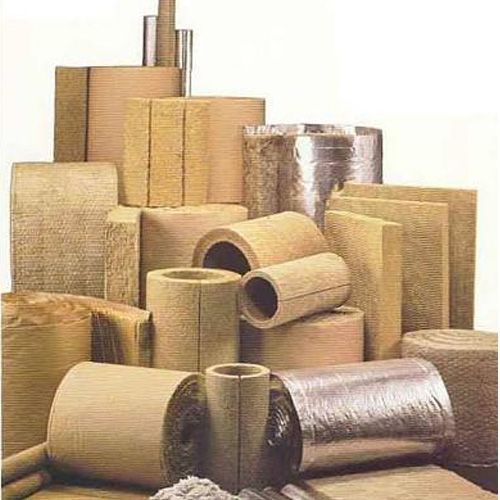

Variety of systems and types of thermal insulation

Currently, there are various thermal insulation systems and various types of thermal insulation materials on the domestic market.

Initially, the process of selecting the required thermal protection of buildings is determined by the task and the planned budget.

It should be borne in mind that there is external thermal insulation, intended for the production of insulation work outside, and there is internal, which can only be used indoors.

The thermal conductivity of thermal insulation materials, their density and thickness, as well as the presence of additional properties or elements, such as the presence of a foil or self-adhesive layer, are of great importance when choosing a specific type of thermal insulation.

Characteristics of thermal insulation materials, their specific properties and additional parameters, as well as reviews and advice from experts, ultimately determine the choice that the consumer makes.

Foil Reflective Thermal Insulation

One of the most used options for insulation, used not only in everyday life, but also on an industrial scale, is thermal insulation with foil. It is produced on the basis of foamed polyethylene foam, mineral wool rolled thermal insulation of the MBOR type, as well as in the form of individual basalt mats or slabs of various thicknesses.

Foil thermal insulation additionally enhances the refractory properties of building elements and increases the group of their fire-retardant efficiency. Naturally, reflective thermal insulation, in addition, significantly reduces the thermal conductivity of the thermal insulation materials themselves, as well as the structures protected by it.

The advantage of rolled thermal insulation can be considered the convenience of its use and a large range of available thicknesses, up to very thin options. This becomes very important when insulation is carried out in a limited, narrow space, for example, on a balcony, in attics and attics, where the issue of space volume is of paramount importance.

Nevertheless, modern high-temperature thermal insulation makes it possible to obtain excellent fire and heat-shielding characteristics even with small thicknesses of the heat-shielding material.

foam insulation

Recently, the use of foamed thermal insulation has become quite popular, which allows for quick and efficient work to enhance the heat-shielding properties of various equipment and household premises.

Ultra-thin thermal insulation made of polyethylene foam can have a self-adhesive layer, and also have an additional foil coating. The range of thicknesses offered by manufacturers for this type of thermal insulation is so wide that it will meet the needs of the consumer for any type of thermal insulation work.

The most famous type of foamed thermal insulation on the domestic market can currently be considered the Penofol thermal insulation, which is in constant steady demand among Russian consumers.

There is also a large number of similar heat-shielding materials, for example, self-adhesive thermal insulation "Magnoflex" or "Black Start Dakt Al".

Thermal insulation with mineral wool

In addition to polyethylene foam, one of the most popular materials for thermal insulation is basalt wool. Its natural composition allows it to withstand huge high-temperature loads for a long time.

Basalt thermal insulation with slabs is mainly used in the construction of large residential buildings and industrial facilities. The issue of thickness here is not as relevant as in the case of thermal insulation made of polyethylene foam, and determines, first of all, not the convenience of its use, but the degree of heat and fire protection of such materials.

For thermal insulation with mineral wool, a rolled basalt canvas is also used, sometimes even with an additional foil layer, which makes it a very effective thermal insulation material when working on thermal insulation of pipelines.

There is also the possibility of thermal insulation with mineral wool insulation such as basalt mats with various types of facings.

