Installation Features

When deciding to install a heating device, you can not turn to the services of specialists. Do-it-yourself installation of a warm water plinth will not be difficult. Before proceeding directly to work, it is necessary to study the scheme, as well as carry out the necessary calculations and measurements.

All the necessary tools should be prepared: adjustable wrenches, pliers, wire cutters, sharp scissors, a hammer and a drill. To install the plinth, you will need thermal boards, as well as additional components. The latter include:

- connecting adapters for various sections and plastic pipes;

- pipes for connection;

- rotary corner pipes;

- protection tubes in red and blue.

Don't Forget Pivot Corners

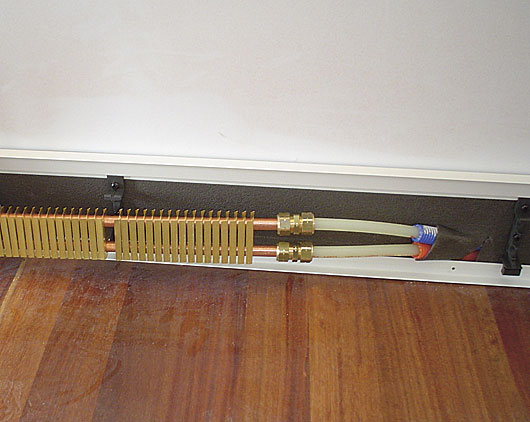

Installation of a water plinth should be carried out strictly following the instructions. The scheme of its installation is as follows:

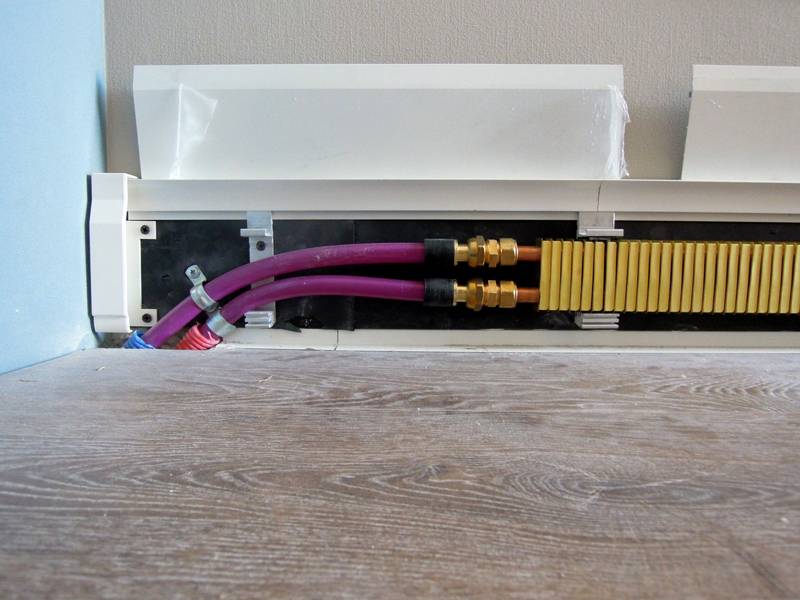

- Pipes are laid, while the distribution manifold serves as a reference point.

- The distance between the collector connection point and the baseboard itself is measured.

- The pipes are adjusted in size according to the measurements taken and laid into the wall so that the blue icon is on top and the red one is on the bottom.

- The place where the plinth is mounted is pasted over with self-adhesive electrical tape.

- Installation of the aluminum profile starts from the corner.

- The profile is attached to the wall with self-tapping screws or silicone.

- It is necessary to retreat from the corner of 15 cm, drill holes for the dowels and install the clips at a distance of 40 cm from one another.

- For the installation of convectors, the plastic pipes must be adjusted so that they are connected as precisely and firmly as possible to the skirting board section.

- To properly install the coupling, you need to put a nut and sleeve on each pipe and provide them with a rubber gasket.

- A sleeve must be inserted into the plastic pipe for support.

- An adjustable wrench is used to twist pipes.

- The termbord is applied to the wall, the number of brass ribs is regulated (excess can be removed with wire cutters).

- The next section is connected with an adapter. During installation, an indent of 1 cm should be made under the decorative elements.

