Chemical compositions

How to flush the heat exchanger of a gas boiler? The safest option is citric acid. Industrial products for washing the gas boiler heat exchanger - Cillit, DETEX, Sanaks.

Hydrochloric acid is more effective. But its use is more dangerous for both the user and the system. Concentrated acid can destroy the internal protective layer of the heat exchanger, as well as increase the brittleness of the metal.

External processing of contaminated parts is carried out by special compositions to remove soot and carbon deposits. In extreme cases, you can use household detergents.

Video about flushing the heat exchanger of a gas boiler.

Periodic flushing of the gas boiler heat exchanger is a basic requirement for the maintenance of heating equipment. Cleaning significantly affects the smooth operation of the entire system and greatly extends the life of the home heating device. When should I flush and can I do it myself?

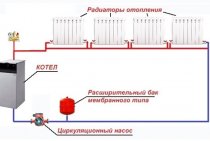

During operation of the gas boiler, a layer of scale forms, which prevents the necessary cooling of the heat exchanger. In this case, the circulation pump takes on a large load. Therefore, without flushing the heat exchanger, the heating unit may fail.

At home, cleaning should be done every two years. If the water in the house is hard enough, then it is recommended to reduce the interval between flushing.

The first signs for the user that the heat exchanger needs to be flushed are:

- prolonged heating of the gas boiler;

- decrease in heat output;

- partial heating of the system;

- the presence of extraneous sounds during the operation of the heater;

- significant increase in gas consumption.

When scale appears in double-circuit boilers, the water may not completely warm up or the pressure level may decrease.

It is advisable to avoid the combination of such symptoms. But if there are warning signs, flushing should be done immediately.

In addition to the internal cleaning of the heat exchanger, external cleaning of its body from soot is used. Socialized services are engaged in the elimination of scale and pollution in the gas boiler system. Their services are not cheap. Therefore, sometimes you can flush the heat exchanger yourself.

Activation of the gas boiler

Necessary tools: multimeter, pliers, flat-head screwdriver, alcohol liquid, open-end wrenches - 9, 10, 12. Troubleshooting involves, first of all, revision of the thermocouple, solenoid valve. Having previously found the draft sensor on the gas duct, it is necessary to remove the two terminals, and tightly connect them with pliers in order to close each other, while simultaneously attempting to ignite.

If, nevertheless, the ignition problem remains, then the cause of the problem is probably in the traction sensor, which needs to be checked in this way - the contacts are firmly fixed, the integrity of the paronite gaskets, and there is a gap between the hole in the gas pipeline and the sensor plane. It is necessary to examine the rating of the sensor, if there is a temperature discrepancy, it will not open. The presence of oxidation on the contacts, even imperceptible, is not allowed. Then the traction sensor is checked for the degree of resistance using a tester. The sensor must be replaced if the resistance is deviating, that is, not minimal. You should find an identical serviceable sensor with similar temperature performance.

In the case when no failures were found with the sensor, then it is time to wipe the contacts and terminals of the circuit using alcohol, then dry and tighten them. Then the traction sensor returns to its place and the ignition attempt is repeated again.

It is necessary to monitor the draft of the burner, after each ignition attempt, bringing the palm to the sensor and noting the absence of heat flow. The problem must be fixed if there is a flow.

Igniter in a gas boiler

The next possible cause of failure may be the combination of the traction breaker and the sensor contacts. The manipulations with the terminals are repeated again, the measurement of resistance, the norm of which is up to 3 ohms. Next, the open-end wrench “9” is taken, the nut is unscrewed, which fastens the thermocouple to the draft breaker. This breaker includes 2 components - a brass sleeve and a plastic insert, the removal of which allows you to completely unscrew the part.

If the ignition is not successful in the pilot, the problem may lie in the thermocouple, due to the fact that malfunctions in the operation of the solenoid valve rarely occur. Further, for diagnostic purposes, the thermocouple is connected to the solenoid valve and secured with a key. The thermocouple is not hopeless and amenable to error correction, for example, it is possible to solder a disconnected contact, instead of an irrational replacement of a part.

Don't forget to inspect the dielectric pad and replace the thermocouple, note the location of the tip. Recall that cleaning procedures are carried out with an alcohol-containing liquid and high-quality drying is carried out before assembly.