Insulation selection criteria

When choosing a facade insulation, it is necessary to take into account the type of wall material, thickness, architectural features and dimensions. Climate and weather conditions are also taken into account. The thickness of the insulation layer is determined by the building density of the area - a building that stands alone requires a larger layer of insulation than a house located in the central part of a densely populated village.

The thermal insulation layer in facade systems is made from extruded or ordinary expanded polystyrene, as well as from laminated or ordinary mineral wool. Both types of material are supplied in slabs. Mineral wool is made from glass, soda, limestone and sand. Its structure is represented by vitreous thin fibers. Positively characterized by high steam permeability.

Expanded polystyrene is a polymer with the following positive qualities: it does not enter into chemical reactions with other substances, it is resistant to moisture and is not subject to decay and fungus. It is recommended for use in the insulation of basement slabs. According to the statistics of the last 3 years, consumers prefer systems made of expanded polystyrene as the cheapest material.

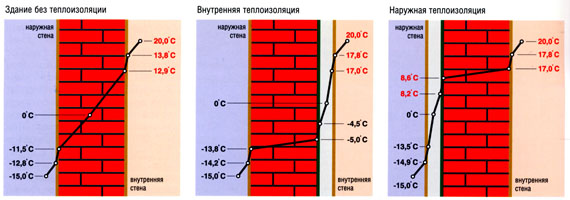

Efficiency of the house facade insulation system

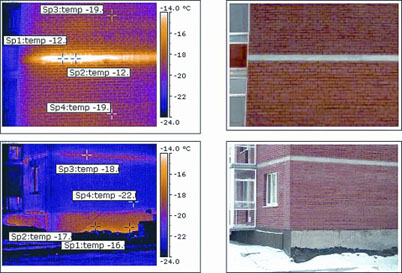

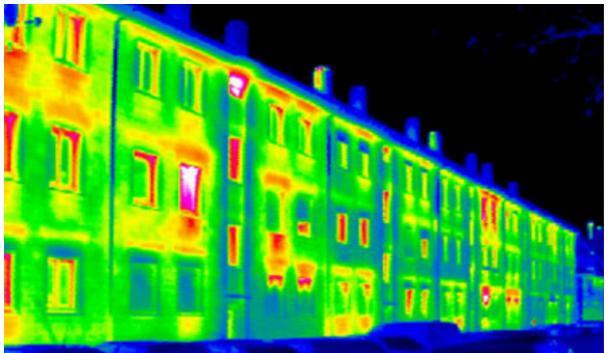

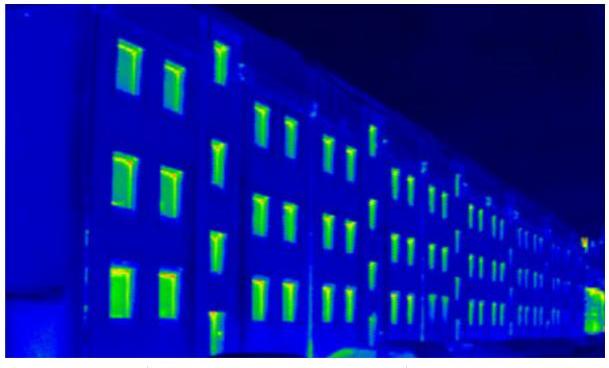

It is generally accepted that heat loss through external walls is approximately 40%, the rest falls on the roof, windows and foundation. On images taken with a thermal imager, you can see the difference in temperature differences in different parts of the facade of a stone building in comparison with the temperature of the street air. In especially critical places, the difference reaches 120 °C. The photographs show a panel building, insulated according to the principle of "insulation inside the building envelope" (well masonry). In such structures, the freezing zones are interfloor concrete floors. In addition to intense heat loss, condensation forms in such places, leading to corrosion in steel reinforcement, destruction of bricks, as well as the appearance of fungus and mold.

