Do you always need to insulate pipes in the attic?

If the family has sons, daughters, it is worth making an effort to adapt this part of the house to the needs of children. A tent house, a place for witchcraft - it's all an attic. It will be easier for a bachelor, bachelorette, lovers, a young family to manage household chores, take care of their well-being if the attic is turned into a room with a minimum risk of injury. Dust, through cracks, moisture, open pipes interfere more than a low ceiling, poor lighting.

The attic can be a mysterious room. It will be possible to revise an old photo album out of the box, sing your favorite song by turning on karaoke, right here. Or he will become a room in which there is something frightening, the mere thought of him will spoil the mood. The owner chooses what he should be. Hide pipes, decorate them - the first thing to do in the attic. More precisely, the first thing to do is to take care of thermal insulation.

Any pipe will freeze in winter. By insulating all the pipelines in this part of the house, you can achieve the following goals:

- prolong their service life;

- improve functionality;

- optimize the life support system in the house.

External and internal thermal insulation of ventilation pipes

Insulation of exhaust pipes performs the following functions:

- Provides fire resistance, prevents the spread of fire in case of ignition.

- Prevents the formation of condensate on the outer and inner surface of the pipe.

- Reduces heat transfer between the outside environment and the air in the system.

- Reduces vibration and noise generated during air movement.

Insulation of the ventilation pipe can be done from the inside or outside. With internal thermal insulation, it is required to increase its cross section in order to maintain the required throughput of the duct.

External thermal insulation of the duct

Today, providing sound insulation through thermal insulation material is not relevant, since often this problem is now solved by soundproofing measures in the sound source or by installing silencers. Therefore, at the moment, the use of external insulation is preferable.

Another circumstance when choosing whether it is necessary to insulate the ventilation pipe internally is the possibility of the appearance of foci of bacteria with such a decision, the appearance of deposits of dirt and dust, due to which the material may begin to lose its properties. With external insulation, these disadvantages are absent. Thermal insulation outside the pipe in the event of a fire greatly reduces the risk of fire spreading.

Installation of thermal insulation on ventilation pipes

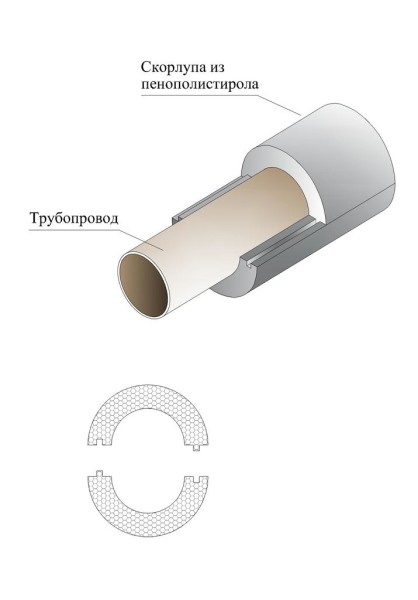

Expanded polystyrene insulation

Ventilation pipes insulated with polystyrene foam are less susceptible to corrosion, which greatly increases their service life.

To install the polystyrene shell, you do not need special skills. For its installation:

- Determine the size of shell you need.

- Cut the shell with a saw or knife.

- Install the parts of the shell on the pipe with an offset of several centimeters between each other, carefully close the side joints.

From the ventilation pipes, which are insulated with polystyrene foam shells, in the event of an emergency, they are quite easy to dismantle and just as easy to install back.

Polypropylene and polyurethane foam

These materials have significantly lower thermal conductivity and high refractoriness. Ventilation pipes are insulated with polyurethane foam and polypropylene as follows:

- Determine the required size.

- Cut material into semi-cylinders.

- Provide an allowance for the cover layer.

- Install half-cylinders on the ventilation pipes.

- Securely fasten the joints with bandages.

PPU (polyurethane foam) shell for pipes

Polyethylene foam insulation

This material insulated pipe for ventilation is the most popular today. Foamed polyethylene is a ready-made shell that completely encloses and insulates pipes.

For pipe insulation:

- Take material measurements.

- Divide the insulating sheath along a special seam.

- Fix the shell on the pipe.

- Using mounting tape or glue, fix the joints and seams of the insulating shells.

