Types of suitable underfloor heating for parquet boards

Considering that the heating system gives an additional temperature load on the coating (in particular, the parquet board), it is important to choose the most suitable type of underfloor heating. At the moment, there are 3 types of underfloor heating - infrared, electric and water - in order to choose the best option - consider each type separately

Infrared systems

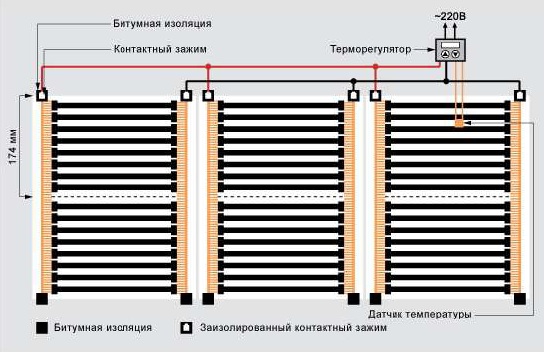

Infrared heating systems consist of graphite elements in a polymer film. When heated, the elements that make up the composition emit thermal energy in the infrared range, which is transferred to the parquet flooring. When operating an infrared heating element in combination with a warm floor, it is undesirable to warm the coating over 28 degrees.

Electrical systems

Electric heating systems function at the expense of thermal cables. This heating system is one of the most budgetary, conductors in combination with wood coating increase the risk of fire. In this regard, a parquet board under a warm floor of this type is not recommended for use.

Water systems

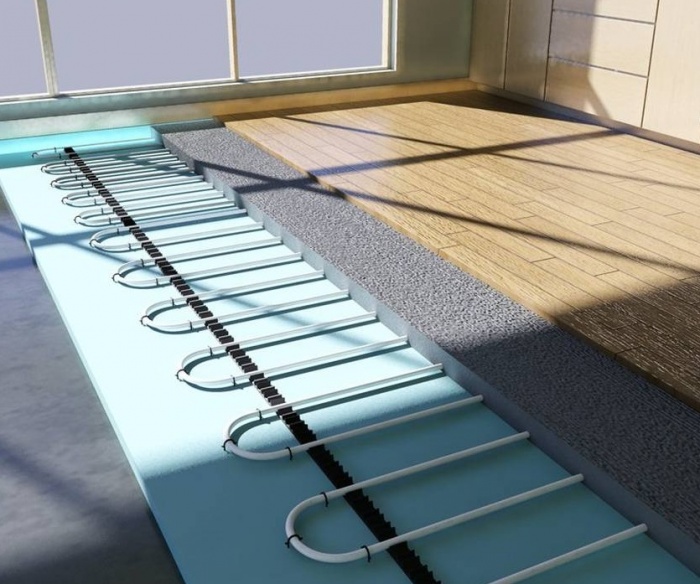

Water heating systems consist of plastic pipes, inside of which there is water heated to the required temperature. This system evenly heats the floor and is completely safe, although the possibility of leaks is not ruled out. That is why a parquet board for a warm water floor is an ideal option.

Is it possible to put parquet or parquet board on a warm floor

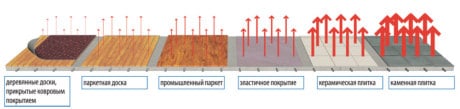

We have explained why parquet, parquet board and solid flooring are not the most suitable types of flooring for underfloor heating. Suitable - ceramic and stone tiles, acceptable - laminate, non-insulated linoleum and carpet with a low pile. So after all, is it possible to put parquet or a parquet board on a warm floor? We answer: it is impossible. But if you really want to, you can. You just need to understand that, firstly, this will adversely affect the efficiency of the heating system. Secondly, such a solution imposes a number of restrictions both on the functioning of the heating system and on the selection and installation of wooden floors. More about this:

Features of the device of a warm floor under a covering from natural wood

So that cracks do not appear in the parquet or parquet board during the heating season, floor heating should not be strong. If you remember about formaldehyde, a warm floor under a parquet board should not heat up over 26 ºC. But that's not all. Manufacturers of solid parquet and parquet boards state that the difference between the temperature of the coating and the air in the room should not exceed 2 ºC in order to avoid deformation of the wood and to preserve its service life. If you adhere to the norm of +18 ºC for residential premises, the floor cannot be heated above 20 ºC. At this temperature, the floors will not feel cold, it will be possible to walk on them barefoot. But the heat they give off is not enough to warm the room during the cold season. Of course, if we are talking about Central Russia, and not about Sochi. No, in a super-insulated, energy-efficient passivehouse with forced recuperation ventilation, even such a small fraction of thermal energy is enough for heating, but how many such buildings have we built? Therefore, in an ordinary house in a room with natural wood floors, radiators should be the main heating devices, and underfloor heating should only complement them, only slightly warming up the parquet.