In the figure, you can see the thermal imaging of the facade of a panel building before the application of the thermal insulation system (photo on the left) and after (photo on the right). The dark uniform surface of the facade in the photograph on the right indicates the absence of cold bridges and approximately equal street temperature and the surface of the facade. So the effect is obvious.

Step-by-step instruction

The Ceresit system is nothing complicated. However, its installation must strictly comply with the established rules of the manufacturer. Consider the stages of work.

Comprehensive foundation preparation

Warming begins with an inspection of the facade itself, the roof structure and the basement. The walls and the basement area are checked for various damages, existing irregularities are eliminated.

Also, experts study the general condition of the roof and cladding, including waterproofing coatings and the finishing facade layer. After inspection, the nature and amount of pollution on the building envelope is determined. All problems found should be fixed.

Installation of tile heat insulator

Installation of plates begins from the corner of the structure. The first horizontal layer is placed on a perforated profile element. The height of the belt along the perimeter is 25 cm, the thickness is 4-8 cm. Expanded polystyrene products are glued with the Ceresit CT-85 composition.

Plates are mounted three days after the preparation of the building. Dowels equipped with cartridges and washers are used as fasteners.Holes for doweling are drilled either with a puncher or with a drill - the main thing is not to damage the surface of the previously mounted plates.

Waterproofing and reinforcement meshes

First, a waterproofing composition is applied, on top of which a reinforcing mesh is placed. The corners of the slabs are insulated with a perforated aluminum corner. The dimensions of the corners are 25 * 25 * 0.5 mm. In addition, it is necessary to strengthen the corners near windows, doors and convex ribs well. The profile is mounted in a fresh layer of the composition, after which it is puttied with it.

Further work is reduced to applying a reinforcing mesh to the adjacent wall to cover the profile, 10 cm in size. To glue the mesh, Ceresit CT-85 or Ceresit CT-190 is used.

The thickness of the second waterproofing layer ranges from 1-1.5 mm. If the system involves underground insulation, then after creating this layer, it is necessary to waterproof the underground areas with Ceresit materials of the CR, CP or BT group. As soon as they dry, the soil is poured back.

Finishing work

The finishing layer, as well as additional fasteners, is applied three days after laying the waterproofing insulation. First of all, it is necessary to prime the surface to be treated with the composition "Ceresit ST-16". After 3-6 hours, the structure is covered with one of the following decorative materials - Ceresit CT-35, CT-64, CT-36, CT-63, CT-137, CT-60.

Preparation of Ceresit CT-35 or CT-36 is carried out by mixing with water in a ratio of 1: 0.2-0.22. The ratio for Ceresit CT-137 is 1: 0.17-0.22. The duration of action of Ceresit CT-35 or CT-36 is 1 hour, CT-137 - 1.5 hours.

When insulating with mineral wool, finishing materials must have good vapor permeability. Because of this, the finishing layer can only be made from polymer or mineral plasters. In the system, they are represented by silicone compounds.

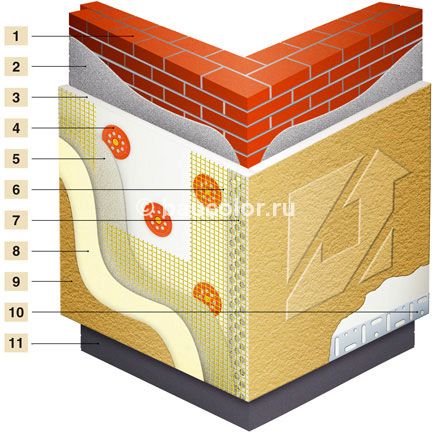

BAUKOLOR B1 system

Elements of the "BAUKOLOR A2" system

|

|

The BAUKOLOR V1 thermal insulation system can be used:

- on buildings of 1, 2 and 3 degrees of responsibility;

- on residential buildings with a height of up to 75 m inclusive (according to SNiP 2.01.02-85 and SNiP 21-01-97);

- operation at an average daily minimum temperature of the coldest five-day period of the year not lower than 55 ° C;

- in dry, normal, humid climatic zones;

- relative humidity of indoor air is not higher than 85%;

- the maximum thickness of the insulation is 200 mm.

