Types of industrial ventilation systems

There are several types of industrial ventilation systems:

- General exchange systems are systems that are used for the entire room.

- Local ventilation systems are used for a specific area.

- Local systems are used to remove contaminants and harmful substances, vapors and gases, in places where they are emitted.

In addition, there are still such types of ventilation as: emergency, which accompanies certain technological operations.

For natural ventilation, the movement of air masses is driven by wind or gravity, and for mechanical ventilation, various devices are used: fans, etc. With natural ventilation of the production premises, air flows are used that spontaneously penetrate through various openings, leaks in windows and doors. Their extraction occurs through exhaust ducts. The performance of this type is highly dependent on the temperature difference between indoor and outdoor air, pressure drop, wind speed and direction. Deflectors are sometimes used as auxiliary devices for natural ventilation, and for better air exchange and mixing of air flows, the effect of aeration is often used in production workshops.

With a mechanical ventilation system, air exchange is carried out through air ducts or channels,. Depending on the direction of the air flow, mechanical ventilation can be supply and exhaust. Industrial exhaust ventilation is arranged in the upper part of the room, and supply - at a height of 1.5-1.8 m from the floor.

In some cases, a mixed type of ventilation is used, due to the large volume of air removed through natural exhaust openings, there is a need to use forced industrial ventilation.

In addition to natural and mechanical ventilation, some enterprises began to use a third type - a combined system. This happens if none of the types of ventilation individually can create an effective air exchange. For example: in the paint shop, along with, they also introduce a local one, which is installed in places where harmful substances are released, and prevents mixing of air flows, thereby increasing ventilation efficiency with minimal air circulation.

Methods for calculating artificial ventilation systems

the main goal

calculation of general exchange systems of artificial

ventilation - determine the amount

air to be supplied and

remove from the premises When calculating

ventilation in workshops, air exchange,

usually determined by calculation

specific data on the amount of harmful

emissions (heat, moisture, vapors, gases)

For workshops where

harmful substances are released, air exchange

determined by the amount of harmful gases,

vapors, dust that enter the working

zone, in order to dilute them with supply

air to the maximum allowable

concentrations:

(2.1)

where

U

- the amount of harmful emissions in the workshop,

mg/h;

To1,

— maximum permissible concentration

harmful emissions in the air of the shop, mg/m3,

k2

- concentration of harmful emissions in

supply air, mg/m3.

V

in accordance with SNiP k2

≤k1.

For

rooms where harmful emissions

absent (or the number of them

slightly) air supply (exhaust)

can be determined by the multiplicity

air exchange

(k)

- the ratio of the volume of ventilation

air L

(m3/h)

to the volume of the room Vp

(m3):

(2.2)

multiplicity

air exchange shows how many times

within an hour it is necessary to change the entire

air volume in a given room

creating normal air conditions

environment. Having determined the multiplicity from the reference book

air exchange at a known volume

rooms can calculate the volume

supply air or exhaust.

For rooms in

which do not contain harmful secretions

and excess heat and no need

in creating meteorological comfort

you can use the formula:

(2.3)

where

l

— minimal

air supply per worker

in accordance with sanitary standards

(with the volume of the room for one

operating, up to 20 m3

– 30m3/h,

a

with a volume of more than 20m3

— 20 m3/h);

n

- the number of employees in the room.

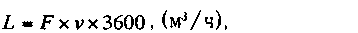

When calculating the local

exhaust ventilation air quantity,

removed by local suction (umbrella, panel,

cabinet) can be determined by the formula:

where

F

- cross-sectional area of the local hole

suction, m2;

v

- the speed of movement of the removed air

in this hole (taken from 0.5 to

1.7 m/s depending on toxicity and

volatility of gases and vapors).

natural and

artificial ventilation must meet

next sanitary and hygienic

requirements.

- create in

the working area of the premises corresponding

meteorological working conditions

(temperature, humidity and speed

air movement);

- fully

remove harmful gases, vapours,

dust and aerosols or dissolve them to

maximum allowable concentrations;

- not

bring polluted air into the room

outside or by suction from adjacent

premises;

- do not create

workplaces of drafts or harsh

cooling;

- to be available

for management and repair in the process

operation;

- not

create during operation

additional inconvenience (for example,

noise, vibration, rain, snow)

It should be taken into account

what about ventilation systems,

installed in fire and explosion hazardous

rooms are presented with a range of

additional requirements that

this section is not covered.

Conditioning

air

is the creation and automatic

maintaining indoor permanent

or changing according to the program certain

meteorological conditions, most

favorable for workers or

required for normal flow

technological process. Air conditioning

air can be full and incomplete.

Full air conditioning

provides for the regulation

temperature, humidity, mobility and

air quality and, in some cases,

the possibility of additional processing

(disinfection, aromatization,

ionization). With incomplete conditioning

only part of the parameters can be adjusted

air.

