Node characteristics and features of work

According to the diagrams, it can be understood that the elevator in the system is needed to cool the superheated coolant. In some designs there is an elevator that can also heat water. Especially such a heating system is relevant in cold regions. The elevator in this system starts only when the cooled liquid is mixed with hot water coming from the supply pipe.

According to this scheme, it can be understood that the node significantly increases the efficiency of the entire heating system in the house. It works simultaneously as a circulation pump and a mixer. As for the cost, the node will cost quite cheaply, especially the option that works without electricity.

But any system has its drawbacks, the collector unit is no exception:

- Separate calculations are required for each element of the elevator.

- Compression drops should not exceed 0.8-2 bar.

- Inability to control high temperature.

1 What is a thermal energy metering unit

Thermal unit - a set of equipment, the installation of the project of which is provided in order to provide basic accounting and regulation of energy, the volume of the coolant, as well as the registration and control of its parameters.

Thermal energy metering unit

Heat energy metering unit - an automatic module, which is installed to the pipeline system to provide accounting data for the project of operation and regulation of heating resources.

1.1 Where are the heating units installed?

Installation of thermal units and their maintenance, as a rule, is carried out in typical apartment buildings, with communal heating systems.

In turn, heat energy metering units are installed in an apartment building to perform the following tasks:

- verification and regulation of the operation of the coolant and thermal energy;

- testing and regulation of hydraulic and heating systems;

- records of fluid data such as temperature, pressure and volume.

- the product of the monetary calculation of the consumer and the supplier of thermal energy, after the verification of the received data is carried out.

Installation of heat energy metering units

When implementing the installation of a heating equipment project, it should be taken into account that the consumption of resources supplied to the central heating in an apartment building incurs certain financial costs for users (in this case, residents of an apartment building).

The apartment building will be able to reduce costs, as well as maintain the performance of the unit built according to the previously designed scheme for a long time, if competent checks of accounting equipment and its maintenance are provided in a timely manner, including high-quality installation of equipment and pipelines.

Ventilation and air conditioning systems.

Clean air is the key to health, therefore, without modern and efficient ventilation and air conditioning systems, not a single residential or industrial facility can be put into operation.

The ventilation system is designed to supply fresh air, remove harmful impurities from it, which are constantly formed indoors. Such systems are:

- artificial and natural;

- exhaust and supply;

- monoblock and type-setting;

- local and public.

With regard to air conditioning, in this case, such functions as cleaning, cooling, heating, removing excess moisture, as well as ionizing the air in the room are considered. Conventionally, air conditioning systems are divided into:

- industrial;

- household.

Principle of operation

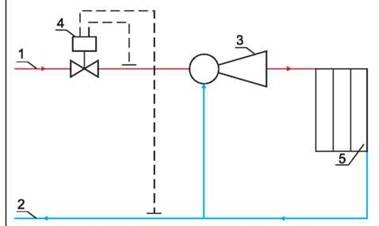

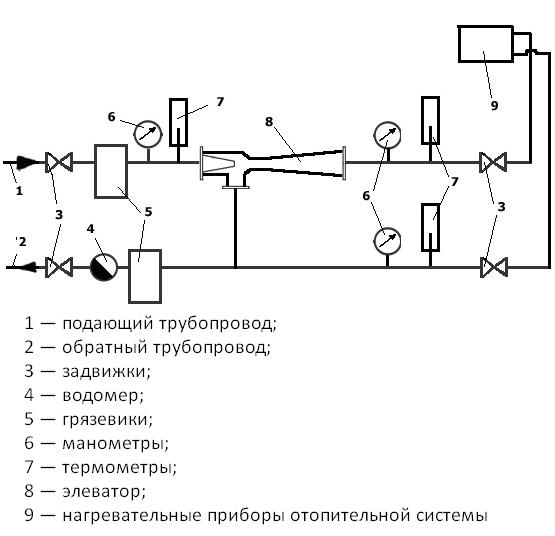

To understand how the node works, it is necessary to give an example.To do this, we will take a three-story house, since the elevator unit is used specifically in multi-storey buildings. The main part of the equipment that belongs to this system is located in the basement. The diagram below will help us better understand the work. We see two pipelines:

- Serve.