- At the corners, special corner pipes should be used that repeat the shape of the corner. They are installed in the same way as connecting pipes using bushings, nuts and gaskets.

- The final section is a corrugated stainless steel, fastened by analogy with other couplings.

- The plinth cover is attached as follows: its inner surface is pasted over with electrical tape, applied to the profile and snapped into place with clips.

- At this stage, decorative plastic plugs and corner joints are mounted.

- The last step is to connect to the collector and start the water.

Installation of electric warm plinth:

Device and technical features

Externally, the heating device looks unremarkable: it is a long baseboard with a width of no more than two tens of centimeters.

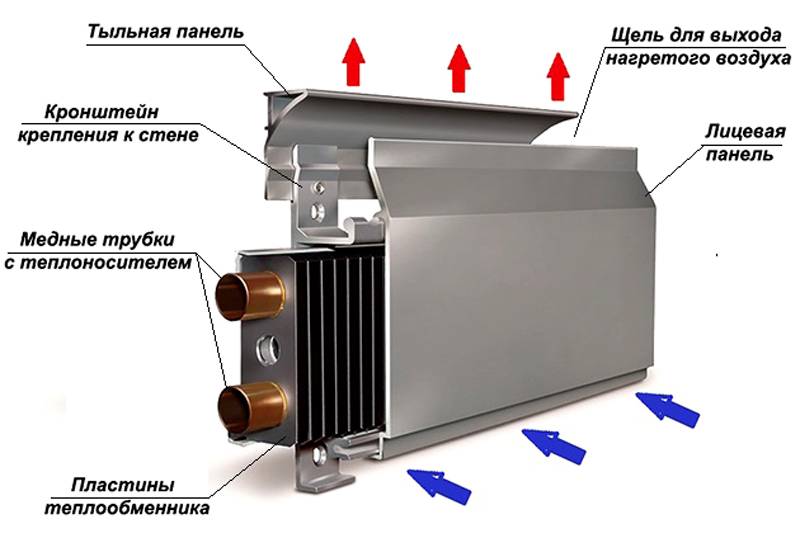

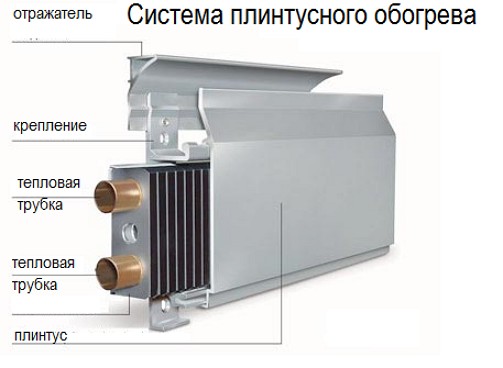

The design of the device includes:

- brass radiators in the form of thin plates, they warm up and give off heat to the air;

- a module containing a coolant, pipes through which the liquid circulates;

- decorative closing panel with a slot for the passage of heated air;

- rear bar protecting the wall from the high temperature of the heater.