Conditioning

air is provided by air conditioners,

which are divided into central

and local. Central air conditioners

designed to serve large

for the size of the premises.

Types of industrial ventilation

Such natural ventilation of industrial premises is based on the natural draft of air, the appearance of which is influenced by the following factors:

- The difference between outdoor air temperature and indoor temperature (aeration).

- The difference in atmospheric pressure between the lower level in the room and the hood, which is mounted on the roof.

- Wind speed and pressure.

The organization of the work of natural ventilation of the premises will not require significant investments in equipment. Installation of natural ventilation is the simplest of the existing systems and does not require an electrical supply. Disadvantages - dependence on temperature, pressure, wind direction and speed.The exact calculation of the natural ventilation of industrial premises is carried out according to the formulas:

Efficient ventilation and air conditioning of industrial premises is calculated by the air exchange rate (L, m³ / h):

L = n ˣ S ˣ H

n is a multiple of the air exchange for a particular room. Usually for apartments and houses n=1, and for warehouses, retail or industrial space n=2.

S - area, m².

H - height, m.

Ventilation performance by the number of people in the room (L, m³ / h):

L = N ˣ Lnorms

, where:

N is the nominal number of visitors to the premises.

Lnorm - air consumption per person, m³ / h. For one person Lnorm = 20-60 m³/h.

4.2. natural ventilation

Natural

ventilation is provided by

room air temperature difference

and outside air (thermal head)

or the action of the wind (wind pressure).

Natural ventilation can be

unorganized and organized. At

unorganized ventilation unknown

volumes of air that enter and

are removed from the premises. Air exchange

depends on the direction and strength of the wind,

outside and inside temperatures

air. Organized Natural

ventilation is called aeration. For

aeration in the walls of the building make holes

for the intake of outside air, and in

top of the building set

special devices (lights) for

exhaust air removal. V

As a result, it is necessary to calculate

areas of supply and exhaust aeration

holes providing the desired

air exchange.

Energy Saving Recommendations

- The supply of supply air should be carried out in the working areas with a mandatory increase in temperature differences by increasing the temperature of the exhaust air itself.

- Excess heat must be absorbed by adjusting the cooling devices installed in the factory.

- Places in production where pollution of any nature is released should be equipped with special devices to capture these pollution.

- The use of recycling units allows heating the supply air.

- The coldness of the outside air can cool process equipment.

- Specific equipment that requires certain air parameters must be defined in local systems of a special type.

The role of air purification in industrial ventilation systems

Cleaning of polluted air plays a huge role in modern ventilation systems. It comes in several types:

- Gravity. As a rule, these are dust settling chambers, which are used in industries with strong dust formation. They are used to deposit the largest particles in the air.

- Inertial, dry type. They can be cyclonic and louvered. They differ in design and compactness, but they serve to purify the air from non-sticking dust.

- Inertial, wet type. Effectively remove dust from the air by humidifying it.

- fabric filters. They purify the air by accumulating it in a special fabric.

- Porous air filters tend to accumulate a large amount of contaminants from the air stream in the numerous pores of the filter element.

- Electrostatic precipitators purify the air from mechanical impurities by means of their electric charge, after which the impurities settle on one of the filter electrodes.

There are sorption-catalytic, acoustic, plasma-catalytic filters that are used to purify air in industrial ventilation systems.

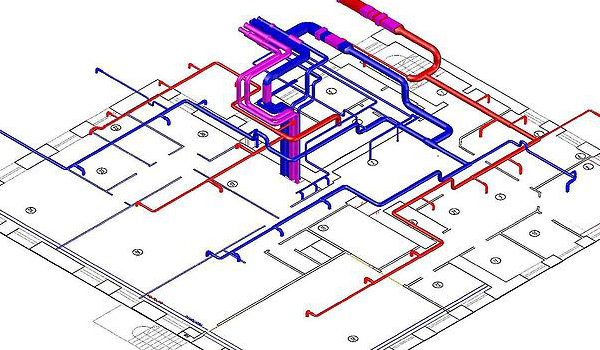

The main stages of industrial ventilation design

- Calculation of air circulation in each production room.

- The main task that the ventilation system must solve.

- Localization of emitted harmful substances and its maximum permissible values.

- Choice of systems of cleaning of air streams.

- Feasibility study of the proposed supply and exhaust equipment.

Designing consists of the following main stages:

- Preparation of technical specifications. The customer independently or with the help of specialists is engaged in its development. The terms of reference take into account many factors, such as: the layout of production facilities, the material from which the building is made, the thickness of the walls, the number and schedule of personnel, and some features of the technological process.