- Back.

Now you need to find on the diagram a thermal chamber through which water is sent to the basement. You can also notice the shut-off valves, which must necessarily stand at the entrance. The choice of fittings depends on the type of system. Gate valves are used for standard construction. But if we are talking about a complex system in a multi-storey building, then the masters recommend taking steel ball valves.

When connecting a thermal elevator unit, it is necessary to adhere to the norms. First of all, this concerns the temperature regimes in boiler rooms. During operation, the following indicators are allowed:

When the temperature of the liquid is in the range of 70-95°C, it begins to be evenly distributed throughout the system due to the operation of the collector. If the temperature exceeds 95 ° C, the elevator unit starts to work to lower it, since hot water can damage the equipment in the house, as well as the valves. That is why this type of construction is used in multi-storey buildings - it controls the temperature automatically.

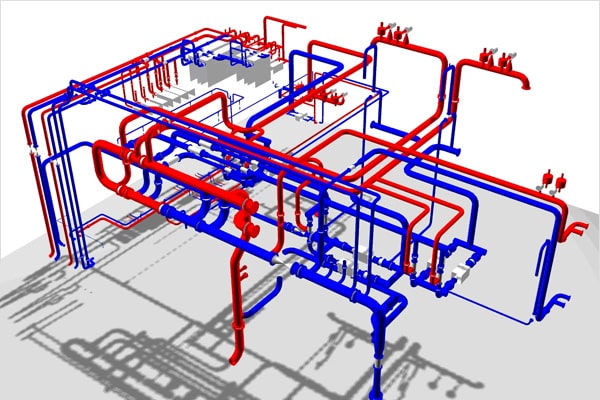

Central heating of apartment buildings

Through the main pipelines, the coolant from the central boiler house is supplied to the heat unit of the apartment building and then distributed to the apartments. In this case, additional adjustment of the degree of hot water supply is carried out directly at the heat point, for which circular pumps are used. This method of supplying the coolant to the end consumer is called independent (for more details: “Centralized heating is both pros and cons“).

In addition, dependent heating systems are used in apartment buildings. In this case, the coolant is transported to apartment batteries without additional distribution directly from the CHP. At the same time, the water temperature is independent of whether it is supplied through a distribution point or directly to consumers.

Possible malfunctions

A frequent malfunction can be called a mechanical failure of the elevator. This may occur due to an increase in the diameter of the nozzle, defects in the valves or clogging of the sump. It is quite simple to understand that the elevator is out of order - there are noticeable temperature drops of the heat carrier after and before passing through the elevator. If the temperature is low, then the device is simply clogged. In case of large differences, repair of the elevator is required. In any case, when a malfunction occurs, diagnostics are required.

The elevator nozzle becomes clogged quite often, especially in places where the water contains a lot of additives. This element can be dismantled and cleaned. In the case when the nozzle diameter has increased, an adjustment or complete replacement of this element is necessary.

Other malfunctions include overheating of devices, leaks and other defects inherent in pipelines. As for the sump, the degree of clogging can be determined by the indicators of pressure gauges. If the pressure increases after the sump, then the element needs to be checked.

The procedure for concluding a heat supply agreement

Resource supply of housing and communal services > Heat supply > 808 resolution. Organization of heat supply of the Russian Federation

The procedure for concluding a heat supply agreement

35. To conclude a heat supply contract with a single heat supply organization, the applicant sends an application to a single heat supply organization for concluding a heat supply contract containing the following information:

36.The following documents are attached to the application for concluding a heat supply contract:

