Attic insulation with sawdust

Sawdust is finely chopped wood.

- naturalness;

- no toxic impurities;

- light weight;

- material availability.

Attic insulation technology with sawdust

before proceeding with the insulation with sawdust, they need to be prepared. Namely, mix cement and water with sawdust in a ratio of 10:1:1.

Pour the attic floor with the finished mixture and level it. It is worth noting that it is possible to use sawdust as a heater without using a frame only in a non-residential attic. Otherwise, when walking on the floor, sawdust will be compressed, and the concrete screed will collapse.

build a cellular structure from a bar. Pour a solution with sawdust into each cell. The advantage of this method is that a subfloor can be laid along the timber. And the attic will be usable

Attic insulation with polystyrene foam

Everyone who is wondering how to insulate the attic has the idea to use polystyrene foam. And this is not at all accidental, since this material is even more common than mineral wool. It is also used by professional builders in their work, and it is perfect for independent work.

The main feature that polystyrene has is an acceptable price. It is actually the cheapest building material that can be used as attic insulation.

It is also important to note that expanded polystyrene is much denser than cotton wool, and therefore it is a pleasure to lay it, since it is an “obedient” material. It can be easily processed and laid in the right place.

In addition, there are a number of other advantages:

- Perfectly keeps its original shape.

- Not affected by moisture.

- Low thermal conductivity, an order of magnitude lower than that of mineral wool.

- The ability to create excellent sound insulation.

But along with a large number of advantages, this material also has significant disadvantages, which include such indicators:

- Highly flammable, just one spark is enough for the foam to begin to smolder.

- It does not let steam through, and therefore it is impossible to achieve the effect of "breathing walls" with this insulation.

- If you do not additionally protect the polystyrene foam, then the rodents will gnaw it “with pleasure”, and therefore you can end up without attic insulation.

Despite all its shortcomings, polystyrene still remains one of the leaders in the field of attic insulation. After all, fires do not happen so often, additional protection of the material can be used from rodents, but the “breathing effect” is not so important on the mountain.

Therefore, we can conclude that for such a low price, this is just a great option.

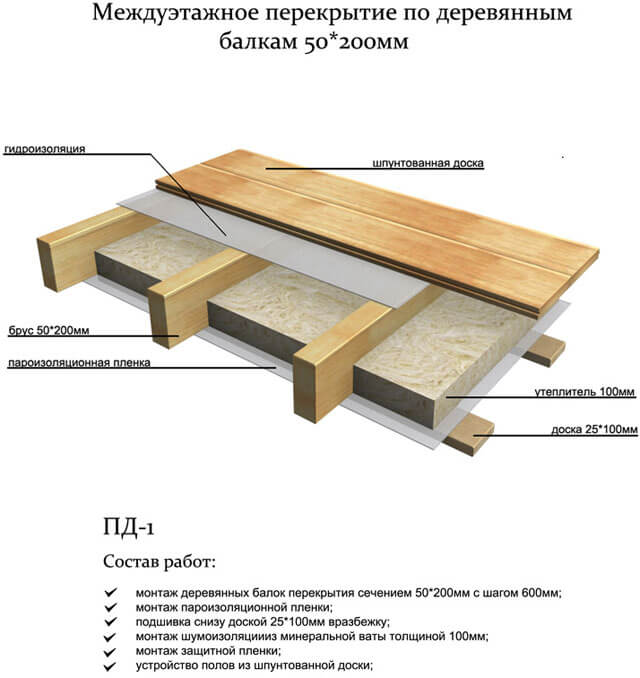

We insulate the wooden floor

The question is often asked: “How to properly insulate an attic with a wooden base?” Many private households have just such a cold attic.

The procedure for insulating the attic floor is as follows:

- Carrying out the processing of load-bearing structures with special compounds to prevent decay, pest damage, and increase fire resistance;

- Installation of a vapor barrier film from the side of the premises, followed by installation of the crate;

- Laying insulation of the required thickness;

- The device of the subfloor from the side of the attic.