- Calculations made by a design engineer of industrial ventilation systems, guided by regulatory documents and existing standards. The calculations include values such as:

- Air exchange - this is how often the air in the room will be completely replaced with a new one. The main indicator of this value will be .

- Climatic parameters for a particular building. Calculations are made separately for the cold season, for the transition period and for the warm season. The customer of the project himself determines in those. task, what microclimatic indicators he would like to receive.

- Air ducts. Due to the calculation of air ducts, the optimal variant of the material from which they should be made, their sections and shapes is selected.

- The next design stage is the choice of equipment. This takes into account the economic justification for the feasibility of using a particular type of equipment, previously made calculations, features of the layout of the premises and the technological process.

- The final stage in the design of ventilation for an industrial facility is the preparation of drawings, diagrams, graphs and explanatory notes. Based on this, the design engineer draws up a feasibility study for the entire project.

Lecture

7. Ventilation

1.Ventilation

industrial premises

2.Purpose

and classification of ventilation systems

3.Natural

ventilation

4.Artificial

ventilation

Industrial premises ventilation project

Meteorological conditions in the working area of industrial premises of boiler houses should be taken according to the Sanitary Design Standards for Industrial Enterprises, based on the following categories of work according to severity:

light - in the premises of switchboards and laboratories;

heavy - in boiler rooms and ash rooms when operating solid fuel boilers with manual maintenance of combustion devices:

medium - in other rooms.

Table 10.2 When designing heating systems, the design air temperatures in the premises should be taken according to Table 10.2.

In rooms with heat emissions, heating should be provided only in cases where excess heat does not ensure the maintenance of air temperatures in the production area indicated in Table 10.2. At calculated outdoor temperatures of minus 15 ° C (parameters B) and below, the heat balance in the lower zone of the boiler room (up to 4 m high) should be additionally checked.

Air heating systems should be designed for industrial premises. In auxiliary premises, as well as in laboratories, switchboards and workshops, it is allowed to accept heating systems with local heating devices. The limiting temperature on the surface of heating devices in rooms where dust is possible, when installing boilers for working on coal and shale, should not exceed 130 ° C, for working on peat - 110 ° C. In these rooms, heating devices with a smooth surface should be provided, as a rule, registers from smooth pipes.

For rooms with obvious excess heat, natural ventilation should be provided.If it is impossible to provide the necessary air exchange due to natural ventilation, mechanically driven ventilation should be designed. Ventilation systems, methods of air supply and removal should be taken according to Table 10.2.

For boiler rooms, in the presence of permanent service personnel, working on gaseous fuel, it is necessary to provide for at least three air exchanges in 1 hour, without taking into account the air sucked into the furnaces of boilers for combustion. The design of exhaust fans installed in these boiler rooms should exclude the possibility of sparking.

When designing ventilation of boiler rooms, it is necessary to provide for the purification of air removed by aspiration plants (before being released into the atmosphere), in accordance with the Sanitary Standards for the Design of Industrial Enterprises.

For premises of liquid fuel pumping stations, tenfold air exchange per 1 hour should be provided. Air removal from these premises should be provided in the amount of 2 /3 from the bottom and 1 /3 from the upper zones of the total amount of air removed. In the premises of liquid fuel pumping stations with production facilities of category B, two supply and two exhaust ventilation units with a capacity of 100% each should be provided; it is allowed to use one supply and one exhaust unit with backup fans.

With a room height of less than 6 m, the air exchange rate should be increased at the rate of 25% for each meter of height reduction.

Air temperature in the working area of industrial premises, ventilation systems, methods of air supply and removal

Ventilation of industrial premises should solve two main tasks: to remove exhaust air and to supply fresh air. The first task is important, since the exhaust air can contain harmful substances in the form of gases, heavy impurities, as well as excess heat. The second task is determined by SNiP in order not to violate the technological process in production.

Using the emergency ventilation system

SNiP provides for such a design, where industrial ventilation is associated with emergency. Emergency ventilation is a completely independent type of installation, which is used to ensure safety at work. First of all, this applies to those industrial buildings and premises where the release of harmful gases is possible, as well as in explosive production.

Emergency ventilation system

Ventilation of industrial buildings of an emergency type can be used:

- All major ventilation systems with redundant fans. Such installations are usually designed for emergency air flow.

- If the main systems and the emergency one do not cope with the task, then backup fans are connected to the ventilation, which are available for industrial ventilation.

- Only an emergency system when the use of the main one is impractical or impossible for various reasons.

Emergency industrial ventilation is arranged only in such a way as to ensure the extraction of exhaust air. It is not performed as a supply air due to the avoidance of mixing fresh air with harmful gases, as well as due to the inadmissibility of the transfer of exhaust air from one room to another.

For example, ventilation of the battery room is necessary so that hydrogen, which is released during storage of batteries, does not mix with oxygen, forming an explosive mixture.