Cons of brick ovens

But before you make such a device for yourself, it is important to familiarize yourself with its shortcomings:

- If the dimensions of the dwelling are large, brick ovens will have to warm up the cooled air for a long time. Therefore, in order to normalize the temperature until the stove is fully warmed up, it is recommended to purchase a heating device for gas or electric.

- The design of the device itself is large, so it needs a lot of space, and such options are not suitable for all owners of a private home.

- If the construction of a brick oven is carried out with violations, the device will not function correctly. Therefore, there is no other option how to completely redo the stove.

For good combustion of firewood, it is necessary

- dry firewood (drying for 2-3 years under a canopy) (standard: 6-7 cm log thickness,

length of logs (written: up to 75-80 cm.) (Now I meet my local standard everywhere: by default, 50 cm)

—space above the fuel layerequal or greater fuel bed height

- high temperature (for the evaporation of volatile combustible substances from the fuel and their combustion reaction)

-Also, sufficient air is needed for combustion (excess air dries out, and if there is not enough air, it smokes and clogs the channels)

- TIME: According to Podgorodnikov, 1-2 seconds so that all combustion processes take place in a hot furnace, and are not quickly thrown into the first cold channel or pipe.

That's why he always set hailo.

Firebox length- along the length of firewood + (7-10 cm.)

Firebox width- for small furnaces (in terms of power) 1 brick = 25 cm.

In many ovens 32 cm (brick + 1/4 brick) (considered appropriate).

Usually 1.5 kirp. (37cm) - Enough for almost all occasions.

Powerful stoves for individual use have a firebox width of 2 bricks. ( 50 cm) .

6 Step-by-step manual for the construction of a brick sauna stove

For the first time with your own hands, it is better to fold the oven, which does not differ in design features. The scheme of the heater should be extremely simple and functional: a furnace and ash chamber, a heater, a hot water tank, the beginning of the chimney. More complex designs will be mastered as skill grows.

Having laid the starting layer of bricks on a concrete base, we proceed to the formation of an ash chamber. Raising the second row of bricks, we leave an opening for the door. To fix it, you will have to use asbestos and wire. We attach the wire to the door frame in four places and pull it inside the ash chamber so that it does not fall out of the stove. We use asbestos cord as a sealant. When erecting the third row, we fix the ends of the wire extension in the solution.

Fourth row - install the grate. To do this, special grooves must be cut in the bricks. By the way, given that the temperature of birch charcoal reaches +1200° C, it is recommended to remember which brand of brick is better able to withstand such loads. That is, the inner layers are best formed from fireclay material.

The fifth row is the formation of the combustion chamber. Naturally, taking into account the temperature loads on the furnace, we use refractory bricks.

On the sixth row, we install the furnace door (the procedure has been worked out on the ash chamber) and continue to build the furnace array - which brick should be used, I think, is understandable. On the ninth row we close the door, and on the tenth row we install a hot water tank and mount metal crossbars / pipes under the heater.

The eleventh row is laid out from ordinary bricks and presses the laid pipes. Further, up to the nineteenth row, we simply increase the height of the structure. Having finished with this row, we lay stones on the crossbars reinforced inside the furnace. At about the same stage, we have to shut off the hot water tank. Given the severity of the brick, we will reduce the pressure on the container by installing channels.

From the twenty-first to the twenty-sixth row, we leave a window in the side wall of the furnace - water will be supplied to the stones through it. In the future, we will install doors here. By the way, if you leave the structure as it is, you get a gray bath. On the twenty-seventh row, this door is blocked, and metal channels are thrown from one wall of the furnace to another - these are kind of rafters.

The next four rows are the overlap of the furnace, the formation of the chimney, the installation of the valve and the formation of the chimney.

Selecting the type of device depending on the operating conditions

When people have a choice between metal or brick ovens, they often forget to answer several important questions before purchasing:

- First of all, it is worthwhile to clearly understand what is a priority: the rate of heating of a room, house, or the time during which heat is transferred from the furnace of the structure.

- Depending on the specific region where the premises are located, one of the devices will always be several points better in terms of operation, but in this matter everything is very individual.

- What are the technical features of the house, is it possible to build a foundation and other construction issues.

- Budget - structures made of certain types of metal can cost several times cheaper than brick structures.

If we compare and determine under what conditions it is better to build a brick oven, then first of all such structures are installed in houses where the only source of heat will be just such a furnace: if it is well and correctly heated during the day, then the room will be provided with heat for all night.

Moreover, such structures must be monitored, and if it is not possible to periodically heat the chamber outside the heating season, then it is still better to opt for a metal product.

It is necessary to consider where the furnace will be located and take care of the construction of the foundation. If all these conditions are met at home, then we can say with confidence that the choice was made correctly.

