Heating element installation

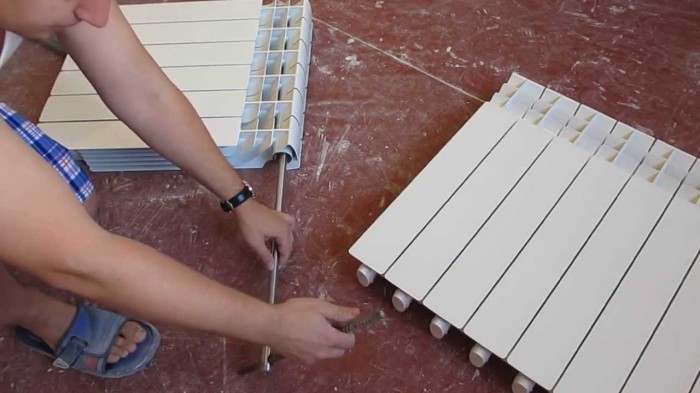

The installation of the heating element takes place according to the following scheme: one of the plugs of the heating battery is unscrewed, and a heating element is installed in its place using a threaded connection. To ensure the tightness of the joint, it is recommended to use a rubber gasket. It is necessary to clarify that it is best to screw in the heating elements instead of the bottom plug. There is a logical explanation for this: heated water will rise, and cold water will fall. This will ensure the most efficient operation of the heating element. This procedure must be repeated in all rooms of the apartment. We remind you that it is better to plan the installation before the start of the heating season.

Types and design, as well as on the functioning

Structurally, a heating element for heating a house is a metal tube with a wire spiral inside, made of a material with high electrical resistance. When energy is supplied from the network, the spiral heats up and gives off heat to the shell of the heating element, which in turn heats the coolant in the radiator.

The installation of the heating element is carried out in a specialized socket of the heating battery, whether it is an aluminum, metal or cast-iron version. The heating element is also used as the main heating element in electric boilers.

Most tubing uses stainless steel or carbon steel. If low-quality metal was used in production, then the heating element can quickly “burn out”. The power of the spiral and the shape of the tubes are determined by the purpose of the device, in which particular radiator or boiler it will be used.

Models are available with fins, the presence of additional plates around the tube to increase heat transfer. Ribs significantly increase the dimensions of the product, so they can not be used in all cases.

In addition to devices that heat water, space heating with an electric heating element can be carried out using an air device that heats air instead of water. But due to their low efficiency, they are rarely used.

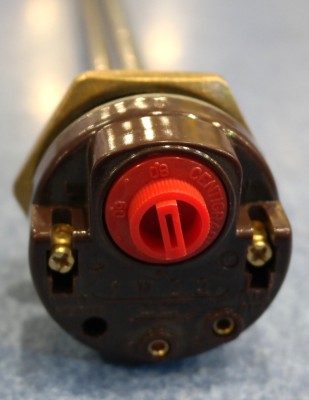

The thermostat, which is part of the heating element, measures the temperature of the surrounding coolant in the radiator and, if necessary, supplies power to the coil. After reaching the specified temperature parameters, it breaks the circuit. And as the water cools, it reconnects the spiral to the network and heats the water. The presence of a thermostat allows you to adjust the temperature parameters, such that are most comfortable for those present in the room. In its absence, the heating element will operate at maximum power, constantly consuming electricity, which will dramatically increase bills for it.

Some models of electric heating elements for home heating are equipped with additional functions: “turbo mode” (turns on the device for a short time at maximum power) and “antifreeze” (prevents the coolant from freezing, maintaining its temperature at a minimum).

Features of choice

Electric heaters designed for heating batteries can differ in several parameters. Therefore, the choice should be approached wisely

Below we will consider what you should pay attention to when choosing a heating element.

Power is one of the most important parameters, since the heat transfer of the device depends on it. Therefore, first of all, you need to calculate the required power for comfortable heating of the room.

