GRU REQUIREMENTS

GRU can be located in the room where gas-using equipment is located, as well as directly at thermal installations for supplying gas to their burners.

It is allowed to supply gas from one GRU to thermal units located in other premises of the same building, provided that these units operate in the same gas pressure regimes and the premises where the units are located have round-the-clock access to the personnel responsible for the safe operation of gas equipment.

The number of GRU placed in one room is not limited. Moreover, each GRU should not have more than two control lines.

GRU can be installed at an inlet gas pressure of not more than 0.6 MPa.

At the same time, the GRU is located:

Decided to turn on the gas? But don't know where to start? Start with a Call

+ 7 (495) 989-18-49

in the premises of categories G and D, in which gas-using installations are located, or in adjacent premises connected to them by open openings of the same categories, having ventilation according to the production located in them;

in rooms of categories B1-B4, if the gas-using installations located in them are built into the technological units of production.

It is not allowed to place the GRU in the premises of categories A and B.

EQUIPMENT FOR Fracturing, GRPB, ShRP AND GRU

GRP, GRPB, ShRP and GRU should be equipped with a filter, a safety shut-off valve (PZK), a gas pressure regulator, a safety relief valve (PSK), shutoff valves, control measuring instruments (CIP) and a gas flow metering unit, if necessary, as well as bypass gas pipeline (bypass) with two sequentially located disconnecting devices on it.

It is allowed not to provide for a bypass device in the ShRP intended for gas supply to a single-family house.

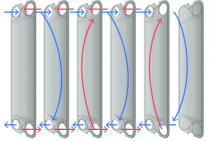

At an inlet pressure of more than 0.6 MPa, hydraulic fracturing or GRU with a gas flow rate of more than 5000 m3/h, and ShRP with a gas flow rate of more than 100 m3/h, should be equipped with two reduction lines instead of a bypass.

When placing a part of the shutoff valves, instruments and equipment outside the building of the hydraulic fracturing plant, the gas distribution unit or the ShRP, the conditions for their operation must be ensured, corresponding to those indicated in the passports of the manufacturers. Equipment located outside the PIU, GRBP and ShRP building must be fenced.

Filters installed in the hydraulic fracturing, gas-fracturing, SHRP and GRU must have devices for determining the pressure drop in it, which characterizes the degree of clogging of the filter cassette at the maximum gas flow rate.

PZK and PSK should provide, respectively, automatic interruption of the supply or discharge of gas into the atmosphere when the pressure in the gas pipeline changes, which is unacceptable for the safe and normal operation of gas-using and gas equipment.

In the hydraulic fracturing, gas-fracturing, gas-distribution and gas-distributing substation, a system of purge and discharge pipelines should be provided for purging gas pipelines and discharging gas from the PSK, which are led outside to places where safe conditions for gas dispersion are provided.

In GRP, GRPB, ShRP and GRU, indicating and recording instruments for measuring the inlet and outlet pressure of gas, as well as its temperature, should be installed or included in the APCS RG.

Portable devices can be used in SRP.

Control and measuring devices with an electrical output signal and electrical equipment located in the premises of hydraulic fracturing and hydraulic fracturing with explosive zones should be provided in an explosion-proof design.

Instrumentation with an electrical output signal in the normal version should be located outside, outside the explosive zone in a lockable cabinet made of non-combustible materials or in a separate room attached to the fire-resistant gas-tight (within the adjoining) wall of the hydraulic distribution and hydraulic distribution plant.

The input of impulse gas pipelines into this room for transmitting gas pressure pulses to the instruments should be carried out in such a way as to exclude the possibility of gas entering the instrumentation room.

The electrical equipment and electric lighting of the GRP and GRPB must comply with the requirements of the rules for the installation of electrical installations.

Cabinet gas control points

Purpose

Gas control points of types GRPSH, GRP, GRPN, UGRSH, GSGO are used to reduce the medium and high pressure of natural gases, as well as other non-aggressive gases, to the required level. increase in outlet pressure. In gas control points, the technological equipment is located in a metal cabinet with refractory insulation (installed at the request of the customer). Including gas control points are used in gas supply systems of agricultural, industrial, public and municipal enterprises.

The conditions for the use of gas control points are drawn up in accordance with climatic modifications in accordance with GOST 15150:

• UHL4 at temperatures from 0 to +60ºС – production on a frame. • У1 (ХЛ1) at temperatures from -40 to +60ºС (from -60 to +60ºС) – production in a cabinet; The average service life is at least 15 years. The intended service life of the gas control station is 40 years. Briefly about the composition of gas control points.

