Open circuit with gravity circulation

This option is easy to perform even for a beginner. Here, water circulates in the system due to the difference in density of cold and hot liquids. According to the laws of physics, hot water begins to flow upwards (since its density is less), and then it cools down and returns to the starting point.

Despite the fact that this type of strapping is quite simple, it requires compliance with a number of requirements. Firstly, in order for water to circulate freely in the system, it is necessary to install heating equipment half a meter lower than the batteries are located in the house. Secondly, in order to minimize the manifestation of water resistance, pipes with a cross section of up to 5 cm are needed, while distribution pipes on batteries can have a value of 2.5 cm. Thirdly, locking devices and fittings directly affect the free circulation of water in the system, Therefore, there should be a minimum of such elements.

But for the sake of fairness, it is worth saying that an open system with natural circulation has a number of its advantages. Besides the fact that it is the easiest to arrange, the financial costs of it are not so great. True, the owner will not be able to constantly control the temperature regime of the coolant at the outlet, which is why the heating of the circuit is somewhat reduced. Also, the expansion tank occasionally remains open, which means that oxygen has contact with the coolant, which gradually increases the risk of corrosion.

Summing up, it is worth saying that experts recommend this type of heating scheme only for those private houses where people live from time to time, and not on an ongoing basis, for example, for summer cottages.

Brands of Russian-made solid fuel boilers

An analysis of the technical characteristics will help to get a general idea of solid fuel boilers for long burning. Consumer reviews on independent forums give an objective assessment of domestic developments.

Table 1. Solid fuel boilers Zota Mix and Pellet manufactured by the heating equipment and automation plant (Krasnoyarsk):

Table 1. Solid fuel boilers Zota Mix and Pellet manufactured by the heating equipment and automation plant (Krasnoyarsk)

- The efficiency of boilers of the Zota Mix model range is 80%, Pellet is 90%;

- combined steel solid fuel boilers Zota Mix operate on any type of fuel (liquefied or natural gas, electricity, liquid fuel);

- the combustion chamber and the ash box are located inside the water jacket;

- adjustable chimney damper, mechanical draft regulator and air suction by an ejector, which is installed in the furnace door, ensure complete combustion of fuel with minimal draft;

- the outer surface of the case is covered with an anti-corrosion polymer composition;

- a removable door behind the front panel provides access for cleaning the flue;

- the possibility of repair.

Boiler design Zota Mix

- need a supply of fuel and a place to store it;

- costs of delivery, unloading and storage of firewood, coal, briquettes;

- decrease in productivity of Zota Mix boilers when using low-quality fuel (lignite by 10÷20%, raw firewood by 60÷70%);

- for Zota Mix - manual loading of fuel, cleaning the ash pan, furnace walls, gas ducts and flue pipe;

- mandatory preparation of boiler water (hardness up to 2 mg-eq / l);

- installation in a separate room;

- for boilers of the Zota Mix line, it is necessary to install a heat accumulator, a smoke exhauster, and a boiler.

Table 2. Apparatuses combined solid fuel with a water circuit (AKTV). Manufacturer OOO Sibteploenergomash (Novosibirsk):

Table 2. Apparatuses combined solid fuel with a water circuit (AKTV).Manufacturer Sibteploenergomash LLC (Novosibirsk)

- a budget option for solid fuel boilers with a water circuit for the home (price 11,000 ÷ 25,000 rubles);

- compact size;

- the water heat exchanger covers the furnace from all sides (except the front);

- retractable ash drawer;

- mounting socket for draft regulator;

- the ability to connect to a chimney of any configuration;

- a steel heat exchanger allows a simplified connection to the heating piping (without admixture);

- the design is adapted to work on gas and electricity.

Boilers "Karakan" from the manufacturer LLC "Sibteploenergomash"

- outdated design, primitive low-quality automation;

- the technical characteristics declared by the manufacturer (power, heated area and efficiency), according to consumer reviews, do not correspond to actual indicators.

Table 3. Solid fuel pyrolysis boilers Bourgeois & K from NPO TES LLC (Kostroma):

Table 3. Solid fuel pyrolysis boilers Bourgeois & K from NPO TES LLC (Kostroma)

- ensures stable combustion of fuel of any grade and degree of humidity;

- effective operation of the boiler from one tab for 8 hours;

- economical fuel consumption;

- generator compatibility with natural or forced circulation systems;

- environmentally friendly unit, the fuel goes through a cycle of complete combustion, without forming harmful emissions into the atmosphere;

- the design of the firebox provides an effective mode of operation in 40 minutes.