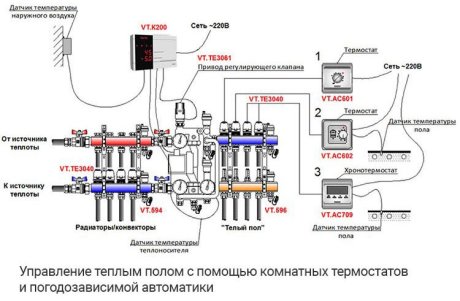

A standard mixing module for warm water floors will not be able to provide accurate and smooth temperature control at such low values \u200b\u200band in a narrow range. You will need additional equipment: a floor temperature sensor (namely the floor, not the air in the room) and a control valve servo.

And do not forget that wood does not transmit heat well from heating pipes, so you need to increase the thickness of the heat-insulating layer from below so as not to waste energy and money in vain.

Features of the selection of parquet and plank flooring for underfloor heating

For a heated floor, parquet and parquet boards made from the most stable wood species should be selected. Oak, ash and walnut are best suited. Robber behaves well. Exotic breeds other than teak and iroko should not be used. Beech and maple are categorically not suitable, they are most susceptible to temperature and humidity expansion. It is desirable to use a larch floorboard.

You should choose a parquet board of medium thickness - 13-17 mm. Thin 10 mm can warp, and thick will not let heat through. It is better to choose parquet with a thickness of 16-18 mm, and a floorboard - 25 mm.

Features of installation of parquet flooring on underfloor heating

If the floor heating temperature specified above is maintained, any type of wooden floor can be used as a covering: solid parquet and parquet board, glued multi-layer parquet board, massive floor board. However, the coating installation technology should be taken into account:

The multilayer parquet board is laid in a "floating" way on the substrate without fixing to the base. There will be no problems with careful installation of such a floor; the recommended thickness of the substrate is 2-3 mm.

Massive parquet on a concrete screed should be laid on plywood, which, in turn, must be glued and fixed with dowels to the base. During the laying of heating pipes, it is necessary to make a very accurate diagram of their location and, when drilling holes in the screed for dowels, be very careful not to damage the pipe.

The choice of underfloor heating technology

Before laying a warm floor, you need to decide on its type. It is best to use an electric underfloor heating under the parquet, as in this case there is no danger of damaging the parquet board. When using water heating in case of emergency, for example, water leakage, the parquet may swell and deteriorate.

Scheme of the device of a heat-insulated floor under a parquet.

By itself, the work of laying a parquet board is quite lengthy, so if there is a violation in the heating system, this coating will have to be removed, which is quite problematic.

Of great importance is the fact that the parquet board can be attributed to good heaters and if it is properly laid, floor insulation may not be required. But still, if you install a warm floor under the parquet, then you need to remember that under it there must be a fireproof coating.

Stages of installation of a warm electric floor

The most modern way to insulate a parquet board is with an electric cable. But in this case there is 1 drawback - fire insecurity

Because of this, it is important to properly organize the insulation. At the first stage of work, the base is cleaned, all irregularities and debris are removed

For leveling, you can use putty. Then a layer of waterproofing composition is applied. Support logs are installed on the base of the floor. They are made at a distance of 50-60 cm from each other. The surface between them is filled with waterproofing materials. Penofol or other sheet foam materials can be used.

Scheme of installation of infrared film underfloor heating under the parquet board.

