Functional Features

Main advantages

The main advantage of liquid insulation for work inside buildings is thermal insulation without reducing space.

It is important to note the resistance of the material to temperature extremes, which occurs in winter during the heating season: minus outside, and plus inside, condensate collects, which forms a favorable environment for the development of the fungus. Additional benefits:

- environmental friendliness - the paint does not emit harmful toxic compounds at high temperatures, does not react with other building materials;

- savings in payment for heat due to thermal insulation;

- strengthening of treated surfaces.

The main parameters and advantages of insulating paint

The paint that is used for thermal insulation, in comparison with traditional types of insulation, has the following distinctive features:

- The thermal conductivity of the material declared by the manufacturer at 0.001 W. / (m. * K.) allows you to replace 50 mm. a layer of mineral wool - this allows you to reduce the amount of space occupied by the heater.

- The material has good adhesion, can be applied to metal, concrete, wood, plastic, glass.

- When applied, the operational layer of the material is usually 1 - 4 mm.

- The coating is waterproof, therefore it performs anti-corrosion functions, its use prevents the appearance of condensate on the metal surfaces of water pipes and gas pipelines.

- The material is resistant to biological effects, inhibits the development of fungus and mold.

- The paint is resistant to sunlight and temperature extremes, reflects about 85% of thermal radiation.

- The material does not lose its properties at temperatures from -60 to +250 C. and has maximum heat resistance compared to some types of insulation - this allows it to be used in conditions where other heat insulators cannot withstand temperature loads.

- Thermal paint is applied to the surface with a temperature of 5 to 150 C. - this in many cases allows you not to turn off the pipeline supply system.

Fig. 4 Thermal insulation of communication surfaces and containers with thermal paint

- Due to the airless content of microspheres in the acrylic base, the thermal insulating paint is light in weight (a 20 liter bucket weighs 9.5 kg.).

- The application technology is not very complicated and does not require special equipment; you can cover the surfaces yourself with your own hands using a conventional paint brush.

- The material is not combustible, can be used inside any premises without additional fire protection equipment.

- Teplokraska is an environmentally friendly and safe material for health, it can be used without restrictions in healthcare and catering establishments.

- The coating has a high maintainability - in the event of a violation of the insulation, a little paint is applied to the damaged area.

- Thermal paint is available in white or gray colors, the range is easy to change by adding to the tinting composition.

- The finished coating is elastic, has a high resistance to impact.

- The paint has a high operational service life from 12 to 40 years.

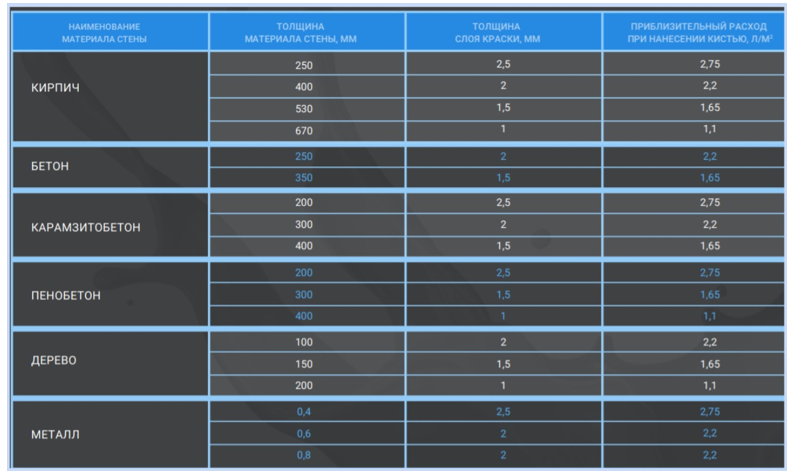

Fig.5 Approximate consumption of liquid insulation when finishing various types of surfaces

Liquid thermal insulation of communications

Usually, all pipeline systems in the area of heat supply are in an open state, and a significant part of the heat goes outside without getting inside the room. For thermal protection of pipelines, mineral wool, polyurethane foam, foam styrene and other materials are usually used. But, as practice shows, such materials, in comparison with liquid thermal insulation, have a short lifespan.They are exposed to precipitation, so their protective properties are quickly lost.

