Use of the safety valve

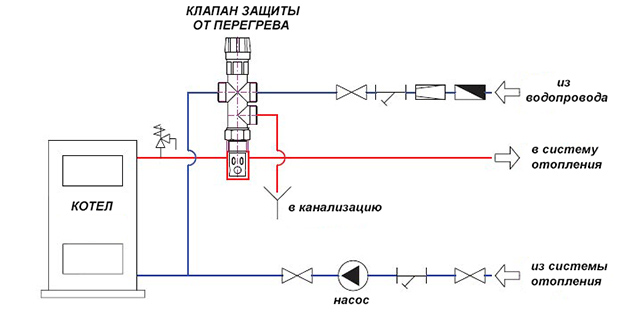

This is not the same as a safety valve. The latter simply relieves pressure in the system, but does not cool it. Another thing is the boiler overheating protection valve, which takes hot water from the system, and instead supplies cold water from the water supply. The device is non-volatile, connected to the supply and return lines, water supply and sewerage.

At a coolant temperature above 105 ºС, the valve opens and, due to the pressure in the water supply system of 2-5 bar, hot water is forced out of the heat generator jacket and cold pipelines, after which it goes into the sewer. How the solid fuel boiler protection valve is connected is shown in the diagram:

The disadvantage of this method of protection is that it is unsuitable for systems filled with antifreeze liquid. In addition, the scheme is not applicable in conditions where there is no centralized water supply, because along with a power outage, the water supply from a well or pool will also stop.

Chimney Requirements

To determine what characteristics the manufacturer himself claims, you need to read the instructions, because they give specific data, what is the minimum pipe cross-section needed, height, temperature conditions - these factors in a particular case are fundamental and you need to focus on them. As a rule, the manufacturer's instructions are in the instructions writes which chimney is better for a solid fuel boiler and what technical parameters need to be taken into account. The above characteristics, such as the height and length of the chimney, will allow you to choose a reliable, and most importantly, functional channel from the point of view of this particular model.

Consider the diameter of the chimney for the solid fuel channel, because not every channel will be able to remove the generated amount of gas in a certain time, and the accumulated cinder, gases can enter the room through leaky joints and cracks.

Technological requirements

The following technical requirements must be observed:

- A special area should be provided to disperse the smoke. It is a vertical pipe installed behind the branch pipe of a solid fuel boiler. The accelerating section is made one meter high.

- The chimney is installed only vertically. A deviation of no more than 30 degrees is allowed.

- Bends are prohibited.

- The length is very important (3 - 6 meters).

- Three horizontal sections are allowed. Moreover, the length of each should not exceed half a meter.

- The elevation of the head above the roof must exceed 100 cm.

- Fastening the pipe to the wall is carried out in increments of 1.5 meters.

- To create a sealed joint, the pipes are liberally lubricated with a heat-resistant sealant.

To get the perfect draft, it is necessary that the design of the chimney has a minimum number of turns. The best is considered a flat pipe.

The chimney can be installed inside or outside the building. For the first option, it is necessary to protect the pipe so that it does not come into contact with combustible materials. A special metal screen is used, installed at the place where the pipe passes through the ceiling. The chimney must be located at a distance of more than 25 cm from the wall.

External structures look much safer. They are much easier to maintain. Masters consider this method the most preferable.

Causes of overheating

The only reason for overheating is that the boiler produces more heat than is consumed by the heating system. But if everything was fine before, but now the boiler has overheated, then the problem is not that the boiler is very powerful, but the problem lies elsewhere.

It is possible that you just have a clogged dirt filter in front of the circulation pump.In this case, you need to unscrew it and clean it and the problem will be solved. With such a problem, your return line will be cold.

There is an option that the circulation pump just broke. With such a problem, your return line will also be cold. Change the pump.

But the most common problem is overheating as a result of a power outage. Everything is perfect with you - a clean filter, a serviceable pump, but it simply cannot work. And there is overheating. You can solve the problem by extinguishing the boiler or pulling out the burning fuel from the boiler furnace - but this is far from the best option. The best option is to make the heating system insensitive to power outages - make it gravity-fed or install an uninterruptible power supply.

Watch the video with the occurrence of overheating of the boiler when the power supply is turned off.

And here is a video with a way to solve the problem of overheating of the boiler and heating system.