On average, 1 kW of power is required for every 10 m 2. For a more accurate calculation, it is necessary to take into account the region and the heat loss of the room. True, if the heaters are used as an additional heating element, then half the power is sufficient.

Note! It makes no sense to use a heater more powerful than 75 percent of the heat output of the radiator itself, since its capabilities will not be fully used.

Bimetal radiator with electric heating element

Radiator type

Heating elements for aluminum heating radiators and bimetallic batteries do not structurally differ from heating elements for cast iron appliances.

However, the differences are in the following points:

- The shape of the outer part of the body.

- Stub material.

The heating element for an aluminum radiator has a plug with a diameter of one inch. The plug diameter for standard cast iron batteries is 1¼ inches.

Therefore, before purchasing a heater, you should pay attention to what types of batteries it is intended for. This information is usually contained in the instructions that are included in the kit.

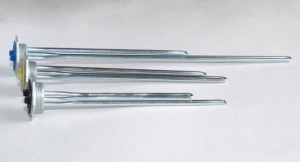

Heating element length

An important selection parameter is the length of the heating element. As you might guess, the uniformity of heating of the battery and the circulation of the liquid depend on this. Accordingly, the length is selected depending on the number of sections of the device.

Ideally, the heating element should be 10 cm shorter than the battery. In this case, the heating of the liquid will be carried out as evenly as possible.

Automation

Automation can be built-in and outdoor. It should be noted that a radiator heating element with a built-in thermostat is cheaper than the components separately. However, outdoor electronics tend to be more functional.

The choice depends on the purpose of the heater. If it is to be used as the main heat source, external electronics can be installed to ensure maximum heating comfort. If the device is planned to be used as an additional one, a heating element for heating radiators with a thermostat in one housing is also suitable.

Inexpensive heating element with a thermostat for a cast-iron radiator

Manufacturer

As for the manufacturer, in this case the choice is not so important. The fact is that well-known European companies are not engaged in the production of this equipment. Therefore, on the market, as a rule, you can find products of Polish, Ukrainian and Turkish production.

All these heating elements are quite similar in quality, so more attention should be paid to their characteristics. The only thing is that it is better to refrain from purchasing Chinese products, since suppliers often import the cheapest, low-quality models. However, even among them worthy heaters sometimes come across.

Here, perhaps, are all the main points that are important when choosing heating elements for batteries.

The use of heating elements for radiators does not provide any benefit compared to other types of electric heating. However, these heaters are an excellent option for heating all kinds of utility rooms. In addition, they can be used as an additional or emergency source of heat.

You can get additional and useful information on the designated topic from the video in this article.

What are electrics

Now popular are tubular electric heaters for heating, which consist of one or several nichrome spirals in a metal sheath. Periclast is placed between the spiral and the shell - this material has excellent insulating qualities.

Modern devices have heating elements that have good strength and at the same time can change their size and shape under the influence of high temperatures. At the same time, TENs do not change their technical characteristics. These electric heating elements are used in the production of not only heating equipment for domestic purposes, but also various industrial appliances. TENY in industrial devices must have high power.Any tubular element, regardless of its type, has a long service life. Today, there are several types of heating elements that are produced by manufacturers of electric heating equipment. First of all, they differ in the way they are made, but also have other features. Manufacturers take into account the needs and interests of consumers: some heating devices are produced in large quantities, while others are produced in small quantities. Heating equipment produced in small quantities, as a rule, is used in heating systems that have certain features. Accordingly, electric heating elements in such devices are more expensive.

The main type of heating

- They are used in small rooms with a non-permanent stay of a person in them, for example:

-

- utility rooms;

- garages;

- various kinds of workshops.

Tip: with this use case, the heating element is installed in a radiator filled with low viscosity oil.

The refusal to use water in the heater is due to the possibility of its freezing at low temperatures. Such a heater is identical to an oil cooler and does not need to be connected to a central or local heating system. Oil circulation occurs exclusively inside the heater.

