself. A shallow foundation, that is, not reaching the level of freezing, most often suffers from heaving of the soil, experiencing strong lateral pressure and pressure from below. And the base of deep occurrence suffers from high humidity when the soil thaws.

The following types of external insulation of the foundation are known:

- vertical insulation - involves the installation of heat insulator plates with your own hands from the outside over the entire surface of the foundation, including the basement. The method provides excellent protection against moisture and high-quality insulation;

- horizontal - the base of the building is insulated from below. The material is laid on the bottom of the trench before pouring concrete. Thus, freezing of the base is prevented;

- blind area insulation - a horizontal concrete strip that protects the foundation from rainwater. Penoplex is laid under the blind area. This helps to redistribute the load during severe heaving.

Prices for insulation of the foundation with foam slabs depend on the type of insulation and the amount of accompanying work. For example, vertical thermal insulation can be carried out on the basis of an already built building, but for this you need to dig out the foundation to the depth. This, of course, increases the cost of the work.

Characteristics of penoplex

As a heat insulator, various materials were used and are now being used - polystyrene foam, mineral wool, expanded clay, and so on. However, it is extruded polystyrene foam that takes first place in the rating of builders.

The main advantages that ensure its use as a heat insulator are:

- extremely low thermal conductivity - of all modern materials, foam plastic conducts heat the least: 0.03-0.032 W / m C;

- high compressive strength - we are talking about the foundation, and the loads on it are significant;

- water resistance - the material does not absorb moisture and guarantees protection from groundwater;

- operating temperature range from -50 degrees to +75 degrees;

- light weight - makes it easy to install with your own hands;

- penoplex is not subject to rotting or mold action, chemical is inert.

The disadvantages of the material include only its weak resistance to fire. But since during insulation the polymer is under a layer of earth, this property can be neglected.

Do-it-yourself foundation thermal insulation technology

Fastening penoplex - the work itself is simple and easy to do with your own hands. But if the foundation of the building first needs to be dug out, then one cannot do without the involvement of assistants.

Initially, a trench up to 1.5 m wide is dug along the perimeter of the building. The depth of the trench should reach a sand cushion.

Penoplex is resistant to moisture, but with a high level of groundwater, drainage will not be superfluous. To do this, a layer of sand, crushed stone and geotextile is laid successively at the bottom of the trench, and a drainage pipe is placed on top. The pipe is sprinkled with crushed stone and covered with geotextile edges. The system perfectly copes with the removal of both groundwater and storm water.

The surface of the base is cleaned of dust, leveled with your own hands if necessary. Then waterproofing is carried out: bituminous or water-based polymer mastic is applied to the surface. Despite the fact that this process is laborious and dirty, the quality of foundation protection will be high!

After the foundation is prepared, you can begin work on its insulation. To fix the foam, an adhesive solution is used, which is prepared according to the instructions. Glue is applied to the plate in the corners and in the center. The plate is pressed against the foundation and held for several seconds. The next one fits tightly with it using the “thorn in the groove” method. The second layer is fixed in the same way, but placed so as to overlap the joints. The gaps between the foam boards must be filled with mounting foam or acrylic adhesive.

The material on the underground part of the base does not need additional fastening, since it is already held by the ground. On the aboveground part, the fasteners are duplicated with dowel-nails with a wide head (5 pieces for each plate).

After the insulation work is completed, the surface of the insulation must be plastered to protect it from the external environment. Then the trench is covered with soil (it can also be sand or expanded clay), and a warm blind area is built on top. The plinth with fixed foam can also be finished with plaster, stone or clinker tiles.

The proposed video discusses in detail the technology for insulating the foundation with foam plastic. Vertical thermal insulation is the most popular way to protect the foundation, as it is the most affordable. Horizontal insulation can only be carried out when laying the building. The blind area is often built in parallel with the first option on soils characterized by strong heaving. Combined insulation - both vertical and horizontal, can also be done in this way: use foam plastic as a fixed formwork. The material in this case helps to form a correct, geometrically accurate foundation, and protects it from freezing and moisture.

