Heaters for ventilated facade

When choosing a heater for a ventilation facade, it is necessary to evaluate a set of properties:

- The vapor permeability of the insulation should not be less than the vapor permeability of the wall;

- The insulation must provide thermal insulation of the walls;

- Noise reduction due to the presence of soundproofing properties will be an additional plus;

- The insulation should not be hygroscopic, at least it should be easily dried due to air flows between the ventilated facade and the wall.

Such properties are available for expanded polystyrene, polystyrene, polyurethane foam, mineral and basalt wool.

Expanded polystyrene, foam plastic, polyurethane foam

Such heaters are distinguished by a common set of the following properties:

- They do not absorb moisture due to the fine-meshed structure;

- Able to withstand temperature changes without losing their properties;

- Moisture resistance - even if the outer layer of expanded polystyrene and polystyrene gets wet, elasticity saves them from destruction, insulation withstands multiple cycles of freezing / thawing water in the pores;

- High rates of heat and noise insulation;

- No shrinkage;

- The low vapor permeability of polyurethane foam and other polymer insulation provides a complete vapor barrier.

Mineral wool

The cost of mineral or basalt wool is significantly less than that of polymer insulation. Such a heater has the following properties:

- High vapor permeability;

- Great weight;

- Chemical, biological resistance;

- Does not burn;

- Easily absorbs moisture and dries without problems;

- Good indicators of noise and heat insulation (not as high as those of polymer materials).

The main disadvantage of mineral wool is the loss of volume, the material quickly loses its shape. This is due both to the structure of the mineral wool and to the fact that the movement of air in the gap carries the fibers with it and breaks the structure of the insulation. This not only reduces its service life, but also worsens its thermal insulation properties. That is why the choice of a material such as mineral wool for creating facades of high-rise buildings is not the best.

The greater the height of the building, the greater the speed and strength of the air flow, destroying the material - the greater should be the density of the material. As for the thickness of the insulation, to calculate this value, you can use special calculators that will take into account both the climatic features of the area and the parameters of the selected material.

Features of the installation of polystyrene foam, polystyrene foam and polyurethane foam

The technology for installing thermal insulation from foam boards when creating a facade is somewhat different. For such lightweight closed-cell insulation, there is no need to create a crate. Plates can be simply glued, cleaning the wall of dirt.

The only thing is that the frame will need to be made if expanded polystyrene plates are used as thermal insulation - in this case, the foamed insulation is fixed with wide caps. They are inserted into the joints between the plates. It is not necessary to mount the plates closely - it is reasonable to leave gaps between the edges. This will level out thermal expansion, since PPU, PPS and foam plastic increase slightly in size when heated - the presence of gaps will help to avoid warping of the material.

Advantages of hinged facades

The popularity of VF designs is due not only to their beautiful appearance, but also to a number of undeniable functional advantages:

- Universal technology. Hinged facades are equally successfully used for external cladding of any type of buildings, regardless of their purpose.

- Mounting speed. To install a ventilated facade, it is not necessary to pre-prepare and level the outer walls of the building.

- protective qualities.In finished form, the ventilated facade is an additional shell that protects the building from various destructive factors, which significantly extends the life of the building and eliminates the need for frequent repairs.

- Variety of appearance. Hinged facades allow you to give the building almost any exterior, starting with ultra-modern forms and ending with a very reliable imitation of antiquity. Exterior wall cladding can be made of wood, glass, metal, artificial stone, plastic and other materials.

- Simplicity and ease of repair. If necessary, it is not difficult to dismantle and replace damaged elements. Possibility of application in restoration works. Old, ruined and dilapidated facades can be easily restored using this technology.

- Moisture, noise and heat insulation properties. The special qualities of the materials used and the structure of the facade, reminiscent of a "layer cake", protect the interior of the building from temperature extremes, humidity, wind, noise and adverse external conditions. In addition, a ventilated facade makes it possible to significantly save on heating in winter and cooling in summer.

- Durability. Subject to the construction technology and proper operation, the ventilation facades can last at least 30-50 years.

Installation of hinged ventilated facades

Installation of hinged ventilated facades is now a very common phenomenon. This can be seen on a large residential high-rise building, where almost every tenth tenant has equipped the outer side of the wall of his apartment. And this is not at all surprising, because today it is easy to do the installation yourself or using the services of specialized companies.

If you trust only professionals, go to https://dpk.by/statii/fasady-i-ventiliruemye-fasady.html. There you can learn more about the services offered. If you want to try to make such an installation yourself, read the article to the end.

Advantages

This article is about ventilated curtain walls. Why exactly them? Firstly, they provide natural air circulation between the wall and the facade itself, thereby relieving residents of moisture, which will extend the life of the facade of the house itself.