37. As documents confirming the connection of the heat-consuming installations of the applicant in the prescribed manner to the heat supply system, the issued acts on connection, connection, technical specifications with a mark on their execution, work permits of heat supply organizations are used. In the event that the applicant loses documents confirming the connection of heat-consuming installations to the heat supply system, and the unified heat supply organization does not have them, the specified organization is obliged, within 10 working days from the date of the relevant application to it by the applicant, independently at the expense of the applicant, check whether the heat-consuming installations are properly connected to the heat supply system and draw up an appropriate act on the performance of work and the coordination of the connection. At the same time, the amount of compensation levied from the applicant for the costs of a single heat supply organization for checking the availability of proper connection cannot exceed 500 rubles per 1 object. In the event that such heat-consuming installations are connected to networks that do not belong on the right of ownership or on other legal grounds to a single heat supply organization, verification of the proper connection is carried out by authorized representatives of the heat supply organization in agreement with the heat grid organization to whose networks the applicant's heat-consuming installations are connected, or with the owner of the heat source. energy, to which the consumer's heat-consuming installations are connected, with the drawing up of an act on the delimitation of the balance sheet in accordance with the Rules for connecting to heat supply systems, approved by Decree of the Government of the Russian Federation of April 16, 2012 No. 307. 38. The consumer has the right not less than 90 days before expiration of the term of the heat supply contract, send an application for changing the declared volume of consumption of heat energy and (or) heat carrier. The change (revision) of thermal loads is carried out in the manner determined by the authorized federal executive body. 39. If the application does not contain the information or documents specified in paragraphs 35 and 36 of these Rules, the unified heat supply organization is obliged to send the applicant a proposal to submit the missing information and (or) documents within 3 working days from the date of receipt of such documents. The required information and documents must be submitted within 10 working days. The date of receipt of the application is the date of submission of information and documents in full. 40. The unified heat supply organization is obliged to send 2 copies of the signed draft agreement to the applicant within 10 working days from the date of receipt of a properly executed application and the necessary documents. The applicant, within 10 working days from the date of receipt of the draft agreement, is obliged to sign the agreement and send 1 copy of the agreement to a single heat supply organization. 41. If the applicant fails to provide the information or documents specified in paragraphs 35 and 36 of these Rules, in the manner prescribed by paragraph 39 of these Rules, or if the application does not comply with the conditions for connection to heat networks, the unified heat supply organization is obliged, after 30 days from the date of sending the applicant a proposal for providing the necessary information and documents in writing, notify the applicant of the refusal to conclude a heat supply contract, indicating the reasons for such refusal. 42. The contract for the heat supply of a consumer citizen with a single heat supply organization is considered concluded from the date of connection of his heat-consuming installation to the heat supply system. 43.A heat supply contract concluded for a certain period is considered extended for the same period and on the same terms, if one month before the expiration of its validity period, neither party declares its termination or the conclusion of the contract on other terms.

_________________________________________

Types of house systems

Apartment buildings with a full range of utilities have several types of provision. Each of them is responsible for the transfer of a specific resource. According to the types of transferred resources, they can be divided into:

- Mechanical.

- Electrical.

- Sanitary.

Mechanical engineering equipment

In most cases, these amenities are represented by elevator facilities and a garbage chute.

The elevator economy includes all elevators, passenger and cargo, located in each entrance of the house. Each elevator consists of an elevator shaft, an engine room, a cabin and floor-by-floor entry-exit mechanisms.

The garbage chute is represented by a transport channel with floor loading hatches and a garbage receiving chamber. These items of equipment are common.

Electrical

Electrical elements can be divided into common house and apartment.

Common house contains:

Switchboard. It contains:

- input-distribution device (ASU), which includes a common power supply cable, and cables diverge for each entrance

- electricity metering unit

- protective and safety equipment (machines).

- Cable lines running from the switchboard to the floor switchboards.

- Distribution boards on each floor with protective and safety switches (RCD, automatic devices) placed in them for each apartment or other premises in an apartment building and individual meters.

- Lighting of common areas.

The apartments consist of:

- Electrical wiring laid in the interior of each consumer.

- Wiring accessories (sockets, switches, etc.)

Sanitary

Plumbing equipment in apartment buildings and residential buildings consists of water supply, sewerage, ventilation and heating networks. Of these, one fully relates to the common house - this is ventilation.

