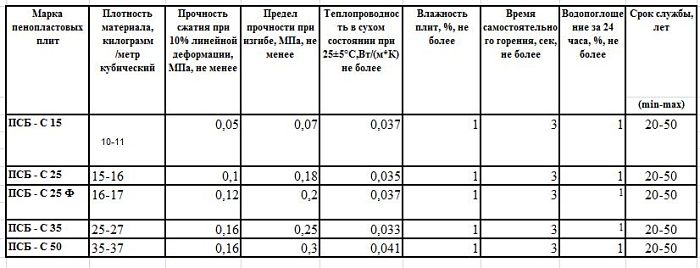

Physical properties of foam

The main characteristics of porous polystyrene include:

- strength - the foam does not have outstanding strength characteristics and is able to crumble and break even with a weak mechanical impact. It can be easily damaged with sharp objects or by simply hitting the surface. To reduce the likelihood of destruction, the foam is covered with layers of a harder material that evenly distributes external loads;

- flexibility - expanded polystyrene is weakly amenable to bending influences and can break under them at any time. For the same reason, foam boards are installed only permanently, avoiding any torsional loads;

- thermal conductivity - the presence of gases (natural heat insulators) in hollow capsules provides the material with a low heat transfer coefficient. This is also facilitated by the absence of convection inside the pores due to their small diameter. It will take a long time to completely warm up a piece of foam to a given temperature;

- Tendency to shrink - free-standing EPS boards are susceptible to slight shrinkage caused by gravity. The shrinkage is 1.5-3 mm within six months. At the end of this period, the natural compaction of the material stops;

- thermal expansion - with increasing temperature, the linear dimensions of the plate increase (the process is reversible). Numerical indicators of expansion correspond to approximately 1 mm per 1 m of foam plastic plate with a temperature change of 15-20 ° C;

- vapor absorption - foam plastic is less resistant to diffusion penetration of moisture than to liquid water, therefore, in especially humid rooms, its surface is additionally covered with a layer of metal foil. In its absence, part of the water vapor can penetrate through the layer of material and condense when the temperature drops, which adversely affects the entire thermal insulation system.

Foam specifications

Thermal conductivity

One of the main positive properties of polystyrene is its unique heat-insulating ability. This can be explained by the fact that the multifaceted cells of the foam are completely closed and, therefore, prevent air circulation, which prevents the cold from penetrating and retains heat.

Wind protection and sound insulation

The reason for the high degree of wind protection and sound insulation also lies in the cellular structure. The greater the thickness of the layer during the installation of the material, the better sound insulation can be achieved in the building.

Due to its structure, it is very difficult for the wind to penetrate the foam layer already 2-3 cm.

Low hygroscopicity

Of course, compared to other materials, foam plastic has a rather low moisture absorption.

This is due to the fact that water penetrates only through individual gaps between the cells. However, with prolonged exposure to time and cold, this process can become destructive.

Strength and durability

Even when exposed to negative factors, the foam will last about 10 years, which is a considerable period.

Withstands high pressure without deforming. It is used even in the construction of runways for aircraft.

Resistance to biological and chemical attack

Very resistant to salts, lime, cement, paint, varnish, various acids. Aggressive chemical compounds, such as: solvents, acetone, turpentine, diesel fuel, diesel, fuel oil, kerosene, alcohol and substances containing animal and vegetable oils, will have a negative effect.

When exposed to them, the structure can completely collapse and dissolve. Styrofoam is not a suitable medium for the reproduction of microorganisms, but if contaminated, they can appear there.

Ease of installation and ease of use

The material is extremely light in weight and therefore foam boards are easy to install and handle.Can be cut into desired pieces without the use of special tools.

Protective equipment is not needed when working with it, because polystyrene foam is a non-toxic material.

fire safety

Although the manufacturers of this product claim that it is absolutely fireproof, this is not entirely true. Of course, compared to wood, the temperature at which it will light up will be twice as high, and the temperature of the combustion itself will be several times lower.

It ignites only upon direct contact with a fire source. When the impact wears off, burning stops within a few seconds. These indicators characterize it as a relatively safe building material.

1 Definition and advantages of rigid foam

Durable foam plastic obtained by the pressing method is resistant to microorganisms and is not destroyed by rodents, it can be easily processed with carpentry tools, it bends and stamps well when heated, its sheets stick together perfectly both with other materials and with each other.