With what conditions provide for the construction of a stone oven, everything is clear. It remains to consider the question of the feasibility of installing a metal structure. Such a product can be installed in rooms where there is another source of heating, whether it be a central system or a boiler.

Considering that such systems heat up many times faster, they are recommended to be installed in rooms where it is necessary to warm the air to a comfortable temperature as soon as possible, for example, if it is a country house that people come to in winter.

There is no need to build a foundation to install metal stoves, so they are suitable for installation on basement floors. A wide range of heating appliances from modern manufacturers will help you choose exactly the option that fits perfectly into the interior.

The stove doesn't have to be rough, solid cast iron. It can be represented by a steel structure, where glass or ceramic firebox doors are installed, which looks very stylish.

Good operational and saving functions are endowed with models in which a system of smoldering or long-term combustion of fuel is already installed. They allow you to use fewer materials to create a comfortable temperature in the room, but at the same time they are able to maintain it for a long period of time.

Summing up, we can conclude that metal stoves must be installed in those rooms where it is necessary for the space to heat up faster, but at the same time there is also a main heating.

https://youtube.com/watch?v=GJHxuMkCD1w

Each homeowner must decide for himself what budget he has for equipping the heating system in the house, and also clearly understand whether he can independently build a brick oven, because this process is complicated, and if not implemented correctly, the design will be completely useless.

sign in

adblock detector

1 Comparison of metal and brick sauna stoves

It is foolish to deny the advantages of metal bath stoves. They cost several times cheaper than brick counterparts, are easier to install, heat up the room faster, but at the same time they are inferior to them in a number of parameters:

- 1. Durability.The average service life of a factory sauna stove is 10 years. A properly built brick heater lasts for decades;

- 2. Comfort. When the metal is heated, infrared radiation appears, burning oxygen in the steam room and burning the skin. A soft, comfortable warmth spreads from the stone oven;

- 3. Maintaining the temperature - a metal furnace, quickly heated up, also cools down quickly. The brick oven will cool down for a day;

- 4. Fire safety. To ensure the safe operation of a metal product, additional protective equipment will have to be used.

Brick ovens are more durable and safer than metal ones.

As you can see, at least four parameters speak in favor of a brick sauna stove. But there are also negative factors:

- 1. Price. A brick for a stove costs a lot, but delivery costs and the cost of consumables are also taken into account. Well, if you are able to fold a brick oven with your own hands. Otherwise, you will have to pay the stove-maker, and his services are expensive;

- 2. The complexity of the construction. The construction of a brick heater is a long and difficult process;

- 3. Heating rate. It will take several hours to heat a bath with a brick oven. While a properly selected metal heater will cope with the task within an hour.

These shortcomings forced brick heaters to make room, and in some places give way to metal competitors. However, on closer inspection, they are not fatal. For example, a brick for a stove is not cheap, but you also build a bathhouse for more than one year.

The bath with a stone oven heats up slowly - a fact that you cannot argue with. But after all, going to the bathhouse is a ritual that does not endure fuss: several visits to the steam room, steaming brooms and drinking tea in the relaxation room. Against this background, the minutes won are invisible. In other words, a bath is leisure, and it is not customary to rush on vacation.

2 Types and features of brick sauna stoves

There are four types of brick ovens for baths. Some of them are obsolete, others are in demand among connoisseurs today. The expression "bathhouse in white" or "in black" is familiar and does not cut the ear. But there is also a bathhouse “with a stove” or “in gray”.

Black baths were popular in the villages. Feature - no chimney. On the one hand, this gave the atmosphere of the room an unforgettable bath aroma, on the other hand, it imposed restrictions on its use. I had to wait until the firewood completely burns out and the smoke disappears. The highlight of such a bath is soot on the walls.

The stove for a bath "in white" is now the most common

Furnaces that are heated "in gray" are the evolution of baths "in black". A chimney was added to the design of the heater. But even in this case, fire and smoke are in contact with stones. Consequently, soot is deposited on them and in order to wash, you will have to wait for the complete combustion of the fuel.

“Bath with a stove” is an interesting expression that reflects the design feature of the stove. In this model, the stones, the hot water tank do not come into contact with an open fire, but lie on two separate cast-iron plates. The metal water tank is enclosed in a brick casing on three sides, which keeps its temperature.

Similarities and differences

When deciding which stove is better, the first step is to determine its functional tasks, because it will depend on them what is more suitable for the homeowner in each case.

All solid fuel designs have a number of identical parameters:

- In both metal and brick products, there will be an open flame inside the firebox.

- At the moment when the body of the structure is heated, the room is filled with warm air and a comfortable temperature is created in the rooms.