Roll materials are also widely used, such as mineral wool, for example. You need to lay them in stripes. Fasten with special glue or overlap them by at least 10 cm. After that, you need to make a finishing floor. To do this, you need a parquet board. A galvanized mesh is placed on top. The electric cable itself, in order to insulate the parquet board, is placed next to the bars at a distance of at least 1 cm from them.In the bars, cuts are not made to the full thickness of a width of about 3 cm, foil is laid, and an electric cable is laid on it. The cable is attached with mounting tape. On top of the cable, you will need to again make a layer of fireproof material. After that, it is necessary to organize a finishing floor. The warm floor under the board is ready. It is recommended to use plywood or wood-fiber materials (MDF) as a base for a parquet board, which are fixed with self-tapping screws. In this case, a sheet of plywood 50 x 50 cm must be fixed in 8 places.

The main disadvantages of parquet insulation

As already mentioned, it is not necessary to insulate the parquet board. Before doing this, you need to know the possible negative consequences during the work. Firstly, the parquet itself does not let cold air through, thus, in the presence of a layer of insulation, the work of the parquet board in heating the room worsens. The parquet flooring in the apartment does not need additional thermal insulation. Secondly, in the presence of a heating layer, parquet can dry out and crack. Its appearance changes and aesthetics decreases. In the end, all this will require major repairs from the residents, or you will constantly have to periodically repair cracks, putty the floor with your own hands.

The underfloor heating system is more suitable for tiles than planks. Therefore, it is advisable to insulate the floor in the bathroom, on the loggia, toilet. Thirdly, the technical side of the process is also of great importance. In addition to the possibility of emergency situations, there is a possibility of damage to the insulation system itself: pipes or electrical wires. The thing is that the best option for parquet insulation is using plywood, which is fastened with screws to the screed. In this case, there is a possibility of damage to wires or pipes, and it will be very difficult to find this area. An alternative to perquet is laminate.

Features of heating such a floor

To summarize, there is only one feature - caution. The maximum water temperature should not exceed 50 degrees

But the lower surface of the tree should not heat up more than 40 degrees.

The above parameters are very easy to control by the equipment that is part of the heated floor, and, on the contrary, in a situation of heating with electricity, it is very difficult to adhere to them. Therefore, parquet is better suited for a water floor heating system.

Specialists who study parquet flooring have long noticed that under more or less traditional conditions of our climate in winter, gaps will be clearly visible between the parquet floorboards, which will disappear in the warm summer. This is also the result of temperature fluctuations, from which the humidity indicators are subject to drops.

If you want to minimize gaps, it is worth laying planks of a minimum width.

Answering the question about the advisability of using parquet for warm water floors, let's say that it is quite possible and even effective. If you follow certain rules, everything will work out in the best way.

Laying parquet on underfloor heating all the pros and cons

Professional builders-finishers still cannot come to a consensus on whether a warm floor under a parquet board is an acceptable option.

Each side has its own strong arguments "for" and "against" laying natural wood flooring on a warm floor.

"Against"

First, consider the arguments of those who categorically oppose the use of parquet boards for underfloor heating.

- Poor thermal conductivity. Due to the fact that natural wood has a low coefficient of thermal conductivity, the transfer of thermal energy from the heating elements to the room air will be significantly hampered. Accordingly, underfloor heating will lose one of its main advantages: higher efficiency compared to wall-mounted radiators.To maintain a comfortable temperature in the room, it will be necessary to heat the electrical wires or the liquid coolant to higher temperatures. The cost-effectiveness and efficiency of ultra-modern underfloor heating will eventually become on par with the century-old "classic" - suspended heating radiators. The substrate under the parquet board, which is an integral element in the installation of flooring, will only aggravate the situation.

The next argument "against" is related to the operational features of natural wood. The use of a parquet board as a conductor of thermal energy can adversely affect its condition. Under the influence of regular temperature changes, even a well-mounted coating can soon acquire an unpresentable appearance. Dry, creaking floorboards, cracks and deformation of wood, peeling varnish are possible consequences of exposure to high temperatures.

For a warm water floor, there is another argument against laying a parquet board over it. It's all about the coolant circulating through plastic pipes. Despite years of warranties from water floor manufacturers, there is a chance of water breaks or leaks. As a result of such, even if purely hypothetical, accidents, your expensive flooring may become unusable: the fungus and rot that breed under it will quickly do their job. For more information on the use of parquet on underfloor heating, see this video:

However, in spite of everything, a number of experts consider parquet flooring over underfloor heating to be quite acceptable. To do this, you only need to follow certain rules and recommendations.