Solid fuel pyrolysis boilers "Bourgeois & K"

- complex installation: the connection must be made by employees of specialized enterprises licensed for this type of activity (otherwise the guarantee from the manufacturer does not apply to the unit);

- manual loading of fuel and cleaning of the combustion chamber;

- great weight.

Installation and operation of solid fuel boilers must be carried out in accordance with fire safety rules

For heating a country house. garage or greenhouse, it is possible to manufacture solid fuel boilers for long burning with your own hands. Videos with materials on this topic can be found on the Internet. But remember that the main condition for the use of heating equipment is fire safety. And only a certified manufacturer can guarantee the fulfillment of this condition under proper operating conditions and equipment installation.

https://youtube.com/watch?v=3sfw2qpCMrY

https://youtube.com/watch?v=1z6OOs3WdH4

Protection of a solid fuel boiler against overheating

In a solid fuel boiler, burning fuel, and the boiler itself, have a rather large mass. Therefore, the process of heat release in the boiler has a large inertia. The combustion of fuel and the heating of water in a solid fuel boiler cannot be stopped instantly by cutting off the fuel supply, as is done in a gas boiler.

Solid fuel boilers, more than others, are prone to overheating of the coolant - boiling water if the heat is lost, for example, when the water circulation in the heating system suddenly stops, or more heat is released in the boiler than is consumed.

Boiling water in the boiler leads to an increase in temperature and pressure in the heating system with all serious consequences - the destruction of the heating system equipment, injury to people, damage to property.

Modern closed heating systems with a solid fuel boiler are especially prone to overheating, as they contain a relatively small volume of coolant.

Heating systems usually use polymer pipes, control and distribution manifolds, various taps, valves and other fittings. Most elements of the heating system are very sensitive to overheating of the coolant and pressure surges caused by boiling water in the system.

The solid fuel boiler in the heating system must be protected against overheating of the coolant.

To protect the solid fuel boiler from overheating In a closed heating system not connected to the atmosphere, two steps must be taken:

- Shut off the combustion air supply to the boiler furnace in order to reduce the combustion intensity of the fuel as soon as possible.

- Ensure cooling of the heat carrier at the outlet of the boiler and prevent the water temperature from rising to boiling point. Cooling should take place until the release of heat is reduced to a level at which boiling water becomes impossible.

Consider how to protect the boiler from overheating, using the heating circuit as an example, which is shown below.

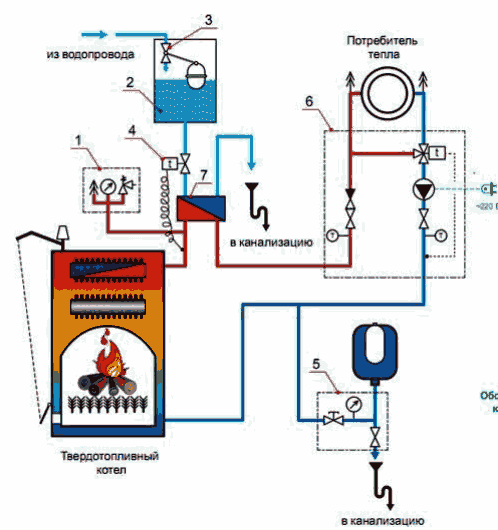

Scheme for connecting a solid fuel boiler to a closed heating system

Scheme of a closed heating system with a solid fuel boiler.

1 - boiler safety group (safety valve, automatic air vent, pressure gauge); 2 - a tank with a supply of water for cooling the coolant in case of boiler overheating; 3 - float shut-off valve; 4 - thermal valve; 5 - group for connecting an expansion membrane tank; 6 - coolant circulation unit and boiler protection against low-temperature corrosion (with a pump and a three-way valve); 7 - heat exchanger protection against overheating.

Boiler protection against overheating works as follows. When the temperature of the coolant rises above 95 degrees, the thermostat on the boiler closes the damper for supplying air to the combustion chamber of the boiler.

Thermal valve pos.4 opens the supply of cold water from the tank pos.2 to the heat exchanger pos.7. Cold water flowing through the heat exchanger cools the coolant at the outlet of the boiler, preventing boiling.