From this article you will learn what problems can arise in the automation of gas boilers, why it is not possible to ignite the igniter, because of which the boiler can turn off for no reason, and most importantly, we will figure out what actions need to be taken to diagnose and eliminate this malfunction.

The owners of non-volatile gas boilers are probably familiar with the situation when, for some reason, it is not possible to ignite the boiler, or a lot of time is spent on ignition. In this case, the problem lies in the automation of the boiler.

Today, in domestic and imported gas equipment, the EUROSIT 630 gas valve is most often used. It is he who performs the functions of maintaining the set temperature of the coolant and, in the event of an emergency, completely shuts off the gas supply to the burners. Further start-up of boilers with such automation is possible only manually. However, not always the reason for the emergency shutdown of the boiler is a real accident.

Let's try to understand this using the example of the Zhytomyr-3 boiler. Of the automation, it provides protection against the loss of the flame on the igniter and violation of traction.

Note:

All gas hazardous work must be carried out exclusively by representatives of specialized organizations that have the appropriate permits. Therefore, this article is provided for informational purposes only. Also, this article will help to control the work of the master and, possibly, save you from the need to purchase unnecessary spare parts.

Let's decide what we will call the ignition of the igniter. The EUROSIT 630 valve control knob allows you to switch the boiler to three main modes:

- disabled;

- ignition;

- temperature control (1–7).

To ignite the pilot burner (igniter), it is necessary to turn the control knob to the “ignition” (spark) position, press it and use the piezo ignition button to ignite the pilot burner. Next, the handle is held for a few seconds (no more than 30) and released. The igniter should continue to burn. This is what we will call the ignition of the igniter. If the igniter goes out, you need to repeat the procedure a few more times. If this does not help, you need to look for a malfunction.

At the moment of ignition of the igniter, the flame heats up the thermocouple, which in turn generates EMF (approximately 25 mV for serviceable SIT thermocouples), which flows through the circuit of the automation sensor (sensors) to the solenoid valve.

By pressing the handle of the gas valve, we manually open the solenoid valve, supplying gas to the igniter, which, in the event of correct operation of the equipment, is held by the EMF generated by the thermocouple and remains in the open position after releasing the handle. The thermocouple itself performs the function of protection against loss of flame on the igniter. The sensors in the circuit are normally closed and, when triggered, open their contacts, ensuring a complete shutdown of the boiler.

Combustion products and their cause

- soot;

- resin;

- tar.

The reasons for the appearance of these substances are the following important points:

- Causes of soot:

- there is not enough oxygen for the combustion process;

- fuel combustion temperature is too low.

- Factors affecting the appearance of resin:

- low-quality fuel is used;

- the fuel material has a high degree of moisture;

- the boiler operates at a low temperature;

- too much fuel is loaded into the furnace.

- Tar appears in the following cases:

- weak injection of air flow into the combustion chamber of the pyrolysis boiler;

- incorrect design of the unit;

- low chimney.

As you can see, the main reasons for the appearance of harmful substances are poor fuel and the technical aspects of the organization of the combustion process.

Experts advise: use only high quality fuel - otherwise the wear of the boiler will increase rapidly.

The situation with Zhytomyr

This brand is famous for its devices with piezo ignition. For an example of cleaning the burner, the Zhytomyr 3 model equipped with the EURO SIT technology is used.

The following list of tools is required for the operation:

- Screwdriver. A flat tip is a must.

- Open-end wrenches.

- Ordinary brush and its analogues for cleaning metal products.

- Yorshik.

After blocking the gas with a key, the screw fixing the boiler door is removed. It is taken out in its entirety. So the core of the unit becomes open.

The main burner is concentrated in its lower zone. For its extraction and subsequent purification, it is required:

- Disconnect the cable from which the piezoelectric element and electric ignition work.

- Use the key to remove the thermocouple with its clamp from the valve.

- Mark with a marker the distance of immersion of the nozzle into the burner itself. So it will be easier to return it to the correct position.

- Unscrew the nut securing the valve with the burner. Communication goes through a copper tube.

- Carry out the same manipulations with the ignition electrode.