A real boiler repair specialist is hard to find

Therefore, it is important to understand them on your own, because the master is really not always required and many problems can be fixed by yourself. Consider a list of boiler malfunctions, which covers all possible breakdowns as much as possible.

The article is designed for a non-specialist, but an ordinary person who can eliminate such problems.

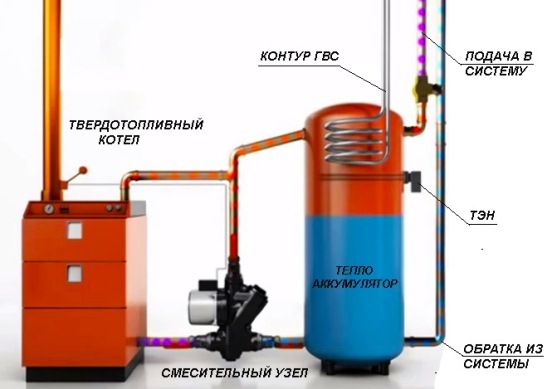

Scheme with a heat accumulator

In a number of EU countries, rules have been introduced, according to which schemes for connecting solid fuel boilers to the heating system must necessarily include a heat accumulator. Without it, the operation of such heaters is simply prohibited. The reason is the high content of carbon monoxide (CO) in emissions during the restriction of oxygen supply to the furnace to reduce the intensity of combustion.

With normal air access, harmless carbon dioxide (CO2) is formed, so the furnace must operate at full capacity, giving energy to the heat accumulator. Then the CO content will not exceed environmental standards. So far, there are no such requirements in the post-Soviet space, respectively, we continue to block the access of air in order to achieve slow smoldering of wood, for example, in a long-burning boiler.

Heat accumulators are commercially available as a finished product, although many craftsmen make them themselves. By and large, this is a tank covered with a layer of thermal insulation. In the factory version, it can have a built-in DHW circuit and a heating element for heating water. This solution allows you to accumulate heat from a wood-burning boiler, and at times of its downtime, provide heating for the house for some time. The connection diagram of the boiler with a heat accumulator is shown in the figure:

Note. In the scheme, instead of a mixing unit consisting of several elements, a ready-made device is installed that performs the same functions - LADDOMAT 21.

What are the ways to protect heating equipment from overheating

Manufacturing companies are trying, in order to increase the consumer attractiveness of their products, to include any guarantees of its safety in the technical passport of boiler equipment. The uninitiated consumer has no idea about the means of protecting the heating boiler from boiling.

There are currently the following ways to ensure the protection of solid fuel units used for autonomous heating systems. The effectiveness of each method is explained by the operating conditions of boiler equipment, and the design features of the units.

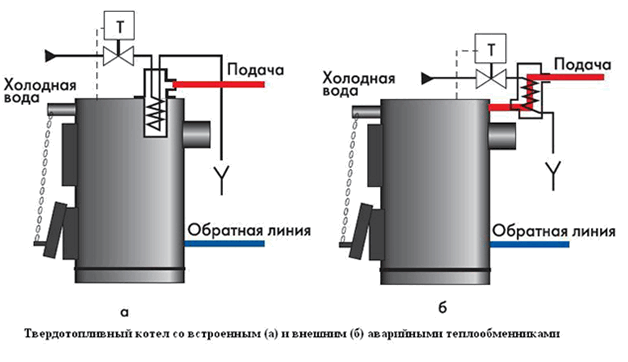

In most cases, in the data sheet for the heater, manufacturers recommend using tap water for cooling. In some cases, solid fuel boilers are equipped with built-in additional heat exchangers. There are models of boilers with remote heat exchangers. A safety valve is used to prevent overheating.The safety valve is designed only to relieve excessive pressure in the system, while the safety valve opens the access of tap water when the boiler overheats.

Exceeding the coolant temperature of 100 0C creates an overpressure that opens the valve. Under the action of tap water, which is supplied under a pressure of 2-5 bar, hot water is forced out of the circuit by cold water.

The first aspect that causes controversy about tap water cooling is the lack of electricity to run the pump. The expansion tank does not have enough water to cool the boiler.

The second aspect that this method of cooling dismisses is associated with the use of antifreeze as a coolant. In the event of an emergency, up to 150 liters of antifreeze will go down the drain along with the incoming cold water. Is this protection worth it?