The installation of the system is carried out in accordance with the installation instructions and the album “Systems “BAUKOLOR A2” and “BAUKOLOR V1” for external thermal insulation of building facades. Album of technical solutions for mass application. Code BK TSF2005".

Fastening Plates made of heat-insulating material are fastened with the mineral composition OK 1000 WDVS-Spezialkleber, BauTherm SP, BauTherm AR and fixed with special facade driven or screw dowels approved for use in the system.

Thermal insulation material As a heat-insulating material, slabs of facade expanded polystyrene grade PSB-S-25F according to GOST 15588-86, average density 15.1–18 kg/m3, flammability group G1–G4 according to GOST 30244-94 are used. The thickness of the plates is set in accordance with the project.

Reinforcement The mineral composition "OK" 1000 WDVS-Spezialkleber, "OK" 2000 WDVS-Armierungsmortel or BauTherm AR is applied to the thermal insulation material and reinforced with an alkali-resistant fiberglass mesh.

Finishing In the thermal insulation system "BAUKOLOR V1" for the final finish, mineral plasters are used, painted with acrylic or silicone paints, acrylic, silicate and silicone decorative plasters, tinted in volume.

In thin-stucco insulation systems, restrictions on the brightness or saturation of the finish coat are adopted, regulated by the Hellbezugswert HBW whiteness index. Below are the HBW values for different types of materials tinted in colors that can be used in BAUKOLOR systems:

In the VISION 5000 color catalog, the HBW value is indicated on the reverse side of each color.

The main document authorizing the use of the system on the territory of Russia is the Technical certificate for the BAUKOLOR A2 and B1 systems of ROSSTROY No. TS-07-2123-08. According to this document, the BAUKOLOR A2 and BAUKOLOR V1 systems are designed for facade insulation: thermal insulation of the outer walls of buildings during new construction, restoration, reconstruction, major and current repairs of buildings and structures for various purposes, including insulation of residential buildings, and as well as thermal insulation of buildings of increased (1), normal (2) and reduced (3) levels of responsibility.

In addition to the main purpose, insulation systems allow you to solve the following tasks:

- reduce the thickness of enclosing structures in new construction and reduce the load on the foundation;

- protect metal from corrosion in reinforced concrete walls, eliminate the problems of repairing interpanel seams, protect against the appearance of fungus and mold by eliminating excess moisture and condensate inside the walls;

- reduce temperature deformations of the walls;

- eliminate the problems of efflorescence in brick and plaster walls;

- reduce the labor costs of exterior decoration during the reconstruction of buildings;

- improve sound insulation from city noise;

- Create a more stable and favorable moisture-thermal regime indoors.

You will find drawings and diagrams of the BAUKOLOR systems in the Technical Units section. For each specific facility where the BAUKOLOR system is used, our company's engineers develop a "Technical Regulation", which describes in detail the entire technological cycle of system installation. Schemes and drawings of the "Album of technical solutions" take into account all the structural features of the facade, and are made in AutoCad format. Interesting additions can be found in the "Frequently Asked Questions" section.

The effectiveness of the thermal resistance of the system is determined by the type and thickness of the insulation that the system is equipped with. In the BAUKOLOR A2 system, the calculated thermal conductivity coefficient of a mineral wool board is 0.042–0.047 W/(m*K), in the BAUKOLOR V1 system, the calculated thermal conductivity coefficient of PSB-S-25 is 0.037–0.045 W/(m*K).

Work performance technologies

How to insulate a house from the outside? For this, two methods are used. Both can be applied to almost any insulation material. The type of heat insulator has almost no effect on technology. But you need to take into account certain recommendations of the manufacturer. For example, as in the case of mineral wool, when a ventilation gap is needed.

There are two technologies:

- insulation of facades with a wet method;

- dry method, when a decorative coating is applied, fixed on the frame.

Wet facade

This method has a relatively low cost, loads the foundations of the building less.