So, a hinged ventilated facade has a number of advantages:

- high installation speed

- universal and optimal installation technology for most facades,

- attractive decorative properties,

- the possibility of subsequent installation,

- good wall protection

- long service life (with proper installation, the facade can last more than half a century!),

- thermal insulation.

Mounting and installation

If you decide to install a hinged ventilation facade on your own without the help of specialists, first make sure that the wall does not have steep ledges (an ideal wall is not required). Apply a primer to its surface, and then mark on it where you want to install the facade.

Make fastening brackets treated with anti-corrosion agents. Install a paronite gasket between the bracket and the wall.

To provide hydro- and thermal insulation, install plates and a membrane. If you want to insulate the facade in two layers, then place the second layer with an offset to the first.

Install the wind barrier film from the bottom up - fix the junction with a stapler. Be sure to lay the film on the correct side.

Then you should horizontally mount the profile, which in turn will form the frame. It should be borne in mind that the corner profile is installed first.

Mount the facing material itself from the bottom up. Fix it on the profile with hardware. Avoid gaps and gaps - if they are, you can get rid of them with the help of overlays.

There are many technologies and nuances regarding the facing material itself.Regardless of it, after installation, be sure to edit the corners.

Installation of hinged ventilated facades Installation of hinged ventilated facades is now a very common phenomenon. This can be seen on a large residential high-rise building, where almost every tenth tenant has equipped the outer side of the wall of his apartment. And this is not at all surprising, because today it is easy to install it yourself or using

Manufacturers and prices

Today, the construction market has a sufficient number of manufacturers, each of which offers its own range of products.

If quality comes first for you, then you have to pay attention to the following manufacturers:

- Rockwool Venty Butts - the price of mineral wool is 450 rubles;

- Thermostack Vent Facade - the price of mineral wool is 350 rubles;

- Technovent - the price of mineral wool is 490 rubles;

- Isovent - the price of mineral wool is 475 rubles;

- Ecover - the price of mineral wool is 540 rubles;

- Styrofoam Knauf Them - price 782 rubles;

- Penoplex Comfort - price 1200 rubles.

Insulation for the facade plays a very important role, because in this way you can make the house warmer, and even improve its appearance. There should be no problems with the choice of thermal insulation material, because today the market is literally overflowing with a wide variety of heaters. The choice of the appropriate option should be made based on the design features and climate in your area.

The historical homeland of ventilated facades is Germany, in which, since the fifties of the last century, such technology has been developed on the basis of a metal frame and facing materials.

The procedure for carrying out installation work

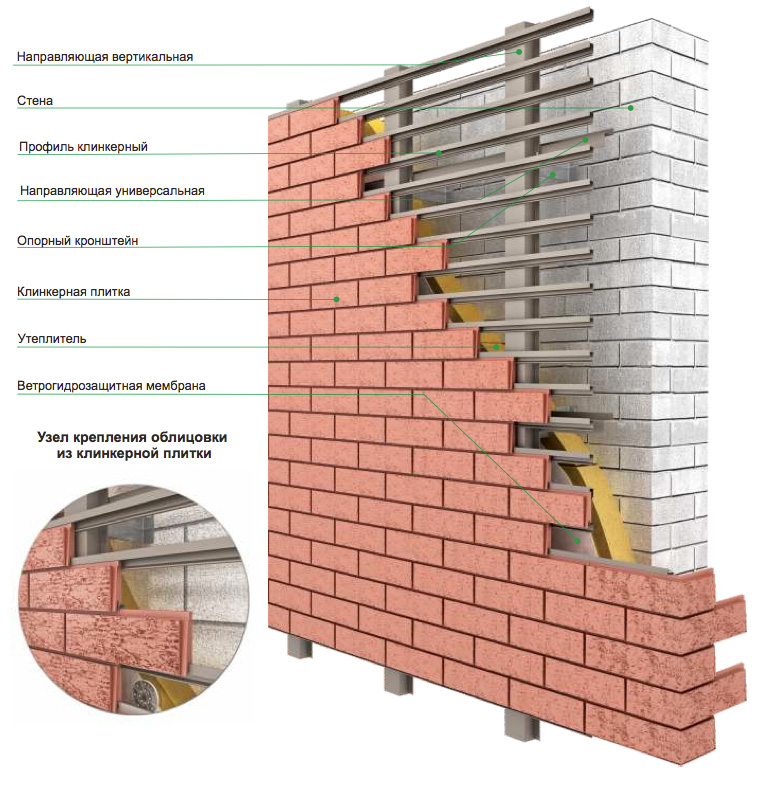

The technology of installation and insulation of ventilation facades is as follows:

- Preparatory work. At this stage, crumbling and fragile plaster is knocked down, if there is destroyed brickwork, it must be restored. The prepared wall is marked out, maintaining the standard distance between the brackets for fasteners - horizontally, the distance should be within 400-600 mm, vertically 800-1400 mm.