The supply of water in the tank pos.2 is necessary in case of lack of water in the water supply, for example, during a power outage. Often a common storage tank is installed in the water supply system of the house. Then the water for cooling the boiler is taken from this tank.

A heat exchanger to protect the boiler from overheating and coolant cooling, pos. 7 and a thermal valve, pos. 4, are usually built into the boiler body by boiler manufacturers. This has become standard equipment for boilers designed for closed heating systems.

In heating systems with a solid fuel boiler (with the exception of systems with a buffer tank), thermostatic valves and other automatic devices that reduce heat extraction must not be installed on heating devices (radiators). Automation can reduce heat consumption during the period of intensive fuel burning in the boiler, and this can cause the overheating protection to trip.

Another way to protect a solid fuel boiler from overheating is described in the article:

Read: Buffer tank - protection of a solid fuel boiler from overheating.

Continued on next page 2:

Installation progress of solid fuel boiler

Despite the progress in the field of electrification and gasification of the country, there are still many places where these communications are practically absent. But even where they are, many people prefer to arrange independent heating and hot water supply in their homes.

To do this, a solid fuel boiler is installed, which allows you to get heat and hot water in a private house, cottage or cottage at much lower operating costs and financial investments. The choice of this type of equipment is quite large, but all of it has fairly clear connection schemes for various types of heating.

From theory to practice

More often, those who want to make equipment with their own hands opt for a vertical solid fuel boiler. The manufacturing process will be considered using the example of a solid fuel boiler for heating a house with an area of 100 m2. This system consists of seven radiators and a plumbing system.

So, we make a heat exchanger:

- we manufacture vertical bases of the heat exchanger. To do this, we take four profile pipes 30 cm long each, which will be located on the side of the combustion chamber;

- in them with a gas cutter we make four holes with a diameter of 5 cm.Irregularities are removed with an angle grinder (grinder). You should get eight holes;

- in the pipes that will be located at the rear of the equipment, we make four holes with a diameter of 40 mm and four with a diameter of 50 mm. All of them should be located on the side of the connection with the front pillars. The result should be eight holes;

- in a profile pipe with a length of 500 mm we cut a hole for fastening a branch pipe through which waste water will be discharged;

- in the upper part of the rear rack we make a hole for the water supply to the system.

Then we proceed to the assembly of the heat exchanger. Vertical bases are connected by a profile pipe. To do this, we put it on the bases installed perpendicular to the surface. The joints are welded. We connect this entire structure on the reverse side with a profile pipe with holes for water drainage. As a result, we obtain the front wall of the heat exchanger.

Next, we install the vertical bases perpendicularly, and weld with four round pipes. It turns out the back wall of the heat exchanger. We connect the front and back walls with each other. To do this, it is necessary to bring the longitudinal pipes to the holes and boil them, and then we weld the nozzles to the structure for the supply and output of water. We weld the joints using pieces of metal and check the strength of the heat generator.

After checking the strength of welding, we close the pipe for draining water with a cork, and pour water into the hole for supplying water. We check the tightness of the welding joints for visible leaks.

Making the case will also require effort. To do this, we cut out eight walls from sheets of heat-resistant steel - 2 front, 2 rear and 4 side. The area of each of them should be 850 x 300 mm. We make all measurements with a meter ruler, cut the material with a grinder. Then we cut out two plates measuring 450 x 450 mm: one for the bottom, the other for the top plate of the boiler.

We make two holes for the doors in the front wall: the first is at the level of the grate for igniting fuel and cleaning the combustion chamber, and the second is slightly higher in level for loading fuel. We use a drill and a grinder in our work. From the sheet we cut stiffeners 80 cm long.

Rules for the organization of solid fuel heating

The main difference that a heating system with a solid fuel boiler of a closed type has is the type of fuel used. Coal, firewood, peat or fuel briquettes are used as an energy carrier. All of them are characterized by high energy intensity and, as a result, by intense heat release.

In order to make heating with a solid fuel boiler with your own hands, you will need to familiarize yourself with the rules for its organization. They directly depend on the chosen scheme, the piping system and the coolant used.

A characteristic feature is the correct installation of heating with a solid fuel boiler. The source of heat energy and fuel must be located in different rooms, and in addition to the installation rules, safety measures for the operation of heating are observed.