TEPLOKRAS perfectly copes with its work despite the weather conditions, as well as at the highest temperatures. Efficiency at high temperatures makes it possible to use liquid thermal insulation in thermal power engineering - it will act just as efficiently. Depending on the complexity of the design of the product, you can apply TEPLOKRAS paint both with a spray gun and with a brush. Due to its excellent adhesive properties, liquid thermal insulation perfectly adheres to the surface and covers it tightly.

|

Efficient ultra-thin liquid thermal insulation of all types of surfaces: pipes for hot and cold water supply, walls of residential and industrial premises, air ducts and other technological equipment. Thermal insulation for systems "Warm floor". Permanently rid of fungal growths and mold. Liquid thermal insulation can be coated with any acrylic paint. It is allowed to wallpaper, apply plaster, putty, tile and any facade and decorative systems. Liquid thermal insulation is intended for application to coatings: metal, concrete, brick, glass, plastic, wood, when operating objects from -60*C to +260*C. |

|

Waterproofing of sewerage, water supply facilities, including sewer collectors; Waterproofing of swimming pools; Replacement and repair of acid-resistant tiles, fluoroplastic, graphite plastic, plastic and enamel sheets; |

Designed to prevent the formation of ice on pitched roofs, bridges, TV towers, power line supports, gas pipes. It is waterproofing, anticorrosive and belongs to slow-burning materials. Has a high atmosphere. |

Efficiency assessment from experts

- extruded polystyrene foam in fact (50 mm) costs 300 rubles. (sq. m);

- assume that the thickness is 1mm, the price is per square. meter - 6 rubles;

- it turns out the total cost in the equivalent of ultra-thin thermal insulation - 450 rubles / liter;

- at the recommended consumption of thermal paint, its price for the same 1 sq. m. (thickness 1 mm) with a single-layer application is 100 times higher than that of expanded polystyrene.

In contrast to such reasoning, other experts give an example that the heat-insulating properties of the extruded polystyrene foam given as an example are at least 50 times lower, and the surface emissivity due to the roughness of the thermal paint is much higher.When the surface is treated with "liquid ceramics", the effect of a "thermal mirror" is obtained. To believe one reasoning or another is an individual matter, but experts agree that there is no alternative to liquid ceramics in hard-to-reach places. It is difficult to imagine warming with mineral wool under the windowsill or in other places, and the thermal insulation paint does an excellent job of this task, leaving no seams and bends.

Varieties

A variety of heat paint is conditionally divided according to two characteristics:

A variety of heat paint is conditionally divided according to two characteristics:

- composition: acrylic or water base;

- by scope: for indoor work, for pipes, facade - exclusively for outdoor work.

Heat-insulating paints for interior work

For work inside buildings, both acrylic and water-based compositions are suitable. An important task is to determine the functional load, as well as to study the composition, in which toxic components should not be present. For processing pipes, heating mains, gas pipelines indoors, use paint for interior work, preferably acrylic-based, and for painting cold walls, you can use a water-based composition.

Insulating paints for outdoor work

For work outside, it is necessary to choose heat-insulating materials, taking into account the functional features of the surface and environmental conditions (humidity, frost, sunny side). It is better to choose a mixture with minimal water resistance and the highest vapor permeability, so heat will be retained and the treated surfaces will not deteriorate.

For work outside, it is necessary to choose heat-insulating materials, taking into account the functional features of the surface and environmental conditions (humidity, frost, sunny side). It is better to choose a mixture with minimal water resistance and the highest vapor permeability, so heat will be retained and the treated surfaces will not deteriorate.

Main manufacturers

Minimizing heat loss is the task of most people who do not want to spend money on endless bills. The production of such materials is relatively new, but today there are leaders in the market in terms of quality and price:

Heat-insulating paint for pipelines cons

The disadvantages of thermal paints include the great doubts of many experts and users about the objectivity of the information provided by the manufacturer. The main arguments of opponents of heat paints are as follows:

- Based on tests of heat-insulating paints by the Ukrainian Institute of Technical Thermophysics, the coefficient of thermal conductivity of the paint is 0.05 - 0.09 W/(m*K). This indicator corresponds to conventional heat insulators and is equal to the characteristics of porous acrylic resin. This does not contradict the logical point of view - the heat-conducting material of the paint is an acrylic binder, in which practically useless microspheres are located, moreover, their ceramic shell is an excellent heat conductor.

- The manufacturer does not provide correct test data, replacing them with promotional marketing ploys with a heated iron or temperature measurements on the surface of painted objects. This has nothing to do with the thermal conductivity of paint and raises doubts about objectivity.

