Preliminary preparation

Welding of polypropylene pipes is impossible without a number of preliminary works. Surfaces must be wiped with a rag and degreased with special liquids.

After this, work must be done in the following order:

- Warm up the welding machine. The heating time directly depends on the ambient temperature and can take from 2 to 10 minutes. The optimum temperature is about 260 degrees.

- Checking cutting tools. For high-quality soldering, the cut also plays a huge role - it must be perfectly even, without cracks and burrs. If this does not work, it is necessary to sharpen the tool well and check the quality of the cut on a test sample.

- Pipe preparation. Before starting work, they must be cut to predetermined sizes. If you have to solder elements with a diameter of more than 4 cm, a bevel should be made at the end at an angle of 45 degrees. This approach will avoid bullying when trying to connect.

- Markup. A mandatory action before starting work is marking the depth of the pipe entering the fitting. It is strictly forbidden to start it all the way! There should be a gap of about 1 mm inside.

Polypropylene pipes have excellent aesthetic and performance qualities.

Polypropylene pipes have excellent aesthetic and performance qualities.

For those who wish to perform all work exclusively according to the rules, there is a special table where the temperature and heating time for the most common pipe options are clearly stated.

The technology of soldering polypropylene pipes we work independently without a team of plumbers

Every home needs a heating system. There are non-traditional technologies, such as the Russian stove or the Buleryan heater, but this is the exception rather than the rule.

Traditional steel or cast iron pipes are practically not used. In the first case, ubiquitous corrosion, and cast iron requires welding.

An alternative material is copper. Pipes made of this metal are practically eternal, quite easily processed, and have sufficient strength. There is also a disadvantage - the high cost.

The same applies to plumbing. Steel pipes quickly become unusable, become an incubator for the reproduction of bacteria. With copper, everything is also clear.

Recently, homeowners have been offered a compromise option - polypropylene. Pipes made of this material have a long service life, are absolutely indifferent to corrosion and do not attract limescale.

Do-it-yourself soldering of polypropylene pipes - preparation

First, let's take a look at the technology. The pipe and the connecting element (clamp, tee or angle with an inner diameter corresponding to the outer size of the pipe) fit tightly into each other. The joint must be sealed. No glue or sealant will work. The connection technology is embedded in the properties of polypropylene.

The softening point (as well as the dew point) should be determined automatically, or “by eye”? There are many questions. So that the soldering of polypropylene pipes does not fall off in the first heating season.

Consider the features of technology

Choosing the right pipe

This is not about size, but about classification by temperature and strength.

- The most inexpensive option is PN-10. Thin walls, weak strength. It can be used for the "warm floor" system at a coolant temperature of up to 50 ° C. Also suitable for secondary water mains (no high pressure).

- If you are laying a pressure pipe, its class must be PN-16. Can be used in heating systems at temperatures not exceeding 60°C.

- The following class PN-20 is applied in any systems, except for steam heating. This is the most common pipe option, but not the most economical (in terms of cost).

- And finally, aluminum foil reinforcement pipe PN-25.The strongest and most heat-resistant construction. Withstands high pressure at 95°C.

Of course, the characteristics of the application are somewhat arbitrary. For example, you can use a PN-10 pipe for heating, but its service life will be reduced from the prescribed 50 years to 5-10. Or a pipeline of class PN-16, heated to 90 ° C, may not withstand the normal pressure for cold water.

Soldering temperature of polypropylene pipes

Actually heating is carried out at 255-265 ° C, this is the standard for most pipes. If a different value is required, this will be indicated in the documentation for the material. The main condition that must be observed is the time of heating, docking and cooling. The value depends on the diameter of the pipe.

Heating mode table

Explanations for the table

- The overlap depth is the distance that one pipe is immersed inside another

- Warm-up time - the pipe is applied to the soldering iron with a set temperature

- Connection time - how long can pipes be moved relative to each other when docking

- Cooling time - set joint strength

- The soldering temperature is set according to weather conditions.

Soldering iron selection

There are many manufacturers and designs. The selection criteria are simple - good does not come cheap. And vice versa.

Soldering polypropylene pipes - process

- First, we prepare the joints using a special tool. There should be no burrs or shells on the surface. At the end, we check the pipes, joining them without heating. Contact should be tight, without distortion. Before starting heating, the pipes should be cleaned of dirt and grease stains. The presence of traces of lubricant on polypropylene will reduce adhesion during connection.

- Then we warm up the welding machine (soldering iron) to the required temperature. The appliance must be placed on a stable base, without touching the walls and furniture with the heating element.

Equipment and tools for welding polypropylene pipes

The installation of polypropylene pipes for welding ensures maximum reliability and tightness of the joints, subject to the quality of the work and compliance with the technological regulations.

Since the parts of the pipeline connected by welding cannot be digested again, due attention should be paid to the accuracy of the work, using special equipment and tools to perform them. The set of tools used for welding polypropylene pipes is as follows:

The set of tools used for welding polypropylene pipes is as follows:

- a soldering iron, also called a welding machine;

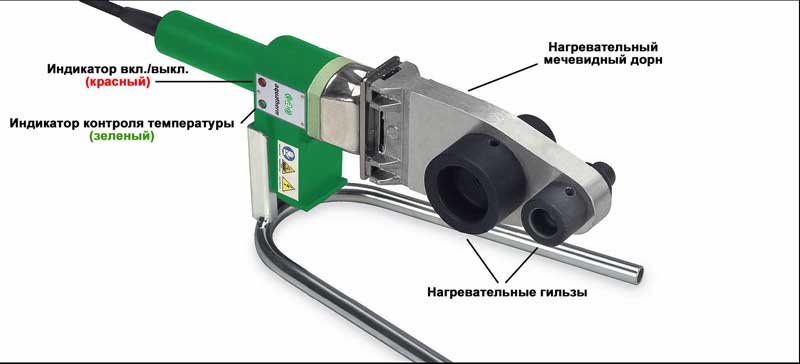

- a set of nozzles of various sizes for welding (each nozzle consists of a mandrel for heating a fitting and a sleeve for heating a pipe section);

- special scissors for cutting pipes into sections of the desired size;

- trimmer for processing the edges of pipes before welding (used to remove aluminum foil from the ends);

In addition to this equipment for welding, you must have a tape measure, caliper and alcohol marker on hand. The presence of a complete list of tools will allow you to avoid unnecessary fuss when it becomes necessary to determine the dimensions on site and perform the work as efficiently as possible.

