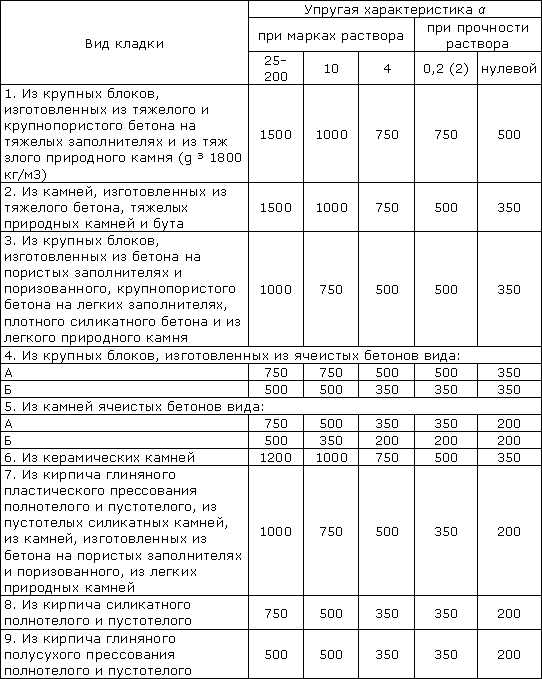

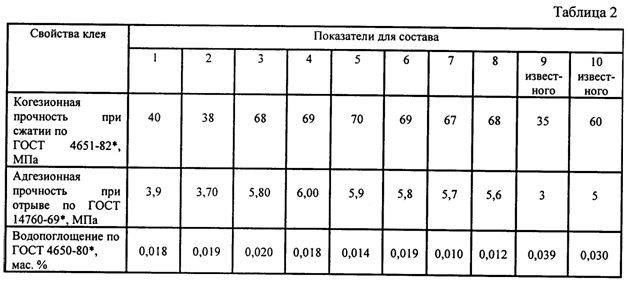

tables

The elasticity index is formed from many factors, including:

- brand of solution;

- the strength level of the cement mixture;

- type of masonry.

Similar data is shown in the table below. It can be noted that the separation occurs depending on the group of building material used. The total number of groups is 9 (6 types of stone, 3 types of bricks).

A brick or block can be made from various materials with their own elasticity. As can be seen from the table above, the modulus of elasticity of a ceramic brick differs from that of, for example, a large block.

The number of storeys of the future building, design features, compatibility of one or another element of the building, etc. are taken into account. Reinforced concrete masonry is considered the most resilient, and the coefficient is not calculated, and has a constant value of 2000 units.

Relative deformation

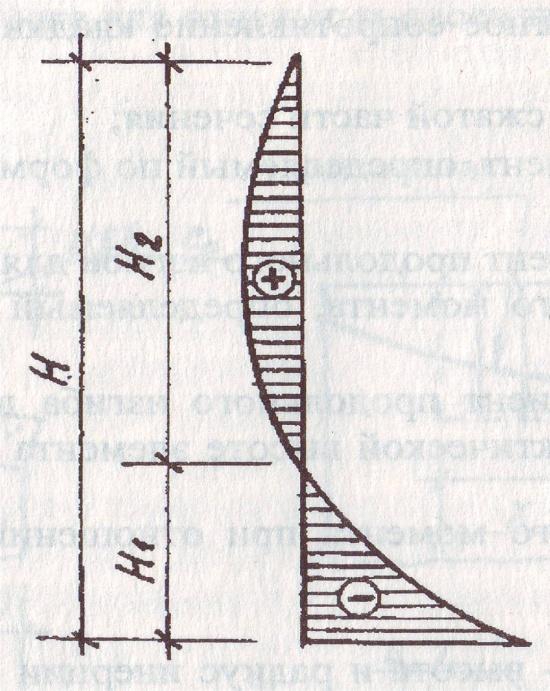

The modulus of elasticity of a ceramic brick is calculated due to the value of the relative deformation, which is obtained from the formula:

e = v*(σ/E0), where σ is the stress, v is the creep coefficient. As a rule, these data are taken from special tables, which significantly speeds up the design and construction process.

Nuances

You should not rely entirely on the calculations performed and the data given in the tables. Experienced builders navigate on an intuitive level. Indeed, even in the most accurate calculations, there may be a certain amount of error, which is not the best way to affect the quality of the object being built.