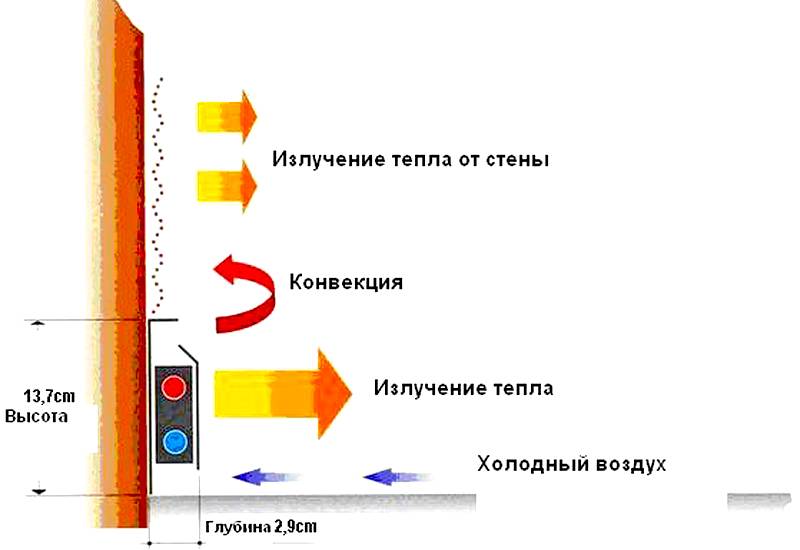

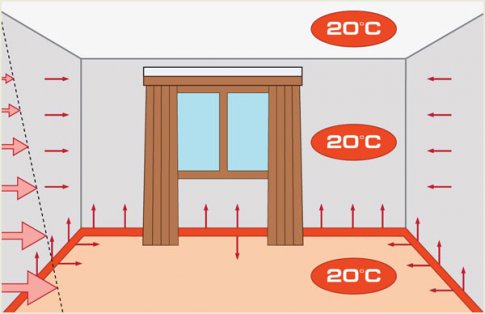

The principle of operation of the heater is very simple. Water is heated in the boiler of the system, then heat is distributed through pipes around the entire perimeter of the room. The heat flow moves from the floor to the ceiling, evenly warming up the entire space of the room. Heat flows along the walls, warming their surface. The wall also begins to give off thermal energy to the air.

The coolant in the baseboard can be heated up to 70 degrees, but it is not recommended to maintain such a high temperature due to possible damage to the walls and their decorative coating. The optimum temperature of the radiators is about 40 degrees. This indicator will ensure uniform heating of the air in the room to a comfortable temperature for a person of twenty-four degrees.

What is the design of a warm plinth

As you might guess from the name, this design is very similar to a regular skirting board. The outer collapsible box is made of durable materials; its width is about 3 cm, and its height is 14 cm. Inside it, a coolant (water or an electric heater) is placed on specially provided holders.

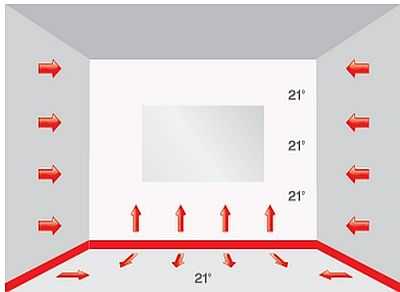

A warm plinth is laid around the entire perimeter of the room or along one massive wall. It heats the walls, which in turn reflect heat into the room. Such thermal radiation provides comfortable and uniform heating, and also has a high efficiency. But it should be remembered that the wall must have good thermal conductivity: for example, a warm baseboard will be ineffective next to wooden walls.

In the best way, warm skirting boards will show themselves along damp and cold walls, in a room with panoramic windows (for example, in a greenhouse, insulated balcony), in apartments with high ceilings. You can put them at the head of the bed or next to the workplace by the window. They are mounted in the pool, in the store, in the office.

Standard indicators

The standard unit, which is manufactured at the factory, has a power of 240 watts. This is the optimal indicator for a room whose perimeter is approximately twenty meters (taking into account the average height of the ceilings).

Frequently asked questions relate to the possibility of self-manufacturing such a radiator. In principle, it makes sense to do this on your own, but you need to be prepared for the fact that the process will take a lot of time, effort and finances. In some cases, such an experiment turns out to be more expensive than buying a ready-made warm baseboard.

Skirting heating is comfortable, beautiful, economical

Radiator heating and underfloor heating are not the only way to heat a room. Recently, warm skirting boards have become more and more popular. This type of heating appeared on our market only a few years ago and so far there is not much experience in its operation. Nevertheless, it is quickly gaining popularity - it is the most inconspicuous and very comfortable type of heating.

Warm plinth - heaters of small size, located along the floor along the perimeter of the room. They are named so because of their location and size: the thickness of such a heater is 2.5-3 cm, which is comparable to the size of a standard floor plinth. Height is more: 12-15 cm, but everything looks organic

What is important: such a system does not limit the installation location of furniture and decor items, since heat is transferred not by convection, but by radiation.

