A brief overview of the main materials for thermal insulation of a gas chimney

To insulate the chimney, materials with a low thermal conductivity and high temperature resistance are used. The second requirement is not met by most modern insulating materials, which include polystyrene, foam plastic, foam rubber, cellulose porous insulation and materials based on foamed polyethylene.

The effectiveness of a heat insulator depends on the material from which it is made and its thickness, an important characteristic is the ability to absorb moisture.

Rice. 9 Popular heat insulators (glass and basalt wool)

glass wool

It is a material obtained from fine glass fibers, has high heat resistance and low thermal conductivity, is not afraid of moisture and does not absorb water. The service life of glass wool is quite high, but the material has a low density - this makes it difficult to install. Although glass wool is mainly produced in rolls, it is more convenient to use slotted foil hollow cylinders for thermal insulation.

Rice. 10 Thermal conductivity of insulators

Mineral wool

Basalt insulation is widely used in the construction industry due to its high insulating qualities and environmental friendliness. Mineral wool is resistant to high temperatures, but is able to absorb moisture; for insulation, it is better to use mineral wool in the form of hollow cylinders. Mineral insulation has a high density, so it is convenient to install and process it - the material is the main type of insulation for pipe chimneys.

Chimney brick. The industry produces special types of hollow bricks with a hole for the chimney pipeline, the insulation is air cavities in its walls. Chimney bricks are best used with insulation that prevents the pipeline from contacting the brick walls. In addition to its insulating qualities, brick provides a high decorative effect for a residential building, hiding ugly chimney pipes in aesthetic stone columns.

How to insulate an iron chimney pipe

To insulate a metal pipe on the street, they use basalt insulation and metal clamps - the rolled insulation must be wrapped around the pipe and secured with clamps after 30-40 cm. A tool that is useful for insulation:

- Hammer, pliers, screwdriver, clamp, and other metalwork tools;

- Roulette, metal ruler or square, building level, pencil or marker;

- Cutter or scissors to cut the insulation for chimney pipes to size;

- A device for riveting and rivets that connect the casing. Instead of rivets, short press washers can be used;

- Screwdriver or electric drill, drills Ø 3-4 mm for rivets;

- If the chimney is plastered, then you will need: a spatula and a bucket for mortar;

- For sealing cracks and joints - a construction gun and bituminous mastic.

Base for chimney insulation

During the passage of smoke through the pipe, the inevitable cooling of warm flue gases occurs. As a result, the heat from the flue gases heats up the walls of the tube to remove the smoke into the atmosphere.

The draft in your stove is directly proportional to how quickly the walls of the chimney warm up. When the draft is reduced, the smoke begins to go along the path of least resistance, and simply begins to move from the furnace to the scrap, and this is fraught with carbon monoxide poisoning, especially if in a private house, the stove is located directly in a private house, and not in a designated boiler room.

Another important factor in favor of the insulation of the chimney and pipes. There is such a thing as the time for which the moment of manifestation of condensate is overcome.

The time spent on warming up the chimney channel depends largely on what it is made of.

Table for calculating the temperature regime of the structure of the chimney

A chimney lined with brick can warm up in 15-30 minutes

Photo of a brick chimney

A chimney made of steel warms up much faster - in 2-5 minutes;

Steel chimney

Since the hot stove chimney is constantly in contact with cold atmospheric air, condensation in the chimney can not be avoided. Together with the appearance of condensate, due to the mixing of water with carbon dioxide and other combustion products, an acid solution is formed, which, being absorbed into the walls of the chimney channel, gradually destroys it.

If the chimney is made of brick, then the condensate moisture is absorbed into the brick walls, and this most often leads to freezing of the brickwork of the pipe. The pipe, which has cooled down overnight in the frost, warms up again in the morning, it is from such frequent temperature changes that the brickwork of the chimney inevitably collapses.