- Using a screwdriver, remove the two fixing nuts of the other burner (pilot). There is a pad underneath. If it is damaged or deformed, replace it.

- Remove the nozzle from the burner. If the process is difficult, gently tap around this part with a wrench.

To dismantle the main burner, the screw connecting it to the boiler body is released. Then it is taken out. To do this, you need to take hold of its lower part and the copper tube and pull it sharply out of the valve.

A screw is loosened in it, fixing the distance of entry of the nozzle part.

For the cleansing itself, a brush and a brush are used. Carbon deposits are carefully removed.

A vacuum cleaner is used to clean the holes. All work affects both external and internal components.

This algorithm is also suitable for the procedure with the burner of Dani devices of the AOGV series, for example -11.5; 23.2 and 29.

You can do the same with many similar units: Aton AOGV 16-EM, ZhMZ-AOGV 17, etc.

Injectors also need to be cleaned. The deposit from the upper side is eliminated with a brush. To clean the holes, a wire or a thin needle is used.

After that, all the details are assembled in the reverse algorithm.

Rules for using a gas boiler

Consider how to properly use a gas boiler.

Ignition instructions

One of the components of the design of gas boilers, in which they differ from each other, is the ignition system. Therefore, when starting boilers of various types, there may be certain subtleties.Before putting the device into operation, it is necessary to study the operating instructions. How the ignition sequence looks like this:

1. Visual inspection of the system for leaks. To do this, set the thermostat to the maximum. In this case, automatic switching takes place.

2. When performing this operation, the boiler must be connected to the mains. After it starts to work, a slight noise will be heard and after filling the heat carrier system, the automatic ignition of the system will work and the boiler will return to the set operating modes.

How to turn off the boiler

Self-diagnosis

The operation of gas equipment will be greatly simplified if it has a self-diagnosis system. Most manufacturers have been installing such systems on their products for quite some time. Error messages are displayed on the built-in monitor. For some manufacturers, error A7 indicates a malfunction of the temperature sensor. Self-diagnosis of gas equipment simplifies its operation. The decoding of the codes that are displayed on the monitor is usually given in the instruction manual.

Frost protection

One of the key rules for the safe operation of gas equipment is to guarantee the presence of a minimum temperature of the working medium, which will not allow it to freeze. If the water poured into the heating system freezes, this will lead to irreparable consequences, in particular, a radiator rupture.

In most models in use today, constant monitoring of the state of the coolant. They provide frost protection, one of the components is a circulation pump, which is turned on to ensure the forced movement of water (coolant) through the system. As a rule, it turns on automatically when the water reaches a temperature of 10 degrees. If, due to certain reasons, the temperature drops even lower, then in addition to the pump, an auxiliary heater is turned on, heating the water to a predetermined level, for example, 18 degrees.

What to do if there are malfunctions

Even during the correct operation of the boiler equipment, certain problems can occur. In some boilers, the following interruptions may occur:

- boiler overheating;

- temperature sensor failed;

- during operation, the boiler is too noisy.

As a rule, some breakdowns can be caused by violations of operating modes, factory defects, a pressure drop in the gas pipeline, a voltage drop in the mains, errors made during the installation of a gas boiler.

Some owners of gas appliances try to solve the problems on their own, but it is more expedient to call specialists from a service organization.

General safety rules

Manufacturers of gas heating equipment pay much attention to its safety, despite this, equipment of this class can be a source of danger.

The Fire Department of the Ministry of Emergency Situations does not get tired of constantly talking about precautionary measures, in particular, it is unacceptable to purchase gas boiler equipment from companies that do not have the appropriate license. The package must include a manual or instruction manual

Installation of equipment and its commissioning can only be employees of the relevant organizations. Such equipment must be checked for technical condition.As a rule, this is done once a year.

It is unacceptable to store items in the boiler room that are not related to the operation or maintenance of the installed equipment. And yet, the upper limit of heating the coolant should not exceed 90 degrees.

flushing

How to clean the heat exchanger of a gas boiler from scale with your own hands? With a small amount of plaque inside, you can do with manual washing using a solution of citric acid.

With a thick layer of scale, a flushing unit will be required, which will circulate the detergent for several hours. For this purpose, a 10-liter tank with a pump is suitable (you can use a circulation pump from the circuit). Two hoses from the pump are connected to two pipes of the heat exchanger.