- Manufacture and installation of the frame of the crate for cladding. Frame elements are mounted with screws directly on the wall. The parameters of fasteners are determined at the stage of calculations. It should be borne in mind that it is forbidden to drill a hole for dowels in hollow bricks and building blocks using a puncher. After installation, the brackets are aligned into a single working plane.

- Laying heat and waterproofing. At the stage of thermal and waterproofing, the plates selected on the basis of thermal engineering calculations are attached with fungi or stickers, depending on the selected material. Laying starts from the bottom row and continues from the bottom up. When performing double thermal and waterproofing, after installing the insulation, a material is laid that protects the sheets from moisture - this layer is also attached using plate-type dowels.

- Installation of a ventilated facade system. L-shaped strips are installed on the mounting brackets with screws. After installation, the surface of each plank is leveled into a single surface. At the final stage, the cladding is fastened. Bones, aluminum panels, siding, porcelain stoneware, fiber cement and asbestos cement panels, natural stone, granite and so on can be used as a finishing material.

In general, the installation of a ventilated facade is a complex technological process, which often requires the involvement of special equipment. That is why the installation of facade systems should be entrusted to specialists.

A ventilated facade is a structure that provides thermal insulation and performs the function of a cladding.

Design features of a ventilated facade

The ventilated facade consists of thermal insulation, fixings and facing plates. The load-bearing basis of the facade are elements that provide fastening of the material for cladding.These include vertical and horizontal rails, brackets and other accessories. A space is formed between the thermal insulation and the facing material, the size of which depends on the length of the brackets. The insulation plate is tightly attached to the wall with brackets and dowels. The reliable load-bearing basis of the facade is usually made of stainless steel or aluminum.

The choice of insulation

Mineral wool insulation is used as thermal insulation, which can be installed in one or more layers. The choice of insulation should be determined by factors such as:

- load-bearing wall material;

- purpose of the building;

- climatic region.

The heat-insulating material must be fire-resistant and have a low coefficient of thermal conductivity, thereby ensuring effective heat saving. Insulation plates must be rigid, durable and elastic in order to prevent their geometry from being disturbed and to facilitate the installation process.

Especially for ventilated facades, TechnoNIKOL Corporation has developed a group of materials TECHNOVENT STANDARD and TECHNOVENT PROF. They are made using rocks of the basalt group.

"Pros" of ventilated facades

Ventilated facades protect the walls from the negative effects of the environment (precipitation, sunlight, etc.) After installing a hinged facade, there is a significant reduction in heat loss and energy consumption, and the microclimate in the room improves. A ventilated facade is also a profitable solution, because such a facade is not whimsical in maintenance and has been serving for decades. In addition to excellent technical characteristics, hinged facades have a beautiful stylish design.

How to make money on the installation of hinged ventilated facades

Bookmarked: 0

The business idea of mounting hinged ventilated facades is likely to be of interest to men, especially if their profession is close to this topic. There comes a time when you do not want to work for someone else's uncle, but there is a desire to work for yourself.

In fact, this business is very attractive.

- First, it's interesting.

- Secondly, you will have to invest only in the purchase of working tools. Everything else is at the expense of the customer. The entrepreneur is only required to cooperate with the wholesale base in order to receive discounts for the client on the purchase of material.

Benefits of a curtain wall installation business

- Low competition.

- Easy to install, even for a beginner.

- Fast payback.

- production mobility.

- There are no problems with the choice of material.

- Acceptable material prices.

- Large amount of work.

Leading in the demand market - stone panels.

How to install facades

The principle of operation is similar to covering the house with siding.

Before starting installation, it is necessary to prepare the surface.

- Check her condition. The wall must be level and solid.

- Remove drainpipes and other structures that may interfere with installation.

- Make sure that there are no electrical cables, gas pipelines, plumbing and other divorces in the wall.

Mounting technology

- Attach brackets with paronite gaskets to the wall.

- Attach the insulation (at the request of the customer) dowel - bolts.

- Protect the thermal insulation with a windproof membrane.

- Attach guide rails to the brackets: vertically and horizontally. Rails are usually made of galvanized profile.

- Close the structure with an external finish so that there is an air gap between the skin and the insulation.

In fact, there is a detailed instruction with formulas and tables, as well as the usual recommendations. Everything is very accessible.