Carrying out work on your own

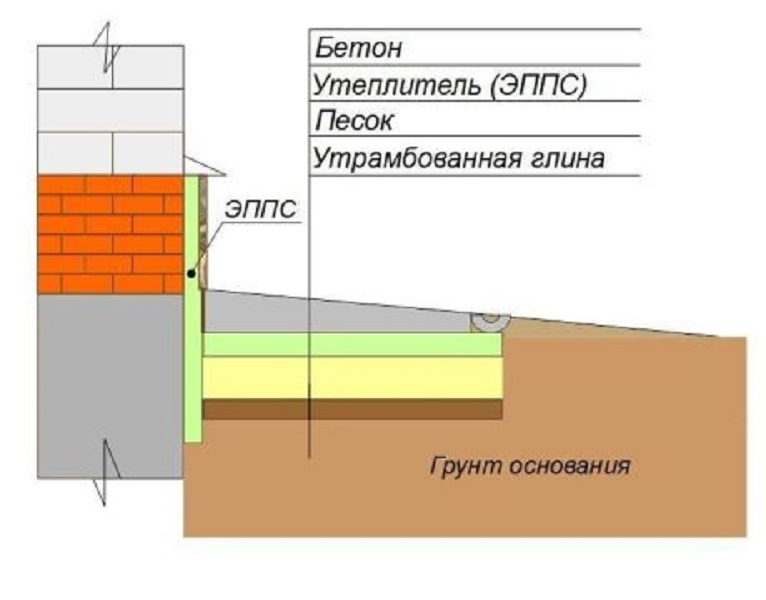

To isolate the basement and the blind area, you will need sheets of expanded polystyrene 10 cm thick

The scheme consists in the following actions: the top layer of the earth is removed to the depth of laying the material, while it is important to remove the root system of plants, which, when growing, damage the base. Along the perimeter of a private house, they dig a trench 0.5 m deep, crushed stone or broken brick is poured as a drainage layer for insulation. The thickness depends on the size of the granules and the parameters of the finish coat.

For the trench, a removable formwork is constructed from wooden boards and bars. To prevent water from seeping in, to insulate the blind area with your own hands, the walls and bottom are lined with clay. A layer 30 cm thick must be carefully compacted. The next step is to fill the sand as a substrate. For good shrinkage, it is watered. Thermal insulation is laid evenly around the perimeter, following the joints, they are filled with foam. The sheets are covered with a waterproofing membrane.

Nuances and possible errors

In any construction or renovation work, the main desire of homeowners is to reduce costs. Therefore, deviation from the scheme, the choice of low-quality materials lead to miscalculations, and the blind area with insulation does not perform the main function of frost protection. The main mistakes homeowners make are:

1. The first leveling layer of insufficient thickness and poor-quality compaction lead to shrinkage and cracking.

2. In the absence of a reinforcing mesh, the insulation does not adhere tightly to the base.

3. If the strips are not coated with a bituminous composition, the blind area and the foundation will not be provided with a flexible interface.

4. Continuous pouring of concrete without an expansion joint leads to ruptures of the insulation.

5. It is impossible to reduce the thickness of the strip closer to the outer edge, since rainfall from the roof will quickly damage it.

6. Without the organization of the gutter and drainpipes, the blind area and insulation will lose performance.

7. When using polyurethane foam, it is not recommended to make a substrate of sand. It is worth placing a layer of rubble on it.

Overview and description of materials

There are many varieties for work, but the most effective and expedient is the insulation of the blind area with polystyrene foam or polystyrene foam. Also, many owners use other polymers - polyurethane, Penoplex and bulk types, for example, expanded clay. To determine the most suitable option for the blind area, you can consider the characteristics and properties of each insulation.

1. Styrofoam.

To protect the foundation and the blind area, an extruded view is often used, since the use of a conventional one is less effective. Standard PPS, as well as polystyrene, must be laid in a layer of 10-15 cm, the joints are blown with foam, rolls of roofing material are fixed on top. Basement insulation with extruded polystyrene foam brings the best result. The technical characteristics of the material make it the most suitable for buildings for various purposes. Compared to other types, it has a one-piece structure, withstands temperatures from -500 to +75°C and 1000 vibration cycles.