But it is important to note that the decorative coating cannot guarantee reliable protection against mechanical stress.

Insulation of external walls in this case is covered with a layer of plaster. Its thickness is usually 40 mm. To ensure strength, a reinforcing mesh (fiberglass or metal chain-link mesh) is used.

Insulation and decoration of the facade of the house are carried out in the following order:

- cleaning the wall from dirt, leveling defects, surface treatment with a primer;

- fixing the vapor barrier material, if necessary (for polystyrene foam and mineral wool);

- installation of insulation boards on the adhesive composition (irrelevant for ecowool, it is simply sprayed onto the surface);

- additional fixation with plastic dowels;

- applying an adhesive solution to the surface of the insulation;

- mesh reinforcement;

- application of an adhesive primer after the adhesive has dried;

- surface plastering.

How to insulate the facade of a wooden house with mineral wool? Only the wet method is suitable here. For other materials, you can choose one of two options.

Finishing and insulating the facade of the house using this technology has one important drawback: over time, the plaster may begin to fall off. This is especially true if the external insulation of the facades was carried out using a metal mesh. It is recommended to choose a more expensive, but modern fiberglass.

dry method

Warming and finishing of facades in this case assumes the presence of facing material. Most often, siding, lining, composite panels, etc. are used. Do-it-yourself insulation of houses from the outside will require a frame for fastening the cladding. The step-by-step instruction looks like this:

- Cleaning the surface from dirt, leveling large defects.

- Fixing vapor barrier material, if needed.

- Installation of the frame for insulation from wooden blocks or boards. When using a metal profile, the racks are installed after the material for wall insulation is fixed from the outside. At this stage, you only need to provide brackets for mounting racks.

- The next step is to attach the heat insulator to the glue. From below, you need to provide a starting profile, which will serve as a support for the first row. After the adhesive composition dries, do-it-yourself facade insulation is additionally fixed to plastic dowels-fungi.

- Waterproofing and wind protection should be fixed on top of mineral wool or foam. For these purposes, it is recommended to choose a modern vapor-diffusion hydro-windproof membrane. How to fasten it correctly? The membrane or film is fixed on a construction stapler. The joints are made with an overlap of at least 10 cm and glued with adhesive tape.

- After completing all the steps, you can proceed with the installation of the cladding. How to finish the facade in each case should be indicated in the manufacturer's instructions.

The dry method of thermal insulation of walls involves the use of cladding and the installation of a ventilation gap

The dry method of thermal insulation of walls involves the use of cladding and the installation of a ventilation gap

You can insulate walls with a dry method in almost any weather. This favorably distinguishes the option from the previous one. Deciding how best to insulate a house depends on the type of finish chosen.

Material thickness calculation

This item will be an important stage of work. Before you insulate the walls, you will need to determine the thickness of the insulation

It is important to know that the value for a wooden facade and for a brick one will be different. This is because wood retains heat better.

Also, the indicator depends on the climatic region of construction and the purpose of the building.

| Town | Recommended insulation thickness for external insulation, mm |

|---|---|

| Saint Petersburg | 100 |

| Moscow | 100 |

| Yekaterinburg | 100 |

| Novosibirsk | 150 |

| Rostov | 50 |

| Samara | 100 |

| Kazan | 100 |

| Permian | 100 |

| Volgograd | 100 |

| Krasnodar | 50 |

The calculation can be done in three ways:

- according to the formulas from the joint venture "Thermal protection of buildings";

- using the Teremok program;

- using various online calculators. The best option would be the Teremok program. It allows you to make accurate calculations and is easy to use. There is both an online version and a PC app.

Building facade insulation systems that are effective for houses and apartments:

- "BAUKOLOR A2" is a system of materials for insulating building facades, non-combustible mineral wool board (NG) is used as a heater. The system is applied to all classes of buildings and structures up to 75 m high.

- "BAUKOLOR V1" is a system of materials for insulating the facades of buildings, PSB-S-F expanded polystyrene is used as a heater, fire hazard class K0.