Universal heating element for heating radiators with thermostat

- Another use case is for occasionally visited country houses or summer cottages. The device is created according to the same principle as in the first case, but more devices are installed.

- In regularly heated houses, buildings, offices and cottages with no centralized heating system. In this case, the main source of heat is also a heating device with a heating element installed inside.

Tip: if the room is heated all the time, instead of oil, you can pour water inside the device and use a heating element for a radiator with a thermostat.

Auxiliary heating of a private house

If there is a centralized heating system in the house that uses a single water circuit, tubular electric heaters can be used for auxiliary heating of the coolant.

Possible applications:

- With boilers using coal or firewood as the main fuel element, heating elements can be used to heat the coolant. This is especially true in those moments when there is no possibility of servicing the boiler and filling it with fuel.

Radiator heater with built-in thermostat to maintain the set temperature in the room

- In heaters operating on liquid fuel or liquefied gas, heating the coolant with heating elements will not be more expensive. And in the case of installing a two-tariff meter for electricity, savings are also possible, the nightly tariff is usually much cheaper than the daytime one.

Auxiliary apartment heating

In multi-storey buildings, offices or various types of industrial and utility rooms with connected central heating, it is also possible to install heating elements in batteries. This method of heating is used if the central heating supply cannot provide the required parameters of the coolant in the radiators.

But this type of installation of heating elements has several negative points:

it is not possible to legally use cast-iron radiators with a heating element connected to the central heating system, since it is very difficult to obtain such permission from a service organization;

A heating element with a thermostat for a cast-iron radiator should be slightly less than the heater in length

- the high cost of work on the re-equipment of the heating system;

- it is not economically feasible during operation, since the additionally heated coolant will leave and heat other apartments.If, however, the radiator is blocked from the flow of coolant from the central heating system, heating bills will still have to be paid.

Installation of a heating element in the lower part of a cast-iron battery

Device characteristics

Consider the positive and negative aspects of using heating elements:

- TENA device

- Tubular electric heaters

- Heating element with electric thermostat

- When should electric heaters be used?

- Selection and use of TENs

- The best qualities of heating elements

- Some Helpful Tips

At the end of the 19th century, tubular electric heaters, in other words, heating elements, were invented in America. The very first models consisted of a spiral that was insulated with a special purpose ceramic material. and placed in a metal pipe. This idea took its rightful place at that time, but the device was unsafe. And only after more than 50 years, the electric heater for heating batteries was finalized and put into mass production. For such a long time, the tubular electric heater has changed a lot, but the principle of its operation has been preserved.

TEN - an ideal "emergency" device for a radiator

Installation steps

Regardless of the manufacturer, a heating element is installed in heating radiators according to a single principle. To install the heating element yourself, just follow the instructions:

- The device where the installation will be made must be de-energized.

- The supply of working fluid to the batteries is suspended, after which it is drained.

- Instead of the bottom plug, a heating element is installed, which must enter the water supply pipe.

- The fluid supply is restored, and then the radiator is checked for leaks.

- The heating element is connected to the mains.

Precautionary measures

When using a heating element for radiators of a heating system, certain safety requirements should be followed.

When installing heating, it is important to check the reliability of the ventilation. Also, when performing work, it is necessary to move flammable and explosive substances to a protected, hard-to-reach place at a safe distance from the heater.

Before connecting a heating device with a heating element and a thermostat, it is worth once again checking how the electrical wiring copes with the load placed on it

Exceeding the permissible power is fraught with overheating of the wires, the occurrence of short circuits and fires.

- When connecting heaters with heating elements, the use of ordinary household carriers should be avoided. The best option is the operation of network filters. This solution allows you to automatically de-energize the device during power surges in the system.

- It is absolutely unacceptable to use batteries with an electric heating element to dry things.

- During the operation of the heating element, the working fluid is intensively heated. Its operation for a long time leads to the burning of oxygen. Therefore, a long stay in such a room hides a health hazard.