This is what baseboard heating looks like. No more other heating appliances

Baseboard heating

Despite the fact that in our country what a warm baseboard is, it became known not so long ago, in Europe this method has been used to heat rooms for several decades. This technology is very simple, but at the same time quite convenient. The basis is metal (most often copper) pipes, they are also a heating element. Pipes are installed in the same place where the plinth usually passes, that is, along the perimeter of the room. Then they are closed with a metal box made of plates with a corrugated surface. Due to this design, the box acts as a heat exchanger, thereby increasing the efficiency of the structure.

In general, a water plinth consists of the following elements:

- front panel with holes that provide airflow (standard size: width - 3-4 cm, height - 15-20 cm);

- rear panel - facilitates installation of the structure and protects the wall from constant exposure to high temperatures;

- a heating radiator that performs the function of heating (standard dimensions - 1 m x 0.4 m x 1.6 m);

- swivel side plugs;

- a heat exchange module consisting of two tubes through which water circulates.

Due to the fact that the skirting board is installed around the perimeter of the entire room, the heat gradually rises up, and then the entire room is evenly heated. As a result, this technology does not cause temperature fluctuations.

Since the heating element is hidden under the front panel, it is not noticeable, which distinguishes it from massive radiators. As you can see in the photo, the warm plinth looks very neat, it can be additionally designed so that it better matches the overall style of the room.

The system is effective, but at the same time quite easy to install. With minimal skills, you can carry out the installation without involving professionals.

How to make a warm skirting board with your own hands

Even Russian-made this pleasure is not cheap. But what if you want to try such a system, but there is not much “extra” money? Do it yourself. There are two working options.

Option one

Unannealed copper pipes with a diameter of 12 mm, sheets of roofing copper 0.4 mm thick were used. The order of work is as follows:

- Cut a strip of roofing copper (60 cm) with a grinder into strips of 15 cm.

- Flange the edges of the strips in full length at an angle of 90 o and a shelf length of 7-8 mm. The length of the strips is not more than 3 meters - it is inconvenient to work with large pieces.

- Solder copper tubes to the back of this plinth. This requires solder (plumbing, containing 3% copper) and a burner. When soldering, point the torch at the tube: the strip is thin and will warp if it overheats. The tube can withstand heat well.

- Bend slightly at the ends of the tube before soldering. So it will be more convenient to put adapters on them.

- Oil-and-petrol resistant hoses were used for assembly, which can withstand working with coolant up to 120 o C (inner diameter 12 mm). At the junctions with the pipe, they were fixed with ordinary clamps.

- To regulate the temperature, a thermostat with manual adjustment by Giacomini is installed.

- The connection points are closed with similar inserts / plinths made of copper, but without pipes.

- The panels are attached directly to the wall using standard mounting clips (for pipes). Do not insert them into the recesses - most of the heat is lost.

Such a system has worked in a wooden house for 9 years. There were no problems or the need for repairs. The temperature of the coolant at the inlet is from 50 o C to 70 o C. In the room 20-21 o C when it rises, it is too hot.

Look in the video about the features of installing a warm skirting board. Might be helpful.

Second option

In this case, do-it-yourself aluminum profiles were used to make a warm plinth for working with drywall. Holes are cut (propylene) in them by a grinder at the top and bottom, after which they are attached to the walls. Two copper pipes are laid on a thin ceiling aluminum profile, screwed with aluminum wire. This whole structure is laid inside and fixed to the wall so that the pipes are one above the other. The assembly of pieces of such a home-made plinth was carried out by welding with copper pipes and fittings. "Front panel" - the same profile, only painted with paint for radiators to match the walls (floor). This homemade warm baseboard is less effective, more difficult to clean, but also very efficient.

“I have such a skirting board at home. In addition to underfloor heating. I also recommend you install it. A warm skirting board does its job well. Of course, it cannot be compared with warm floors in terms of power, but still there is tangible heat from it.

“I bought 9 m 2 “Megador” 600 W in the bedroom.At first it worked at full power, and now we set it to 200 watts to maintain 20 degrees. This is enough for my area, we don’t need a higher temperature, we don’t like it. And at the same time, on the wall where the heater is located, our ventilation hole is almost always ajar. I'm satisfied."

As you can see, reviews of warm skirting boards are positive. This is no wonder: heating is efficient, comfortable, and even unnoticeable. Only the high price spoils the picture, but there are options for making it yourself.