Thermal insulation systems "BAUKOLOR A2" and "BAUKOLOR V1" combine the properties of an effective insulation and a decorative coating in the style of classic plaster facades. Thermal insulation of a house, apartment or building facades with the help of these thermal protection systems is the most optimal and perfect.

Not so long ago, few people knew what the thermal insulation of a house is and what it is intended for.However, now the insulation of premises, whether it is the thermal insulation of a house, apartment or cottage, is one of the most popular types of finishing work. Qualitatively carried out thermal insulation allows you to save on heating, creating a favorable microclimate.

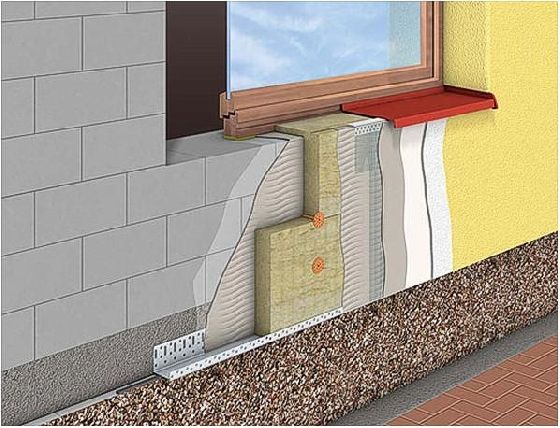

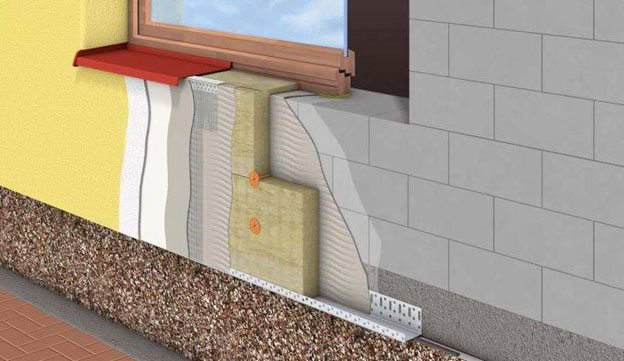

The technology of warming the facade of the house with a wet method

Preparation of walls before thermal insulation of the facade of the house in a wet way:

1. We prepare the surface well, remove any dirt.

2. Align the walls, eliminate cracks, if any.

3. Remove the remains of old plaster from slopes and openings.

4. Fully prime all facade surfaces.

The process of installing the profile on the base.

An important and indispensable condition - install a support bar! From below, a metal bar is fixed along the level (basement profile) so that the mineral wool slabs are laid evenly and to protect against rodents. It is on this profile that the main insulation system will be based.

To do this, mark the entire perimeter of the building along the basement.

• We fix the support bar 30-40 cm from the ground.

• We leave a gap between the planks of 2-3 mm, so that there is an opportunity for the expansion of materials when the temperature changes.

• The profile itself is fastened with dowels in increments of approximately 20 cm.

How to apply glue on thermal insulation?

Sheets of heat-insulating insulation are glued onto the prepared and primed facade of the house. Pre-apply adhesive to the entire perimeter of the insulation and a couple of points in the middle. This will significantly reduce consumption while providing good strength. According to the rules, it is necessary that the adhesive composition covers up to 40% of the area of \u200b\u200bthe insulation.

• the boards are fastened to the wall so that the vertical seams of the lower row at the joints are overlapped by the boards of the upper, subsequent row, in a run-out, continuous seams must not be allowed! This also applies to corners.

• keep the distance between the seams of heat-insulating boards to a minimum, and press the reverse side of the boards tightly to the base when fixing with glue, fix the side part of the board tightly to the adjacent one;

• if there was excess glue, and it protrudes at the seams, it must be removed immediately, without allowing it to dry.

After you have glued a layer of thermal insulation, dry it thoroughly. This will take approximately 2-3 days, after which it is necessary to further strengthen the thermal insulation with dowels, given the porosity of the material.

