Construction material

Before proceeding with the installation of the floor on the second floor on wooden beams, you should make a list of all the necessary materials. This will allow during work to avoid unforeseen downtime and delays caused by the need to purchase some building materials.

beams

The basis of the entire structure of interfloor wooden floors is beams. They play the role of load-bearing elements, and the strength of the structure depends on them. For them, a bar or gun carriage with a section of 15 x 15 cm, or 18 x 18 cm is usually taken.

This section is usually enough to provide sufficient rigidity for a specific load of 400 kg per sq.m. In this case, it is necessary to observe the parameters recommended by building codes: the span is 4 m, and the step between the beams is 60 cm. Based on these parameters, you can also calculate the required amount of timber.

The table shows the recommended cross-sectional dimensions of the bearing beam for a certain span length.

| № | Span length (mm) | Beam cross section (mm) |

|---|---|---|

| 1 | 2000 | 75×150 |

| 2 | 2500 | 100×150 |

| 3 | 3000 | 100×175 |

| 4 | 3500 | 125×175 |

| 5 | 4000 | 125×200 |

| 6 | 4500 | 150×200 |

| 7 | 5000 | 150×225 |

However, in the absence of a beam and small values of the expected loads on the floor, it is quite possible to use boards nailed together in pairs and placed on the edge with a thickness of 50 or 40 mm. This option is suitable for flooring in the attic or in a small country house.

Bars made of wood of stronger species (larch, oak) can rarely be found on free sale, and their price is incomparably higher, and pine wood after appropriate treatment with antiseptics will not be inferior in terms of durability to the same larch.

Flooring

Usually, the flooring of interfloor ceilings is made in two tiers: from below there are rough floors, on which insulation is laid, and from above - pre-finish flooring, mounted on top of the bearing beams. A decorative floor covering is laid directly on it.

To determine the nature and amount of material for flooring, you should clearly consider the design of the floors.

In the device of the subfloor, either 5 x 6 cm bars stuffed onto the supporting beams or grooves made in the beams can be used as a support for the floorboards. The latter option is quite laborious, so most often 5 x 6 cm bars are used to create a support.

To calculate the required number of bars, it is enough to count the number of beams and multiply them by the length of each of them. The resulting footage (the total length of all beams) is multiplied by two more (since the bars will be stuffed on both sides of each beam).

A wide range of materials can be used for finishing flooring. It can be boardwalk, plywood, chipboard, MDF, OSB, etc. Each of these materials has its own advantages and disadvantages, after reading which you can choose one of them. To calculate the required amount of material, it is enough to simply calculate the area of \u200b\u200bthe room.

This will save you from having to interrupt work and buy the missing part.

Impregnation

To maximize the service life of wooden structures, they must be treated with antiseptic materials.

It will also be useful to treat wood with fire retardants, which increase its fire safety.

To calculate the required amount of impregnation, you should read the instructions for its use - it always indicates the approximate consumption of the mixture per sq.m.

Waterproofing

Since wood is afraid of moisture, waterproofing materials are always used in construction.

This can be rolled waterproofing used to create a water-repellent layer between wooden floor structures and the finish coat, or between wood and brick (stone, cinder block, etc.).

Heat and sound insulation

If it is necessary to create a barrier to noise or cold, insulating materials are used in the construction of floors. Most often, for these purposes, use a minplate or foam. Their total number in area should be approximately equal to the area of \u200b\u200bthe room. For more information about floor insulation, see this video:

Fastening materials

For fixing wooden floor elements, you should purchase self-tapping screws, nails, steel corners, anchor bolts and other consumables

When purchasing screws and nails, attention should be paid to their length.

Those. for reliable fastening to the beam of the “magpie” board, you will need 120 mm nails or 80 mm self-tapping screws.

Video text

The Zagorod company makes heating in a country house with an area of 170 m² for a large family. We applied an interesting technical solution: the house will be heated without radiators, only with the help of the “warm floor” system. This method is rarely used and in our long-term practice it has met only 5-6 times. We decided to make a video for you about this interesting project, to talk about the installation of underfloor heating and the features of their installation.

We tried to give as much information as possible in a small review:

What are the benefits of underfloor heating? Why are they so popular despite the high cost? A small digression into history: where did they first use the "warm floor" system? -What is the difficulty of installing a warm floor on the second floor? How do we solve this problem? -How pipes are laid so that the floor heating is uniform. In what cases is it necessary to lay pipes closer to each other? - Do I need to pre-design the heating system? Why should the project be calculated not by company managers, but by experienced heating network engineers? -What to do if a pipe breakdown occurs? By what signs can this be understood and how to correct the situation? - Ways of laying a warm floor: what are their features and which one is more preferable? - What are the options for fixing a warm floor and how do the work time and cost compare for each option?

UyutTeplo LLC provides comprehensive maintenance of heating systems for a country house in the Zaoksky district.