In addition, in atypical situations, this applies not only to the temperature regime, it is more correct to be guided by independent calculations.

The following indicators are taken into account:

shear modulus of shrinkage deformation;

· coefficients of linear expansion;

plane friction.

An individual approach in a given situation will allow you to accurately determine all the necessary values with an emphasis on the type of building material used.

How to decorate brick walls at home

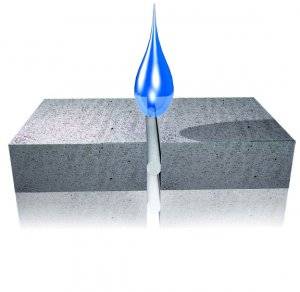

Technology of waterproofing expansion joints

Materials used in sealing expansion joints

- sealants or mastics,

- sealing clamps,

- profile systems,

- waterstops.

Using sealants or mastics is a great way to waterproof seams. Representing a one-component composition based on liquid rubber, the sealant, getting into the cavity, polymerizes, turning into a rubber-like mass. This material is characterized by complete moisture impermeability, resistance to chemically aggressive compounds, durability and high reliability. The disadvantages of this method include significant complexity.

Profile systems are considered to be the best way to protect expansion joints from the damaging effects of moisture. In addition, they provide structural reinforcement of the seam. Profiles can be used for joints in floors, roof slabs, walls, outside and inside the house. Using this material, you can ensure maximum durability of the seams, protect them from moisture and pollutants.

Waterstops are an innovative material that can be used for waterproofing expansion joints for various purposes. They are used outdoors and indoors. High water tightness and elasticity of waterstops allow them to be used in the most difficult operating conditions.

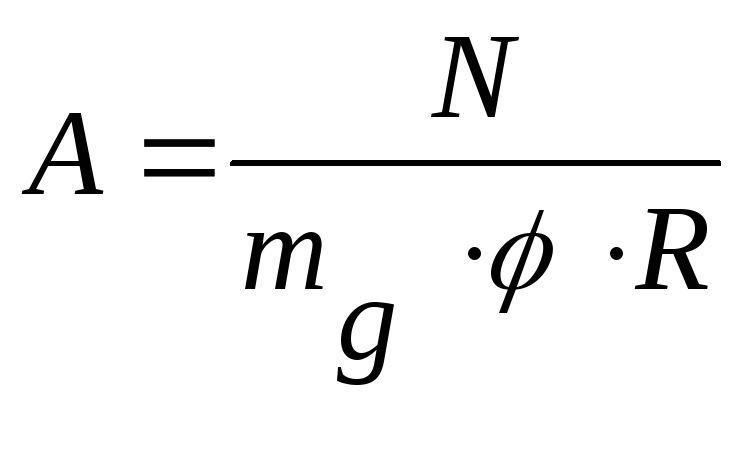

Calculation of the bearing capacity of centrally compressed elements of stone structures.

Payment

unreinforced stone elements

structures under central compression

produced according to the formula

,

,

where

N

is the design longitudinal force; R

- design resistance to compression of the masonry;

φ- coefficient

longitudinal bend;

A

is the sectional area of the element; mq- coefficient,

time-sensitive

loads.

R

(section selection) centrally compressed

element (column) according to the formula (4.1)

carried out by the method of sequential

approximation and is as follows:

a)

loads are determined for the calculated

columns N and Ng

(at the level of a particular floor), calculating

them as the sum of loads from all floors,

lying above the calculated section of the column

with approximate consideration of own

column mass as a load component

5 ... 10% of the calculated;

b)

masonry material is selected (type and brand

stones and the type and brand of solution) and

its calculated resistance is estimated

R;

v)

a certain value of φ is set, according to

to which relevant

λ valuesh

(λi);

G)

according to the found flexibility λh

(λi)

the coefficient η is determined;

e)

using pre-assembled

per column load N and Ng,

coefficient m is determinedg;

e)

by formula (4.1)

cross-sectional area is calculated

column A

responsible

at a given load masonry material

and the accepted coefficient φ;

g)

the value of A from formula (4.2) is expressed through

specific cross-sectional dimensions

column h x

b

=A,

if the post is rectangular, or h

x

h

=A,

if the post is square, rounding up to

multiple values (taking into account the thickness of the seams

masonry) the dimensions of the brick (stone) in terms of;

h)

according to the accepted geometric dimensions

post cross-section, elastic

masonry characteristic α and calculated

the height of the column, its flexibility is calculated

λh

(λi);

and)

we find the coefficients φ and η corresponding to

λh

(λi)

according to p. h) and determine the coefficient mq;

To)

the obtained values of φ and mg,

more precisely, the product of these coefficients

φ mg,

compare with the original. If received

product (φ mg)floor

differs from the original (φ mg)ref

more than 5%, i.e. there is an inequality

,

,

then

the calculation should be repeated, taking

the obtained values of φ and mg

for the original.