- It is established that paint with a porous ceramic filler was produced in the USA in the 70s and was used to protect objects from heating due to the high reflectivity of solar radiation. The fact that the Russian thermal paint is no different from the American counterpart is also confirmed by the conclusions of the Ukrainian Institute, which recommends its use only for thermal protection from solar radiation.

Rice. 7 Airless sprayer and automatic thermal paint gun

Advantages and disadvantages

Liquid heat-reflecting composition has significant advantages over other insulating materials. Its advantages include the following qualities:

- Use significantly reduces heating costs.

- The coloring layer well hides cracks and irregularities.

- The composition perfectly adheres to the surface and paints even hard-to-reach places.

- It has good protective properties. Metal protects against rust, and concrete from destruction.

- The protective layer is highly resistant to thermal and mechanical influences, as well as to ultraviolet radiation.

- The material is environmentally friendly and does not cause allergies.

- Has a long service life.

- Prevents the appearance of fungal formations and mold, as well as condensation on the surface.

- The composition is easy to use. To apply a protective layer to the surface, no special skill is required. Anyone can do the job.

These paints have a relatively low fire resistance.

In addition to the advantages, thermal insulation paint has some disadvantages. The most significant of them include:

- High consumption of material for the formation of a high-quality insulating layer.

- High price.

- Low fire resistance.

Read also: about the features of heat-resistant paint.

Information on the composition and principle of operation of heat-insulating paint

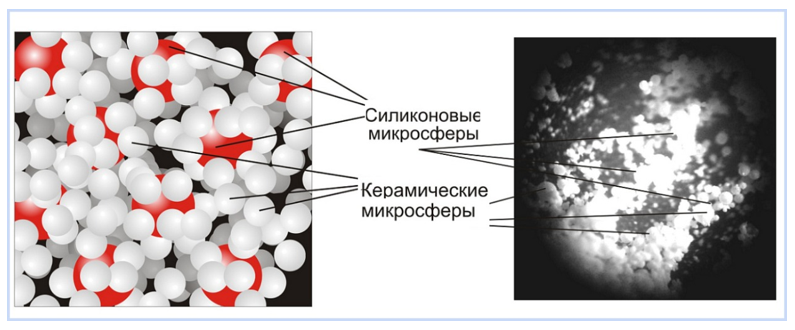

Thermal insulation paint is quite widespread in the construction market, it is produced by about a dozen Russian manufacturers. All brands have a composition, the main component of which is an acrylic or latex binder with the addition of heat-insulating microspheres with a vacuum inside, made, depending on the manufacturer, of ceramics, polymers or glass.

If we consider one of the manufacturers - RE-THERM, then its product includes an acrylic binder with technological additives, ceramic (10 - 30 microns in diameter) and silicone (50 - 80 microns in diameter) microspheres. In the structure of the acrylic composition, silicone spheres are surrounded by ceramic components - the result is a foil structure in which the ceramic component is a reflector, and the silicone components play the role of a vacuum layer between them.

It should be noted that there is practically no information on the technology of manufacturing vacuum microspheres from various materials and the equipment used for this - it is reasonable to assume that this information is a trade secret of the manufacturer.

Rice. 2 Structural structure of RE-THERM

Areas of use

The manufacturer claims that with a layer thickness of several millimeters, thermal paint can replace 50 mm mineral wool insulation, and a reflectivity of 1 sq.m. its surface efficiency is 50 sq.m. foil.

Such high performance and other technical parameters contribute to the fact that the scope of use of thermal paint is very extensive. Liquid insulation is divided according to its purpose: for interior and exterior work on interior decoration or for metal surfaces, and is used in the following works:

- Thermal insulation of roofs and facades of buildings, window slopes and cold concrete floors.

- Reducing losses in hot water pipelines, steam pipelines and various containers with high-temperature working fluid (boiler protection).

- Insulation of air ducts in cooling and air conditioning systems.

- Protection of water mains from freezing in cold weather.

- Warming of automobile and special equipment, industrial equipment.