Ventilation in most residential buildings is represented only by the exhaust component, which includes ventilation ducts and end devices - deflectors installed on each channel above the roof.

Water pipes. The public part of this network includes:

- entrance to the building

- metering unit

- a network of distribution pipelines (bottling) along the technical underground of the building to risers and to a water heating point (boiler)

- cold and hot water risers

All shut-off and control valves installed on these communications also belong to the general house.

The residential component includes:

- individual counters

- pipes laid inside consumer premises

- disassembly points (faucets, taps, etc.)

Sewerage. Common elements:

- pipelines in the technical underground of the building

- sewer lines.

The individual part includes the internal sewerage pipes in each apartment.

Heating. Are common:

- thermal unit

- thermal energy meter

- device for heating hot water supply (boiler)

- branching pipelines along the technical underground (bottling)

- risers and internal pipelines

Heating devices belong to individual ones - radiators, heated towel rails.

Intra-house engineering systems are an important component of every home. They are responsible for the uninterrupted provision of its residents with all kinds of amenities.

The physical condition and the degree of their deterioration directly affects the cost of maintaining the house and the comfort of living for its inhabitants.

Why do you need a heating unit

The heating point is located at the entrance of the heating main to the house. Its main purpose is to change the parameters of the coolant.To put it more clearly, the thermal unit reduces the temperature and pressure of the coolant before it enters your radiator or convector. This is necessary not only so that you do not get burned from touching the heating device, but also to extend the life of all equipment of the heating system

This is especially important if the heating inside the house is diluted with polypropylene or metal-plastic pipes. There are regulated modes of operation of thermal units:

These figures show the maximum and minimum temperature of the coolant in the heating main.

Also, according to modern requirements, a heat meter must be installed at each thermal unit. Now let's move on to the device of thermal units.

Approval for operation

When a thermal unit is admitted to operation, it is checked that the serial number of the metering device, which is indicated in its passport, and the measurement range of the established parameters of the heat meter correspond to the range of measured readings, as well as the presence of seals and the quality of installation.

The operation of the heating unit is prohibited in the following situations:

- The presence of tie-ins in pipelines that are not provided for by the project documentation.

- The operation of the meter is outside the accuracy standards.

- The presence of mechanical damage on the device and its elements.

- Breaking the seals on the device.

- Unauthorized intervention in the operation of the heating unit.

What does the shape of your nose say about your personality? Many experts believe that looking at the nose can tell a lot about a person's personality.

Therefore, at the first meeting, pay attention to the nose is unfamiliar

Why do you need a tiny pocket on jeans? Everyone knows that there is a tiny pocket on jeans, but few have thought about why it might be needed. Interestingly, it was originally a place for Mt.

Contrary to all stereotypes: a girl with a rare genetic disorder conquers the fashion world This girl's name is Melanie Gaidos, and she burst into the fashion world quickly, shocking, inspiring and destroying stupid stereotypes.

10 Mysterious Photos That Will Shock Long before the advent of the Internet and the masters of Photoshop, the vast majority of photos taken were genuine. Sometimes the pictures got really unbelievable.

15 Symptoms of Cancer Women Most Often Ignore Many of the signs of cancer are similar to those of other diseases or conditions, so they are often ignored.

Pay attention to your body. If you notice

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don't worry about the shape and length of their hair. It seems that youth was created for experiments on appearance and bold curls. However, already

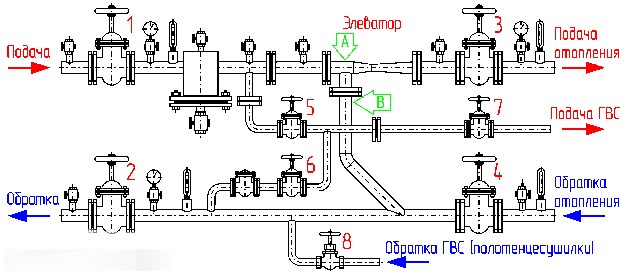

How is the thermal unit arranged

In general, the technical device of each heat point is designed separately, depending on the specific requirements of the customer. There are several basic schemes for the execution of heat points. Let's look at them in turn.