Like everything new, the plinth system has many critics-theorists. Their main thesis: “It is foolish to heat the walls in order to heat the air later. It is better to directly heat the air, and then start heating the walls.” The point of view is clear. It is she who is used for convector heating. But the result and its shortcomings are known to all. And for the effectiveness of heating the walls, an experiment was carried out: in one room the air was +12 o C, and the walls were heated to +37 o C. And the people in it were sweating. In another, the air was heated to +40 o C, and the walls were cooled to +12 o C, and people were freezing.

Benefits of using a warm skirting board

The use of such a modern heating system provides a lot of advantages for consumers, namely:

- the ability to save free space due to its compact size, which is very important for small rooms;

- creating comfortable conditions for all living things in a heated room. The warmth of the skirting boards provides an optimal microclimate for humans, animals and plants. A particularly warm skirting board is suitable for corner apartments, where, if it is used, the walls will completely warm up and thus you can forget about the fungus;

- no condensation on the windows and uniform heating of the entire room;

- due to the absence of convection currents, as with traditional heating, there is a decrease in the dust content of the room;

- high efficiency in work;

- absolute safety and ease of operation;

- ease of installation and the ability to fit into any interior due to the variety of designs and colors;

- energy savings, which is approximately 40%;

- affordable cost.

Water warm plinth

Do-it-yourself assembled warm water plinth can create special comfort in residential premises. If you look at the water plinth from a constructive point of view, then we will see compact "stretched" modules in length.

For the installation of a baseboard water heating system, private households or public institutions are most suitable. The necessary conditions for the installation of warm skirting boards are the presence of a gas boiler and central water supply.

In some cases, boilers operating on solid and liquid fuels are used. You will also need a reserve tank (water tower) to replenish the water level in the heating system.

Skirting convectors with a water coolant are installed along the perimeter of the room. Modular liquid electric heater can be of various lengths. In the corners of the room, the modules are connected with special corner elements, which fill the fully heated perimeter of the room. Thanks to this placement of skirting boards, the room warms up more evenly than when heating with conventional water radiators.

Otherwise, you may be fined and forced to dismantle the heaters.

Water converter design

The design of the plinth is quite simple. The upper pipe, as a rule, leaves the gas boiler system, passes through the entire perimeter of the heated area and passes into the lower return pipe. The lower pipe returns the cooled coolant to the gas boiler.

The pipelines are built into the housings of the finned heat transfer devices. Due to the ribbed structure, the heat transfer surface increases many times, which significantly contributes to the active circulation of heated air masses.

To install a warm water heating baseboard on your own, you must have sufficient experience in installing plumbing equipment. Telling below about the features of installing a warm water skirting board, we turn to just such people. This will help when choosing a particular heating system for your home.

The principle of operation of water plinths

Cold air enters through the bottom groove of the plinth body.

Passing through the heat exchanger, hot air slowly rises, evenly spreading throughout the entire volume of the room.

Installation of skirting water heating system

In construction supermarkets, you can always purchase the ready-made system of water heating for skirting boards that you need. With even a little experience in plumbing work, you can easily make a warm plinth with your own hands. heating with a warm baseboard, see this video:

After the appropriate marking of the mounting points of the brackets and their installation, the fluid modules themselves are mounted (see above the installation of electrical skirting boards). Unlike electric heaters, the installation of liquid modules requires careful control of the tightness of the pipeline connections.

Testing of installed skirting boards

Air molecules are much smaller than water molecules. Practice shows that checking the tightness of connections is more effective by creating a high pressure of compressed air inside the pipelines.

Bubbles will appear where leakage occurs. Leaks in the connections are eliminated and the entire system is re-tested for tightness.

Principle of operation and differences

The manufacturers of baseboard heating claim that the system is more economical than all other types of heating. Savings are 20-30%. This is due to the fact that lower temperatures are required to achieve a comfortable feeling. And all because most of the heat is transferred by radiation, not convection.