The sequence of fixing the insulation with dowels:

The glued insulation is additionally fixed with special dowels, called fungi, at a distance of about 30 cm from each other.

• to begin with, completely make all the markup;

• tightly join the dish-shaped parts of the plates, drill holes for fastening;

• drive in the dowels yourself according to the marking.

Wet façade reinforcing mesh installation technology.

A few days after fixing the insulation, it is possible to mount a fiberglass reinforcing mesh, which is fixed to the mineral wool with an adhesive composition 3-5 mm thick. First, window and door openings and corners of the building are reinforced, preferably with the help of special corner profiles with a mesh.

The walls themselves are reinforced at the end. The overlap of one reinforcing mesh on another must be at least 10 cm.

The sequence of installation of fittings on a wet facade insulation:

• a layer of glue is applied to the insulation;

• then the reinforcing mesh itself is fixed with glue;

• a covering layer of glue 1-2 mm is re-applied from above, which finally fixes and covers the entire mesh.

Remember! According to the technology, the mesh layer plus glue should be 6-7 mm thick, no more. The gaps between the reinforcing layer and the outer surface are not more than 2 mm.

When the covering protective layer dries, the surface is primed.

The final stage is the finishing of the walls of the wet facade.

So, we have come to the final stage of finishing - finishing plastering of the walls. Dry all previous layers well again. In warm sunny weather, this will take about a week.The final finish must be resistant to moisture and have good vapor permeability. And also withstand mechanical stress and temperature fluctuations. I repeat, we start work in dry calm weather.

For finishing a wet facade, finishing with decorative plaster with painting or simply applying vapor-permeable facade paint is suitable.

Warming or thermal insulation of the facade of a house in a wet way, as you can see, is a fairly simple technology and is available to people who have already encountered finishing and are familiar with materials such as plaster. With a competent approach, you can perform the insulation of the facade of your house yourself, but even if you decide to hire a professional team, knowing the technology, you can easily control the quality of work and compliance with all technological nuances.

Watch the video: Insulation of the facade of the house in a "wet" way

https://youtube.com/watch?v=TvgmhmRfk10

Source - Build your own house

Works that we carry out on the installation of the wet facade system

- surface preparation - cleaning from dirt, efflorescence, obsolete coatings, sealing joints, leveling the surface, priming

- installation of a plinth profile for fastening with the adhesive composition of the first row of boards (from bottom to top, with obligatory bandaging of boards)

- fastening of plates with facade dowels

- installation of an adjoining insulator to door and window openings, strengthening (reinforcement) of the corners of the openings

- applying the adhesive reinforcing mixture to the insulation layer and installing the reinforcing glass mesh

- applying a layer of decorative plaster

All installation work is carried out under certain weather conditions - ambient temperature from +50 o C to +30 o C.

Despite the fact that aerated concrete is characterized by high vapor permeability and heat capacity, the final decision on the need to install the insulation system should be made only after analyzing the following information:

- climatic zone in which the house is built

- material thickness, density

- construction joint thickness

- the material from which the mortar is made

Based on the data obtained, it can be concluded that the insulation of a house made of aerated concrete is performed in the following case:

- if the blocks were not laid on the adhesive, but on the building concrete mortar, the use of which leads to the formation of cold bridges

- building material density above D400

- when making load-bearing frames of a house made of aerated concrete blocks

Benefits of the easy wet process

The advantage of facade insulation systems made using the light wet method lies in the location of the so-called "dew point" outside the wall. Thanks to this, the problem of "cold bridges" that can reduce thermal insulation disappears.

Another plus is that the living area is not reduced, because all the necessary work is done outside. Heaters are also versatile materials in terms of finishing. Based on them, you can implement an aesthetically attractive architectural project of almost any complexity - for example, decorate walls with marble chips or tiles.