Brick chimney after regular freezing

So why insulate chimneys? It is precisely due to the fact that the appearance of condensate is practically unavoidable, but on the other hand, we can protect the chimney from freezing and destruction, it is imperative to insulate any chimney, the sooner you do this, the longer it will be in operation.

Basic requirements for chimney systems for gas boilers

When installing chimney ducts, to ensure their efficient operation and fire safety, the requirements prescribed in the regulatory documentation SNiP 2.04.05-91 and DBN V.2.5-20-2001 should be strictly followed. Their main provisions are as follows:

- The cross section of the chimney (pipe diameter) must not be smaller than the outlet pipe of the boiler.

- The main pipe should be located vertically without inclined sections (let's say a slope of not more than 30 degrees), its design should not have curvature and narrowed sections.

- The maximum number of turns in the branch line is no more than three with a side branch length of up to 1 meter.

- The allowable distance between the walls of the chimney and non-combustible surfaces is at least 5 cm, if it passes through combustible walls and the roof, the allowable distance is more than 25 cm.

- The material for the manufacture of the chimney channel must be resistant to high temperatures and have a structure that prevents the passage of gases.

- All connections must be tight, the insulation must not let moisture and gases through.

- In the place where the pipe channel passes through the roof, the structure must be solid and without joints.

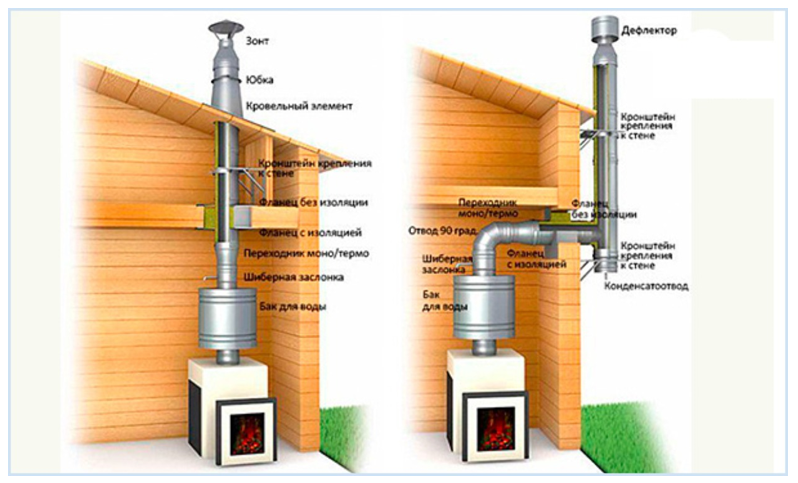

Rice. 3 Boiler piping diagram

- In the lower part of the pipe, there is usually an element for collecting condensate. The material of its manufacture must be resistant to moisture and gas combustion products.

- In places where turns are provided, the location of inspection hatches is required to clean the chimney from dirt and condensate.

- The length of the chimney channel must provide good draft, the height of its outer part must be at least 50 cm above the roof ridge.

- When installing a smoke exhaust duct, it is mandatory to have a protective visor in its upper part to prevent the ingress of pollution and precipitation.

How to insulate a chimney

You can make a chimney insulated using different materials. Their cost is not of serious importance, since the insulation itself will take a little

But the owner should pay special attention to the insulation technology itself. Usually the chimney is insulated from the outside.

To ensure decent insulation, it is better to focus on fibrous insulation. These include mineral and glass wool. It will be possible to increase thermal insulation with the help of cinder concrete, broken bricks and similar materials.The most important thing is that the insulation used is highly fireproof, because the heating temperature of the pipe can be very significant.

It is better for the owner of the house to dwell on such heat-insulating materials that can be laid on their own. Before performing any procedures, you should read the manufacturer's instructions.

Particular attention should be paid to working with glass wool, as it releases dangerous crumbs. You can't do without protective equipment while working with it.