The presence of a UPS will make it possible to maintain the operation of a circulating pump in a critical situation, with the help of which the coolant will evenly diverge through the pipeline without having time to overheat. As long as the battery capacity is sufficient, the uninterruptible power supply guarantees the operation of the pump. During this time, the boiler should not have time to heat up to critical parameters, the automation will work, starting the water through the spare, emergency circuit.

Another way out of a critical situation would be to install an emergency circuit in the piping of a solid fuel unit. The shutdown of the pump can be duplicated by the operation of a spare circuit with natural circulation of the coolant. The role of the emergency circuit is not to provide heating for residential premises, but only to be able to remove excess heat energy in an emergency.

Such a scheme for organizing the protection of the heating unit from overheating is reliable, simple and convenient in operation. You will not need any special funds for its equipment and installation. The only conditions for such protection to work are:

- the presence of an expansion tank or storage tank in the system;

- the use of a check valve only petal type;

- the pipes of the second circuit must be of a larger diameter than the conventional heating circuit.

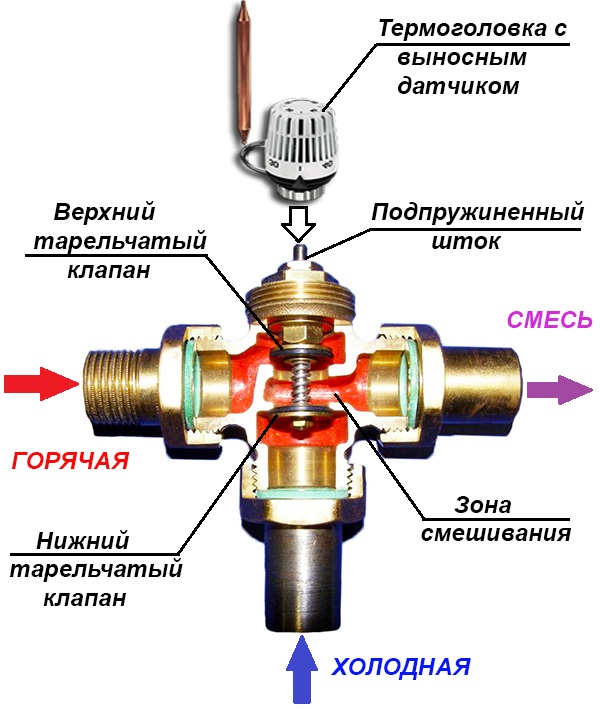

How a thermostatic control valve works

The thermostatic valve is installed on the supply in front of the bypass section (section of the pipeline) connecting the supply and return of the boiler in close proximity to the boiler. In this case, a small coolant circulation circuit is formed. The thermoflask, as mentioned above, is installed on the return pipeline in close proximity to the boiler.

At the time of boiler start-up, the coolant has a minimum temperature, the working fluid in the thermoflask occupies a minimum volume, there is no pressure on the thermal head rod, and the valve passes the coolant only in one direction of circulation in a small circle.

As the coolant heats up, the volume of the working fluid in the thermoflask increases, the thermal head begins to put pressure on the valve stem, passing the cold coolant to the boiler, and the heated coolant into the common circulation circuit.

As a result of mixing cold water, the return temperature decreases, which means that the volume of the working fluid in the thermoflask decreases, which leads to a decrease in the pressure of the thermal head on the valve stem. This, in turn, leads to the cessation of the supply of cold water to the small circulation circuit.

The process continues until the entire coolant is heated to the required temperature. After that, the valve blocks the movement of the coolant along the small circulation circuit, and the entire coolant begins to move along the large heating circle.

The mixing thermostatic valve works in the same way as a control valve, but it is not installed on the supply pipe, but on the return pipe.The valve is located in front of the bypass, which connects the supply and return and forms a small circle of coolant circulation. The thermostatic bulb is fixed in the same place - on the section of the return pipeline in close proximity to the heating boiler.

While the coolant is cold, the valve passes it only in a small circle. As the coolant heats up, the thermal head begins to put pressure on the valve stem, passing part of the heated coolant into the common circulation circuit of the boiler.

As you can see, the scheme is extremely simple, but at the same time effective and reliable.

The operation of the thermostatic valve and thermal head does not require electrical energy, both devices are non-volatile. No additional devices or controllers are needed either. It takes 15 minutes to heat the coolant circulating in a small circle, while heating the entire coolant in the boiler can take several hours.