- Uniform heating of the entire surface of the floor covering. An ideal option that allows you to seamlessly combine parquet and underfloor heating is IR heating elements. Infrared floor heating under the parquet board provides the most uniform heating of all floorboards. As a result, the risk of joint cracking or wood deformation is minimized.

- You should not buy a parquet board made of natural maple and beech for flooring on warm floors. Their wood is very sensitive to temperature changes, which causes its deformation and cracking.

- The optimal thickness of the parquet board is 12 mm. Thinner options will deteriorate too quickly under the influence of temperature changes, and parquet that is too thick will create an unnecessary obstacle to heat circulation.

- A damper tape should be fixed along the perimeter of the walls at the level of the flooring. It will play the role of a shock absorber during compression and expansion of parquet under the influence of temperature differences. For the same purpose, parquet should be laid in a “floating” version without a rigid bond with the base of the floors.

- Recently, special varieties have appeared on the construction market, combined with underfloor heating systems. They are individually marked, as well as recommendations for their mode of operation.

In no case should self-tapping screws and dowel-nails be used: the probability of damage to water pipes or a power cable poured into the screed is too high. For more information about laying parquet on a film floor, see this video:

Having become acquainted with the features of parquet flooring and floor heating systems, each owner can independently weigh the pros and cons, choosing the most suitable option for him.

Water floor installation

A water floor is a good solution, which is often taken when it is necessary to lay a wooden floor. Thanks to this, space heating occurs without problems, and an additional heating system is not required. The advantages of systems of this type:

- the minimum amount of electricity is consumed;

- they are safe and environmentally friendly;

- the base heats up evenly.

However, water heating elements have their drawbacks. You should also know more about them:

- temperature control is much easier than infrared or electric floors;

- in the process of laying plastic pipes, the floor level rises by 10 cm;

- when laying a water floor, it is impossible to completely eliminate leaks;

Due to the shortcomings that a water floor has, it should not be laid in apartments of multi-storey buildings. If a leak occurs, several problems will arise - the coating material will warp and the wiring will close.

Floor heating systems

To understand how compatible the warm floor and parquet board, you should take a closer look at their design and operational features.

Floor heating attracts, first of all, the possibility of uniform heating of the room. Unlike classic wall-mounted heating radiators, underfloor heating creates the most comfortable temperature in the lower half of the room, that is, in the area where residents are usually located.

In the case of wall-mounted radiators, the air heated by them first rises to the ceiling, and only then begins to spread to the bottom. In this regard, the efficiency of underfloor heating systems is much higher.

Today, there are three main types of underfloor heating on sale:

Each of these systems has its own characteristics, advantages and disadvantages.

Water floors

The heat source in this case is the heated coolant. The entire heating structure consists of a hot water boiler, from which the heat carrier is supplied by a circulation pump to the pipe system laid under the floor covering.

Most often, flexible plastic acts as a material for pipes. Such pipes, unlike metal ones, are easily deformed under external influence, which can create obstacles for the normal circulation of the coolant.

Therefore, water floors after installation are poured with a cement screed, which in this case plays not only the role of protection against physical influence from the outside, but also a heat conductor.

Cable and infrared film floors

This type of underfloor heating uses electricity as a source of thermal energy. True, there are significant differences in their design and operation.

Cable floors are electrical wires enclosed in an insulating braid and which, under the influence of current, begin to heat up. From them, heat is transferred to surrounding objects, first of all, to the floor covering.

Film floors also run on electricity, but infrared radiation is used to transfer heat. Special graphite heating elements enclosed in a protective film convert electricity into infrared radiation. By means of IR rays, the heat from the film floors is transferred to the surrounding surfaces.

In connection with this feature of the work, infrared floors are not enclosed in a concrete screed. In this case, it can only be used as a leveling base.

As you can see, all floor heating systems, regardless of their design features, have one main common feature: the floor covering is initially heated, from which thermal energy is transferred to the surrounding air.

In this context, the compatibility of parquet and underfloor heating should be disassembled.