The technology of pipe insulation is also determined by what material this element is made of. Most often, brick, steel and asbestos cement are used to create a chimney. Each of these cases has its own characteristics of thermal insulation work.

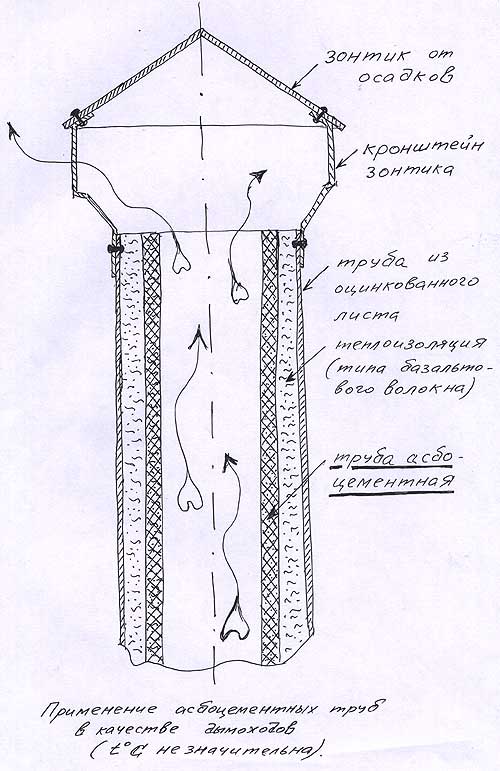

How and how to insulate an asbestos chimney pipe

The chimney pipe made of asbestos cement must be insulated with mineral wool. Before the main work, the presence of dust and debris should be removed from this element. The insulation will be laid in a special casing, which is made of galvanized iron. The diameter of the casing is selected so that it is 6 cm larger than the diameter of the chimney.

The length of such a design for insulation may be different. But it is made up of parts that are inserted into each other. Each element has a maximum length of 1.5 meters. When the casing is put on, a heater is laid between it and the pipe. After its tight tamping, you can put on the next element, thus building up the pipe.

The remaining voids are filled with cement mortar. The last element of the casing must be tilted. Sometimes owners manage to do without a metal casing. If this option is chosen, then mineral wool must be wrapped with clamps. But it is better to use several mineral wool slabs.

To increase the operational life of such a heat-insulating structure, it is necessary to additionally carry out vapor and waterproofing. Otherwise, the mineral wool will deteriorate.

How and how to insulate a steel chimney pipe

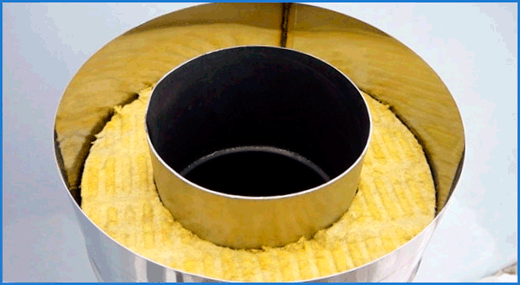

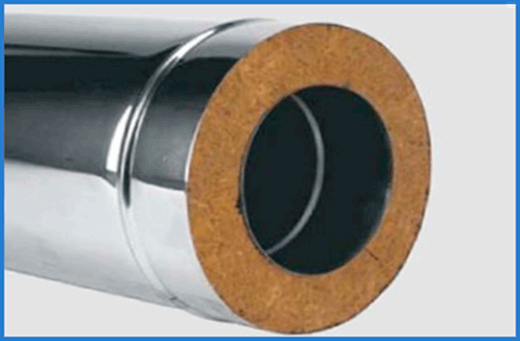

Finding a steel chimney in a hardware store that has an additional heat-insulating layer is not difficult today. This design is carried out using two pipes having different diameters. In the space between these elements is a fire-resistant heat-insulating material. But you can perform such insulation yourself.