Payment

considered completed upon satisfaction

inequalities

.

.

O

pole cross section dimensions

match last value

(φ mg)ref

in the described process of sequential

approximations.

Process

successive approximation is more convenient

start with φ=1.0. In this case, η=0 and mg

ref=1,0.

One should also take into account the condition mg=1,0,

if h≥30 cm or i≥8.7

cm.

Calculations

show that, as a rule, it is enough

1-2 approximations to meet

inequalities (4.4).

Strength of masonry in tension, shear and bending.

Regulatory

and design resistance of stone

masonry.

Strength

tensile masonry

Strength

masonry when working on them

stretching, shearing and bending depends mainly

way from the amount of adhesion between

mortar and stone.

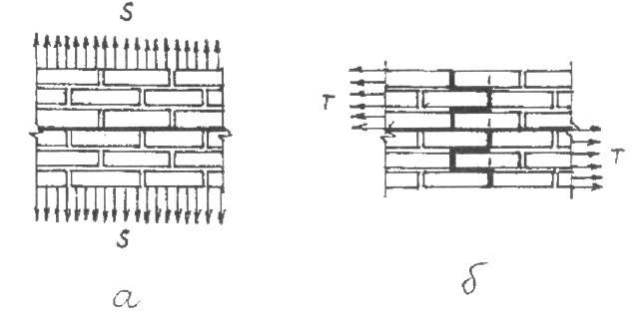

Distinguish

two types of clutch: normal - S (Fig.

10.9, a) and tangent - T (Fig. 10.9, b).

Experiments

showed that tangential cohesion in

twice the normal

T=2·S.

Clutch

increases over time and reaches 100%

after 28 days.

V

vertical seams of masonry, due to

mortar shrinkage during curing, adhesion

its with the stone greatly weakened

or completely violated with one of

adjacent side surfaces

stone.

So

in calculations of adhesion in vertical

seams are not taken into account, but are taken into account

adhesion only in horizontal seams

masonry.

V

according to tangent and normal

There are two types of clutch

sprains

masonry: stretching on unbandaged

and over the tied seam.

Fig.10.9

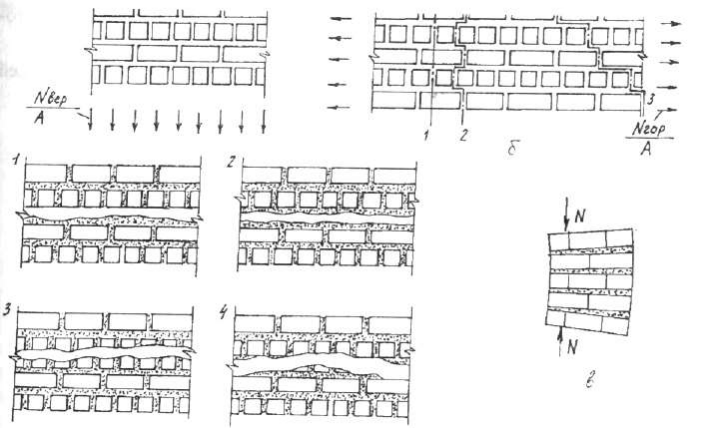

Rice.

10.10. Correct masonry work

tensile molds:

a

- on non-bandaged sections (cases

1-4); b - according to the tied sections; in - by

unbandaged

sections

under eccentric compression

Strength

cutting masonry

Limit

strength of masonry when sheared along

unbandaged sections is determined

on

law

Coulomb (Fig. 10.11, a), according to which

Wed

= sc

+ ƒ

where

sc

- tangential adhesion (sc

= 2 ss,ss,

— normal grip);

ƒ

- coefficient of friction in the seams of masonry,

equal: 0.7 - for masonry from solid

brick

and

stones of the correct form; 0.3 - for masonry

from hollow bricks and stones with

vertical

voids;-

mean normal compressive stress

at the lowest longitudinal force.