In addition to the noted mechanical properties, rigid foam is highly heat resistant and can be used in the temperature range from -60 to +80 degrees Celsius. Its thermal insulation properties are unique: a 20 mm layer of rigid foam is equivalent in terms of thermal resistance to brickwork 860 mm thick or a layer of wood 150 mm thick.

High-density foam has close to zero capillarity, which makes it very low in moisture absorption capacity, and, when in a humid environment, it is much less prone to deformation than non-pressed foam.

Due to its low bulk density and closed pore system, this material is characterized by good buoyancy. The densest foam, when in water, does not lose this ability for several years and has a significant advantage over natural cork.

The sound absorption coefficient of solid foam is also relatively high. In order to improve soundproofing properties, its blocks are perforated. The chemical resistance of this material should also be noted. It is resistant to mineral acids and strong and weak alkalis.

Some disadvantages of dense foam

We have already dealt with all the “pros”, so it remains to clarify the “against”. So, its mechanical strength is not as good as we would like. So after warming with this material, it is necessary to carry out work on its additional protection against possible mechanical damage. Another nuance is flammability. Of course, special additives are introduced into the composition to minimize this property, so a small spark is not dangerous. However, if there is a fire, the foam plastic will flare up very quickly.

Plus, there is an opinion about toxicity. In this regard, you should choose such products very carefully. Be sure to ask the seller for a quality certificate, while keeping in mind that the percentage of residual styrene should not exceed 0.1%. Otherwise, the product should be discarded. Also, finishing will help to slightly reduce the already small impact in the case of a quality product, without which this foam will certainly not remain in your home, for example, apply plaster.

Chemical properties

The operational parameters of the material, which determine the durability under the influence of external factors, include:

- chemical resistance - expanded polystyrene is immune to many substances, except for solvents and oxidizing acids. Mixtures based on acetone, ethers and light hydrocarbons quickly dissolve the foam, leaving no visible traces of it. Styrofoam is moderately stable with alkalis, however, it is still not worthwhile to specifically expose them to exposure;

- temperature resistance - the foam has a low temperature limit of destruction.Already at 60-70 °C, gases begin to be released from it, which are products of the destruction of the original polymer. At temperatures above 100 ° C, the decomposition of polystyrene occurs especially intensively and is accompanied by an even greater amount of toxic emissions. Severe effects on the body can occur even a few days after inhalation.

The fire safety of polystyrene is interpreted in two ways by supporters and opponents of the material. The first claim about its high resistance to flame, arguing that the ignited foam plastic practically does not support fire without an external source of heat. The second complain about the release of a large amount of gases during a fire, harmful to humans. From an objective view, polystyrene is a rather combustible substance that requires proper handling when decorating buildings.

Insulation disadvantages

When purchasing a heater, you must remember that all manufacturers, when advertising their product, emphasize only the positive aspects of their product.

The myths about orange insulation discussed below are those facts that you will not find in advertising leaflets, but which have a direct impact on human safety and health.

Fireproof or not?

Insufficiently high fire resistance is one of the main disadvantages of orange insulation. In general, the issue of combustibility of foam plastics is not as simple as it might seem, if you do not delve into the essence of the matter.

For the reason that their various modifications have different degrees of fire safety and in terms of combustibility they belong to materials of different categories - from G1 (low combustible) to G4 (highly combustible).

Pure polystyrene foam is a flammable material, which is its main drawback. It easily ignites from any open flame - a lit match, a burning blowtorch, even welding sparks. Therefore, unmodified polystyrene is rarely used in construction.

To increase its fire safety, flame retardants are added to it - flame retardants (substances that prevent ignition). Foam plastics with additives of flame retardants are called self-extinguishing.

The burning or smoldering of expanded polystyrene is accompanied by the formation of thick black smoke, which, due to the additives it contains, can be very toxic.

In addition to carbon monoxide, it may contain hydrogen cyanide, phosgene, hydrogen bromide, etc. Inhalation of such substances has a detrimental effect on the respiratory system and the human nervous system and can lead to rapid death.

It would seem that the issue with the fire resistance of expanded polystyrene is solved simply: add more flame retardant - and the problem is solved. But, firstly, this makes the material more expensive, and secondly, some types of fire retardants contain toxic substances.

Such as, for example, hexobromocyclododecane, which is a bioaccumulative toxin and has been banned for use in the EU countries since 2015.