For a ceiling with wooden floors, it is extremely important to get protection from pests, fire and moisture before the start of insulation work, since in the future it will be impossible to do this without dismantling the insulation. Work on the insulation of the ceiling from the attic should begin with the isolation of the insulation from the steam coming from the heated premises

Vapor barrier of the attic floor is made with reinforced films made of polypropylene and polyethylene.These films have a multilayer structure, which allows them not to let steam from the side of the heated room into the insulation layer. One of the layers is reinforcing, which allows it to carry loads on holding heat-insulating boards. The vapor barrier must be continuous and tight. For proper laying of the strips, an overlap of at least 10 cm is made with the overlay secured with double-sided construction tape

Arrangement of floor beams and lathing is carried out taking into account the expected load. Thus, when insulating the attic floor of a cold attic using bulk materials, it is necessary to provide for a reinforced base. The weight of this layer will exert an increased load on the floor beams and the crate.

Mineral wool and basalt heaters, or loose and foamed materials are used as a heat-insulating layer. The most popular attic insulation is mineral wool because of the ease of installation.

Loose insulation must be leveled and filled with all the voids. Cold attic floor insulation completed.

The floor of the attic can be arranged in the form of:

- lathing or subfloor from edged (unedged) boards;

- finishing floor made of plywood and other wood sheet materials;

- leveling screed (installation of waterproofing on top of the insulation layer is required).

2 Why mineral wool is used to insulate the attic

In most cases, when insulating attic floors, the choice of the consumer falls on mineral wool. Its advantage lies in the fact that its installation does not require special skills.

Mineral wool has excellent thermal insulation properties. Its structure consists of thin vitreous fibers, the length of which ranges from 2 to 60 millimeters.

Attic insulation with mineral wool

High soundproofing characteristics are provided due to the presence of a large number of air pores.

These pores are located in the space between the fibers and can occupy 95% of the total volume of the insulation. Mineral wool is presented in three varieties, it can be basalt glass and stone.

Basalt wool is made using molten basalt rocks, to which binders are added.

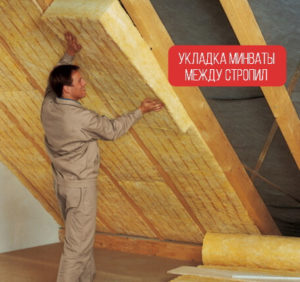

2.1 Technology of insulation of attic floors with mineral wool

During work related to mineral wool, it is important to comply with all safety requirements and regulations. This is due to the fact that in the process of cutting and laying such material, the air is filled with tiny particles that can enter the respiratory organs and thus cause harm to human health.

This is due to the fact that in the process of cutting and laying such material, the air is filled with tiny particles that can enter the respiratory organs and thus cause harm to human health.

When carrying out installation, be sure to take care of the availability of personal protective equipment. Goggles, a respirator and thick rubber gloves should be available.

The process of warming attic floors begins with the selection of the necessary tools and additional materials. Can't do without:

- Boards and plywood;

- vapor barrier film;

- Mineral wool (an excellent insulation for a mansard roof);

- Waterproofing;

- adhesive tape;

- Roulettes;

- Knife;

- Construction stapler;

- spatula.

The essence of the insulation technology lies in the fact that the insulation must be carefully laid in the space between attic floors or beams.

To enhance the thermal insulation qualities, reliable vapor barrier should be used. Warm and moisture-saturated air will continuously rise from the living rooms and go up through the ceiling.

There, in the roof space, he will collide with a layer of insulation. Due to the fact that mineral wool is generally considered to be a vapor-tight material, it will take all the outgoing moisture into itself.

If it is left without the necessary access of air and sunlight, it will gradually shrink and, in the end, will lose all its heat-insulating qualities.

Attic cold interfloor overlapping 20 cm min.

In order to avoid such destructive consequences, it is necessary to lay a vapor barrier material under a layer of mineral wool.

Before starting the main work, it will be necessary to carefully calculate the required amount of insulation.

To do this, it is necessary to calculate the total area of the entire surface of the attic space, and then purchase the highest quality and most reliable insulation, which must meet all the necessary requirements.

A bit from the history of roofing

Since ancient times, people have built private households so high-quality that they could stand for 100 years. At the same time, it was not cold to live in them, and the natural wood roof frame was always dry. As for the shape of the roofs on such buildings, they were most often erected with two slopes, and had a slight slope.

This choice was explained by the fact that the snow that fell in winter had to linger on the roof and act as a natural insulation. In the attic of the building, one, less often two windows were made. They were closed for the winter and then the air in the under-roof space played the role of a heat insulator.