Rice.

10. 11. Correct stone masonry cut

forms:

a

- for unbandaged sections; c, d -

cut along an untied seam in a masonry

retaining wall and at the heel of the arch; e - cut

masonry along the bandaged seam in the cantilevered

overhang

Strength

masonry in bending

bend

in masonry causes tension,

which determines the strength

masonry

over the stretched area.

Mel

= t

= t(10.4)

On the

in fact, thanks to the fact that

masonry, in addition to elastic, there are also

plastic

deformations, diagram of normal stresses

curvilinear (Fig. 10.12, b) and, if its

take rectangular (which is very close

to the actual plot), we get:

mpl

= t=

t(10.5)

then

there are 1.5 times more than with elastic

work. In practical calculations

enjoy

formulas

resistance of materials and moment

resistance W is determined as for

elastic

material. Design resistance

masonry tensile bending

bandaged

section Rtb take about 1.5 times

more than estimated

resistance

masonry under central tension Rt.

Kinds

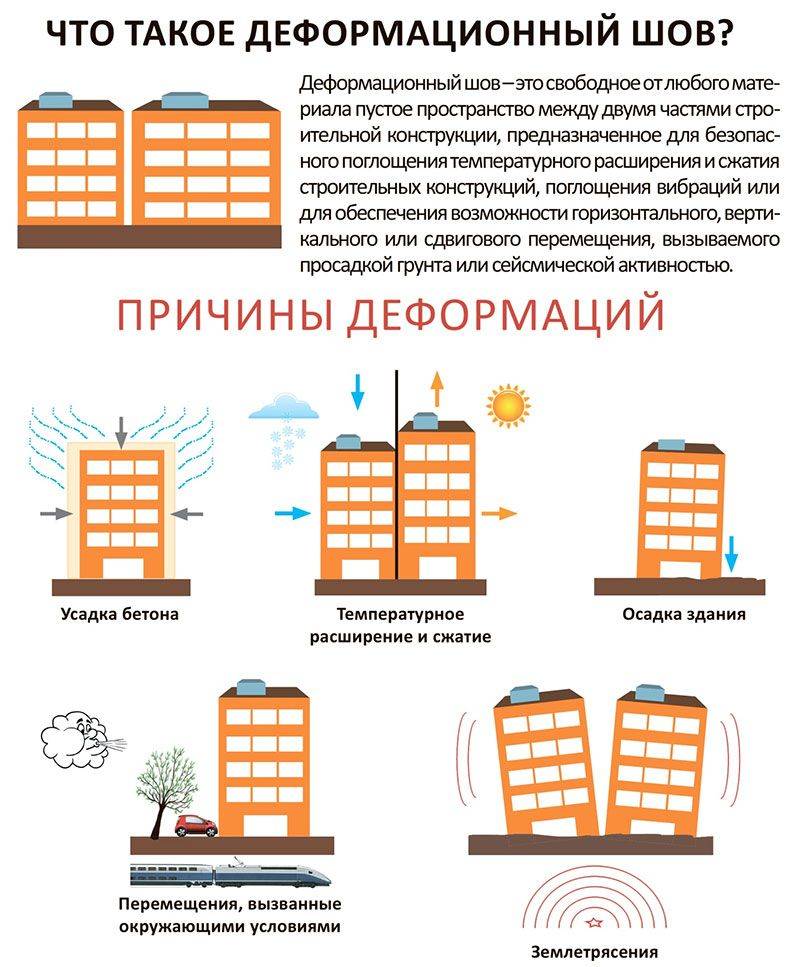

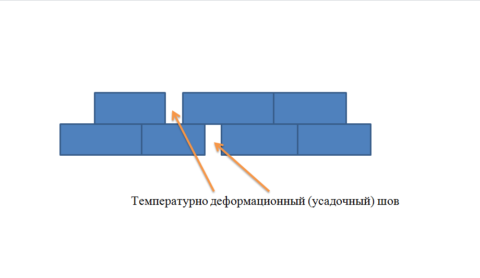

There are several types of seams that increase the stability of the structure to various factors affecting its durability:

Temperature connections provide reliable protection of walls from the negative effects of changes in ambient temperatures. Their device complies with the regulations of SNiP II-22-81, paragraphs 6.78-6.82.