Thermal unit based on the elevator.

The scheme of a thermal point based on an elevator unit is the simplest and cheapest. Its main drawback is the inability to regulate the temperature of the coolant in the pipes. This causes inconvenience for the end consumer and a large overconsumption of thermal energy in case of thaws during the heating season. Let's look at the figure below and understand how this circuit works:

In addition to what is mentioned above, a pressure reduction reducer can be included in the thermal unit. It is installed at the feed in front of the elevator. The elevator is the main part of this scheme, in which the cooled coolant from the "return" is mixed with the hot coolant from the "supply". The principle of operation of the elevator is based on the creation of a vacuum at its outlet.As a result of this rarefaction, the coolant pressure in the elevator is less than the coolant pressure in the "return" and mixing occurs.

Thermal unit based on a heat exchanger.

A heat point connected through a special heat exchanger allows you to separate the heat carrier from the heating main from the heat carrier inside the house. Separation of heat carriers allows its preparation with the help of special additives and filtration. With this scheme, there are ample opportunities in regulating the pressure and temperature of the coolant inside the house. This reduces heating costs. In order to have a visual representation of this design, look at the figure below.

The mixing of the coolant in such systems is done using thermostatic valves. In such heating systems, in principle, aluminum heating radiators can be used, but they will last for a long time only if the quality of the coolant is good. If the PH of the coolant goes beyond the limits approved by the manufacturer, then the service life of aluminum radiators can be greatly reduced. You cannot control the quality of the coolant, so it is better to play it safe and install bimetallic or cast iron radiators.

Domestic hot water can be connected in this way via a heat exchanger. This offers the same benefits in terms of hot water temperature and pressure control. It is worth saying that unscrupulous management companies can deceive consumers by lowering the temperature of hot water by a couple of degrees. For the consumer, this is almost not noticeable, but on the scale of the house it allows you to save tens of thousands of rubles a month.

Schema parsing

As you understand, the assembly consists of filters, an elevator, instrumentation and fittings. If you plan to independently engage in the installation of this system, then you should understand the scheme. A suitable example would be a high-rise building, in the basement of which there is always an elevator unit.

In the diagram, the elements of the system are marked with numbers:

1, 2 - these numbers indicate the supply and return pipelines that are installed in the heating plant.

3.4 - supply and return pipelines installed in the heating system of the building (in our case, this is a multi-storey building).

6 - this figure indicates coarse filters, which are also known as mud collectors.

The standard composition of this heating system includes control devices, mud collectors, elevators and valves. Depending on the design and purpose, additional elements may be added to the node.

Interesting! Today, in multi-storey and apartment buildings, you can find elevator units that are equipped with an electric drive. Such an upgrade is needed in order to regulate the diameter of the nozzle. Due to the electric drive, it is possible to adjust the heat carrier.

It is worth saying that every year utilities are becoming more expensive, this also applies to private houses. In this regard, system manufacturers supply them with devices aimed at saving energy. For example, now the circuit may contain flow and pressure regulators, circulation pumps, pipe protection and water treatment elements, as well as automation aimed at maintaining a comfortable mode.

Another variant of the thermal elevator node scheme for a multi-storey building.

Also, in modern systems, a thermal energy metering unit can be installed. From the name you can understand that he is responsible for accounting for heat consumption in the house. If this device is missing, then the savings will not be visible. Most owners of private houses and apartments seek to install meters for electricity and water, because they have to pay much less.

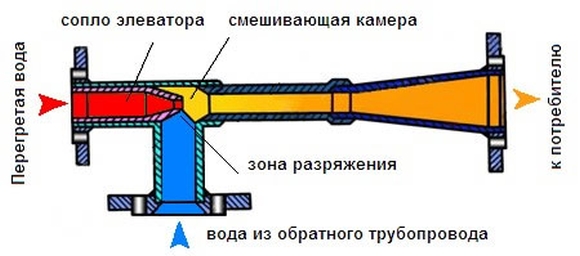

Principle of operation and design description

The most obvious solution is to reduce the temperature by mixing the cooled coolant from the return pipe.This task is performed by the elevator temperature unit.