The main rules for the design and practical implementation of the scheme of heating systems for solid fuel boilers and furnaces are as follows:

- Use of non-flammable materials. When installing a stove or boiler, the floor, walls and ceiling in the chimney area must be fireproof. Those. when exposed to high temperatures, these materials should not spontaneously ignite or smolder;

- Work stabilization. The main danger in the operation of a solid fuel boiler for water heating is overheating of the water in the heat exchanger. To prevent this, the boiler or stove provides for the possibility of regulating the air supply necessary to maintain the combustion process of firewood. This may be a system of valves connected to a mechanical temperature controller;

- Supply and exhaust ventilation.The classic scheme for installing heating from a solid fuel boiler provides for air exchange in the room where the equipment is installed. During its operation, combustion products will inevitably enter the room. Supply and exhaust ventilation will remove them, thereby preventing a dangerous concentration of CO2 for humans.

Factory or home-made solid fuel heating boilers should be installed in separate boiler rooms. Exceptions are models with low power, which are equipped with a hob. But even in this case, all safety measures must be taken in the kitchen.

The basic rules for the arrangement of boiler rooms in which double-circuit solid fuel heating boilers will be installed are described in SNiP II-35-76. Read this document before installing the equipment.

How to choose the right boiler connection diagram

In order for the house to be warm, it is not enough to know about what heating schemes with a solid fuel boiler are. Masters who have been creating heating systems for more than one year give the following recommendations:

- When creating a drawing of a heating scheme on a solid fuel boiler, you should first familiarize yourself with the types and principles of operation of such heat generators. It can be a constant or long burning heater, a pyrolysis or pellet unit, a buffer. Each of these devices has its own performance criteria, which for some can become minuses, and for others pluses.

- To get an ideal heat supply scheme, you need to be able to combine the operation of the boiler with the tank, since this element accumulates thermal energy. This is justified by the fact that the water heating element can change its temperature in the range from 60 to 90 degrees. There is no fixed indicator. Since solid fuel boilers are inert devices, this distinguishes them favorably from gas, diesel and electric counterparts.

- When choosing a heating scheme, it is necessary to objectively assess the risk of a power outage. If a power outage occurs frequently in an area, then a system with a water pump will not only not pay for itself, but can quickly fail. Therefore, it is better to choose the type of heating with natural circulation.

- When choosing a harness, it is worth considering in advance the safety lines between the boiler and the tank. They are located at the points of the inlet and outlet pipes so that they are as close as possible to the water heater. Also, to achieve the maximum effect, you need to try to keep the distance between the boiler and the expansion tank to a minimum. But here it is no longer possible to mount safety valves or taps.

- If a scheme with a pump was chosen, then it is installed on the return pipe, as close as possible to the heat generator. Thus, even if the light is turned off and the pump stops working, the water will continue to move along the circuit, that is, the minimum heat will remain. The device must be installed along the bypass. Only then will it be possible to disconnect it from the network (if necessary), and block the bypass itself using cranes.

- There is such a thing as a bypass. These are jumpers with taps that are placed between the supply line and the return pipe. Such an arrangement contributes to the return of "excess" hot water when the volume is changed by means of a thermostat.

- A stainless steel valve must be installed in the chimney. Since there is moisture in the smoke, albeit in small quantities, but it is she who can provoke the destruction of the inside.

Binding is a process that should be given special attention. Therefore, they design and mount it only if there is complete confidence in their abilities.

Nikolay Avramenko, 51 years old, Energodar

After reviewing the article, I would like to make my comment. Here the topic of operational characteristics of solid fuel boilers was touched upon. It was pointed out that they have such a feature as high inertia.I would like to say that this phenomenon is not characteristic of pellet boilers. This is due to the fact that such devices have a burner that receives wood pellets in batches. Therefore, when the supply of raw materials stops, the flame immediately goes out. Although these boilers are not so cheap.

Anton Abramov, 29 years old, Omsk

At one time, I was interested in the work of solid fuel boilers, as they offered a position related to this area. I would like to leave a few words about the thermostat and its regulatory features. You need to understand when a certain temperature is set, for example, at 85 degrees, although the damper is covered, burning and smoldering continue. Because of this, the water still heats up by a couple of degrees, and only then it will be established exactly. Therefore, you should not turn the thermostat back and forth, otherwise, this can lead to a breakdown of the entire system.