Their peculiarity lies in the fact that such seams are arranged in accordance with the height of the walls, without affecting the foundation.

A brick wall at a temperature of + 20 ° C in the hot season and -18 ° C or lower during the winter cold expands and narrows. Accordingly, its height changes.

Sedimentary joints are designed to protect the load-bearing walls of the building from deformation and premature destruction under the influence of increased loads. It is these loads that lead to uneven shrinkage of the building and the appearance of cracks on the walls.

These defects occur most often during the construction of multi-storey buildings. Sedimentary expansion joints begin to form from the foundation of the house.

Anti-seismic seams are those whose device is mandatory in areas with increased seismic hazard. Soil mobility and tremors lead to significant deformations, which result in cracking of the walls and their subsequent destruction.The peculiarity of such seams is that with their help the building is divided into separate stable blocks.

The ability of the building to withstand deformations, its reliability and durability depends on the quality of the filling of the seam.

Device

The most common is the temperature expansion joint, since significant temperature changes are becoming one of the most common reasons why the walls of buildings crack and collapse. The width of the arranged seam also depends on the temperature level.

In accordance with the regulations, it cannot be less than 2 cm, and in some cases reaches 3 cm. This is due to the fact that the expansion joints have sufficient horizontal mobility. The distance between the seams is at least 15 and not more than 20 m. In the hottest areas, this distance can be reduced to 10 m. For more information about the need for masonry joints, see this video:

- harnesses;

- elastic fillers, characterized by the ability to maintain elasticity after hardening;

- bentonite or other substances that contain a small percentage of concrete;

- high elasticity sealants.

The construction of the expansion joint begins during the construction of the house. To do this, it is enough to retreat the required distance from the main masonry and fill it with insulation or sealant. The installation process will be easier if the depth of the sealant is small.

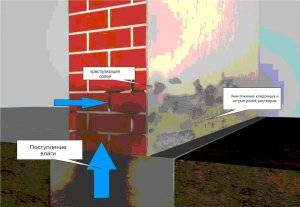

Waterproofing masonry main types

- paint waterproofing. We clean the surface of debris, dry and primer. Next, we apply several layers of waterproof composition. The quality and service life of the insulation depends on how even and continuous the layer will be. Therefore, all defective areas should be processed several times. These can be bitumen emulsions, pastes, mastics, bitumen-polymer, polymer-cement compositions. Hot compositions have increased frost and moisture resistance. Cold mastics, pastes and emulsions may crack when frozen; - simultaneous application of horizontal and vertical waterproofing of brickwork. With this method, a solution of cement or asphalt or roll insulation is used. A layer of screed is applied to the foundation slab and walls, followed by masonry. If you use the roll method of protection against moisture, then pasting should be carried out in stages. We apply a layer of mastic on the surface, then a layer of material (for example, roofing material), then a second layer of mastic and the next layer of roll material. We clean the vertical surface of dust and soil and run it in with mastic, glue the layers overlapping with horizontal insulation, so that subsequently moisture cannot penetrate into the joints. - penetrating protection against moisture. The penetrating composition forms crystals in the pores of the building material, which reliably block the access of moisture to the inside of the structure, but at the same time do not impede air circulation. Penetrating compositions are applied to a brick wall using a special technology: - strobes are created in the masonry joints for 2/3 of the thickness of the masonry using a chisel and a perforator; - strobes are cleaned and washed; - a penetrating compound is placed in the seams; - a penetrating mixture (waterproofing plaster) is applied to the entire surface of the wall in several stages. Over the next 3 days, you need to constantly moisturize.The reinforcement of the plaster is carried out using a fiberglass mesh, which is then impregnated with a special alkali-resistant composition. The thickness of the insulation layer reaches 30 mm; - injection waterproofing. It is a kind of penetrating moisture protection, characterized by high technical qualities and durability. The materials are liquid rubber or liquid glass. Liquid glass is added to a concrete solution or used in its pure form. Liquid rubber is applied by spraying.