The design consists of 3 nozzles:

- Input. It receives hot water from a common line with an elevated temperature.

- Back. Connected to return line.

- mixing. It supplies the coolant with a normal temperature to the heating devices of the premises.

To ensure autonomous operation, an injector is provided in the design. It is necessary to reduce pressure to normal, but, in addition, it performs a very important function.

Superheated water enters the injector nozzle and enters the mixing zone at high speed. This creates a vacuum (a zone of reduced pressure), which ensures the flow of cooled coolant from the return pipe.

The resulting pressure in the elevator thermal unit allows you to create a constant flow rate. This to some extent facilitates the work of water pumps and contributes to the creation of the same temperature regime for all consumers, regardless of the order of connection to the heating system.

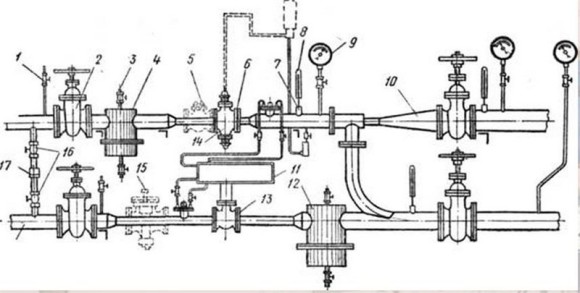

Regulation methods

An important parameter in the operation of the elevator unit is the regulation of the supply of superheated coolant. Depending on external factors, the water temperature in the return pipe may vary. This is affected by the number of users currently connected, the time of year, and the condition of the building.

To ensure optimal temperature conditions, the elevator unit must be equipped with temperature sensors and pressure reading devices. Each such set must be installed on all three connecting pipes.

One of the most common options for tying the elevator assembly is shown below.

1 - three-way valve. 2 - valve, 3 - plug valve, 4, 12 - mud traps, 5 - check valve, 6 - throttle washer, 7 - fitting, 8 - thermometer, 9 - pressure gauge, 10 - elevator, 11 - heat meter, 13 - water meter, 14 - water flow regulator, 15 - steam regulator, 16 - valves, 17 - bypass.

This circuit works in manual mode. The design of the elevator provides a control valve, which reduces (increases) the flow of hot water.

The advantages of this system are:

- Its operation is possible without connecting the power supply.

- Low design and installation cost.

- Reliability.

Flaws:

- There is no automatic mode of operation.

- Low efficiency, since the temperature of the coolant at the inlet can change at any time, which will immediately affect the heating of residential premises.

But at present, there are automatic systems that allow maintaining the desired temperature without human intervention.

For this, distribution valves with an electric drive and a circular pump are used. The electric drive is connected to the temperature sensor and when it changes, it shifts the valve gate. The pump is also necessary to ensure the circulation of the coolant in the system.

The procedure for installing the metering unit

Before installing a thermal energy metering unit, it is important to conduct a survey of the facility and develop project documentation. Specialists who design heating systems make all the necessary calculations, select instrumentation, equipment and a suitable heat meter

After the development of project documentation, it is necessary to obtain approval from the organization that supplies thermal energy. This is required by the current rules for accounting for thermal energy and design standards.

Only after agreement can you safely install thermal metering units. Installation consists of insertion of locking devices, modules into pipelines and electrical work.Electrical installation work is completed by connecting sensors, flow meters to the calculator and then starting the calculator to conduct heat energy metering.

After that, the thermal energy metering device is adjusted, which consists in checking the operability of the system and programming the calculator, and then the facility is handed over to the coordinating parties for commercial accounting, which is performed by a special commission represented by the heat supply company. It is worth noting that such a metering unit should function for some time, which varies from 72 hours to 7 days for different organizations.

In order to combine several metering nodes into a single dispatching network, it will be necessary to organize remote removal and monitoring of metering information from heat meters.

