The order of construction work

By adhering to a certain procedure for the construction of a bath or sauna and following building codes, it is quite possible to build a small bath or sauna on your own.

The foundation for a bath of foam blocks

Lightweight strip foundation

If the area of \u200b\u200bthe bath is small, then a lightweight strip foundation with a depth of no more than sixty centimeters and a width of forty centimeters (according to the width of the foam concrete block) is quite suitable.

For a small bath or sauna, a foundation with a height of seventy to eighty centimeters is the most optimal solution.

Walling

The erection of walls - the first stage of work

The procedure for erecting walls from foam blocks with your own hands:

- A layer of waterproofing is laid on a completely dried foundation.

As a waterproofing material, roofing material is used, laid on a layer of hot bitumen in two layers. - As a working solution for laying blocks of foam concrete, a conventional aqueous solution of cement and sand is used in a ratio of one to two.

- The first row of masonry walls should be laid out evenly, for which a plumb line and a level are used.

The first row of masonry must be adjusted to the foundation, leveling all its protrusions and height differences. - It is recommended to lay the subsequent rows of masonry walls from foam concrete blocks on a specialized adhesive designed for foam concrete.

Adhesive dry mix for foam concrete will significantly reduce material consumption. It also provides a high density of masonry, smoothing joints and transitions. - The seam when laying foam concrete walls should be no wider than 0.5 centimeters.

- For the strength and durability of the building, it is recommended to mount a reinforcing metal mesh with small cells every three rows of masonry.

Roofing for a bath or sauna

The choice of roof design depends only on the tastes and preferences of the developer. The main thing is that the waterproofing of the ceiling of the building should be made of built-up waterproofing materials.

Roof erection

For a steam room made of foam blocks, an ordinary roof of two slopes with a ridge in the center is well suited.

When choosing the length of the rafter legs that will be joined in the ridge using an ordinary tenon-groove connection, be guided by the width of the bath, the desired slope of the slopes, as well as the climatic features of the area. For example, for regions with a damp climate, roofs with a slope of about 50-60 degrees are better suited. The recommended overlap of the roof overhang on the walls is about 50 cm.

The design of the rafters for a gable roof

Use staples to tie the rafters. Fix the bars themselves at a distance of about 1-1.2 m

It is important to choose the right raw materials for arranging the truss system. Check that the material is of high quality, free of knots and any kind of defects.

gable roof

gable roof

Roof

After installing all the rafter legs, proceed to the arrangement of the crate. Make it from high-quality smooth boards. The crate can be made solid or sparse. Choose a specific option taking into account the characteristics of the finishing roofing.

Bath roof

The crate for roofing material should be double, single for slate. If the roof will be covered with tiles, make a crate of bars. Suitable bars with a section of 5x5 or 6x6 cm.

The roof must be insulated with moisture-proof material, insulation and vapor barrier.

Finish by laying the selected finishing material. At this point, focus on your personal preferences and available budget.

Bath from foam blocks photo

Photo of a foam block bath

Assessing what a foam block bath looks like, the photo of which is presented on the Internet, you can achieve a similar result on your site. It should not be forgotten that a photo represents a more real appearance than a drawing or a three-dimensional image in 3D graphics. But the latest versions of the image show the exterior design and interior layout in more detail than the photographs, which reflect only part of the building.

People who decide to acquire a bathhouse in their suburban area often use foam blocks as a building material. Even an amateur can handle foam blocks. But, despite the ease of use, many details must be taken into account: instead of a cement mixture, it is better to use a special glue, then it is necessary to prime and insulate, otherwise the foam blocks may begin to collapse.

This follows from the physical properties of the foam blocks - the cement mixture has a different thermal insulation, and the thermal insulation of a special adhesive is comparable to foam concrete. It absorbs water well, so walls made of foam blocks need insulation from moisture.

We also advise you to make heat insulation with moisture insulation. These works are all finishing. Further, we will learn more about the internal and external decoration of the bath from blocks, foam blocks and bricks.

First of all, in a foam block bath, the interior decoration should improve the interior appearance, give it zest and originality, accuracy and completeness.

There are also technical indicators of finishing, which should not only not spoil the properties of the main building material, but only improve them. The finish must be highly vapor-tight so that heat loss does not occur. And also it should absorb moisture to a minimum in order to prevent rapid damage to the finishing material.

Features of foam concrete

Foam concrete is a cellular material that appeared on the construction market several decades ago, but continues to be in great demand and is widely used in the construction of premises. For its production, a simple technology is used, which reduces the cost of the final product and allows you to make building materials at home.

Pros and cons of the material

The popularity of the foam block is due to its operational properties and advantages. First of all, it is increased thermal insulation and resistance to temperature fluctuations. Experts say that even with constant exposure to high temperatures, the material does not begin to deform and retains its initial strength. It also meets all the requirements of environmental safety, is not afraid of corrosive or putrefactive processes, and also does not become an object of attack by rodents.