The composition of gas control points includes the following main equipment:

• heating system (from an external source, from a gas heater or from electric heaters in an explosion-proof form); • gas filters for cleaning gases from mechanical impurities; • gas pressure regulators types RDGD, RDU-32, RDSK, RDBC1,RDG, RDNK and other regulators acceptable for use; • safety relief valves such as PSK, KPS; • safety shut-off valves type KPZ, PKN; • pressure gauges for visual control of the working pressure of the measured gas at the inlet and outlet; • shutoff valves; The heating system is installed at the request of the customer. Also, according to the requirements of the customer, gas control points can be supplemented with pressure drop indicators necessary for measuring pressure drops on the filter or with a differential pressure gauge.

According to the requirements of the customer, gas control points are manufactured:

• with one reduction line and a bypass line (bypass); • with two reduction lines (main and reserve); • with two reduction lines with two outlets; • with two regulators connected in series;

According to customer requirements, you can choose the direction of location of the inlet and outlet nozzles:

• with horizontal or vertical gas supply; • entrance-exit from right to left; • input-output from left to right; • entrance-exit from one side;

According to the customer's requirements, gas control points are completed with a set of waste plugs.

Note!

Gas control points can be upgraded with a control and monitoring system, which are equipped with mobile communication devices based on a control and monitoring cabinet of the ShKU GRP in an explosion-proof form. ShKU GRP is made for permanent remote control of the technical parameters of gas control points using standard mobile communication channels.

Regarding the configuration of the HCU, the hydraulic fracturing implements the registration, transmission and collection of electronic signals:

• about the pressure drop across the filter; • gas contamination inside the cabinet; • from pressure and temperature sensors; • about unauthorized opening of premises and other parameters at the request of the customer.

At the request of the customer, gas control points can be improved:

• differential pressure sensor to measure the differential pressure across the filter; • gauges of excessive pressure for control of input and output pressure;

The advantage of gas control points equipped with control and monitoring cabinets is as follows:

• convenient location of automation equipment inside the gas control points, providing good access for maintenance; • complete delivery of equipment; • remote access to the settings of the fracturing control panel via mobile communication channels; • high level of automation based on modern industrial controller; • flexibility of software and hardware configuration; • the ability to integrate into existing automated process control systems; • high quality and reliability; • low cost of components;

Shrp what is decryption

Dictionary of abbreviations and abbreviations. Academician. 2015 .

See what “SHRP-” is in other dictionaries:

cabinet gas control station (SHRP) - a technological device in a cabinet design, designed to reduce gas pressure and maintain it at specified levels in gas distribution networks; Source ... Dictionary-reference book of terms of regulatory and technical documentation

Cabinet gas control station (SHRP) 1 is a technological device in a cabinet design designed to reduce gas pressure and maintain it at specified levels in gas distribution networks. Source ... Dictionary-reference book of terms of regulatory and technical documentation

STO Gazprom 2-3.6-033-2005: Regulation on the organization and implementation of control over ensuring the operability and safe operation of gas distribution systems - Terminology STO Gazprom 2 3.6 033 2005: Regulation on the organization and implementation of control over ensuring the operability and safe operation of gas distribution systems: Accident3 destruction structures and (or) technical devices, ... ... Glossary-reference book of terms of regulatory and technical documentation

ShR - plug connector Dictionaries: Dictionary of abbreviations and abbreviations of the army and special services. Comp. A. A. Shchelokov. M .: AST Publishing House LLC, Geleos Publishing House CJSC, 2003. 318 p., S. Fadeev. Dictionary of abbreviations of the modern Russian language. S. Pb .: ... ... Dictionary of abbreviations and abbreviations

Scotland is an administrative political part of the United Kingdom of Great Britain and Northern Ireland. It occupies the northern part of Great Britain and adjacent islands: Hebrides, Orkney, Shetland. Sh. has some autonomous ... Great Soviet Encyclopedia

SCOTLAND - (Scotland) ist. an area in Great Britain (until the middle of the 17th century it was an independent state). Occupies sev. part about. Great Britain and adjacent small islands, as well as the Hebrides, Orkney and Shetland Islands. Area 78.7 thousand km2. US. 5227.7 thousand people ... ... Soviet historical encyclopedia

cabinet gas control station - ShRP Technological device in cabinet design, designed to reduce gas pressure and maintain it at specified levels in gas distribution networks. [PB 12 529 03 Safety rules for gas distribution and gas consumption systems, ... ... Technical translator's guide

OST 153-39.3-051-2003: Technical operation of gas distribution systems. Basic provisions. Gas distribution networks and gas equipment of buildings. Tank and balloon installations - Terminology OST 153 39.3 051 2003: Technical operation of gas distribution systems. Basic provisions. Gas distribution networks and gas equipment of buildings. Tank and balloon installations: SDR standard dimensional ratio ... ... Dictionary-reference book of terms of regulatory and technical documentation