Therefore, difficulties in mounting hinged ventilated facades should not arise.

For cladding, the choice is great: panels made of wood, natural stone, profiled sheet panels, and so on.

Pros and cons of hinged ventilated facades

In order for customers to be interested in the offer to perform the installation of hinged facades, the businessman himself must know their advantages in order to convey information to the customer.

pros

Facades provide warmth and dryness.

Soundproofing, which is important for the city.

Durability. They have a service life of up to 50 years.

Fast installation.

Minimum waste in the process. Cons

Minuses

This is the only negative, but it's worth it. Most customers are not deterred by the price.

When a novice entrepreneur receives his first order, it is important to do everything in good faith and with high quality. Before you start mounting hinged ventilated facades, you need to carefully consider every detail

The materials must also be of high quality. There is no room for error here. After all, you have to redo it, and this is a loss of finances and, consequently, the next orders. Reputation in business is everything. There will be no positive reviews, so there will be no profit. Eventually, things will burn out.

How to make money on the installation of hinged ventilated facades Learn about the benefits of a profitable business in the installation of hinged ventilated facades and the secrets of their installation.

Which basalt insulation is better for a ventilated facade

What basalt insulation should be used for a ventilated facade? Which manufacturer's products are of good quality at not the highest cost?

Here it is not so difficult to decide on the choice of the manufacturer of basalt wool. There are excellent foreign insulation manufacturers such as Rockwool and Paroc. I think these are the best manufacturers on the Russian market today. But our manufacturer does not stand still. Of ours, I would recommend TechnoNIKOL. Of the Russian suppliers of basalt wool, they are the undisputed leaders. Well, in order not to overpay, calculate everything. In the first layer, take less dense cotton, and in the second layer, more dense.

When choosing a suitable basalt insulation for a ventilated facade, you need to know what characteristics it should have. First, density. It should not be less than 50 kg/m3. If the material is below this density, then it will be much easier for it to pass heat. Experts recommend using basalt wool having a density of 80 kg / m3, with a thickness should not be less than 10 cm. This solution allows you to remove the accumulated condensate to the outside. Secondly, you need to choose a durable material. Water absorption should not exceed 1kg/m3, and thermal conductivity at a temperature of 283oK should not exceed 0.035 W/m*K.

When choosing the necessary material, it is worth considering its cost. TekhnoNIKOLevsky basalt insulation is considered the best material from domestic manufacturers. It costs from 700 rubles and more. From European brands, you can choose Rockwool, its cost is cheaper than domestic.

The choice of insulation for ventilated facades depends on several factors, the main of which is the density of the material. It must be large enough so that the plates can withstand the pressure of the wind.

You should also pay attention to the tensile strength, due to which the plates do not collapse

High-rise buildings are insulated with two types of insulator - on the upper floors, where air flows are stronger, they use material with a high density. The lower floors can be insulated with lower-density slabs - they are cheaper.

In systems of ventilated facades, only basalt insulation with the appropriate performance characteristics and manufacturer's permission for use in ventilated facades is used. The accompanying documentation gives recommendations on how to use the material - as an internal or external insulating layer. The choice of materials is also influenced by thermophysical calculations of the ventilated facade.

Popular basalt insulation materials include Technovent insulators from TechnoNikol, such as Technovent Standard, Technovent Optima, Technovent Prof. These are lightweight, durable, non-flammable materials that do not attract rodents. They do not absorb moisture, do not rot, do not lose their shape, but the vapor barrier will significantly extend the life of the material. They can be used with single-layer insulation and as an inner layer with two-layer insulation.

The most inexpensive insulation for ventilated facades is Technovent Standard with a density of 72-88 kg / cu. m.

The denser ones are Technovent Optima (81-99 kg/cu.m.) and Technovent Prof (90-100 kg/cu.m.). Dense materials can not be protected with a wind barrier film.

Isovent insulation (density 90-100 kg/cu.m.) produced by ZAO ISOROK has similar properties. The insulation fibers are additionally impregnated with water-repellent compounds, but manufacturers still recommend using additional wind-hydro-barrier protection.

It is also worth paying attention to the Izorok insulation (density 125 kg / m3)

It is not only a good thermal insulator, but also an excellent noise insulator. This semi-rigid material is additionally impregnated with water-repellent and dust-repellent compounds to extend the service life.

Which basalt insulation is better for a ventilated facade? Here it is not so difficult to decide on the choice of the manufacturer of basalt wool. There are excellent foreign insulation manufacturers such as Rockwool and Paroc. I think these are the best manufacturers for today ...