Which underfloor heating to choose for parquet and parquet board

Water heating

This system is a network of polymer pipes through which hot water circulates, supplied from a boiler or a central water supply system. A screed is poured on top, on top of which the top coat is laid. It is a contact heating system, i.e.the coolant, passing through the heating circuit, gives off its heat to the screed, which in turn heats the flooring. This system is quite complex and expensive to install. In the event of a failure, finding and fixing the problem is not an easy task. The use of such a system in apartment buildings is prohibited (clause 11.9 of Decree of the Government of Moscow No. 508-PP dated 10/25/2011).

Why wood flooring is not suitable for heated floors

There is no worse flooring for underfloor heating than natural wood. Whichever way you look at it, this solution has some disadvantages. Consider the problem from two points of view: heating and finishing.

Heating problem

The entire structure of the warm floor in the room: pipes with a coolant circulating through them, a concrete screed or a rack or floor system that replaces it and a coating - this is one large heating device

For a heater, it is important that the maximum possible part of the thermal energy enters the room without encountering obstacles in its path. Cast iron battery without problems gives off heat to the environment

Also, a warm floor, where the pipes are filled with a layer of concrete about 4 cm thick, and ceramic tiles are laid on top, gives off heat energy well to the room. This is because metal, concrete and ceramics have high thermal conductivity.

You can conduct an experiment: in winter, wrap the radiator located in the room under the window in a warm blanket. After a while, we will feel that the room is noticeably colder. The blanket prevents heat transfer, the coolant returns to the system at almost the same temperature as it entered the battery. If we wrap all the radiators in the house in blankets, the rooms will become cold, and the boiler may overheat.

Natural wood has low heat transfer and works like a blanket, reducing heating efficiency. In addition, thermal energy, encountering an obstacle for its distribution from above, will tend downward, into the ceiling or subgrade of the floor. In order not to lose a significant part of the heat, you will have to additionally insulate the floor structure from below. And these are financial costs and a decrease in the height of the room due to an increase in the thickness of the insulation. The foregoing indicates that it is not economically feasible to use natural wood flooring for underfloor heating.

Coating problem

Natural wood is a "living" finishing material. Wood fibers easily absorb and release moisture, while the geometric dimensions of the products noticeably change. Wet wood swells, when it loses moisture, it shrinks, the changes are especially great across the fibers. Relative humidity indoors in summer is 40-65%, at these values wooden furniture and floors “feel” good. During the heating season, with radiator heating and no humidifiers, the humidity can drop to 20-35% or lower. At the same time, the wooden floors dry out: gaps appear between the parquets and the closer to the batteries, the wider the gaps in the floor. Let's imagine that the entire floor is a large radiator, constantly heating the entire surface of the wooden floor. Under the influence of heat, the wood will dry out, the parquet or boards will decrease in size and noticeable gaps will appear between them over the entire area of \u200b\u200bcoverage. The higher the temperature of the heated floor, the stronger the wood will dry out during the winter.

A multilayer parquet board will behave a little more stably. Due to the fact that it consists of several layers of wood, the fibers of which are arranged perpendicularly, the humidity-temperature deformations of the glued parquet board are not as great as those of massive parquet and floorboards.

But here another danger awaits the consumer. In the manufacture of parquet boards, an adhesive containing formaldehyde is used. Up to a temperature of 26 ºC, it is bound in the adhesive and the parquet board is safe.When the specified temperature is exceeded, harmful formaldehyde vapors begin to be released and enter the air. At the same time, the operating temperature of the heat carrier in the heated water floor system, which is provided by standard equipment, is 40ºC. The floor surface can be heated up to 35 ºC.

What is parquet board

Parquet board is a relatively new type of flooring used as an alternative to parquet.

This type of board has a number of the following advantages:

- environmental friendliness, the composition includes natural wood;

- ease of installation / dismantling, the board is sold already processed and it is not required to carry out additional preparation of the material before installation, which saves time spent on installation, and a convenient lock connection simplifies the laying technology;

- if necessary, flooring from parquet boards can be easily dismantled without damaging the material itself; after dismantling, the parquet board can be reused;

- the possibility of operation immediately after installation, after the flooring of the parquet boards has been installed, it can be used immediately. it does not require additional work - coating with oil, varnish, etc.;

- price, the advantages of this material include a relatively low price;

- presentable appearance, thanks to the presentable appearance, the parquet board will look favorably in any room;

But in addition to the advantages, this material also has disadvantages that are important to consider:

reduced moisture resistance, this material does not differ in moisture resistance - therefore, when carrying out installation work, special attention must be paid to protection against moisture;

the claim of material delamination, during improper operation or installation there is a risk of material delamination, which, of course, will negatively affect the appearance of the coating and the room as a whole;

increased requirements for the base surface, a prerequisite for laying parquet boards is a perfectly flat surface.