High-quality waterproofing of expansion joints and brickwork will reliably protect the house from moisture, eliminate the risk of corrosion of reinforcement used in reinforced concrete foundations, increase the chemical resistance of building materials, and prevent the formation of mold and mildew in the house.

expansion joints

6.78.Thermal shrinkage joints in

walls of stone buildings should be arranged

in places of possible concentration

temperature and shrinkage deformations,

which may cause unacceptable

operating conditions masonry breaks,

cracks, distortions and shifts of masonry along

seams (at the ends of extended reinforced

and steel inclusions, as well as in places

significant weakening of the walls by holes

or openings). Distances between

temperature-shrinkable seams should

set by calculation.

6.79.Maximum distances between

temperature-shrinkable seams, which

allowed to be accepted for unreinforced

external walls without calculation:

a) for elevated stone and large-block

walls of heated buildings with a length

reinforced concrete and steel

inclusions (lintels, beams, etc.)

more than 3.5 m and the width of the walls is not less than

0.8 m - according to the table. 32; with inclusion length

more than 3.5 m masonry sections at the ends

inclusions should be checked by calculation

strength and crack opening;

b) the same, for walls made of rubble concrete - according to

tab. 32 as for concrete masonry

on solutions of grade 50 with a coefficient

0,5;

c) the same, for multilayer walls - according to

tab. 32 for base material

structural layer of walls;

d) for unheated stone walls

buildings and structures for the conditions specified

in paragraph "a", - according to the table. 32 multiplied by

odds:

for closed buildings and structures - 0.7

for open structures - 0.6

e) for stone and large-block walls

underground structures and foundations

buildings located in the zone of seasonal

soil freezing, - according to the table. 32 s

doubling; for walls

below the seasonal line

soil freezing, as well as in the zone of eternal

permafrost - no length limit.

Table 32

|

Distance |

||||

|

Medium |

from clay |

from silicate |

||

|

on solutions |

||||

|

50 or more |

25 or more |

50 or more |

25 or more |

|

|

Minus 40С |

50 |

60 |

35 |

40 |

|

Minus 30С |

70 |

90 |

50 |

60 |

|

Minus 20С |

100 |

120 |

70 |

80 |

|

Notes:1. For intermediate

2. Distances between temperature-shrinkage |

6.80.expansion joints in walls

associated with reinforced concrete or steel

structures must match

seams in these designs. If necessary

depending on the design scheme

buildings in masonry walls should be provided

additional expansion joints without

cutting seams in these places of reinforced concrete

or steel structures.

6.81.Sedimentary seams in the walls should

be provided in all cases

when uneven settlement is possible

foundations of a building or structure.

6.82.Deformation and sedimentary seams

should be designed with tongue and groove or

a quarter filled with elastic

gaskets to prevent

blowing seams.

Insulation and insulation options

In order to protect against environmental influences and prevent the occurrence of drafts inside the building, all deformation gaps without exception are insulated. For this, a protective hermetic layer is created using elastic materials. The choice of insulation depends on the size of the expansion joint. In this case, one type of material or a combination of them is used. The table shows the type of insulation depending on the width of the temperature gap in the brickwork:

| Seam width, mm | insulation | |

|---|---|---|

| up to 30 | Mounting foam | |

| over 30 | Vilaterm | Mounting foam |

| Styrofoam |

For sealing insulated seams use:

- two-component sealant;

- galvanized expansion joint.

Polyurethane sealant is used because it has a long service life and a high level of flexibility of the sealing layer. Strengthening and sewing the joint with a galvanized expansion joint with a deformation bend will last a longer period. Its durability is determined by the aging of the metal. In case of damage to the tightness of the expansion joint or its insulation, repair work is carried out.

How to make expansion or shrinkage seams

Now directly about the performance of work. As you can see, their design is almost not specified in the norms. It is difficult to find literature on this subject. Therefore, we will give practical advice based on existing project documentation and building structures.

Location of shrink joints

With the location of the temperature expansion joints, everything is clear, the maximum distances between them are taken according to SNiP (you can take less, but why).

But the question arises - where to arrange shrinkage seams? Sometimes it is clear that we cannot do without them, the ground is weak and cracks are visible on many buildings located nearby, which means that our house may also be in a similar situation.

It is clear that no one will study geology and carry out calculations if we build a house with our own hands. We will move away from SNiP (if cracks appear in your personal building because of this, then no one will punish for this) and arrange them without calculations.

It’s easy to decide where to make seams - look at where shrinkage cracks most often form in houses, as a rule, at a distance of 1-2 meters from the corners. There we will make shrink seams.