Almost all existing heating systems do not create the best thermal picture: warm air accumulates at the top, cold air remains at the bottom. If the room has not very high ceilings, the situation is tolerable, but in rooms with a high height it is critical. To even out the temperature picture, forced convection is used: fans are built into the heaters, which more or less effectively mix the air masses. But the active movement of air carries dust and germs. At the same time, stagnant zones still remain in the corners of the premises, in which cold air accumulates.

When using baseboard heating, there is no thermal cushion at the top, the air is fresh, and the feeling is comfortable

Uneven temperatures and dust in the air are not all the troubles of convection heating. There is also dampness that appears on the walls. This is because convection heats the air. The walls remain cold. When warm air and cold walls come into contact, condensation forms, the walls get wet, fungi and mold develop. Moreover, this picture is typical for houses and apartments with good insulation.

Baseboard heating works differently

The first important difference: the lower layers of the air immediately heat up, which is already comfortable. Gradually and slowly rising up along the walls, the air cools down, transferring heat to the walls.

Because it turns out that the top is not warmer (or not much warmer) than the bottom.

It takes only about 20-30% of the heat to heat the air by convection. Everything else goes to heat the walls

And this is the second important difference. Heated air rises along the walls, instead of mixing with the rest (this effect was noticed by the scientist Coand)

Therefore, the ascending warm current cuts off the cold from the walls and heats them up. Yes, while the walls heat up and dry, there is a large consumption of energy (and fuel). But after that, the entire surface begins to radiate heat.

This is where the saving zone begins: a person feels comfortable if the temperature of the walls is 36-37 o C and the air is 16 o C. We simply feel the heat coming from the walls with the entire surface of the body. At the same time, the cost of maintaining the temperature of dry walls is low. After all, it is the water contained in the materials that is the best conductor of heat, and the air that replaced it, on the contrary, conducts heat poorly.

This is what one of the options looks like

That is why with such heating it is not so important whether pieces of furniture stand along the walls or not: the walls are mainly heated, not the air. Let them take away some of the heat, but then they themselves will begin to give it away

And the walls get hot anyway.

The principle of operation of baseboard heating

Skirting heating is quite effective due to the fact that it is not the air that is heated at all, but the walls of the room. The walls here act as radiators that maintain the temperature in the room. In order for the air to normally flow to the heat carrier of the plinth and leave it unhindered, special two slots are provided in the boxes.

For baseboard heating, the main thing is materials that must have high thermal conductivity. Heating the coolant to very high temperatures is not so important here.

It should also be noted that this system can work as a device that lowers the temperature in the room. All you have to do is fill the system with a special coolant. The effect of such an application will be significantly lower than when heated, but quite noticeable.

Of the advantages of this system, it should be noted:

- the complete absence of convection, which means the absence of dust suspension in the air;

- plinth heating is absolutely safe for humans;

- heat is distributed evenly throughout the room;

- boxes and walls have a temperature that is safe for animals and humans;

- dry walls and air;

- amazing ease of installation;

- the absence of any contraindications for use;

- plinth radiators look quite aesthetically pleasing and also save space;

- significant fuel savings;

- ease of dismantling and repair;

- Possibility of mounting thermostats.

- high price of components - aluminum and copper;

- making the right baseboard heating with your own hands will not work;

- the most permissible length of the heating circuit should definitely not be more than 15 meters;

- the impossibility of any decoration of the plinth;

- the impossibility of installation close to the walls of furniture;

- the location of the heating elements very close to the wall leads to the rapid destruction of the wall covering.

In today's conditions, when the materials used in decoration and construction help to minimize all heat losses, and the installation of double-glazed windows restricts air access to the room, baseboard-type heating has become quite relevant.

Video "Plinth heating":

Installation of a warm plinth

Preparatory work

Before proceeding with the installation of a warm skirting board, it is necessary to select in advance the most suitable type: water or electric, depending on the most available source. Based on this, further work will be carried out. So, if it is a water plinth, then you should think about how to connect it to central heating or to an individual boiler, and if it is electric, then ensure a safe connection to the outlet.

Determining the number of skirting boards

In order to correctly calculate the required number of skirting boards, you need to take into account the total power of such a system, adjusting it for possible heat losses for each of the rooms. The latter depend on the level of wall insulation, window glazing, outside air temperature, etc.