There are three cleaning methods:

- mechanical;

- chemical;

- hydrodynamic.

In the first case, a brush, scraper, vacuum cleaner can be used to remove plaque. Heat exchanger parts are pre-soaked in solutions of cleaning agents.

During chemical treatment, an acid wash solution is pumped into the system using a booster and driven through a heat exchanger for several hours. Acidic solutions remove iron and carbonate deposits well. At the end of cleaning, the agent is drained and a neutralizing agent is poured.

The hydrodynamic method is the injection of water with abrasives into the system under pressure. Thus, the internal surfaces are cleaned mechanically, but the cleaning efficiency is higher than with manual processing. Flushing can be performed without dismantling the system, but it is quite expensive. When cleaning yourself, you need to monitor the pressure in the circuits to avoid rupture of the heat exchanger.

Connection nuances and verification

Connect the thermoelectric converter to the measuring device using a compensation cable. To minimize the measurement error as much as possible, the cores of this wire are made of the same material as the sensor itself.

Check the functionality of the thermocouple as follows:

- one end of the device is connected to a multimeter;

- the other end is manually heated with a lighter or gas burner.

To check the performance of the thermocouple - one end of the device is connected to a multimeter

To check the performance of the thermocouple - one end of the device is connected to a multimeter

If the device is in good condition, this is evidenced by the presence of a voltage in the region of 50 mV.

Working with AOGV

It starts when the gas supply is blocked - the corresponding valve closes. And this is a general principle for such work with any boilers and columns.

How to clean the burner of a gas boiler AOGV? After shutting off the gas, this element is removed from its position. The burner has a nozzle

It is carefully unscrewed and carefully cleaned with a brush. The burner itself is cleaned by blowing using a special pump

Then the nozzle and burner are returned to their place.

These are general criteria. And the details are presented on the following two models.

First. AOGV 11.6-3. It is a reliable and practical device.

But after a certain operational period, it is thoroughly cleaned. The process goes like this:

Removing the burner block

To do this, the pallet of the apparatus is rotated, and three tubes are disconnected from the automation unit: contact, gas and thermocouples.

Carefully unscrew the nuts located on the fittings of the automation mechanism.

The paronite gasket on the main gas pipe is removed and its condition is studied. If it is damaged, it needs to be replaced.

The designated pallet is taken out through the groove, which is as close as possible to the tubes

Along with it, the casing is also pulled out. Fixing the lower part of the pallet, direct it towards yourself and remove the remaining holders (two pieces) from engagement.

This whole knot falls to the floor.

The main burner is being studied and cleaned. The igniter nozzle is examined.

The wick and thermocouple are unscrewed.

A box-shaped casing is separated from the pilot burner.This clears the way to the nozzle. If it is brass and there is a coating on it, it can be removed with fine-grained sandpaper.

Nozzle cleaning. For this, a thin copper wire and a blowing method under strong pressure are used. The second action is carried out by a special pump from the side where the tube is connected to the tee.

The same sandpaper very carefully cleans the bend of the thermocouple tube.

After this work, all the details are assembled in the reverse algorithm. Gently, avoiding distortions, lift this block as a whole. The burner must be inside the housing, and the igniter and thermocouple must not touch the flange of the casing.

From the side of the tubes, the entire assembly should be pushed towards itself with a slight downward slope. The opposite side of the pallet should rise.

Then feed it forward and synchronously put on a pair of distant holds. They should be on the flanging of the casing. The near hook is a cut groove. After it enters there, the entire pallet rotates in the opposite direction to the clockwise movement. The gas pipe must be positioned only under its branch pipe of the automation unit.

Next, it is tested how well the gaskets fit, and all the tubes return to their places. The wrench tightens the nuts on two tubes: igniter and gas.

Before reassembling the thermocouple tube, its contact areas are carefully but carefully cleaned. The nut is finger-tight.

The final stage is to check the tightness of all connections for potential leakage. In their absence, the boiler turns on. If available, these places are covered with sealant, the nuts are tightened tighter.

The second model is AOGV-23.2-1 Zhukovsky.