The main element of the equipment is an apparatus for welding polypropylene pipes (or a soldering iron) with a set of nozzles. The device is a heating device similar in principle to a conventional iron. To automatically maintain the set temperature parameters, the soldering iron is equipped with a thermostat.

The heating surface of the soldering iron has holes for attaching nozzles of various diameters (standard sizes of nozzles included in the welding kit: 20, 25, 32, 40 mm). For the convenience of working with pipes of various diameters, most devices for welding polypropylene pipes have the ability to connect several types of nozzles at once.

Parameters for welding products made of polyethylene and polypropylene

Melt flow index of materials (MFR)

Welding of high density polyethylene (PE-HD, HDPE)

Products made of high density polyethylene melting group index 005 (MFR 190/5:0.4-0.7 g/10 min.), group 010 (MFR 190/5:0.7-1.3 g/10 min. ) or groups 003 (MFR 190/5:0.3g/10min) and 005 (MFR 190/5:0.4-0.7g/10min) are suitable for welding with each other. This is confirmed by the DVS 2207 part 1 (DVS - German Welding Association) and confirmed by the DVGW (German Gas and Water Association) documents.

Welding of polypropylenes: polypropylene homopolymer (PP type 1, PP-H) and polypropylene block copolymer (PP type 2, PP-C, PP-R)

The weldability of polypropylenes is indicated within the melting index group 006 (MFR 190/5:0.4-0.8 g/10 min.). This is confirmed by DVS 2207 part 11.

The temperature of the welding process of polypropylene and polyethylene

Hot gas welding

| Air, l/min. | Nozzle temperature ˚С | Gas speed cm/min | ||||

| Nozzle diameter, mm | Speed nozzle diameter | |||||

| 3 | 4 | 3 | 4 | |||

| Polyethylene welding | 60-7060-7060-70 | 300-340300-340270-300# | 10-1510-15- | ok.10ok.10- | 50-6050-6025-30 | 40-5040-5020-25 |

| Polypropylene welding | 60-7060-7060-70 | 280-320280-320280-320 | ok.10ok.10ok.10 | 50-6050-6050-60 | 40-5040-5040-50 |

Hand extruder welding

| Extrudate temperature measured at nozzle exit, ºC | Air temperature measured at the warm air nozzle, ºC | The amount of air, liters / min. | |

| PE hard PP | 200-230200-240 | 210-240210-250 | 350-400350-400 |

Influence of humidity

Welded products (sheets, plates) and a welding rod made of polyethylene and polypropylene can, under certain conditions, absorb moisture. As a result of studies carried out by a number of manufacturers, it was found that polyethylene and polypropylene welding rods made of polyethylene and polypropylene absorb moisture depending on the material and the environment. In extrusion welding, the presence of moisture may appear in the form of shells in the seam or a rough surface of the seam. This phenomenon increases with increasing thickness of the weld.

In order to prevent such undesirable consequences, the following recommendations have been developed:

- Installation of moisture and oil separators in the air supply system,

- Prevention of a significant temperature difference between the parts to be welded (condensate moisture),

- Store the welding rod in a dry place, if possible,

- Drying of the welding rod at 80°C for at least 12 hours,

- Welding of wide seams (>18mm) in several passes.

Depending on the type of heating of polypropylene and polyethylene, the following types of welding are distinguished:

- Welding of thermoplastics with hot air (hair dryer)

- Extruder welding of thermoplastics

- Welding thermoplastics with a heating element

- Thermoplastic high frequency welding

- Laser welding of thermoplastics

What is welding of polypropylene pipes

Polypropylene is characterized by increased rigidity, and fittings from the same material are used to create systems of the required configuration. These are various angles, tees, bypasses, adapters, couplings, etc. They are connected to pipes by soldering. This process is also called welding, but its essence does not change: two elements are heated to a melting point and, in a hot state, are connected to each other. When done correctly, the connection turns out to be monolithic and serves no less than the pipes themselves.

Fittings for polypropylene pipes allow you to create a system of any configuration

To connect polypropylene with metals, there are combined fittings in which one part is made of metal and is connected using a threaded connection, and the second - polypropylene - is welded.

How to solder

Polypropylene pipes are welded using a special device called a soldering iron or welding machine. This is a small metal platform, inside of which there is an electric spiral that heats up the surface. Because of this design, this unit is also called an iron.

Two designs of PP pipe welding machine

To connect two elements, the spliced surfaces are heated to a melting point (+260°).To heat the element to the desired depth, two different Teflon-coated metal nozzles are installed on the welding platform:

- a mandrel (smaller diameter) is used to heat the inner surface;

- a sleeve is placed to heat the outer surface.

Nozzles for soldering polypropylene pipes

Two connected elements are simultaneously put on the corresponding nozzles, held for a certain period of time (several seconds), then connected. This is how polypropylene pipes are welded.