Dry ventilated facade with efficient insulation

A private house must be insulated so that its total heat loss does not exceed the established standards. The owner is interested in this in order to avoid serious extra cash costs. The design of the house should indicate the economically feasible insulation of all structures and other measures aimed at saving heat.

But if there is no project, then users can privately provide the house structures with sufficient thermal insulation.so that their resistance to heat transfer is not lower than the regulatory requirements. This is achieved mainly by using an effective insulation of sufficient thickness.

The question arises - how to effectively, reliably insulate the walls of the house so that they always remain dry? After all, as you know, at the dew point, steam leaving the house will condense ...

What gives the use of a ventilated facade

The most effective insulation scheme is a ventilated facade. Where the insulation is constantly ventilated by a stream of air that moves along the gap between it and the facade finish.

At the same time, the insulation remains dry and does not get wet when vapors condense, since the humidity is minimal and the dew point is very low.

The scheme achieves such advantages.

- Installation with dry processes only. Dismantling, alteration, simple replacement of a heater after the expiration date of its validity or replacement of front decorative panels is possible.

The minimum humidity of the wall and the insulation layer is ensured (dry construction), therefore, the materials have the longest service life and the highest heat-saving qualities.

Effectively prevents the impact on the load-bearing structures and the insulation of precipitation, their soaking.

The best passage of steam through the walls is provided, the insulation layer does not create a significant obstacle to the movement of steam and air penetration. The design remains breathable.

It is possible to arrange a dry ventilated facade on uneven walls, due to the flexibility of the insulation itself, without their costly leveling, which in some cases gives a very significant economic benefit.

Typical design of effective dry insulation

The thickness of the ventilation gap, for drying the insulation, is actually set by the thickness of the metal guides - 40 - 50 mm.

It is better to use a special suspension system made of corrosion-resistant materials designed for a ventilated facade system.

But it is possible to create a durable structure with the help of wooden beams dried and treated with antiseptics.

The first row of horizontal battens is attached directly to the wall. Then a vertical crate provides a ventilation gap of 40 mm. The disadvantage is the presence of cold bridges, a decrease in efficiency due to the presence of wood.

A more complicated and expensive option, devoid of these shortcomings, is a horizontal crate and a vertical crate for heaters, with more bars on top to create a ventilation gap.Scheme of a ventilated facade using wooden beams - a triple crate

Whether to make a crate from special metal elements, or from specially processed dry wood - the decision is rather based on economic feasibility.The economy option is to use conventional suspensions and SD profiles for partitions and suspension systems, provided that light external panels are used.

Heaters for ventilated facade

Mineral wool remained the only suitable insulation for the ventilated facade system, which has the highest vapor permeability and therefore provides effective drying of the wall.

But samples of wool with a density of up to 80 kg / m3 are easily blown through with air, as a result of which the efficiency of insulation drops sharply. Therefore, it is necessary to use either special slabs with a windproof coating in the system, or a two-layer laying - from below, a cheaper main layer of low-density cotton wool, from above - not blown and not weathered by micro-dust, expensive, but thin slabs.

Dry ventilated facade with efficient insulation It is necessary to make a ventilated facade so that the wall remains dry, and is also effectively insulated. The system has the best performance and ensures the safety of the wall if t

What is ventilated facades

A ventilated facade is a system of cladding materials that is attached to a monolithic ceiling or load-bearing wall layer using a frame made of galvanized steel, stainless steel or aluminum. The main feature of such a system is the gap between the wall and the cladding - air moves freely through it, which allows solving the problem of condensate in the structure.

For additional insulation of the building wall, a layer of insulation is included in the system - it must be non-hygroscopic

When insulating a ventilated facade, it is important to maintain a gap between the wall and the insulation of about 40 mm, so that air flows circulating between the facing material and the thermal insulation layer rid the latter of moisture. In general, the size of such a gap is standard, but in different countries the standards range from 20 to 50 mm.

The list of advantages of ventilated facades includes the following:

- Wide range of colors;

- High thermal insulation characteristics;

- The multilayer construction allows for good sound insulation, which is important for large cities;

- Natural ventilation, which saves the materials used and the building itself from high humidity and destruction;

- Timely disposal of condensate ensures the preservation of the properties of the insulation - wall insulation with a ventilated facade reduces heat loss during the cold period for the entire period of operation;

- Durability - the service life of such a structure is 50 years;

- fire safety;

- Operational installation, which can be done in any season of the year;

- Protection against overheating in hot weather;

- The design is repairable - partial damage can be repaired.

Do not forget about aesthetics - the facade, ennobled in this way, looks modern and attractive.

All these advantages are relevant only in cases where the ventilated facade is mounted in compliance with all installation rules.