It works like this:

- The nut is unscrewed so that the gas pipe passes.

- The angle, igniter and thermocouple are unscrewed.

- All burners in the kit stretch outward, move out to the side towards the user. If there is difficulty with their movement, loosen and unscrew the studs with pliers. Clean all jets and other components.

- Burner disassembly. To do this, the studs are unscrewed 4 pieces on both sides.

- The slotted plates are removed from the top of the burners, then the springs. Every detail is thoroughly cleaned.

- Assemble all elements in reverse order.

After reassembly, a tightness test is arranged, it is studied how tightly the burners adjoin the body.

Other models

In practice, the cleaning of burners follows the same principles. The differences are in their removal and reassembly.

The following examples are provided:

For example, in the Helios AOGV 4 parapet apparatus, Eurosvit 360 automation and burners of European brands Bray and Polidoro are installed.

A set of burners is removed following the example of the Zhytomyr process. A pump is used to clean the nozzle, hard brushes are used to clean the surfaces.

The Conord line stands out in particular.

The automation options here are:

- AGU-T-M (Russia),

- Eurosvit (Italy),

- Honeywell (USA).

The most popular is the second variation:

It includes a sectional burner, Polidoro tubes, igniter, thermocouple, gas valve, temperature indicator and wires.

A similar system is in the Lemax Premium 12.5 model.

Only the burner here is a microtorch. The mechanism is very easy to remove by removing the top cover and lightly unscrewing the fixing bolts.

Its analogues are also found in Siberia models.

Ecological burners "Vorgas" are used here.

The company "Beretta" does not lag behind in this regard. Her Novella Maxima 108 N RAI and Mynute Boiler models stand out here.

Automation "Honeywell" is as follows:

She has a similar principle of working with the Eurosvit system. The differences are in the materials of some components.

It is often found in wall modifications, for example, in Baksi Fortech 24

It also has an ecological burner that does not leave combustion products.

No less popular device is Ariston ALTEAS X 24 FF NG.

Many Daewoo models also function with similar automation. For example - DGB 200 MSC.

Whatever model and brand you have, carefully follow the suggested instructions for removing and reassembling the burner assembly. Clean it thoroughly with the right products 1-2 times a year. Serve other machines as well. And then your boiler will work properly for a long period.

Causes and consequences of clogging

Energy dependent are divided in turn into:

- processing gas;

- electrical installations;

- solid fuel and liquid fuel equipment;

- combined models.

Volatile boilers can turn off for a number of reasons:

- surges and surges in power lines

- lack of electricity

- failure of factory settings.

Often used in homes: AOGV, Zhukovsky boiler, gas "Hearth", Lemax, Signal, Conord.

Do-it-yourself furnace for working out: drawing, scheme of work. Read here.

Connection to the city water supply network: documents, prices:

Mechanical ones can work intermittently due to wind flow entering the chimney. In addition, due to insufficient oxygen, the flame may go out.

You should pay attention to the hood (for cheaper models it is not always present)

When the chimney is contaminated, modern devices have an alert system that will notify you of problems and the need for cleaning.

How to check it

The safety of your home is a working thermocouple sensor. The thermocouple needs to be checked and adjusted several times a year. To do this, invite a wizard who will make a safe and accurate analysis of the device.

When checking thermocouple readings, consider the measurement quality of the device itself by systematically checking its operation.

Causes of incorrect operation of the thermocouple:

- incorrectly carried out soldering of two metal rods;

- the presence of electrical noise;

- you smell gas, there is a leak;

- thermoelectricity is inhomogeneous.

To resolve these issues, during device installation, you should:

- choose a thermocouple with a thick and large wire;

- avoid temperature fluctuations;

- prevent tension and vibration of the metal wire;

- use a sensor that has an operating temperature spread.

You need to check the health of the thermocouple by following the step-by-step instructions.

- The thermocouple has two ends. When checking, one of them must be heated with a flame from the igniter, and the second - with the help of a nut, fasten to the thread of the valve (electromagnetic).

- The next step is to separate it from the boiler. Then you need to provide a stable flame. For this purpose, a gas burner is also used. But experts advise using a candle flame.

- The tip of the device is immersed in the flame, it should be about 1 cm above the flame. Here you need to remember that the fire heats the device almost to half, so it is better to hold it by the tip.