For large buildings, it is also desirable to additionally make a seam in those places where the structure and properties of the soil are clearly changing. For example, on the border of natural and bulk soil.

How wide should the seams be?

There is no mention of this in the rules either. But almost always the width of the seam is chosen at 10-20 mm. If you use special seam profiles for sealing, then we select this value in accordance with the width of the profile.

We arrange the seams

As already mentioned, the seams should have a quarter or groove profile. When doing masonry, this is easy to do in most cases.

- If the wall is a quarter or half a brick, then you will have to chop or cut the bricks, choosing a quarter or ridge and groove profile in them. This is time consuming but, as a rule, such small thickness masonry is not used for load-bearing walls that require the creation of shrinkage and expansion joints.

- With a brick wall, we achieve the quarter effect with the help of ordering - in the area of \u200b\u200bthe seam, it will look something like this.

When performing expansion joints, it is desirable that the mortar squeezed out during the installation of the brick does not get into it and accidentally connect the rows on both sides. Therefore, we distribute it so that on the edges of the bricks facing the seam, we get a “wasteland”.

Also, if you want the seams not to stand out on the wall surface, you can make them not in the form of vertical lines, but in a zigzag pattern in accordance with the vertical order. This makes it easier to lay, but then it will be more difficult to fill the seams with insulating material.

Seams in masonry that has been laid before

Such an option is also possible. When the foundation is settling, instead of reinforcing it (especially with weak soils), you can simply make shrinkage seams. Such an approach is possible in principle, although its implementation will cause difficulties.

You can cut through a wall one and a half two bricks thick with a large-diameter disc, and seam saws with such a working body, as a rule, are designed to work on horizontal surfaces (floors and roads) and not on vertical ones.

Types of expansion joints in a brick multi-storey building

In addition to temperature, there are other types of expansion joints in masonry, such as:

- shrinkage;

- sedimentary;

- seismic.

All types of special gaps protect each structural unit of the house from destruction and prevent the formation of cracks in load-bearing and other walls. Temperature and shrinkage voids are made in all brick houses without exception. Sedimentary ones perform a protective function against destruction under high loads and are needed in multi-storey buildings and houses with an extension. They are made starting from the foundation, but the device is made according to the principle of vertical temperature gaps, so it is possible to combine them into heat-shrinkable ones and create them in one firmware. It is expedient to make seismic voids only in areas with increased seismic activity.

Temperature joint

How to create an expansion joint? This will require:

- perforator;

- only;

- tow;

- clay castle (clay, sand, water, straw).

This type of protection is provided in a horizontal projection even during bricklaying and must be indicated in the project of the house. For its arrangement, a tongue and groove is used in the masonry, which is lined with two layers of roofing paper, then tightened with tow and coated with a clay castle on top.

A tongue and groove is created in the masonry even during construction, but if this was not provided for, but the work needs to be done, then it can be organized with your own hands using a perforator, but this should be done very carefully. A tongue and groove is a recess in something (for example, a brick wall), which serves to attach a part that has a reverse structure.

Such notches are always horizontal. A sheet pile is made 2 bricks high and with a depth of 0.5.

It is covered with two layers of roofing felt, and tow is clogged inside. Due to their properties, they do not react to temperature changes and will not allow a brick wall to react to them.

At the final stage, expansion joints should be coated. Many use cement mortar, but a clay castle will be much more effective, because. has three necessary functions at once: decorative (with brickwork, such a castle will not attract unnecessary attention), thermally insulating (clay perfectly holds any temperatures, and clay houses are compared with thermoses), waterproofing (clay castle will not let moisture in and will not get wet, no matter what It happened). Such a seam can be done quite carefully, after which it will no longer be necessary to veneer it to create a design.

Conclusion and Conclusions

After finishing work on the seams in the brickwork, the clay should be allowed to harden. This should take at least a day.This will make it even stronger and more durable. Despite this, from time to time it is still worth checking the condition of the house, and if suddenly there are signs of problems, immediately eliminate them. The frequency of inspections may not exceed 1 time per year.

The temperatures act simultaneously over the entire area in the brickwork, therefore, if such a seam is made on each floor immediately above the partition, this will protect the entire house, and the quality of the structure will not suffer in the end. Many builders during the construction of buildings and structures make not only horizontal expansion joints, but also vertical expansion joints.