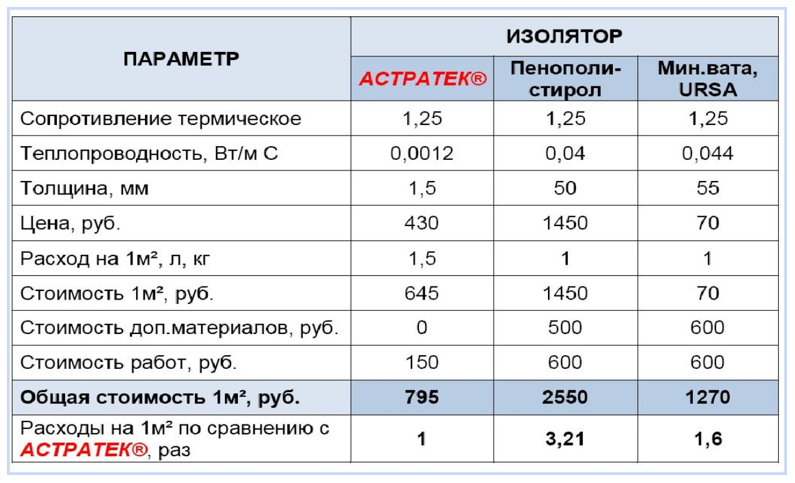

Fig. 3 Comparison of the effectiveness of paint with popular heaters

The choice of thermal paint and the main manufacturers

The Russian construction market has a wide range of liquid heat insulators from various manufacturers, when choosing a paint, you need to read the application instructions, compare prices, because the product belongs to the category of expensive ones. You can determine the required amount of material according to the consumption rates indicated on the packaging for various types of treated surfaces.

Corundum

The manufacturer produces a wide range of paints, the main brands:

- Classic - used for finishing interior and exterior objects with a working temperature range from -60C to +250C.

- Facade - provides thermal insulation of the outer surface of buildings, has good vapor permeability and moisture resistance.

- Anticorrosive - applied to cleaned metal surfaces or with traces of rust, provides high anticorrosion protection of objects during operation

- Winter is a brand intended for application in frosts at temperatures down to -10 C.

The average price of a 10-liter container of all brands of Corundum is 100 USD.

Fig. 8 Heat insulating paint for pipes - application options

Astratek

Durable paints with a service life of up to 30 years and a temperature of the coated surfaces up to 150 C. The product line consists of several grades of gray and white colors:

- The station wagon is used for thermal insulation of internal and external walls of buildings, the paint can withstand several freezing cycles, it is diluted with water.

- The metal is produced in gray color, during operation the coating performs anti-corrosion functions, can be used for painting metal objects and roofs of buildings.

- The white facade is used to insulate the facade walls of buildings, it has increased water resistance and vapor permeability, a viscous consistency is designed to work with a spray or spatula.

The average cost of 10 liters. heat paint Astratek is 110 c.u.

Rice. 9 Popular brands of heat-insulating paints

Armor

Liquid thermal insulation Bronya consists of several varieties:

- Classic - performs the functions of a heat insulator in heating and hot water systems, can be used to insulate chimneys. The paint is not subject to solar radiation, protects the treated surfaces from corrosion and condensation, thereby extending their service life.

- Anticorrosive - designed to cover rusty metal objects, further providing their high anticorrosion protection.

- Winter - additive polymers and foam glass granules are additionally introduced into the composition, it can be used in winter at temperatures up to -35 C. and is designed for operation in cold weather, has a rather high price - about 162 USD. for 10 liters.

- Facade - in addition to thermal insulation, it performs protective functions, preventing the formation of condensate, fungus and mold, and has high vapor permeability.

Products under the Bronya brand are among the most budgetary (with the exception of Winter), the average price for 10 liters. is 75 c.u.

Rice. 10 Liquid thermal protection on the roof

Compared with the use of traditional heaters, thermal paint has higher performance properties, its use allows you to quickly and efficiently paint rooms, heating systems, steam pipelines and hot water pipelines. With your own hands, it is easy to paint the insulated object with a roller or a paint brush; to obtain the desired consistency, the paints are diluted with water.

Does heat-insulating paint help to save the budget, can it be used without health risks indoors? Further in the article is an overview of popular options for additional wall insulation without narrowing the space.

Calculation of the amount of thermal insulation paint

When planning the calculation of the consumption of liquid insulation, it is necessary to take into account:

- area for application;

- roughness;

- layer thickness;

- surface type: smooth or embossed;

- application method.

So, for concrete, brick or wood, the overrun is 5-12%, and for metal 3 - 6%, the relief will also increase the volume of material by 20%. The average consumption of liquid insulation in calm weather is 1 l / sq. m. with a layer thickness of 1 mm. Thermal insulation is a top priority for every homeowner. Today, in the era of all kinds of building materials, you can choose the best option for additional insulation of the walls of houses, and liquid paint insulation is the best solution.