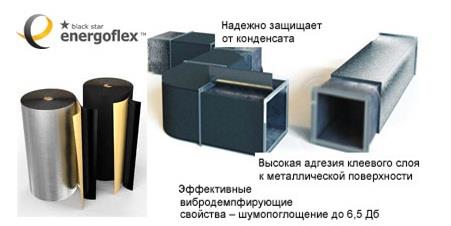

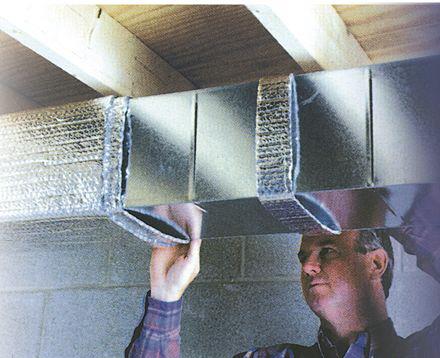

For square-section air ducts, polyethylene foam is produced in rolls (for example, Energoflex Star Duct)

Regardless of how to insulate the chimney, the location of the heat-insulating material, the main thing is to prevent cold bridges, which reduce the effectiveness of insulation, and ensure high vapor resistance

To do this, special attention should be paid to the places where the channels join the building structures, where there is the greatest probability of the appearance of cold bridges.

Materials for insulation of ventilation systems

Thermal insulation of ventilation pipes is made using various materials:

- mineral fibers. Thermal insulation materials made of glass wool or mineral wool are produced in the form of semi-rigid or rigid pipe panels and sections, in the form of a material that can be given the required shape and density by pressing during installation.

- Felt. During internal laying, rolled felt is protected with glass fiber with surface impregnation. At the outside - aluminum reinforced kraft sheet. Pipe sections are used for external cladding with aluminum reinforced protection.

- Foam elastomers are flexible, closed cell foams. They are self-extinguishing materials. This insulation is not subject to the action of microorganisms and mold, resistant to vapor permeation and moisture absorption.

- Derivatives of polymerization of carbohydrates (polyethylene, polyurethane, polyvinyl chloride). As a rule, they are produced in the form of pipe sections, blocks, plates.

Styrofoam shells

materials

And, finally, the cherished question: how to insulate the ventilation pipe? Let's arrange a short review of modern heaters that can be successfully used for ventilation ducts.

Requirements

Let's start by formulating our wishes.

- Thermal insulation qualities will, of course, be a priority characteristic of the insulation.

- Fire safety. In the event of a fire, an insulated ventilation pipe should not become a conduit for the spread of flames.

- The price should not be exorbitant if possible.

Mineral wool

Unbeatable cheapness. Any other heater will cost more.

Mineral wool 50 mm thick is supplied in rolls.

Absolute fire safety.

- Pretty laborious installation. The ventilation duct is wrapped with a layer of mineral wool; then it is wrapped in foil (which is permissible only in interior spaces) or protected by galvanization. Outside, the structure is pulled together with bandages.

- The need to protect the respiratory system and eyes when working with the material. Anyone who has ever worked with mineral wool (or glass wool, which differs only in the thickness of the fibers), probably retained the most unpleasant memories of it.

- The material shrinks over time. There are gaps in the insulation.

- Humidification leads to a loss of thermal insulation qualities.

Some of the shortcomings are devoid of a ready-made solution based on mineral wool - an insulated corrugation for ventilation, which is a two-layer sleeve made of aluminum foil with steel wire reinforcement. However, it involves laying ventilation from scratch.

Styrofoam

A ready-made detachable shell made of dense foam (polystyrene foam) is more convenient in many respects.

The process of warming is not associated with a health risk and is relatively simple.How to insulate a ventilation pipe with a foam shell? Just put two halves of detachable thermal insulation on the ventilation and squeeze them so that the tenon-groove connection is fixed.

The diagram makes it clear how to connect.

- The material provides excellent thermal insulation and practically does not change its thermal insulation properties over time, regardless of humidity fluctuations.

- Styrofoam is cheap. It is precisely because of its low cost that it is the main candidate among heaters if you are planning to insulate a loggia or the facade of a private house (for more details, see the article How to insulate a loggia and what is required for this).

- Styrofoam burns perfectly with the release of toxic products of combustion.