For this, two pipes are taken, differing in diameter. A smaller pipe is laid in a large one, and the free space is filled with a fibrous heat insulator. In this case, you do not even need to prepare any complex tools. A tape measure, fasteners, a screwdriver, a clerical knife and a grinder are enough to cut the material. An adhesive tape is also useful, with which you can fasten individual pieces of insulation.

How and how to insulate a brick chimney pipe

The owner has the hardest time if he is faced with the task of thermal insulation of a brick pipe. There are two possible options, each of which is worth dwelling on in detail.

1. Warming with plaster

The outer side of the brick chimney is covered with a reinforced mesh. A plaster mortar is applied to it so that its thickness is about 3 cm. It is necessary to prepare the plaster from slag and lime, adding a little cement. Usually 2 layers are applied, the first of which is liquid. When it dries, you can cover the work surface with a thick solution. Having leveled the plaster, you need to rub it well. Then the chimney is covered with lime to make it look better.

2. Warming with asbestos cement and mineral wool

The brick chimney is first covered with mineral wool, after which the asbestos cement lining is formed. In this case, asbestos-cement slabs are used. They can later be plastered.

How to properly insulate a chimney

The most correct decision of the owner of the house will be to insulate the chimney immediately after the construction of the building is completed. If you miss such a moment, the chimney can no longer be saved, as it will begin to collapse. As a result, it will be necessary to replace or repair the chimney completely.

Phased insulation technology

Due to the fact that chimneys come in different types and designs, we will describe how to properly insulate a chimney pipe made of brick, asbestos cement and steel.

Asbestos cement chimneys

Asbestos-cement pipe

To understand how to insulate a chimney from an asbestos pipe, we will analyze the entire procedure in stages, following the recommendations of professional builders:

First you need to thoroughly clean the place of work from dust and dirt;

The next step is to make a special folding casing for the insulation (made of galvanized iron)

When determining its parameters, it should be taken into account that at least 6 cm must remain between the pipe and the iron for insulation;

Pay attention to the fact that a casing assembled from several parts is put on the asbestos pipe, and each of them should not exceed 1.5 m;

First of all, you should fix the lower part of the casing and carefully fill it with a sealant. Then, the second part is put on and the procedure is repeated.

This design must run along the entire length of the asbestos pipe.

Thermal insulation scheme from a home master

This is what an asbestos chimney with a casing looks like

Often, many of the owners of cottages do without a casing. The pipe is simply wrapped with a roll of mineral wool and pulled together with brackets. In order for this method of insulation to become truly reliable, several layers should be wound.

Steel chimneys

So, we sort of figured out the asbestos pipes, now let's see how to insulate the metal chimney pipe. In general, many manufacturers of building materials produce ready-made chimneys made of stainless steel. The design is quite simple and consists of only two pipes of different diameters.

How to insulate a metal chimney? To do this, take a pipe of a smaller diameter and insert it into a pipe of a larger diameter. Then, the remaining space between the pipes is filled with any of the above types of insulation. If you are interested in modern materials, then you can recommend basalt chimney insulation, which in its structure resembles mineral wool, but is much more practical and durable.

Thermal insulation of a steel chimney

In principle, it is much easier to insulate an iron pipe than the same asbestos one, so there should not be any problems here.

brick chimney

Brick chimney

Insulation of a brick chimney is perhaps the most difficult type of all presented in this article. Now we will give several options, of which everyone will choose for himself how to insulate a brick chimney:

Plastering method. To do this, you will need to fix a reinforced mesh on the chimney. Then prepare a solution of lime, slag and a small portion of cement. Spread the resulting solution over the entire surface of the chimney and level it (all work is done in one layer, which must be at least 3 cm).

When the solution dries, it will be possible to add a few more layers, and immediately cover up the cracks that have formed. To give an attractive appearance, in the future the pipe can be whitewashed or painted.

Scheme of thermal insulation of a brick chimney

Mineral wool insulation. To do this, you will need to take a roll of basalt wool and cut it into pieces that correspond to the size of the chimney area. Then, the insulation is glued to the pipe with adhesive tape. The last step of the work is to lay the insulation (for example, Rocklight) with a second layer of bricks or asbestos-cement slabs.

