Differences between drainage and fecal pumps

Despite the similarity of applications, drainage and fecal pumps have many differences. The main one is the different ability to work with solid particles in water: drainage pumps can work with particles having a diameter of 3 to 12 mm (not counting industrial pumps working with sewer systems - such devices can “digest” particles with a diameter of up to 120 mm ). Fecal pumps prefer to work with clean or near-clean liquids, in which only very small particles can be present. For this reason, many fecal pumps are additionally equipped with grinders, which ensure that particles are reduced to acceptable sizes. The impeller of the device is semi-open, monochannel or vortex.

Types of drainage pumps

The entire range of drainage pumps is divided into two categories according to the place of their installation:

-

Surface.

-

Submersible.

Surface option

The first are installed on the ground next to the tank from which dirty water will be pumped out. The latter descend directly into the liquid.

submersible model

Compared to surface submersible drainage pumps, they are more productive, compact, safe and durable. Plus, they work not so noisy, the water dampens most of the sounds. However, they are somewhat more difficult to repair than their counterparts designed for surface mounting.

Principle of operation

In order for the dirty water pump to work normally and properly, the proportion of solid impurities in it should not exceed ten percent. Plus, there are also restrictions on the temperature of the pumped liquid. Many models of pumping devices for drainage are designed only for 35-50 degrees. These are a huge number of options for planning a plot of 12 acres. With drainage pumps, everything is more complicated; there are not so many ways and places to use a particular pump.

Principle of operation

If the device is designed only for 35 degrees Celsius, then it is impossible to pump hotter water with it. He will not work in this mode for a long time. The design of the drainage pump is such that it is cooled by the liquid pumped during operation. If the dirty water is too hot, the pumping equipment will stop cooling. And then - the inevitable overheating and breakdown.

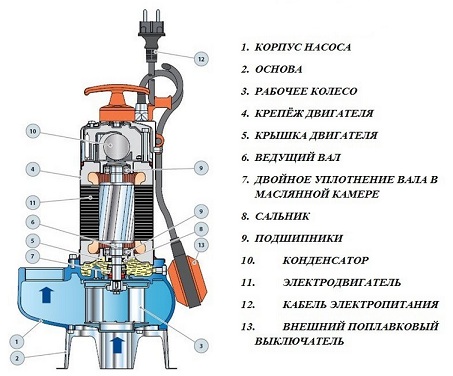

Structurally, the drainage pump consists of:

-

Sealed housing (plastic or metal);

-

electric motor;

-

Impellers on the working shaft;

-

intake pipe;

-

Float switch.

External device diagram

After turning on the pump, the electric motor begins to rotate the shaft and the impeller on it. As a result, air is discharged around the rotating blades, which lowers the pressure in the working chamber. Dirty water is simply drawn in by this vacuum and pushed further out.

Fecal matter pump and its design

This device is very helpful for those homeowners whose plots are periodically flooded with melt water or during river floods. With their help, rapid removal of water from the basement is carried out.

There are such situations that even having a central sewage system, you have to install such a unit. For example, with a long length of a gravity pipeline, when the slope of the pipe must be observed, but this could not be done for some reason. For the normal functioning of the entire system in this case, it is necessary to use a pump to pump out the incoming fecal matter.

According to the method of installation and design, devices are divided into the following types:

- Submersible;

- Semi-submersible;

- located on the surface.

Each type of equipment has its own advantages and disadvantages. Consider what they consist of and what differences there are in functioning.

The difference between drainage and fecal pumps

Fecal and drainage pumps are designed to work with contaminated wastewater - this is their similarity. But, despite the similar purpose, the equipment has differences. They determine the technical parameters and features of the application of each solution. The main difference is the diameter of the channels of the internal type, that is, the conditional passage, which reduces the degree of contamination of liquids for pumping. The size of this passage is 5-12 mm. When choosing a fecal pump, you will notice that the maximum allowable particle sizes are larger - all because the equipment is able to pump more polluted effluent. You can choose a drainage pump with a grinding system and a mechanism for crushing solids. Such models are more expensive, but they can do more than usual.