The less heat loss, the less power a warm baseboard is needed and, accordingly, the cost of such equipment, which is important.

On average, the calculation of power occurs according to the following formula:

- for an electric plinth per 10 square meters, approximately 0.5 kW is needed;

- for water for the same area, you need twice as much power.

Determining the mounting location

- A warm plinth is installed in one row at a distance of 1 cm from the floor and about 15 mm from the wall on two stops. The resulting gap is necessary so that there is no overheating.

- First, the wall is marked with a chopping thread according to the level along which the plinth will be installed.

- Next, mark the holes for drilling by attaching the back panel to the wall.

- Having drilled holes, we insert plastic dowels into them and we mount the plinth module strictly according to the level. And so on until the end, until all skirting boards are installed.

- After that, we install special power jumpers and make grounding.

- Each of the modules is connected in series. At the same time, there should not be more than 17 pcs.

- We turn on the installed plinth to check its performance, and only then can we close the modules with covers, and also put all the plugs.

Installation and connection of the thermostat

- The thermostat is installed on an open wall at a distance of about 1.5 meters from the heating elements.

- To do this, we attach its back panel to the wall in order to mark the holes for drilling.

- We insert 6 mm dowels into the finished holes, and then we mount the thermostat to the wall.

Cabling

- Connection to the network of heating elements, as already mentioned, is carried out in parallel.

- The connecting cable can be hidden in the wall by punching a hole for it or hidden from the outside in a special box.

- The cable is laid to the junction box or thermostat.

After completion of all work, the operation of the entire system is tested.

What is a warm baseboard

A warm baseboard is the latest heating system, which consists of an external collapsible box, in which a coolant is built in (pipes for water circulation or electrical conductors). Heat transfer occurs due to the supply of electric current to it or hot water to a closed circuit. A warm baseboard, as a rule, is installed around the entire perimeter of the room or along the coldest wall. At first glance, it is no different from an ordinary skirting board, it has approximately the same thickness from 2.5 to 3.5 centimeters. The only thing is that the height of the warm plinth is slightly higher than usual and is approximately 14 cm.

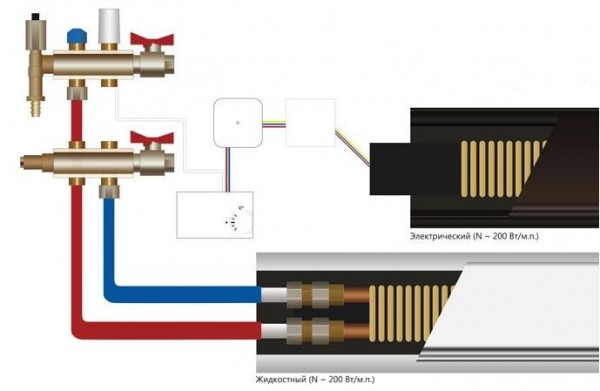

There are two types of warm plinth system:

- what works on a liquid (water or antifreeze) and must be connected to a central heating system or an individual boiler;

- that works from the socket or electric.

System Disadvantages

Skirting water heating also has disadvantages that you should be aware of before deciding to install it:

| Cost of materials | It must be admitted that while the cost of components of the baseboard heating system exceeds traditional batteries. This is a temporary disadvantage. With the growing popularity of such heating, the market supply will also grow. In the competitive struggle, manufacturers will reduce prices, but so far the offer on the market is modest, which cannot be said about prices. |

| Damage to the walls in the places where the plinth fits | One can argue with this shortcoming of the system. Provided that the installation is of good quality, this problem should not arise. Difficulties arise only in an emergency, when the circuit leaks. |

| Reduced work efficiency due to furniture | This problem can be avoided by creating a structure that wraps around large, stationary objects. Such maneuvers will lead to additional costs, but will pay off in the absence of energy losses. |

Installation of a warm plinth system

When a warm water baseboard is installed, PVC pipes are first laid from the distribution manifold, and then the connection points are prepared.You should especially carefully monitor the correctness of the beam wiring, since after pouring the screed it will be difficult to change anything. All supplies are carried out in the process of construction work.