The process of thermal insulation of the chimney with mineral wool

Good luck!

Why insulate chimneys?

To exclude conditions for the formation of condensate on the walls of the chimney. This is due to the fact that flue gases, touching the cold walls of the pipe, deposit a wet film on it, which, interacting with soot (unburned waste), forms harmful chemical compounds that destroy the walls and have an unpleasant odor.

The phenomenon of condensation in nature manifests itself when the moisture content in the air is supersaturated as a result of its cooling, it is compressed, density increases and, having reached the “dew point”, moisture falls out in the form of precipitation (small droplets, fog).

Smoke vapor also has a “dew point”, this point can be located and change its position along the entire length of the pipe. So, for example, when the furnace is ignited, it can be located directly in the furnace and, as the pipe channel warms up, rise higher and higher until it “flies into the pipe”.

By the way, this expression tells us that it is necessary to heat the stove correctly so as not to waste extra firewood: the most optimal option is that the temperature at the beginning of the pipe channel should be in the range of 250-300 ° C, and at the outlet from 100 ° C to 150 ° WITH.

It is necessary to strive to reduce the time for the formation of condensate, and this can be achieved by quickly heating the inner surface of the pipe. That is why it is necessary to insulate chimneys. In homes with year-round use, this must be done to minimize the amount of condensate formed, since its chemical composition contains dissolved harmful substances, including sulfuric acid, which destroys the pipe channel.

Materials and methods of chimney insulation.

If the chimney passes from the outside of the building, then it must be insulated along the entire length. Brick pipes can be insulated by plastering using fiberglass mesh and basalt wool insulation. This method was widely used during the overhaul of "Khrushchev" and was called - a thermal coat. Materials for a thermal coat can be purchased at any construction market. The fur coat includes:

- fasteners (dowel and nail with clamping washer);

- plaster mesh (durable glass fabric woven in a special way - best known as SSSH - 160)

- insulation (plates, mats made of mineral wool or expanded polystyrene)

- polymer-mineral glue (SARMALEP)

- plaster (special finishing composition - SARMALIT)

- paint (special paint for plaster - SOFRAMAL)

The insulation technology is simple: with the help of dowels and nails, the mats are attached to the outer wall of the pipe, the surface of the mat is glued with a mesh overlay, then a layer of plaster is applied and paint is applied to it. This design is very light, does not require additional reinforcement of the walls and emphasis on the foundation.

It happens that it is necessary to install a pipe to additional equipment installed in the utility room or basement. Here you can use a prefabricated system of pipes in the form of a sandwich, which do not require insulation and allow installation through the wall. This is a prefabricated system consisting of heat-resistant stainless pipes (pipe in pipe), the annulus of which is filled with non-combustible material with very low thermal conductivity. You can select pipes of the optimal cross section for your heating system by studying the installation and operating instructions.

Do I need to insulate the outside

When the warm exhaust gases pass through the pipe, they are cooled. During cooling, condensation forms on the walls, which can lead to the destruction of the chimney pipe.

Also, the traction force in the furnace or boiler depends on how quickly the walls of the pipe heat up. If the draft in is weak, then carbon monoxide will not rise to the top, but will go down, that is, into the house, and this already threatens with poisoning.

It is necessary to insulate any chimney, whether it is a stove or a boiler, and regardless of what it is made of (brick, metal, asbestos). Carbon dioxide mixed with condensate forms a weak solution of sulfuric acid.Acid destroys metal chimneys, even despite the appearance of chimneys with oxidation protection.

Brick pipes are destroyed when condensate enters the cracks, which, when moisture freezes in them, expand, which can lead not only to the destruction of the pipe, but also to the roof itself. The conclusion suggests itself - it is necessary to insulate.