Why is it needed

Manufacturers position their products as a solution that turns an existing water heating system into an autonomous one with minimal effort and time.

This is necessary in two cases:

- With frequent interruptions with centralized heat supply.

- When organizing fully autonomous heating in the absence of cheaper sources of thermal energy.

Do-it-yourself instructions for installing a heating element are extremely simple:

- The radiator or heating circuit section is reset.

- The lower blind radiator plug is unscrewed. As a rule, it has a left-hand thread, but if the heater is connected on both sides, the desired plug may also be right-handed.

With a diagonal connection, the heating element is installed instead of a plug with a right-hand thread (bottom right).

- The last sections are cleared of silt.

- The thread of the heating element is wound with sanitary flax with paint or any other sealing material.

- Then the heater is screwed into the heater using an adjustable, open-end or gas wrench. Of course, without excessive effort: brass is a relatively soft metal, and it is easy to strip pipe threads on it.

- The radiator is filled with water or other coolant, after which the heating device is energized. The uniform heating of the radiator surface is ensured by the convection of the coolant.

The use of heating elements

Installation of heating elements is so simple that any home master can perform all the required work. Complete with a heating element, as a rule, everything necessary for installation, protection, connection and automation is supplied. Thanks to this, it is enough to screw a heating element equipped with a thermostat into the radiator socket and connect it to the mains. The system must be filled with coolant. After such simple work, the heating element can be used for its intended purpose. When installing, make sure that the mounted heater is in a strictly horizontal position.

There are models of different capacities on the market. They are suitable not only for domestic but also for industrial use. The basis of the design is a stainless steel pipe with a nichrome wire spiral placed inside. Using a brass nut with a right or left thread, the heating element is screwed into the pipeline. These units can be used with any radiator having a 1" mounting thread.

The heating element for radiators is a collapsible design, so the body can be detached if necessary, even during operation. One of the most important issues that arise when using electric heating is safety. Among all electrical appliances, the heater is the most secure. To protect against overheating, double control is used due to the main and additional temperature sensors. The main sensor is located inside the case, and the additional one is in a special tube.

Differences depending on the model and type of radiator

The heating element for the battery can operate in two modes. When used as the main source of heating, the heating element is turned on at full power. Thanks to this, it quickly warms up the room to a comfortable temperature and maintains it at a given level. In houses with irregular residence, heating elements can be used as protection for an autonomous heating system from freezing. In this case, the device will operate at minimum power, maintaining the temperature of the coolant in the pipes at a level that does not allow it to freeze.

The power of the heating element is one of the main parameters when choosing a model. Low-power products will not be able to cope with the tasks assigned to them. After all, with the help of a small boiler it is impossible to heat the water in the bathroom - you will need a more powerful one. In the same way, when installing a low-power heating element, the water in the system will cool faster than it will heat up to the set temperature.

Important! Before buying a particular model, it is necessary to make calculations that allow you to use the heater with maximum efficiency. When calculating the power, it is necessary to take into account not only the volume of water in the radiator where the heating element will be installed, but also the initial and final temperature of the coolant and the time spent by the device to heat it

To perform the most correct calculations, special formulas are used. For a simple layman, they can be difficult, so a complete calculation is ordered by heating specialists. A simpler calculation is that the temperature of the coolant in the cast-iron radiator should be within +70 degrees

When calculating the power, it is necessary to take into account not only the volume of water in the radiator where the heating element will be installed, but also the initial and final temperature of the coolant and the time taken by the device to heat it. To perform the most correct calculations, special formulas are used. For a simple layman, they can be difficult, so a complete calculation is ordered by heating specialists. A simpler calculation is that the temperature of the coolant in the cast-iron radiator should be within +70 degrees.

In addition to power, other technical parameters of the unit must be taken into account. The main ones are:

- The shape and diameter of the heating element tube.

- Heating tube length.

- The total length of the device.

- Insulator dimensions.

- Attachment type.

- Type of connection to the radiator.