During the summer, the windows were opened slightly at night to cool the temperature in the attic. In the heat they were closed, and the air did not heat up. So in the attic they regulated the temperature.

In winter, when snow fell, it covered the roof with a continuous carpet and thus was a roofing natural heat insulator. Even in severe frosts, the temperature in the under-roof space did not drop below zero. As a result, the house was warm in cold weather.

At the same time, the roof slopes were not insulated so that the snow on them would not melt. The rafter system was left open, thereby allowing its inspection and maintenance. Therefore, in such attics only floors were thermally insulated.

If the roof slopes are insulated, then the attic space becomes a heated attic, which has a different functional purpose.

The need for attic insulation

Comfort and coziness in any living space largely depend on the feeling of warmth. Maintaining the optimum temperature with minimal heating costs is an important point in maintaining a private house.In order to minimize the heat loss of a dwelling, at the stage of building a house, it is necessary to insulate not only the walls, but also the ceiling between the attic and the upper floor. However, insulation of a cold attic can also be performed in an already operated house.

Attic insulation prevents condensation on the ceiling in living rooms. As you know, the humidity content in a warm room is greater than in a cold one. With insufficient insulation of the attic space, warm air in contact with the ceiling forms condensate. Over time, accumulations of moisture will appear on the ceiling and the joints of the floors, mold may form.

This is interesting: Interior decoration of the garage (video)

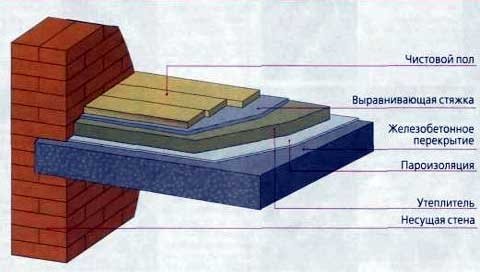

Insulation of attic floor slabs with extruded polystyrene foam

Expanded polystyrene or polystyrene are not very dense materials, so they are used when the attic floor is a structure of logs and beams. If it is necessary to insulate the plates, use the insulation of the cold attic ceiling with extruded polystyrene foam. This material is stronger and therefore denser than conventional foam. Before laying it, the surface of the plates should be leveled. On the warm side of the floor, vapor barrier is not required, since concrete slabs have almost no vapor permeability.

A vapor barrier film is laid on the leveled concrete slabs. Next, slabs of extruded polystyrene foam are laid in a checkerboard pattern. Joints are blown with mounting foam. After the foam dries and hardens, the heat-insulating plates are poured with a concrete solution 4-6 cm thick. When the screed dries, it is already suitable for use as a floor. Although you can go further and put any floor covering on the screed.

Thermal insulation of a cold attic with ecowool

Ecowool is a cellulose, light and loose insulation, consisting mainly of waste paper and newspapers. Other components - borax and boric acid are used as flame retardants.

Before insulation, it is necessary to put a film on the floor. The procedure for laying ecowool is carried out using a special blowing machine. A layer of insulation is applied as a continuous cover, without creating gaps. Since ecowool contains a large amount of air, a layer of 250-300 mm is usually enough.

After the insulation of the ceiling of the cold attic with ecowool is completed, it must be moistened. You can do this with ordinary water or prepare a solution of 200 gr. PVA glue on a bucket of water. Soak a regular broom in this solution and moisten the cotton well. After drying, a crust is formed on the surface of the cotton - lingin, which will not allow the cotton to move.

As you can see, there are plenty of ways to insulate the floor in the attic. Which one to apply depends on each specific situation. The main thing is to follow the correct technology for laying thermal insulation! Then your house will always be warm, and the materials used will last for many years.

Blow-out insulation for the attic

A similar method of warming the mountain in a private house is the most fashionable today. It is used by almost all companies that offer such construction services.

The main advantage that this attic insulation has is that it independently fills all the space, voids and at the same time creates a uniform and continuous layer. You no longer need to cut blocks in order to close up all the holes.

In Russia today, two blown heaters are used: blown wool and ecowool.

The latter consists of 80% cellulose fibers. They are also made from the most common waste paper, but the remaining 20% are a wide variety of additives, which can be boric acid, which acts as an antiseptic, and snowstorm as a fire retardant.

Blown wool is completely composed of standard mineral substances, which are designed for thermal insulation.

It is important to note that it is highly crushed