Primary requirements

If it was decided to lay a wooden floor covering on a warm floor, then, in order to avoid possible problems, the following number of features of such a combination should be taken into account:

- The most suitable type of parquet for laying on a warm floor is a parquet board, since this flooring is better than others able to tolerate changes in humidity and temperature.

- In order for the board not to dry out too much when heated, its factory humidity should not exceed 6..7%.

- It is best to choose a board with the smallest possible width of the plank, because the size of the gap, all other things being equal, is directly proportional to the transverse size of the plank.

- The parquet board on a warm water floor should be laid either by professionals, or at least under their direct supervision.

- The maximum allowable temperature of the parquet surface is 26°C, and it is strictly not recommended to exceed it. Any excess can cause drying and deformation of parquet planks.

- Any change in floor temperature during its operation should be gradual.

- When using a warm water floor system, a waterproofing layer should be installed.

- When choosing a parquet board, you should focus on the one that is made of wood that is resistant to deformation. The most commonly used wood is oak. At the same time, maple or beech wood is the most undesirable choice, since these species are the most sensitive to changes in humidity levels.

- To prevent the humidity level from falling below 40%, a humidifier should be used.

Choosing a warm floor under the parquet board

Without going into particular details related to the organization of heating using electric cables or pipes with hot water as a heat carrier, we only note that both options have found application in repair, construction and design solutions.

At the same time, the organization of electric heating is cheaper in terms of work and materials, while water heating can use different types of fuel and is cheaper to operate.

Electric heating is more often used to solve local problems in separate rooms, and water heating is mainly used for heating houses with their own heat supply system or for heating large objects.

As a rule, underfloor heating systems are used to heat cold floor coverings: tiles, porcelain stoneware, laminate, linoleum. However, if you decide to install parquet or solid oak floors, please read the following guidelines. Wood, as you know, does not have thermal conductivity and by laying parquet or board on a warm floor, you reduce the efficiency of the heating system.

As a possible option - mounting plywood on a two-component polyurethane adhesive. When using it, you can do without self-tapping screws. But this will not save your parquet from drying out. If you still decide to lay parquet or solid board on heated floors, then it is desirable that the wooden flooring at the time of installation has a moisture content of 8+_2%. It is recommended to use the most stable wood species with a cut close to the radial.

It is advisable to use oil as a top coat on underfloor heating. It does not break the coating layer when the plates move, it has a higher allowable operating temperature on heated floors. The oil has a large range of colors for tinting floors, provides the possibility of local repairs and faster, compared to varnish, a complete renewal of the finish layer.

If the finishing of parquet or decking is carried out in production conditions, the use of oil is less laborious and requires less time. The use of parquet with chamfers and an oil coating applied at the factory will allow, avoiding grinding and applying oil on the site, to reduce the time for work. At the same time, it becomes possible to apply oil to the end sides of the laying elements, which provides increased moisture protection of the parquet during operation, including in the presence of gaps between the planks.

The lower wear resistance of oil coatings will require more painstaking and frequent maintenance and reapplication, which, at the same time, is not a particularly difficult and expensive factor.

Underfloor heating under parquet and parquet board

Parquet is a floor covering with a thickness of 15 to 22 mm, made entirely of natural wood. The parquet is not a finished product, so after laying it is sanded and varnished. With careful operation, the average life of piece parquet is more than 50 years.

A parquet board is a wooden flooring made by gluing several layers of wooden planks together. The bottom layer is stabilizing, made of coniferous wood. The middle layer is bearing, also made of coniferous wood. The top layer is decorative, made of precious wood. From above the parquet board is varnished or impregnated with oil. The total thickness of the parquet board is 14 mm, while the thickness of the top layer does not exceed 4 mm. The average service life of a parquet board, subject to the rules of operation and updating the varnish coating every 4-5 years, is 15-20 years.