Thus, drainage pumping stations can optionally be used for pumping out flood waters, draining drainage stones, supplying water for irrigation from open reservoirs, reservoirs, and wells. That is, liquids should not be too contaminated, otherwise the system will fail. Depending on the specific operating conditions, you can choose installations of submersible or surface types. Surface pumps are installed along the edges of tanks and storage chambers, hoses for water intake are lowered down. This option is good for mobility - after completion of work, you can easily transfer an unnecessary installation to another place. Submersible borehole pumps are operated stationary and are attached to the bottom of the tank. Switching on automatically as the tank is filled.

Fecal models are ideal for handling very dirty liquids. They will pump out the contents of the cesspool, septic tank, drain the silted drainage chambers, and storm sewers. The performance is good, the power can be 40 kW or more. Pumps equipped with choppers are needed to handle very dirty effluents. The structures are reliable, normally withstand serious loads, and work without failures.

Category: Useful

Submersible Models

The device is initially created taking into account the factor that will be used with various aggressive substances. Therefore, in the manufacture of components and mechanisms, cast iron or stainless steel is used.

Before choosing such a fecal pump, you need to consider that during operation it must be at the bottom of the well. Equipping it with a special switch and an automation unit allows it to function autonomously.

The cutter pump is mounted as follows:

- At the bottom of the well, a branch pipe is strengthened;

- Along the wall surface there are guides for its descent;

- A chain or a very strong cable is attached to the device;

- Lower the unit along the guides;

- On the pipe, it is fixed under the influence of its own weight.

When it becomes necessary to make repairs, it is easily removed using a cable along the guides. For summer residents, this equipment option is almost ideal. It features simple structure and easy operation.

Watch a video about submersible models:

When solving the problem of which fecal pump to choose for your septic tank, please note that a submersible machine with a power of 40 kW. It is capable of lifting up to 400 m³ of wastewater to a height of two dozen meters in one hour

The main purpose of this equipment is the pumping of wastewater with all kinds of impurities, both long-fiber and solid. To be sure of the high-quality removal of large inclusions, it is better to install a fecal pump with a cutting mechanism installed on it.

How a sump pump works

Drainage pumps can be divided into two fundamentally different types:

- superficial;

- submersible.

To determine which sump pump is best for a particular job, it's worth understanding the characteristics of each type of device and understanding how a sump pump works under different conditions.

Surface pumps, an example of which can be seen in the photo, are installed above the water, near the pit. Water is pumped out using a hose that is immersed in water and reaches the bottom of the tank. The device can also operate in automatic mode, but it requires a float mechanism to control the liquid level in the tank. The rise of water also raises the float, which acts on the control elements and turns on the pump (for more details: “Drainage pump with a float switch, device and principle of operation“).

The drainage pump must have two pipes: an inlet through which the supply of waste water from the tank is ensured, and an outlet that leads water out of the filling tank. Surface pumps must be protected from water entering the motor, since in this case it may fail. That is why the power of the pump must be sufficient to pump out the liquid at a speed exceeding the rate of rise of water in the pit. Professionals advise using pipes to connect the pump to the sewer, but for this you need to know the exact diameters of the pipes that will be connected.

Surface drainage pumps are quite mobile and easy to maintain. If necessary, the device can be easily transferred to another place where fluid transfer is required, and the resulting malfunctions can often be corrected in the field, since the design is quite simple.

Submersible drainage pumps operate on the same principles as surface pumps, so the differences lie in the design of the devices. Firstly, the very name of submersible devices indicates the need to immerse them in water, and secondly, it is this fact that determines the principle of operation of such devices: the liquid is pumped by the pump itself, without the use of hoses or nozzles. Water is sucked in by the pump through a hole in its bottom, and to protect against solid particles, the structure is equipped with a filter.

These pumps operate automatically, using a float system or a plastic bladder that signals a rising water level and turns on the pump.

Considering the fact that submersible pumps need to work under water, manufacturers create the highest quality electrical insulation in order to reduce the risk of a short circuit to a minimum. You can use these devices both at the household level and in different industries - the technical characteristics of different models of pumps can vary over a very wide range. What are the advantages of submersible drainage pumps? They are highly valued by users for their safety and good performance, which in most cases can be used to the maximum.In addition, submersible equipment is reliable and can last a very long time.