Service life of the heater

One of the requirements that apply to heaters is that their service life must be commensurate with the durability of the object that is insulated with it. Domestic standards provide for heaters with an operating time of at least 25 years.

If you believe the manufacturers, then their polystyrene foams more than provide this period.

In some sources, the durability of foam plastics is indicated as 50 years or more. But objective studies do not confirm this. The conducted experiments found that already after 10 years of operation, signs of destruction begin to appear in polystyrene foam.

Speaking about the durability of expanded polystyrenes, you need to pay attention to one more aspect - the safety of the material that is insulated with it. Although expanded polystyrene is a vapor-permeable material, its vapor permeability is low.

Moisture that penetrates into wooden structures from the inside or outside is unable to completely leave them through the insulation layer to the outside.This lack of insulation contributes to the formation of fungi and mold on the wood, leading to its decay.

Although expanded polystyrene is not a breeding ground for fungi, they feel quite comfortable on its surface, especially if this surface is mated with wood.

Safety and environmental friendliness

As for pure polystyrene, it is really safe, but this cannot be said about the components and additives used in the production of expanded polystyrene.

As mentioned above, flame retardants added to foam can pose a direct threat to human health and the environment. But the matter is not limited to them.

In the production of expanded polystyrene, at the foaming stage, not only safe CO2 and isopentane are sometimes used, but also chlorine- and bromine-containing freons. The latter, when heated, are capable of releasing toxic substances, in particular, the well-known phosgene, which is the main component of some types of chemical weapons.

In addition, freons have a detrimental effect on the ozone layer, which protects the Earth from solar radiation. In addition, their greenhouse activity is more than 1000 times higher than that of carbon dioxide. Not without reason in the European Union since 2010 the use of freons is prohibited.

Conclusion from all of the above

When choosing a heat-insulating material for your home, pay attention to the whole range of its characteristics, and not just heat-shielding properties. The right choice depends not only on the comfort and economy of the home, but also on the health of all family members.

eps insulation

-

- low water absorption, almost equal to zero;

- high strength;

- not subject to decay;

- low thermal conductivity;

- high frost resistance;

- non-toxic to humans;

- easy to mount;

- durability;

- light weight;

- environmental friendliness.

This is interesting: depending on the composition and manufacturer, the insulation can be white, gray, blue, orange and even black.

The disadvantages of polystyrene foam insulation include:

strong flammability and intolerance to direct sunlight

It is important to know this, because storing polystyrene foam in the sun can completely ruin the material, and this will be unpleasant;

Although manufacturers claim that mice do not gnaw polystyrene foam, consumer reviews show the opposite;

And of course, the price, but it is quite high .. But what is the difference between Technoplex and Penoplex? What's better?

But what is the difference between Technoplex and Penoplex? What's better?

Insulation Penoplex 20 mm size 1200 x 600 x 20 mm PENOPLEX orange packaging 12.96 sq.m 0.259 cubic meters

Promotion details:

- - from the 28th to the 2nd of each month

- - the promotion applies to all products

- – order amount from 50 000 rubles

- — delivery in Moscow within the Moscow Ring Road or delivery outside the Moscow Ring Road*

- *for delivery outside the Moscow Ring Road, only mileage is paid.

* The order must consist of goods in the above sections.

- Floor insulation Wall insulation

Penoplex plates are a unique brand of heat-insulating plates, which is ideal for insulating country houses or city apartments (insulation of walls, balconies, loggias).

The use of Penoplex thermal insulation boards for thermal insulation of various building envelopes allows you to avoid "cold bridges", providing a comfortable microclimate in the house in any weather.

Penoplex heat-insulating boards are mounted easily and conveniently, like a children's designer, thanks to a clear geometry and an L-shaped edge for easy docking. The safety and environmental friendliness of the material, the absence of chemically harmful substances in its composition, as well as fine fibers and dust, allows you to mount the plates without the use of any personal protective equipment.

Penoplex insulation is a new level of quality that allows you to achieve a balance of high technical characteristics and the best price.

Table for calculating the cost of delivery of orders:

For orders up to 100 kg, a budget shipping cost is offered (delivery time up to 2 days):

| Delivery area | in Moscow | Moscow region from MKAD (up to 15 km)** |

| Load weight up to 10 kg | 290 rub. | 490 rub. |

| Load weight up to 15 kg | 350 rub. | 590 rub. |

| Load weight up to 20 kg | 450 rub. | 690 rub. |

| Load weight up to 50 kg | 550 rub. | 790 rub. |

| Load weight up to 100 kg | 650 rub. | 990 rub. |

* Drywall, insulation, lumber, profile for plasterboard, foam block and brick are calculated from the table from 100 kg.