Nikita Karpenko, 37 years old, Arkhangelsk

When we built a house outside the city, we planned to live there all year round. It's time that it came to heating, and I settled on a closed-type system with natural circulation. Firstly, it was easy enough for me to create it with my own hands, and secondly, we were already a little limited in money. I didn’t have any particular problems in the installation, but when the first cold came, I realized that there was clearly not enough heat for the house. So at school I was good friends with physics, then I realized that heat was “lost” in areas where the pipes remained open. Taking a roll of mineral wool, I wrapped all the pipes that run in open areas. Literally by the end of the first day, our family felt a significant warming in the rooms. Therefore, these moments must be remembered.

Connection of emergency systems

The elements of emergency systems in the piping scheme are used for the following purposes:

- protection against increasing the maximum working pressure in the system;

- protection against exceeding the maximum allowable outlet temperature of the coolant, overheating of the boiler and elements of the heating system;

- preventing the formation of condensate in the boiler due to the large temperature difference of the coolant at the inlet and outlet of the device.

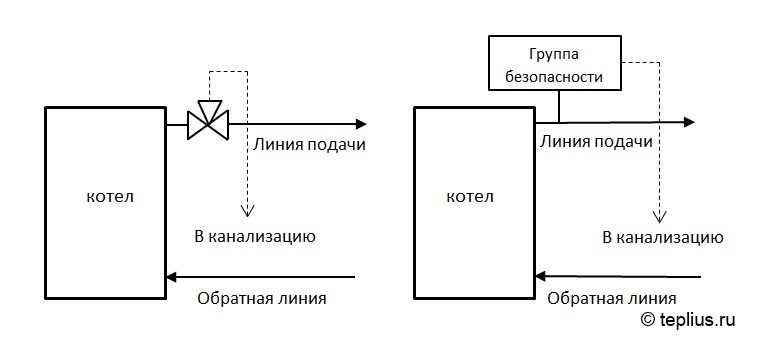

Safety valve

Protection of the boiler and system elements in case of excess of the working pressure of the heat-carrying liquid is provided by a safety valve installed on the supply line at the outlet of the boiler. Such a valve may be part of the boiler safety group, which is built into the boiler itself or connected separately.

How a safety valve works

A drain hose is connected to the pressure relief port of the valve. When the valve is actuated, the excess heat-carrying fluid from the system is drained through the hose into the sewer.

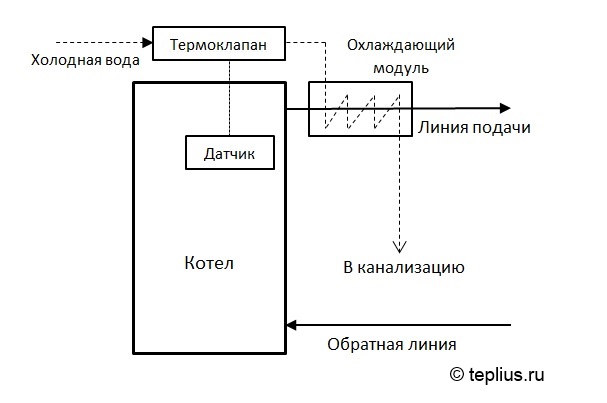

emergency heat exchanger

An emergency heat exchanger is needed to protect the boiler and system elements from overheating.

Overheating of equipment can occur in two cases:

- when the power generated by the boiler exceeds that required for heat consumers;

- when the circulation pump stops working due to its breakdown or power outage.

The heat exchanger consists of a cooling module and a thermal valve with an external thermal sensor set to a certain temperature. They can be installed inside the boiler itself or separately on the coolant supply line to the heating system.

How a heat exchanger works

When the permissible temperature is exceeded, the thermal valve is activated by a signal from the thermal sensor.

It supplies cold water from the water supply line to the cooling module, in which excess heat is removed from the coolant. From the cooling module, the water that has taken away the heat enters the sewer.

Additional circuit

The protection of the boiler against overheating in systems with forced circulation can also be ensured by using an additional natural circulation circuit, to which a DHW storage tank is connected.

Boiler piping with an additional circuit

During normal operation of the system, the pressure created by the circulation pump in the main circuit closes the additional circuit with a check valve, preventing the heat-carrying liquid from circulating in it.