The foam block is lightweight, which reduces the complexity of construction work and simplifies installation. Baths based on this material are characterized by resistance to ignition, and this is an important point in compliance with safety standards.

But, in addition to the mass of pluses, the foam block also has disadvantages. Before use, they must be treated with special compounds that provide the desired degree of moisture resistance. If you miss this moment, the material will deform and quickly lose its presentability.

Despite the affordable cost of raw materials, the installation process can be accompanied by high costs. They are associated with the acquisition of a special adhesive composition, as well as carrying out insulation work.

Finishing technology

Instructions for the interior decoration of the bath:

- Acclimatization of the material - all the material intended for finishing is brought inside the bath, and is there for at least a day.

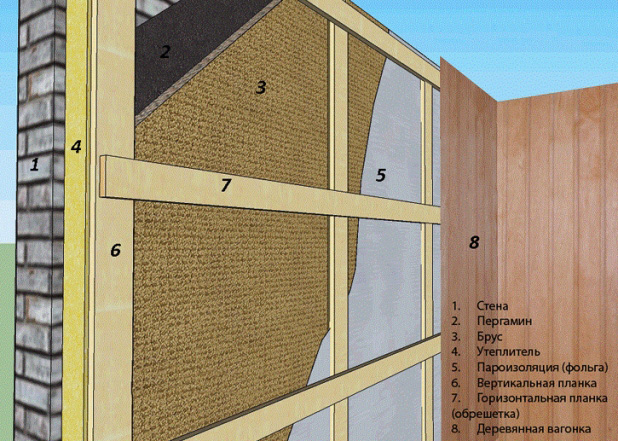

- To fasten the lining, a crate is mounted, consisting of bars, with a section of 5x5 centimeters. The distance between the bars is 50 cm.

- Steam and thermal insulation is being fixed.

- The lining is mounted, depending on the room: hardwood for the steam room, coniferous for the washing and rest room.

- The lining can be mounted both horizontally, vertically and even diagonally.

The floors are either wooden or laid out with ceramics on a concrete base. Many rest rooms and dressing rooms are equipped with a "warm floor" system. But such a system is not suitable for a steam room, where the humidity is very high.

Ready-made projects of baths from foam blocks

Considering the finished project of the bath, you need to make sure that it has a competent layout of the steam room, sink and rest room. Depending on personal preferences, each zone is allocated the required area, while the distribution is different: a large-sized steam room and a small sink, or a large lounge and compact functional areas. The choice is up to the owners. The main thing is that the room is comfortable and properly organized.

The dimensions of the furnace structure are determined by the volume of the steam room, but it is better to take a few centimeters of stock. This rule is mandatory when placing the furnace in another zone, because of which part of the thermal energy will be spent on heating the building itself.

With swimming pool

When a bathhouse is built with their own hands, people prefer options with a pool. But such a tank can only be installed in a spacious building. Otherwise, it will be bulky and impair the comfort of using the bath. If you plan to build a 2-story bath, the pool can be placed on the second tier. A prerequisite for this element is the presence of at least one ventilation window.

There are various types of bath pools available for sale, differing both in shape and purpose. Choosing the appropriate option, you must be guided by the features of the layout of the building and financial capabilities, because. the acquisition of such a design is not a cheap pleasure.

with terrace

Projects of baths from foam blocks with a terrace are quite common. This is due to the stylish appearance of the building and the ability to use every centimeter of area as efficiently as possible. The porch of the bath from the blocks is combined with any type of design, regardless of the parameters of the room.

As a material for creating a terrace, you can use a foam block, and any other alternative, including:

- wood.

- Metal.

- Plastic.

- Decorative rock.

On a well-equipped terrace, you can place useful furniture items (tables, chairs, sofas, armchairs). The main thing is that there are not many of them, because. an overloaded area will look unpresentable. When erecting a bunk bath, the veranda is located on the second floor.

Bath with shower and toilet

The size of the bath with a shower and a bathroom is 5x9 m with a total area of 45 m². The structure has one floor and several separate zones:

- Shower.

- Toilet.

- Restroom.

Such a layout is especially convenient for the construction of a country bath.

Sauna with a font and a summer kitchen

Drawings of baths with a summer kitchen and a font allow you to build a functional room for a cozy pastime with friends and relatives.

In such projects, the summer kitchen serves as a dressing room, and the kitchen stove structure is installed in the bath itself. Both buildings are equipped with the same roof.

Bath with attic floor

The project of a bath with an attic expands the functionality of the room and allows you to effectively use all the available space. The attic floor can be used as:

- Full rest room.

- Sports hall equipped with exercise equipment.

- Rooms with a billiard or tennis table.

- Rooms for storage of bath accessories.

In most cases, the area under the roof structure acts as an attic, where various accessories are located. But the designers decided to get rid of this stereotype and find a more competent use of the area - to equip the attic.

Such a project has the following advantages:

- The owner of the bath receives additional space and rationally distributes the useful space.