- The shell is easy to apply only on straight sections of air ducts.

Polyurethane foam, polypropylene foam

The shell can be made not only from foam. The other two foamed plastics are similar in application to foam insulation.

- Both materials have somewhat higher mechanical strength.

- They are more expensive.

- For fixing it is necessary to impose a bandage. In its quality, ordinary knitting wire is often used.

Shell made of polyurethane foam.

Foamed polyethylene

On sale, this material can be found in the form of split tubes of various diameters. They are put on the ventilation pipe - and, in fact, the work on thermal insulation is completed.

The material is cheap and is not afraid of moisture, moderate mechanical stress and rodents.

However, in cases where you need to insulate ventilation in a cold climate zone, you can pay attention to two other types of insulation based on foamed polyethylene

- Penofol and its analogues are polyethylene foam coated with a layer of aluminum foil. In our case, it is useful because the insulated pipe will collect less dust: the porous surface of polyethylene foam tends to accumulate pollution.

- Self-adhesive insulation based on the same polyethylene foam is equipped with a sticky layer that simplifies work. If you have ever insulated plastic windows or steel doors with a rubber or foam seal, you have already come across a way to fix it: just remove the protective glossy paper and press the material to the surface (see also the article How to insulate windows - getting ready for winter).

The material is very convenient for the insulation of square or rectangular pipes.

The thickness of the insulation can reach 10 millimeters; if necessary, it can be laid on ventilation pipes in several layers.

Features of thermal insulation

The technology for protecting ventilation pipes from cooling depends on the type of insulation and its performance properties. In this case, it is necessary to follow the sequence of work and carefully perform all operations.

Warming with mineral wool

It happens like this:

- the surface of the ventilation pipes is cleaned of dirt and dust;

- a strip of the desired size is cut from the roll, which depends on the diameter of the duct;

- thermal insulation of ventilation pipes made of mineral wool is carried out in one layer, while it is necessary to monitor the tightness of the material to the surface;

- on top of mineral wool, the air duct is wrapped with foil insulation;

- glue the formed seams with aluminum tape.

- mineral wool insulation wrap the pipe in one layer.

- on top of the cotton wool layer, the pipe is wrapped with foil insulation (4 mm thick), which will help retain heat and prevent cold air flows from entering.

Particular attention should be paid to the sealing of the structure, since mineral wool, when interacting with moisture, worsens its thermal insulation properties.

Polyethylene foam insulation

This method is one of the most popular, because it combines ease of implementation and efficiency.For insulation, polyethylene foam is used in the form of shells, with which the following actions are carried out:

- measure the insulation of the desired size;

- cut the shell along a special seam;

- install the resulting elements around the pipe;

- glue seams and joints using glue or mounting adhesive tape.

For pipes with a square section, it is much more convenient to use polyethylene in rolls.

Expanded polyethylene sheaths

Basalt fiber insulation

With it, you can not only protect air ducts, but also gas pipes. Basalt fiber prevents the appearance of fires and the spread of fire. How to insulate gas pipes? For this you need:

- prepare additional wire and aluminum foil;

- wrap the pipe with basalt fiber, and then cover with a layer of foil;

- secure everything with wire, including the longitudinal seam;

- fix the insulation layers with bandage buckles from packaging or aluminum tape.

You can also use basalt fiber with a metallized layer to insulate air ducts.

Warming with basalt fiber

Styrofoam insulation

In this case, the insulation resembles a shell, and the ventilation pipes are insulated as follows:

- measure the halves of the shell of the desired size;

- cut polystyrene foam along the marked lines;

- the halves of the shell are put on the pipe, while shifting them by 20-30 cm.

- close the side connections, ensuring tightness.

PPU protective shells with a foil outer layer

Polypropylene and polyurethane foam insulation is a similar form but has lower thermal conductivity and fire resistance. The fixation of individual parts is carried out using special bandages. Polyurethane foam can also be applied to the surface of the pipe by spraying.

The protection of air ducts has a significant impact on their service life. Choosing the right material for insulating the ventilation pipe, and observing the technology of thermal insulation work, it is possible to ensure the effective functioning of the system for a long time without damage and repair.

Where to insulate

Where exactly do you need insulation for ventilation pipes?