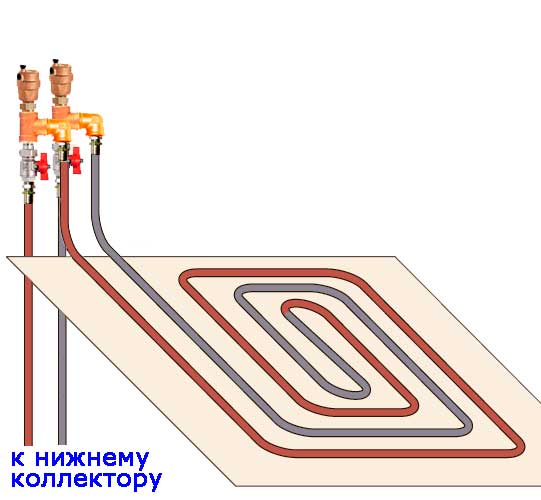

It happens that one or more contours of a water-heated floor need to be mounted above the collector.

For example, the collector provides the main warm floor of the first floor, and on the second floor you need to extend a branch to the toilet and bathroom.

There is a danger that the contour of the second floor will be filled with air bubbles and will not work.

So most likely it will happen if you do not apply a simple chip.

UyutTeplo LLC provides comprehensive maintenance of heating systems for a country house in the Zaoksky district.

It happens that one or more contours of a water-heated floor need to be mounted above the collector.

For example, the collector provides the main warm floor of the first floor, and on the second floor you need to extend a branch to the toilet and bathroom.

There is a danger that the contour of the second floor will be filled with air bubbles and will not work.

So most likely it will happen if you do not apply a simple chip.

Pipes rising from the collector must be brought higher than this upper branch will be. An automatic air vent must be installed on each of the pipes. Continue the contour through the tees. Thus, the upper branch of the water-heated floor will be equipped with its own air vents, will not get airy and will work normally.

On the main manifold, you need to mount the bends directed upwards.

This is how you need to organize the air outlet

Beam device

It is worth noting that replacing the floor in a wooden house with your own hands is quite real, you just need to understand the principle of the work.In order for the floor to be of high quality and last for a long time, you should decide on the number of beams.

To do this, you can use special programs, but developers go the other way, relying on standard approaches:

- A bar with a section of 150x150 mm or 200x200 mm is selected.

- The beams are located at a distance of 0.6 m from each other.

This process requires a special approach, which can be based on certain rules:

- All wooden structures, including beams, should be treated with antiseptics and refractory materials.

- Do not cover any wooden structures with resin, as this can lead to condensation.

- The first beam should be installed at a distance of 5 cm from the wall and no more.

As mentioned above, the installation of floor beams is carried out depending on the structural features of the structure.

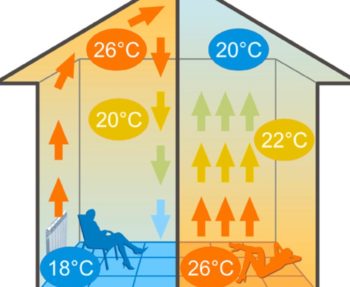

Advantages, disadvantages of underfloor heating

The heating system in the form of underfloor heating has both positive and negative points. There are advantages that are inherent in all types of structures for floor heating:

- high level of comfort: it is pleasant to walk on the floor, sit on it, play for children;

- relatively low coolant temperature;

- no radiators requiring additional decoration;

- the possibility of thermal control;

- underfloor heating is 20% more economical than radiators;

- the design slowly gains heat, but also slowly gives it away, so the temperature in the house is more stable, more uniform;

- no drafts in the room.

Each design has its own advantages, for example, electric floors are characterized by rapid heating and precise temperature control, water systems do not have electromagnetic radiation.

But in the warm floor, in addition to many positive characteristics, there are also disadvantages. The electric floor has some restrictions on the floor finish. In winter, the consumption of electricity increases significantly, there is electromagnetic radiation. Cables are not placed under plumbing fixtures.

The disadvantages of a water-heated floor include the possibility of pipeline leakage in case of violation of the laying technology. After installing water heating, the floor is raised by at least 10 cm due to the concrete screed. To equip the system, additional equipment (a water pump) and a manifold cabinet are required. Temperature control is difficult.

Underfloor heating water installation diagrams, laying methods, installation rules

It is recommended to install underfloor heating in country houses, apartments have problems with connecting to a common house heating system. This rule applies not only to houses of old standard projects, many new buildings, especially in the elite version, have such a heating system. Before proceeding to the consideration of existing installation schemes, one should briefly dwell on their advantages and disadvantages, this knowledge will help to consciously determine the feasibility of installing warm water floors.

Do-it-yourself water-heated floor

- Advantages. Uniform heating of the premises, increase in living space due to the absence of heating radiators, improvement of the interior of the premises. In addition, space heating with underfloor heating is considered the most profitable at the present time, one-time investments can pay off already in the second or third year after commissioning.

- Flaws. Quite complex from an engineering point of view, the design requires expensive additional equipment. A very serious drawback - big problems in case of need for repair work.

If you have made a positive decision and the desire to install warm water floors has not disappeared, then you can proceed to consider possible installation schemes.

3D scheme for arranging a water-heated floor in a private house