**Delivery over 15 km, the calculation is based on the "tariff" + 50 rubles per 1 km.

For orders of 100 kg or more:

| Delivery area | Moscow inside TTK*** | Moscow inside the Moscow Ring Road | Moscow region from MKAD |

| Load weight up to 400 kg * | 800 rub. | 800 rub. | 800 rub. + 25 rub. per km |

| Cargo weight up to 1 ton ** | 1 450 rub. | 1 450 rub. | 1 450 rub. + 25 rub. per km |

| Cargo weight up to 2 tons ** | 1 950 rub. | 1750 rub. | 1 750 rub. + 25 rub. per km |

| Cargo weight up to 3 tons ** | 2 950 rub. | 2 850 rub. | 2 850 rub. + 25 rub. per km |

| Cargo weight up to 4.5 tons ** | 4 150 rub. | 3 950 rub. | 3 950 rub. + 60 rub. per km |

| Cargo weight up to 6 tons ** | 5 850 rub. | 5 550 rub. | 5 550 rub. + 60 rub. per km |

| Cargo weight up to 10 tons ** | 10 000 rub. | 8 000 rub. | 8 000 rub. + 60 rub. per km |

* provided that the ordered goods are placed in a passenger car.

** provided that the ordered goods are placed in a truck of the specified tonnage in terms of volume.

Delivery of unsawn 6 meter lumber (board, timber) up to 2 m3 costs from 3,000 rubles.

When paying for delivery by bank transfer, 5% is added to the cost of delivery.

Additional requirements for the car, such as a low height for entering a parking lot or an open body for vertical unloading, are paid additionally: + 20% to the cost of the standard fare.

Hard and soft foam

The technologies of modern housing construction provide for one of the stages of mandatory thermal insulation of buildings and individual premises, and for this, solid insulation is most effectively used - polystyrene foam, hard wool for insulation, rigid heat-insulating boards and other similar materials. The use of rigid foam is also recommended for interior surfaces of construction sites. Why exactly these materials retain heat in the house better than others, how to use them, what technologies to use for their fastening and operation - this will be discussed below.

3 Important specs to look out for

Density, as they wrote, is far from the only characteristic of the foam. A large number of them go instead of a good addition, for example, when insulating, the sound insulation of the room becomes better, there is no need for additional wind protection. The absorption of water by polystyrene foam and does not actually matter at all in the procedure for insulating buildings

Attention is paid to this indicator only in the case when polystyrene foam is used for some kind of underwater work. By the way, foam plastic - the material is not hygroscopic, in other words, it will not absorb moisture

Only a small amount of superheated steam is able to get into the free space between individual granules, and even then with systematic contact with water.

Much more often, consumers want to know the ratio of foam to low and high temperatures. With the lower limit, everything is simple - polystyrene foam can easily withstand -180 ° C. But as for the upper limit, everything is not so certain. As professionals say, foamed plastic is able to keep the temperature at 95–110 ° C in a matter of minutes. This allows the slabs to be covered with a layer of molten resin or bitumen if needed.

At systematic contact with hot materials, their temperature should not exceed 80 ° C, otherwise the polystyrene foam will shrink and change dimensions.

Expanded polystyrene is often unreasonably accused of being highly flammable. You can destroy this myth yourself - take a not very large piece of material and try to set it on fire on the street.How long did it take to ignite? If this is a traditional PSB polystyrene foam, it will light up without much difficulty, within a couple of seconds after contact with a fire source, however, after a certain period of time, the melted layers of material lead to self-extinguishing. If it is polystyrene foam with PSB-S flame retardants, then it will be much more difficult to ignite it and it will burn for a very short time. And if we foresee the moment that polystyrene foam is located in the middle layers of building structures, under plaster, gypsum or at least a layer of paint, then only the destruction of structures and the presence of a continuous source of fire can lead to a fire. It is known that when polystyrene foam ignites, about 1000 MJ / cu. m. How much heat does wood release when ignited? 7-8 times more! So, no matter how much foam plastic is blamed, it is in no way more dangerous than other building materials.