Due to the unique properties, the thermal insulation is completely waterproof. With a monthly full immersion in liquid, expanded polystyrene gains moisture no more than 0.3% of the total volume. Low conductivity (0.028 W / mK) makes it possible to mount plates with a thickness of 5 mm, while not reducing the area of \u200b\u200bthe foundation. The insulation is not afraid of the influence of an aggressive chemical and biological environment; it does not collapse with constant contact with groundwater. Expanded polystyrene has been used for 40-50 years.

2. Expanded clay.

Differs in high properties of durability and incombustibility. Having a high melting point, it is not able to be exposed to fire and protects nearby surfaces. At the time of heating, it does not emit harmful substances into space, it is environmentally friendly.Its conductivity coefficient is not low enough, so the insulation issue is solved by using a thicker layer of granules. The brand of expanded clay varies depending on its bulk density, the most popular material for warming the blind area is M300 and M600. Water absorption ranges from 8 to 20%, the indicator is affected by the expanded clay manufacturing technology. To protect the foundation, a brickwork scheme is used, in which the granules fall asleep between the bearing plane and the concrete strip.

3. Penoplex.

Refers to extruded types of expanded polystyrene. In the manufacture, a mixture of freon and carbon dioxide is used for foaming. The result is a dense material with a uniform structure containing 0.2 mm cells. It has the lowest energy conductivity coefficient of all types, which is 0.03 W / mK, which means that when insulating the blind area, plates of small thickness will be required. Given the constant influence of groundwater and the peculiarities of heaving soil, Penoplex is resistant to negative impacts and destruction. The light weight of the thermal insulation allows you not to load the foundation, the products are easy to assemble with your own hands. They are not afraid of mold, they are not able to rot and decompose, rodents do not start in them. Penoplex for the plinth and blind area is produced in slabs with a size of 600x1200 mm and a thickness of 20-100 mm, which allows you to choose an option for each individual case when insulating.

4. Polyurethane foam.

The material is applied by spraying, which ensures that there are no joints through which water can penetrate into the foundation. It does not burn, the protective layer is created in a few hours, it is suitable for any surface, there is no need for preliminary leveling. Unlike Penoplex, this insulation contains toxic substances. Before spraying, the arrangement of the substrate is required for uniform distribution. It is not recommended to use sand, as it blows away with a strong jet under pressure. The best option is the laying of expanded clay or crushed stone when insulating the blind area. A layer of foam of 5-7 cm is enough to prevent cracking and apply mastic as an additional protection.

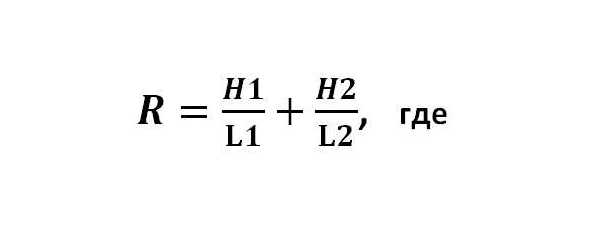

Calculation of thermal insulation

To insulate the foundation with foam plastic, you should calculate the thickness of the slab with your own hands. The nature of the soil and the climatic conditions of the region determine the parameters of thermal insulation. Manufacturers, as a rule, indicate the recommended thickness of the material in the instructions. For reliability, you can do the calculations yourself, using the following formula:

- R is the heat transfer resistance. The required value for each region can be found in the reference book. The thickness of the material must be such as to create the necessary resistance;

- H1- foundation thickness;

- H2 - desired thickness of the foam board;

- L1 - coefficient of thermal conductivity of the foundation;

- L2 is the thermal conductivity of the insulation.

By substituting the reference data for your region, you get the required plate thickness. This value is the minimum. When choosing a penoplex, it is necessary to round its value up.

For reliable thermal insulation, the material is laid in two layers so as to overlap the joints of the plates. Therefore, if the calculated value is, for example, 100 mm, then it is necessary to sheathe the foundation with slabs 50 mm thick, but in two layers.