A simple solution

The simple answer to this question is obvious: where a sharp and significant cooling of the air flow is possible.

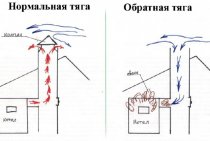

- If the exhaust ventilation is brought out through the main wall, the pipe is passed through a heat-insulated sleeve and insulated up to the deflector.

- In a private house, insulated ventilation pipes go through a cold attic and exit through the gables or roof. Insulation again starts from the point where the ventilation duct cools noticeably (see also the article Attic insulation - we consider the possible options in detail).

Ventilation is of particular note. Here, the possibility of moisture condensation on the outer walls of the supply ventilation duct depends on its length and location.

If necessary, these pipes can be insulated in the same way as exhaust pipes, however, the influx of cold air itself can create some discomfort; adjustable dampers for fresh air ventilation can even freeze.

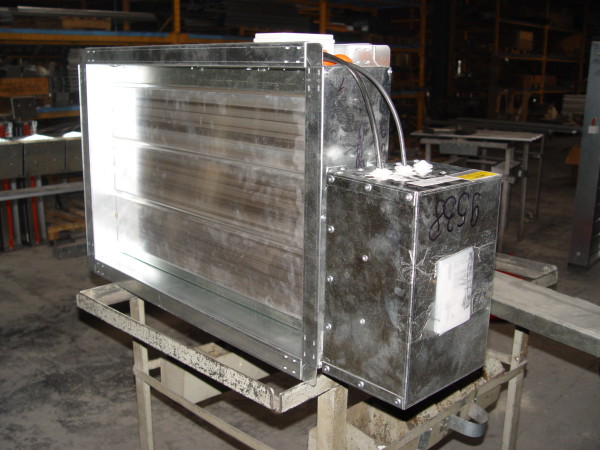

One solution to this problem is an insulated valve for ventilation. Probably, in the imagination of the reader, a ventilation grill with a layer of thermal insulation arose? It wasn't there.

The design in the photo bears little resemblance to blinds for ventilation.

The insulated ventilation damper is a solution for large premises, primarily for office, warehouse and production purposes. It really is an adjustable louvre that allows you to limit the air flow and ... if necessary, heat it up with tubular heaters.

Adjustment can be carried out manually - a system of traction and lever, or using a simple electric drive.The open area of the valve in a fully open state can be up to 3.5 m2, the power of heating elements is up to 8 kW.

The function of heating elements, however, is not to supply warm air into the room. With a valve area of 3.5 m2, 8 kilowatts of thermal energy is a drop in the ocean. Heating elements only warm up the valve flaps before changing their position in order to avoid icing and breakage.

Difficult decision

In some cases, an accurate calculation is desirable: with a large length of ventilation, the cost of insulation will be significant, and it is better to be sure of their need.

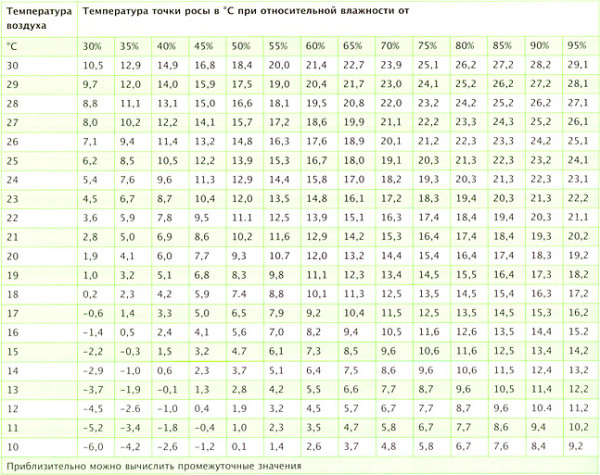

The key concept is the dew point. This is the temperature at which condensation begins to form in air with a certain relative humidity.

A simple measurement of the relative humidity of the air in the room and the surface temperature in different parts of the ventilation duct will give the exact boundaries of the zone that needs to be insulated.

This table will help determine the area of the duct where, at the current relative humidity, condensation will begin.