Video: Chimney heaters

Thus, we protect it from freezing and destruction. So, the sooner we do it, the longer it will serve us.

How to insulate

For insulation, you can use materials such as:

- glass wool;

- fibrous insulation;

- broken refractory or red brick;

- plaster.

Plastering is not the best way to insulate. A metal mesh is fixed on the pipe and a few layers of a solution of slag and lime are applied. With this option, you will have to grease the fallen off plaster every year. Therefore, it is worth thinking twice about the ratio of effort - quality, before choosing this method of insulation.

Backfill - heat-insulating bulk materials of various sizes are used. One of the easiest and cheapest options. You can use rubble refractory or red brick, expanded clay, slag, etc.

Mineral (stone) wool - made from rocks of basalt origin, some add glass (glass wool). The most popular and reliable way. But there is a drawback: protection from a steel casing is required. Without additional protection, cotton wool will not last long - wind and moisture will bring all the work to naught.

When choosing a heater, it is better to focus on the quality of the product, since the material will not be needed very much. How long the chimney will last depends on the quality of the insulation and the work carried out.

How to insulate a metal chimney pipe

Steel chimneys are a separate topic for reflection. A special type of stainless steel is used as a material for modern chimney pipes. The functionality of stainless steel is very high. First, the pipe warms up quickly. Secondly, it does not rust from moisture.

The so-called sandwich chimneys have become common. These are structures that consist of two pipes of different diameters. A heater is laid between them. However, such chimneys have a number of disadvantages, among which one can name their price and operational period. The advantage is that the sandwich chimneys themselves are insulated. You just need to install them correctly. The quality of the chimney insulation is guaranteed by the manufacturer.

Sandwich chimneys help retain up to eighty percent of the heat. This means that this type of chimney can be called the most efficient.

However, you can independently perform the insulation for the chimney made of steel. To do this, glass wool is selected as a heater, which is wrapped around the pipe, then fixed with wire and foil. In addition, some craftsmen create homemade sandwich chimneys. In addition, they are insulated not only in the space between the pipes, but also outside.

When working with mineral wool, you need to be very careful

It is important to ensure that particles of the material do not get on the skin, eyes and respiratory organs. It is recommended to carry out all work with gloves

Insulation of the chimney will allow not only to maintain durability, but also create a beautiful view. It is much more pleasant to look at a plastered brick chimney than at ordinary brickwork. The same can be said about the asbestos pipes sticking out of the roof.

Insulation of chimneys of any type is done by hand - without the involvement of specialists. You just need to carefully do all the work. An important role in the insulation of the chimney is played by heaters. It is necessary to choose a material that is not susceptible to fire. Often it is because of the chimneys in the house that a fire occurs.

Now that all the work is done, you can evaluate the work.First of all, condensate will not form in the chimney. It cannot be said that it will not exist at all. However, this is much less than without insulation. In addition, little soot will form in the pipe, which over time can catch fire and cause a fire.

The insulation of the chimney must be approached responsibly. The job requires care and attention. Otherwise, the desired effect will not be achieved. For work, you need to use only high-quality and safe materials.

Why is chimney insulation necessary?

The main task of thermal insulation of the chimney pipe is to create thermal conditions under which condensation will not form in the pipe cavity. As you know, due to a significant temperature difference between the interior of the operated chimney and cold outside air, condensate forms on the walls inside the pipe in significant quantities. Insulation of the chimney allows you to bring the so-called dew point outside the chimney, thereby eliminating the very cause of moisture condensation.

The condensate formed in the chimney contains water and a solution of sulfuric acid, which is obtained as a result of complex processes that occur during the combustion of fuel. The result of the impact on the pipe of such an "explosive" mixture is its active destruction from the inside.

To the maximum extent, this applies to single-layer pipes made of metal. Sandwich, brick and asbestos-cement pipes are somewhat less susceptible to harmful effects.

Condensation spots due to lack of pipe insulation