When the pump is turned off for any reason, the forced circulation of the coolant in the main circuit stops and natural circulation begins in the additional circuit. Due to this, the heat-carrying liquid in the system is cooled to the required temperature.

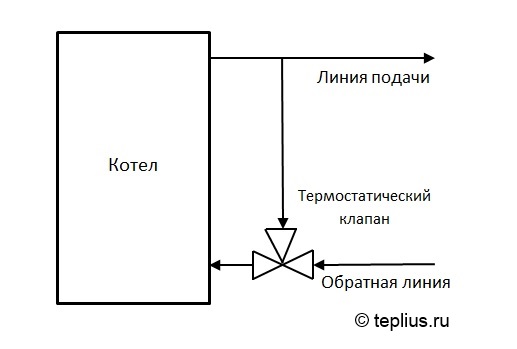

thermostatic mixer

Maintaining the minimum required temperature at the inlet to the boiler, in order to prevent the formation of condensate in it, is provided by a thermostatic mixer.

The device is installed on the return pipeline and connected to the supply line using a jumper (bypass).

Installing a thermostatic mixer

At a low temperature of the heat carrier in the return line, the thermal mixer opens and mixes hot liquid into it. After reaching the required temperature, the thermal mixer closes and stops supplying hot coolant through the bypass to the return line.

This scheme can be used in systems with any type of circulation.

Is it possible to make a solid fuel boiler with your own hands from improvised means?

Selection Guide

The first and main recommendation is to choose a solid fuel boiler for the benefit of the type of fuel used, but with a long-term perspective.

If you have a regular supply of cheap firewood, then we recommend purchasing a classic wood-fired boiler, despite all its shortcomings.

If you choose the right heating unit for power, complete the piping and install a tank for storing heat, then the direct combustion boiler will reliably serve you for many years.

When choosing, you need to consider the following points:

Take the power of the TT boiler according to the heat demand of a private house, only with a safety factor of 1.2. If you need to additionally heat water for hot water supply, then take a unit with a power reserve of 1.5.

The more powerful the boiler, the longer it has a firebox and the duration of burning. The less often you have to visit the boiler room.

Do not rely on a double-circuit boiler if you constantly need hot water in large quantities. It will not provide the required flow rate; it is better to install a solid fuel boiler with an indirect heating boiler.

Choose a model with a maximum working pressure of 3 bar. Cheap heaters made of thin metal can withstand only 1-2 bar.

Try to choose a boiler with a large volume of firebox. The standard size of the firebox, designed for 6 hours of operation at a power of 20 kW, is 60-65 liters; for long-burning units, this figure will be 80 liters or more at the same 20 kW.

A heat generator equipped with a fan works better than a simple one with air supplied through an open door. Such a unit is worth buying only with frequent power outages. Make sure that the ash pan door is controlled by a mechanical draft regulator.

The fan will last longer on a solid fuel boiler when it is on top

On models where the blower is built into the door, the impeller draws dust and dirt from the floor.

Pay attention to the origin of the electronic control unit. Avoid Chinese controllers, when choosing budget models, you can find an inexpensive heater with a more reliable Polish unit.

Do not get carried away with boilers with top combustion of fuel, they have a number of significant drawbacks

Low operating pressure, hanging wood waste on the walls of the firebox and the inability to add firewood “on the go” are on this list.

If you plan to heat your home with coal, pay special attention to the wall thickness of the firebox of the model you like. After all, the combustion temperature of coal reaches 1000-1100 ° C, in order to withstand it for a long time, a steel thickness of at least 3 mm is needed, and preferably 5 mm. Otherwise, your new boiler will not last long.

Unscrupulous manufacturers often use this trick: the parts of the firebox that end up outside are made of 3 or 4 mm steel, and the rest of the elements are made of thinner metal. By pointing to the ends of the parts, the user is convinced that the entire boiler is welded from thick “boiler” steel, although in reality this is not the case.

We can recommend the purchase of a pyrolysis heat generator only if you intend to burn dry wood, fuel briquettes or anthracite. Then it will give the expected result. When using fresh firewood, very little combustible gas is released, and therefore the pyrolysis boiler is inefficient.

It also does not always make sense to buy a solid fuel boiler with a cast-iron heat exchanger, which is much more expensive. Under normal operating conditions, steel will quietly last at least 10 years.