Achilles' heel of polystyrene foam - ultraviolet rays. With systematic irradiation, expanded polystyrene loses its structural strength, the surface of the plates becomes yellow and brittle. Further, under the influence of wind and rain, erosion of the material appears. To prevent this from happening, it is enough to take at least very simple protective measures, for example, paint foamed plastic or apply a plaster layer. Under a layer of protection, expanded polystyrene without changing the structure will last up to fifty years.

2 Disadvantages of high density foam

However, such a foam is not free from disadvantages. For several years, disputes have been going on about the toxicity of expanded polystyrenes, and therefore it can be recommended to purchase them only with sanitary and hygienic certificates, and the content of residual styrene should not exceed 0.1%.

And, finally, the main problem is high flammability, since polystyrene products are easily ignited by a spark or flame. The introduction of special additives solved the problem only partially, eliminating the possibility of ignition from a spark, but did not prevent combustion in a fire. Therefore, any type of foam is recommended to be used only for outdoor needs.

Structure and composition of the finished material

Styrofoam is made from expanded polystyrene balls that are filled with air.

In connection with the foregoing, we can conclude that the concentration of expanded polystyrene affects its thermal conductivity. If this value changes, then changes in thermal conductivity occur within the limits of percentages. One hundred percent preservation of air in the insulation is associated with its exceptional heat-saving ability, since air has the smallest thermal conductivity coefficient.

Due to the low thermal conductivity of the insulation, a high percentage of energy saving is ensured. If we compare brick with foam, then their ability to save energy will be noticeably different, because 12 cm of heat insulator thickness is equivalent to 210 cm of brick or 45 cm of log wall thickness.

3 Rigid foam application

Due to its remarkable properties, dense foam has long been used in various sectors of the national economy and technology: in aircraft and shipbuilding, in industrial fishing and the chemical industry, in radio and electrical engineering. And, of course, as an excellent heat-insulating material, it is indispensable in construction.

Rigid foam is easy to process and glue.Thanks to this, blocks of various sizes and shapes can be obtained from it, which are then planed, milled, sawn and drilled if necessary. For this, many tools are used that are not always available for home use.

It is sawn into boards on band-saw joinery machines. Trimming, milling and planing is carried out on thickness gauges, jointers, planers, circular saws and milling machines. For drilling, vertical and horizontal drilling machines with mechanical and manual feed are used.

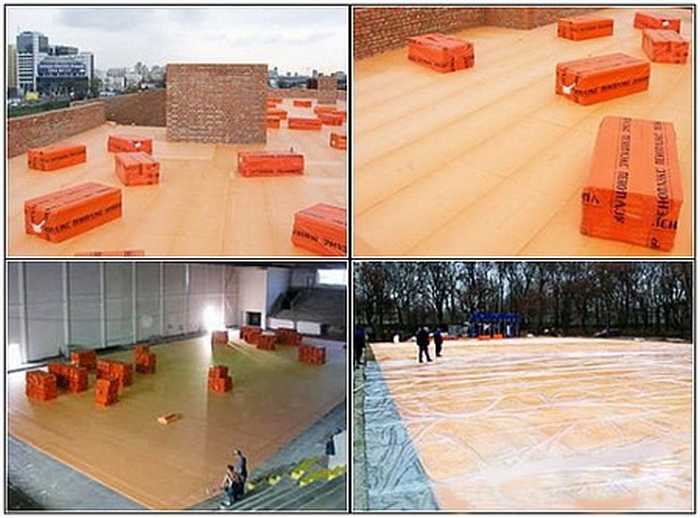

By gluing and machining, reinforced foam is obtained, which is a combination of rigid foam and reinforcing material: metal sheets, plywood, metal mesh or rods. Strength and thermal insulation characteristics make it possible to use polystyrene foam for the construction of an exploitable roof, which makes it possible to build a cafe or, say, a parking lot on the roof of a building.

and reinforcing material: metal sheets, plywood, metal mesh or bars. Strength and thermal insulation characteristics make it possible to use polystyrene foam for the construction of an exploitable roof, which makes it possible to build a cafe or, say, a parking lot on the roof of a building.

This site is for informational purposes only and under no circumstances is it a public offer determined by the provisions of Art. 437(2) of the Civil Code of the Russian Federation.

Fast deliveries. A large assortment. Quality and guarantees. Saving your time.