Flaws

There are some drawbacks to this approach:

- the foam has very low vapor permeability characteristics - sometimes this causes discomfort due to high humidity;

- the problem of the integrity of the exterior finish of the facade during shrinkage processes is not solved, if the plaster layer functions on the cut;

- even with very low vapor permeability, the outer layer of the finish, as well as the adhesive, is impregnated with moisture.

Installing a contact system has its own characteristics. One of them is the careful preparation of the foundation.

Wet facade insulation technique

The LAES facade insulation system is designed for insulation and decorative facades.

The definition of "wet" for this type of thermal insulation was introduced, since various aqueous solutions and compositions are used here: plaster coatings, primers, paints. This method is a well-developed system of materials and substances, a technique for gluing an insulating layer, its fastening and reinforcement, applying ground layers and plaster finishes, a set of technological requirements for installation. As a result, a strong and durable coating with excellent technical characteristics is obtained.

Important! Ceresit (made in Germany). This facade insulation technology is presented in two versions - ceresit WM (mineral insulation) and VWM (expanded polystyrene)

A similar thermal insulator is also used in the LNPP technology, the name LNPP

-P and LNPP

-M.

Stages of work:

- preparation of the surface of the outer part of the building. This includes the detection of damage to the basement floors, violations of the integrity of the walls. They are completely removed. If plaster coatings have defects, they are dismantled. Visually inspect the building for the presence of moss, overgrowth, fungi. Such surfaces are cleaned to a clean base;

- preparation of the surface for applying thermal insulation of the "wet facade" type. Plaster coatings are removed along the slopes of various openings, protruding seams on the surface are processed with a perforator. In conclusion, the entire surface is primed with either Ceresit CT 17 or Leningrad NPP "Universal Strengthening Primer". This will prevent subsequent layers of adhesive mass from being absorbed into the thickness of the wall and significantly increase the technical characteristics of the wall itself, prevent the development of fungi and microorganisms;

- in the case of the presence of volumetric defects on the walls, they are sealed with special putty masses. This is Ceresit CT 29 or LNPP "Shpaklevka". After complete drying, proceed to the installation of the insulation layer;

- first, metal profiles are fixed along the entire perimeter of the building, parallel to its base, 30-40 cm below the floor or ceiling of the basement. The width of the profile shelf should be commensurate with the thickness of the insulation layer. Prepare the adhesive mass in strict accordance with the instructions. It can be Ceresit CT 85 for polystyrene foam boards, Ceresit CT 190 for mineral wool or adhesive reinforcing mixture LAES Extra (universal). Any of them is used within 1.5 hours;

- gluing tiles. provides for gluing thermal insulation directly to the wall surface. Glue in this case is applied to the expanded polystyrene plate at a distance of 20 mm from the edge and one strip in the middle. Laying is done from the bottom up. The plates are tightly stacked to each other. By lightly pressing on the material, the adhesive is evenly distributed over its surface;

- after the adhesive mass has dried, the protruding edges should be grouted;

- installation of a reinforcing mesh, which will give the entire structure the necessary strength. It must be made of inert materials that will retain their integrity in the alkaline environment of the adhesive and primer. The reinforcing mesh is applied to the adhesive. In this case, the same substances are used as when gluing the insulation;

- a plaster layer is applied to the reinforcing surface. The variety of finishes of each of the developers of the "wet type" facade insulation will allow you to choose the material not only of the desired shade, but also of texture.

No matter how much we want to, but winter comes every year and, as always, “suddenly”, moreover, declaring itself loudly with blizzards, frosts and snowfalls. The price of an energy carrier does not fall, but only grows, so you have to think about saving and preserving heat on your own.

It is no secret that possible heat losses are distributed as follows:

- Doors and windows can lose up to 50% of all heat;

- Walls - up to 40%;

- Attics and cellars - up to 20%.

And if everything is clear with doors and windows, doors are insulated once and for a long time, windows are glued either annually during the season, or before the onset of cold weather, the condition of the seals in plastic windows and in wooden windows with double-glazed windows is checked, then the problem is not solved so easily with walls .