The system is installed only after finishing the premises. The first module is connected using a coupling, and then all elements are mounted in series. In the corners and at the very end, the connection is made using swivel polyethylene tubes. Each heating circuit is limited to a length of 12.5 m. Heating is carried out near the outer walls of the house. Internal walls are also used. Skirting boards are not installed in the locations of plumbing, household appliances and bulky furniture. Then pressure testing is performed, all circuits are balanced and the automation system is adjusted.

Radiators do not have to occupy the entire perimeter of the room, but must be located along the walls. Air enters from below to the heaters and exits through the upper slots of the ducts.

Water baseboard heating

The main components of such baseboard heating are baseboard heating radiators, a distribution manifold, as well as plastic tubes that do not allow oxygen to pass through.

The baseboard heating system can be connected to the central heating in the case when the temperature of the coolant is not more than 85 ° C, and the pressure is not more than 3 atmospheres. It is necessary to withstand such parameters in order to avoid the so-called water hammer. When installing heating, it is also necessary to take into account the following recommendations:

- It is preferable to use copper pipes instead of ordinary plastic ones.

- You can use a heat exchanger that receives heat from the central heating and is embedded using special copper plates.

- Mount thermostats to each of the radiators.

- It is possible to install a special servomotor on a special distribution manifold.

- Install circulation pump, thermometer and pressure gauge.

The principle of operation of warm skirting boards

The essence of the very idea of \u200b\u200bheating with warm baseboards is that the heating system is located around the perimeter of the room near the floor. The heated air in the convector slowly rises along the walls. Due to this, the entire volume of the room warms up.

Warm baseboards practically do not take up much space. Despite the high power indicators, furniture and other interior items can be safely placed near the convectors. The surface of the convectors does not heat up to a dangerous temperature level that causes burns.

The trading network offers for sale systems of warm skirting boards of two types. This is an electric skirting board and a warm water skirting board. Consider each heater.

Electric warm plinth

The heater consists of two horizontal copper tubes. The power cable, covered with silicone insulation, passes through the top tube. A tubular electric heater is threaded into the lower copper tube. The whole system is controlled via an air temperature sensor by a thermoregulation unit.

When the temperature inside the room falls or rises, the heaters periodically turn on and off, thus ensuring a constant temperature regime.

They purchase a set of warm skirting boards based on the calculation of the length of the heaters, rotation angles and other related elements. The heating element itself is a tubular electric heater (TEH), enclosed in a copper sheath.

In turn, a copper pipe is threaded through a body of ribbed thermal reflectors (radiator). Electric heating modules are produced in several standard sizes. Depending on the length of the electric heater, its power changes, as can be seen from the table:

| 1 | 700 | 140 |

| 2 | 1000 | 200 |

| 3 | 1500 | 300 |

| 4 | 2500 | 500 |

Installation of electric plinth

Only a person with extensive experience in electrical work can assemble his floor electric heater by hand.Calculating the dimensions of heating elements, making radiator nozzles, installing connecting cables is a very difficult and responsible job. Therefore, it is easier to buy ready-made heating elements for warm skirting boards.

When a heating set of skirting boards has already been purchased, they begin preparatory work.

- I install the mounting box at a height of 4 - 6 cm from the floor. Lead the power wires to the junction box.

- At a convenient height, a switch with a thermostat is mounted on the wall.

- A protective tape 3 mm thick is glued to the walls over the entire height of the plinth.

- Markings are applied to the walls for mounting under heated skirting boards.

- Drill holes for dowels in places where fasteners should be installed.

- Screws are screwed into the dowel through the technological holes in the brackets.

- A thermal heating module is hung on the installed brackets.

- Connect the modules with electrical wires in parallel.

- A residual current device (RCD) is connected to the system.

- Connect the air temperature sensor.

- Make control inclusion of an electroplinth. If a malfunction is found, fix it immediately.

- Install the skirting board.

Work related to the supply of electricity to the plinth, connection to the electric meter, installation of a thermoregulation system is best entrusted to a specialist.

Installation of a warm plinth provides complete electrical safety. The places where the wires are connected to the contacts of the modules are closed with heat shrink tubes. The tubes protect the contact surface from moisture.