How to choose heating elements

Heating element for heating with plates

How to choose the right heater for the heating system? Currently, there are many manufacturers that offer similar products. However, both the quality and the technical parameters do not always correspond to the required

Therefore, before purchasing, you need to pay attention to the following performance characteristics of the heater:

- Rated and maximum power. If a heating element is needed in the heating boiler, its power should be enough to operate the system. The simplest calculation method is for 10 sq.m. houses need 1 kW of thermal energy;

- Mains type. For models with a power of up to 3 kW, you can use a 220 V home network. If it is planned to install a heater for a heating system of greater power, a three-phase 380 V network should be installed. This may be due to difficulties in paperwork;

- The presence of a thermostat. For an electric radiator heating system, this is the main selection factor. If you purchase a ten without the ability to adjust the power, it will constantly work at maximum mode. Thus, electricity costs will rise sharply;

- Price. The average price of a 2 kW model starts at 900 rubles. The cost of more powerful ones can be up to 6,000 rubles. Often they are made to order.

The appearance of the heating element can also affect its performance and efficiency. The best option would be to purchase a finned heating element in a heating boiler. It differs from the usual ones in that additional heat exchange plates are located on the protective shell.

Thanks to them, the heating area increases. This design is typical for heating elements in heating radiators of larger diameter. Reviews about them speak of increased heat transfer even with a minimum operating mode. But not always their overall dimensions make it possible to install them in a battery. Therefore, most often they purchase simple tubular-type heaters. To increase the efficiency, you can buy a block of heating elements with a thermostat. It differs from traditional ones by the presence of several heating elements on the same basis.

TENA device

The heater for heating radiators is an electrical auxiliary heater that operates inside the radiator itself. Electric heaters convert electricity into heat. Today they are the basic devices for heating various capacities.

This device is a metal tube in which a wire spiral is fixed. Both the tube and the coil have high resistivity. The edge of the helix is attached to the tube with mounting clips.

The spiral is isolated from the tube itself by a special filler. Heating elements for heating of new samples are reliable and safe only if a protective case is present. They are suitable for heating radiators made of cast iron, metal and even aluminum.

Additional functions may be provided for heating radiators in TENs, for example:

- "Antifreeze" allows you to keep the lowest temperature of the liquid in the batteries.More often it is equal to 10 degrees. This is necessary so that the coolant in the radiators does not freeze.

- During the activation of the "Turbo" function, the TEN heats the room with maximum power to the specified temperature.

It is possible to use TEN where it is necessary, but on condition that the requirements for use are preserved. During production, the electric heater for radiators undergoes chromium and nickel plating, which gives additional quality to the product. If you carefully and carefully treat the device, then it can last about two years.

Heating elements have fuses that prevent the radiator from overheating and help resist external influences.

Using heating elements for heating radiators is quite simple. To do this, the device must be screwed into a special opening of the battery, which is filled with coolant, and connected to a current source. The coolant can be water or a liquid resistant to freezing (antifreeze).

The complete set of electric heater for heating batteries should include a thermostat and a protective casing, which should protect the heater from liquid ingress, and protect people from interaction with current.

Tubular electric heaters

Tubular heating elements received the greatest popularity. They consist of one or more nichrome spirals and are placed in a metal tube. To isolate the spiral, a periclast is attached between it and the shell.

- The tube should be 6-18.5 mm in diameter.

- TEN can be from 200 to 600 mm long.

- The material in the manufacture of the tube should be steel, stainless steel or titanium.

- The device can have any configuration.

Advantages: this device is very convenient if it is not possible to heat the room with the help of gas installations.

Heating element with electric thermostat

This device can be used as a heater for small rooms, as well as act as an additional device to other heating systems, including a radiator.

The electric heater of this sample contains a heating segment and an electric thermostat, which is designed for long-term use.

In addition to batteries, TEN with an electric thermostat has found its application in tubular and finned heaters and other heating devices. The so-called thermosyphon effect allows this device to work, and the heater acts as a thermodynamic pump.