Cabinet regulatory points

Cabinet regulatory points

Cabinet Regulatory Points (SHRP) , TU U 29.1-20016760-019:2009, are designed to reduce (lower) gas pressure, are used in the domestic and industrial sectors: columns, boilers, industrial furnaces, burners, as well as other gas-consuming equipment that requires accurate and fast regulation of gas pressure, its cleaning and, if necessary, commercial accounting. A balanced compensation system ensures that the outlet pressure remains constant while the inlet pressure varies. In addition, the equipment provides emergency shutdown in case of a sharp increase or decrease in gas pressure.

Feature of this equipment is its compactness, the use of high-quality components of well-known domestic and foreign companies, an original and easy-to-connect and maintain layout that allows you to place the metering unit in the same cabinet with the reduction unit, practically without increasing the size of the cabinet and providing gas supply and output from any side of the equipment. The use of original design and technological solutions allows us to talk about economical gas consumption when using this equipment, which is relevant in the current conditions. At the request of the customer, we can perform supervised installation, service, spare parts, as well as installation of additional reduction lines on previously purchased equipment. For stable and sustainable operation of the heating equipment you need, we suggest ordering it from us together with ShRP. JV "Ukrinterm" offers the production of ShRP for individual orders, after filling out the questionnaire.

Modifications: ShRP are issued both in cabinet execution, and on a frame. They include 1 or 2 lines for reducing (lowering) gas pressure, 1 or 2 bypasses, a gas filter, an additional safety relief valve (PSK, to ensure reliability, in order to prevent high pressure gas from entering the low pressure side), pressure gauges, stop valve.

1 reduction line + bypass 1 reduction line + bypass* 1 reduction line + 2 bypasses 2 reduction lines (1 working + 1 standby) 2 reduction lines + bypass 2 reduction lines + 2 bypasses

* the possibility of increasing the number of reduction lines to two on previously purchased equipment.

Designation example: ShRP/1-300-2/B2 - cabinet control unit, version - 1, maximum capacity - 300 m3/h, 2 reduction lines + 2 bypasses

Outlet pressure ranges for versions: Household: ShRP/B - Pout from 5 to 25 mbar

Industrial: SRP/1 - Pout from 5 to 350 mbar SRP/2 - Pout from 20 to 2000 mbar SRP/3 - Pout from 20 to 2500 mbar

Price list for maintenance and repair of the boiler room

I really want to be a journalist! - with these words, at the age of 13, I confidently entered the office of the editor-in-chief of one of the Oryol newspapers. And I got my first job. It all started with him. After a couple of years, I combined my studies with the work of a journalist. In the 9th grade, I wrote with might and main in my signature column “City Streets”.\r\n \r\nAnd two years later I came to the Faculty of Journalism of OSU with a huge folder of publications.

This type of fuel has a rather high cost, but it should not be immediately abandoned, because firewood, due to its high heat transfer, heats the room well, leaves much less ash, the boiler is loaded quite simply and quickly and the chimney pollution is relatively low compared to other types. solid fuel.

I pulled myself together, I am writing a calm letter to the Tula OFAS. I explain why I am not satisfied with the answer. And again I ask the question: on what legal basis do gas workers require a subscription fee for maintenance from me? I receive a letter - now signed by the head of the department Yu.V. Yelagin. And it does not answer the main question.

In order to find the answer, on what basis the cost of services for heat and hot water is calculated, one should find out how legal relations are organized in the situation under consideration. If the Management Company is the full owner of the rooftop boiler house (there is a boiler house purchase and sale agreement), then the billing should be carried out at citywide rates.

The gas pipeline must be provided with free access for its maintenance. That is, the gas pipeline pipe should not be closed, sheathed with sheets of drywall or other materials. SNiP allows when the gas pipeline on the inner wall of the house can be closed with easily removable panels. But the panels should not be fastened with self-tapping screws.

Question from a reader: “Please help me understand the issue of the cost of heating and hot water supply. Our house is serviced by the Management Company, there is a rooftop boiler house on the roof of the house, but the cost of heating and hot water services is at the city level. Why and what then is the advantage of a rooftop boiler?

The Russian authorities are tightening the requirements for servicing gas equipment installed in apartments, as well as for accounting for gas consumption. The issue of introducing smart meters for gas is currently being worked out, along with smart electricity meters, which will become mandatory for Russians from 2021.

I looked at the receipts for the last year - in them maintenance was estimated at 92 rubles a year. Growth more than 16 times!