- Next, a tester is used that determines millivolts. It is connected to the output contact and to the body of the thermocouple itself.

- If the thermocouple is OK, then 30 seconds after heating, the result will be from 17 to 25 mV. But if this indicator does not exceed the minimum threshold, then this means that it is faulty.

You can find out how to replace a thermocouple on a gas stove below.

The thermocouple for a gas boiler is a thermoelectric converter for automatic control and monitoring systems for gas equipment. The device serves as the main element of gas control protection and is designed to provide the most efficient shutdown of the gas supply in case the flame goes out.

Cleaning methods

Cleaning is carried out in two ways: mechanical and chemical

mechanical cleaning

The method of cleaning is imperfect and involves mechanical action.Soot should be carefully removed so as not to damage the inner surface of the boiler and parts, which in the future can lead to metal corrosion. Often the tools that come with the boiler are brushes, brushes and scrapers. It is also possible to use air cleaning, when warm air is supplied under pressure.

Chemical cleaning

It is recommended to apply parts cleaners in PPE (personal protective equipment), rubber-based gloves are usually used, so it will be possible to protect the skin from interaction with harmful substances. Chemicals clean not only soot, but also metal, which can later lead to its destruction. This method is best used on minor pollution and small areas of pollution.

Hydrodynamic cleaning

Hydrodynamic cleaning or how to clean soot from a diesel boiler.

It is used in boilers with a small thickness of pollution, as well as when speed of execution is required. Equipment for such washing consists of:

- pump and

- containers with high pressure water.

Thanks to this cleaning, soot and soot are removed quite quickly, but this method is applicable only to specialists, it is not recommended at home.

Booster cleaning

The procedure for flushing the heat exchanger with a booster (using the example of cleaning the Zhukovsky boiler from soot):

- First you need to disconnect the pipes from the heating system.

- Next, connect a booster hose to one of them to supply the reagent.

- We connect the second pipe to the second end of the hose. Through it, the spent reagent will be removed. Thus, the system is closed and the reagent will circulate through the pipes.

- After cleaning, the solution must be drained from the tube.

- Rinse the heat exchanger itself with sufficient water.

Booster - apparatus for chemical cleaning. Thanks to him, the reagents circulate autonomously.

During such cleaning, it is recommended to change the reagent several times, as the old one gradually reduces its properties. This method is most often carried out by specialists.

An effective way to descale

To carry out the highest quality cleaning of equipment, you can use a modern device - a booster. It will effectively solve the problem of how to flush a gas boiler from limescale.

What does the booster include:

- circulation pump;

- capacity for loading reagents;

- electrical heating part.

The booster functions as follows:

- the reagent is heated in a special container (in order to increase its cleaning properties);

- the circulation pump injects the heated reagent into the coil;

- chemicals circulate through the heat exchanger and clean the walls;

- the spent reagent with dirt is poured out.

The heat exchanger must be cleaned regularly, at least once a year. However, this procedure can be repeated more often if the quality of the coolant is very low. If ordinary water from the water supply is poured into the system, then it is very simple to determine this: follow how quickly scale forms on the kettle. Hard water suffers from this deficiency.

How to clean the AOGV boiler

For this operation, you will need a regular plastic bottle brush. It can be purchased at a hardware store, it is great for cleaning vertical channels. Tie it with electrical tape to a wooden stick so that you can easily go through the channels along their entire height. In order not to breed excess dirt in the boiler room, take everything that can be transferred to the yard for cleaning.

- Start cleaning from the upper plane of the heat exchanger, clean and sweep down all the soot.

- Then comes the turn of cleaning the channels. Soot will move away from the walls quite easily if it has not yet had time to harden, otherwise some effort will have to be made.

- After completing the cleaning process of the boiler itself, proceed to the removed components and parts.Clean the top cover of the heat exchanger. After it, remove soot deposits on the top cover of the boiler itself and from the hood.

- Last, brush off the soot attacking from above from the burner block with a brush, the burner itself is already clean.

Immediately lightly clean the tube with fine sandpaper. This completes the process of cleaning the boiler and its parts. Proceed to the reassembly of the AOGV boiler.