- The products of fuel combustion are discharged through the chimney pipe.

- The correct draft must be implemented in the chimney, otherwise the stove will not work correctly.

- The combustion process is possible only if oxygen is supplied.

The metal and brick oven has a number of differences that you should pay attention to. First of all, the difference lies in the material of manufacture of the body of the heater

In the first case, it can be cast iron or steel, and in the second case it can be exclusively brick.

Many people wonder why iron stoves heat up a room faster than brick ones. The answer to it is quite simple and lies in the thickness of the walls of the case: the smaller it is, the faster the structure warms up. Steel or metal can be very hot, while brick is an inert material and due to its greater thickness, it does not get so hot.

However, metal stoves have a significant advantage - their furnaces have a clear system for regulating the process of fuel combustion, which makes it possible not to overspend the material, respectively, the cost of maintaining a house during the heating season is reduced.

A brick heater has a significant mass, so it can only be erected after the foundation has been poured. Metal structures do not require this, which simplifies the installation process, and to save space, such a furnace can even be hung on the wall.

4 Solution preparation, ingredient requirements

A high-quality brick oven for a bath largely depends on the solution. As a rule, red or clay fireclay mixtures are used, that is, the same material from which bricks are made. In this case, when heated, the brick and masonry will expand evenly. So, the service life of the furnace will increase.

It was experimentally revealed that the thinner the solution layer, the more reliable the stove. A seam of 5 mm is considered optimal. Thicknesses below this value will shorten the life of the heater.

The solution is prepared not only from clay. Sifted sand is added to its composition. Ideally, the grain size should not exceed 1–1.5 mm. The presence of silt deposits is unacceptable in the composition of the sand

Pay attention to its color - it is desirable that it be uniform

The solution is prepared from clay, sifted sand and water.

Water to the solution must be clean, free of foreign odors, mineral deposits. It is believed that for 100 pcs. bricks enough 20 liters of water. Clay is crushed, placed in a container and filled with water. The amount of water is dosed in such a way that a homogeneous clay mass is obtained - non-liquid and sparse. Knead lumps of clay in the resulting solution and forget about it for 24 hours. After this period, drain the water through a sieve and rub the remaining lumps through it.

ADVANTAGES AND PLUSES OF METAL FURNACES.

They are not afraid of temperature fluctuations and long breaks in the furnace, they do not need accelerating heating after downtime. That is, for those who in the cold season come to a country house only for the weekend, this is the best option. Moreover, such furnaces heat up the air very quickly.

TOOLS FOR HOME AND GARDEN, NEEDLE, ETC. PRICES ARE VERY LOW

Another advantage is the relatively low cost (when compared with a brick oven). Again, to install such a "hot heart at home" you do not need to make a foundation or hire a stove-maker.

Compact dimensions allow you to place a metal furnace almost anywhere

But observe the fire clearances, this is very important (the exact distances are indicated in the installation instructions). However, if the room is extremely compact, the indents are sometimes reduced

And fire safety is provided with the help of protective screens. The walls are fenced off with steel sheets, but not close, but with a 2-3 cm air gap. There is also a gap of 3-4 cm between the edge of the sheet and the floor. Thus, the metal, heating up, increases the convective movement of air near the wall. This protects the wall from overheating.

Last but not least, a metal factory furnace can have a fire safety certificate.This means that it is much easier to get permission from firefighters to use it (provided that the installation was carried out exactly according to the instructions)

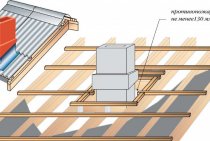

5 Arrangement of the foundation for a brick heater

A high-quality foundation is the key to a reliable brick heater. It is recommended to fill the foundation with some margin, it is desirable that its area is 10 cm larger than the dimensions of the furnace.

In order for the stove to be strong and reliable, it is important to properly equip the foundation.

By and large, the preparation of the base for the furnace is practically no different from the arrangement of the strip foundation:

- 1. With pegs we mark the dimensions of the base to be poured (they depend on the dimensions of the heater);

- 2. We dig a trench with a depth of 0.5–0.6 m at the bottom of which we fill up a pillow of sand and gravel (screenings);

- 3. Having rammed the filled materials, we lay a layer of waterproofing (roofing material or its analogue) on them;

- 4. We mount the formwork along the perimeter of the pit;

- 5. We lower a reinforcing mesh of metal rods into the pit. At the same time, we leave a gap of 5 cm between the metal structure, the walls and the bottom of the pit. For these purposes, you can use special clamps or stands;

- 6. Pour concrete. Keep in mind: we level the surface of the concrete cube using the building level. In addition, you need to leave a gap of 15 cm between the fill and the ground level - this is where the starting row of bricks will lie.