Possible problems

The thermal system of a house is a complex mechanism. Some breakdowns and malfunctions are inevitable. But most often problems arise in the heating unit, namely, elevator breakdowns. Causes of a mechanical nature: defects in shut-off equipment, clogged filters. Because of this, there is a temperature difference in the pipes before and after passing through the elevator. If the difference is not large, then the problem is not serious: you just need to clean the elevator. Otherwise, repairs are needed.

Other problems of the heating unit include an increase in the permissible temperature of the measuring equipment, the occurrence of leaks in the pipes. When filters become clogged, pressure increases in pipes.

Important! In the event of any malfunction, it is necessary to diagnose the entire heating system. As already mentioned in the article, elevator nodes are an obsolete technology.

Gradually, in apartment buildings, they are being replaced by automatic heating units that do not require constant human control and all indicators are regulated by themselves.

As already mentioned in the article, elevator nodes are an obsolete technology. Gradually, in apartment buildings they are being replaced by automatic heating units, which do not require constant monitoring by a person and regulate all indicators themselves.

The disadvantage of such heating systems is the high cost and, like any automated device, it runs on electricity.

However, devices are built into the scheme of single-circuit nodes that make it possible to regulate the temperature and pressure in the incoming coolant. Thus, it allows people to save money when paying for communal services.

What is a heat exchanger and how does it work?

Greetings to everyone who reads my blog! Today I want to offer you another article that is devoted to heating. In this article, I will tell you about a strange place in the basement of your house, which is called a heating point (or heat node). The article aims to give you a general idea of what a thermal node is, how it works and why it is needed. Let's start with the most fundamental of these questions.

2 The device and scheme of the thermal unit

The heating unit, the installation of which is provided according to a preliminary design in the utility systems of apartment buildings, is made from a whole range of equipment and devices. Such a device is capable of performing from one to several functions, such as:

- Measurement of the amount and mass of thermal energy, its pressure, temperature of the liquid circulating through the pipeline and operation time.

- Accumulation and storage of this information on local media.

- Display it on metering devices.

Based on the data obtained, the operation of heating equipment in apartment buildings is checked, its regulation and maintenance are carried out.

The metering device is such a device as a counter, the circuit of which consists of:

- Resistance thermocouple.

- Heat calculator.

- Primary flow converter.

Depending on which model of the primary converter was installed (with vortex, ultrasonic, electromagnetic or tachometric measurement options), the heat meter can include filters and pressure sensors.

Schematic diagram of the thermal unit

The thermal energy metering unit consists of the following elements:

- Stop valves.

- Heat meter.

- Thermal converter.

- Gryazevik.

- flow meter.

- Thermal sensor of the return pipeline.

- Additional equipment.

The installation of a heat metering equipment scheme in an apartment building, in turn, implies the following fundamental requirements

- the need to install the metering equipment scheme exclusively at the interface between the balance sheet belonging to pipelines in places closest to the main valves of the heating source;

- a ban on organizing a project for the selection of coolant for personal needs in the public heating system;

- regulation of average hourly and average daily parameters of the coolant are made according to the readings of accounting equipment;

- metering devices are mounted on the return pipelines of the mains and placed up to the point of connection of the inlet pipeline.

In order to carry out competent regulation and control of the described equipment, competent services carry out a competent check of their installation and functioning.

2.1 Who installs and maintains the heating unit in apartment buildings?

In multi-apartment buildings, central heating (TS) and hot water supply (DHW) operate, the main pipeline for the supply of which is located in the basements, equipping it with shutoff valves. The latter allows you to disconnect the intra-house heating supply system from the external network.

The thermal unit itself is equipped with mud collectors, valves, instrumentation and has such a device as an elevator in its design. Of these, constant maintenance, as a rule, requires a sump, which is a steel pipe with a diameter of DN \u003d 159-200 mm and is necessary to collect dirt coming from the main pipeline to protect pipelines and heating appliances from pollution.

Installation of a thermal unit, its maintenance, including cleaning - the work of locksmiths serving a residential building, fulfilling the requirements of an organization providing housing and communal services.