- The project of a 6x4 bath from foam blocks with an attic floor is often used to equip a guest house.

- A bath with an attic has a more presentable appearance than a simple one-story building.

Two-story bath

To build a comfortable bath from foam blocks with two floors, you need to choose or create your own project with a detailed layout of each zone. Like a single-tier version, a two-story bath should be created taking into account the following requirements:

- The project of a two-story bath from foam blocks provides for places for the installation of ventilation holes.

- If a fireplace is installed on the second floor, a separate chimney must be made from it.

- With special care should be approached the issue of making engineering communications.

- In addition to the furnace design, it will be necessary to provide an independent heating system.

Do-it-yourself foam block bath

A house or a bathhouse made of foam blocks is second only to wooden buildings in terms of environmental friendliness and far exceeds brick and concrete structures. Unlike brick or ordinary concrete, a foam block bath makes it easy to carry out interior decoration, since this material easily includes nails and other fastening methods. Given the reviews, a foam block bath is one of the best solutions in terms of construction.

The fastest way to build is a turnkey foam block bath, in which you do not need to intervene in construction and solve many issues. For baths made of foam blocks, prices depend on many factors, primarily the size, complexity of the project, conditions and construction time. You can build a bath from foam blocks on your own, without resorting to the help of hired construction teams.

The process of building a bath from foam blocks

It is possible to build not only a one-story structure from foam concrete, the presence of a second floor will not make the structure too heavy. If openings of more than 2.5 meters are provided, then the structure is reinforced with reinforced foam concrete lintels. For such construction, a set of building tools for processing blocks is needed.

Since the shape and size of the blocks are standard, they almost do not need additional work. Where the standard block does not fit, it is easy to reduce it in any direction with a regular hacksaw. Foam block masonry is simpler than brick masonry, due to the larger size and lighter weight of the blocks.

Compliance with construction technology is the key to a durable bath

In order for the construction of a bath to be effective, it is necessary to follow the instructions and adhere to the technology.

Marking and earthworks

There are different methods of marking the area in compliance with the scale of the building. But the principle remains the same: it is necessary to correctly determine the installation site

It is important to consider that you will need to install formwork, and then finish on the foundation

Earthworks begin with the arrangement of a trench under the base. Its depth is determined by the approximate weight and height of the pillow.

Foundation pouring

At the stage of drafting the project, you need to determine the height of the base. Experts recommend raising it at least 30 cm.

Further actions will be performed according to the following algorithm:

- The bottom of the trench is compacted with greasy clay and compacted.

- Next comes the arrangement of a cushion of coarse sand, gravel or fine gravel.

- Arrangement of the frame with reinforced elements.

- Pouring cement-sand mixture.

Base waterproofing for masonry walls

In order for the walls of the bath to remain resistant to moisture, it is necessary to provide for good waterproofing of the foundation. It will prevent the rapid wear of load-bearing structures and protect the room from all kinds of decay.Do-it-yourself polyethylene, roofing material or aluminum foil are used as a waterproofing material for a bath.

Construction of walls from foam blocks. Lintels over window and door openings

The process of building walls is not complicated, but its effectiveness is determined by several nuances.

First of all, builders need to inspect the material. Any external defects should be alarming, because. over time, they will lead to the destruction of the supporting structure.

It is imperative to monitor the thickness of the solution

Features of the construction of floors and roofs. Roof device

When arranging the roof structure and overlapping the bath, it is important to monitor the quality of the material. It should be lightweight and have low thermal conductivity.

As additional thermal insulation, a layer of expanded clay, sawdust or shavings is used. But, in order to prevent the rapid decay of such raw materials, it is necessary to responsibly approach the issues of waterproofing.

Installation of water pipes and sewerage

Work on the arrangement of the water supply and sewerage system depends on the purpose and time of use of the building. If there is a desire to visit the bathhouse in winter, it is necessary to provide for the protection of these nodes from freezing. Otherwise, the water will freeze and lead to failure of the entire system.

A complete water supply consists of the following elements:

- Connection pipes for hot and cold water.

- Water heating device.

- Pump with filter elements.

- Emergency drain system.

- Water supply line to the tank.

- All kinds of additional details: valves, taps, pressure gauges.

Floor device

The floor structure in the bath is created from high-strength materials that can withstand moisture. In addition, they should have a comfortable surface and retain heat well. In most cases, the floor in a two-story bath is made of wood.

Waterproofing and vapor barrier of walls

For the arrangement of hydro and vapor barrier, polyethylene film, roofing felt, aluminum foil or other modern materials are used.

Furnace masonry

The stove in the bath can be brick or metal, but the first option retains all the traditions of the classic Russian steam room, so it is in great demand. Laying a furnace is not a difficult process, but in the absence of experience, it is better to entrust the task to a specialist.

Exterior and interior wall decoration

With the independent construction of a bath, it is necessary to pay due attention to the external and internal decoration of the walls. This is necessary to improve thermal and waterproofing.