Condensation is a threat not only to pipes

The main reason for carrying out work insulating the ventilation line, as a rule, is the appearance of moisture spots on the walls and ceiling. Less often, work is carried out due to loud howls of wind in the pipe or its apparent freezing. These and other factors that destroy individual sections of the building are mistakenly considered the main reason for warming. In fact, the situation is much more serious.

As mentioned above, the moisture in the walls is an excellent environment for the development of fungus and pathogens. But in order for the mold to “appear” on the walls, you need quite a lot of time and moisture. And until the moment when it only “appears” on them, its own “ecosystem” is already formed inside the ventilation system, imperceptibly poisoning the house.

The result of this can be an allergy, it is not clear what caused the ailments, chronic headaches. The pathogens that cause them spread through the air, imperceptibly poisoning it. Therefore, proper insulation of ventilation is the protection of not only the walls and ceilings of the house, but also the health of its inhabitants.

Why is ventilation pipes insulated in the attic or above the roof level? What insulation for ventilation is better to use? Is it difficult to do this work with your own hands?

Let's try to figure it out.

Purpose and types of thermal insulation

Insulation of air ducts allows you to maintain a comfortable microclimate and favorable temperature conditions in the premises, prevents the formation of condensate on the surface of the pipes and prevents their destruction. It also reduces the level of noise and vibration that occurs due to the movement of air during the operation of the ventilation system.

Depending on the location of materials in relation to the air ducts, internal and external thermal insulation are distinguished. Warming from the inside is different:

- the need to use larger diameter ventilation pipes;

- carrying out additional measures for compaction, if materials with a loose structure serve as thermal insulation;

- tendency to form bacteria and spread them through the duct;

- low fire resistance.

Internal insulation of ventilation pipes

Ventilation pipes insulated from the outside are devoid of these shortcomings. They are easily cleaned of dust and dirt and are treated with special compounds that prevent the formation of bacteria. In addition, the cost of external thermal insulation is much cheaper than internal.

External insulation of ventilation pipes

When insulated from the outside, pipes can become a source of noise, but this can be easily avoided by installing special devices as silencers.

Usually, the thermal insulation of gas pipes is carried out outside, taking into account the purpose and material of construction.

Why is it needed

The key word is condensation. Without insulation, it will inevitably form on the inner surface of the ventilation duct and flow down the inner walls, flowing through leaky joints into the main walls and ceilings. The consequences are obvious: dampness of walls and ceilings, the appearance of mold and their gradual destruction.

The effect of condensate on the ventilation duct itself depends on what material it is made of:

- Galvanization can suffer if the protective anti-corrosion layer is violated. Which, however, is inevitable when cutting a sheet.

- PVC and corrugated aluminum pipes tolerate contact with moisture without any consequences.

Another trouble associated with moisture condensation is the gradual freezing of frost on the inner walls of the ventilation duct outside a warm room. For several weeks of operation in severe frosts, the pipe clearance can decrease from 100 - 150 millimeters to zero.

Where does the condensate come from?

There are two reasons for its appearance.

- Human life is associated with excessive moisture in the air. When washing dishes, cooking, washing, even just breathing, the atmosphere is saturated with water vapor.

- Meteorologists have long used the concept of relative humidity. The higher the air temperature, the more water vapor it can hold. 100% relative humidity is the maximum amount of water that can be contained in the air in vapor form. However, it is worth changing the temperature - and with the same amount of vapor in the air, the relative humidity will change. With significant cooling, it can exceed 100%, after which excess water will inevitably begin to condense on surfaces with a low temperature. In our case, on the inner surface of the ventilation duct.

Consequences of moisture condensation in the ventilation duct.

A special case

In production, there is often a need for forced ventilation with a high air flow rate. In particular, to remove harmful volatile products of production, sawdust, shavings, etc.

The noise of the air and what it carries becomes a serious problem in some cases. In factory premises, ventilation insulation often aims not so much to combat condensate as to simply soundproof. The methods, however, apply the same.

Conclusion

Which insulation to choose - you decide. The author's sympathies are given to foil materials based on polyethylene foam, but this is more a matter of habit. In the presented video in this article you will find additional information on this topic.

In a private house, the attic can be very warm, used as an extra room. But most often it is used as a storage room. The pipelines that are laid across its area make it difficult to change its purpose. If they are properly decorated, sewn up with boxes, it will be possible to make this room more cozy and comfortable.