This means that using a thermostatic valve, the duration of condensate formation in a solid fuel boiler is reduced by several times, and with it, the time for the destructive effect of acids on the boiler is reduced.

To protect the solid fuel boiler from condensate, it is necessary to correctly piping it using a thermostatic valve and creating a small coolant circulation circuit.

When buying and installing a solid fuel boiler, it is imperative to take into account the features of its operation, namely, the high probability of overheating in emergency situations, which can result in a serious accident and even destruction of the water jacket of the unit (explosion). Also, considerable harm can be caused by the formation of condensate on the walls of the combustion chamber, which happens under certain operating modes. To eliminate such troubles, protection of the solid fuel boiler from overheating and condensate should be provided, which will be discussed in our article.

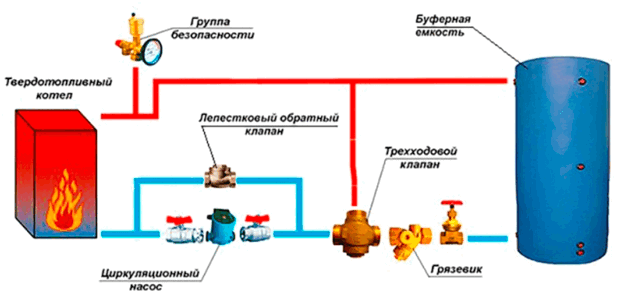

The basic scheme of piping a solid fuel boiler

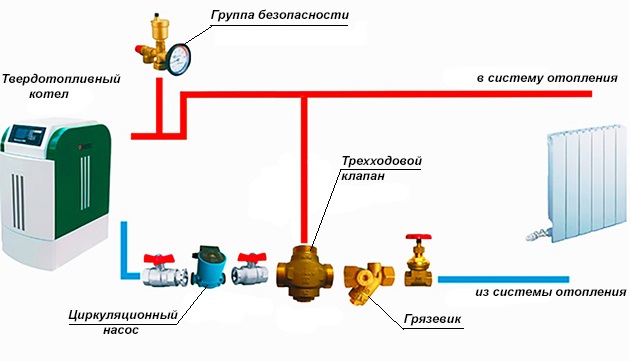

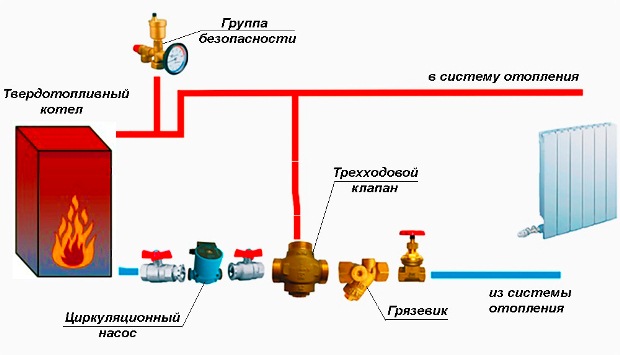

For a better understanding of the processes that occur during the operation of the heat generator, we will show its piping in the figure, and then we will analyze the purpose of each element. In the event that the heating unit is the only source of heat in the house, it is recommended to use the following basic scheme to connect it:

Note. The basic scheme, where there is a small boiler circuit and a three-way valve, shown in the figure, is mandatory for use when working together with other types of heat generators.

So, the first on the path of the coolant from the boiler plant is the safety group. It consists of three parts mounted on one manifold:

- pressure gauge - to control the pressure in the network;

- automatic air release valve;

- safety valve.

When operating a solid fuel boiler, there is always a risk of overheating of the coolant, especially in modes close to maximum power. This is due to some inertia of fuel combustion, because when the required water temperature is reached or a sudden power outage, it will not be possible to immediately stop the process. Within a few minutes after the air supply is stopped, the coolant will still heat up, at which point there is a risk of vaporization. This leads to an increase in pressure in the network and the danger of destruction of the boiler or bursting of pipes.

To exclude emergency situations, the piping of a solid fuel boiler must necessarily include a safety valve. It is adjusted to a certain critical pressure, whose value is indicated in the heat generator passport. As a rule, the value of this pressure in most systems is 3 bar, when it is reached, the valve opens, releasing steam and excess water.

Further, in accordance with the scheme, for the correct operation of the unit, it is necessary to organize a small coolant circulation circuit.Its task is to prevent cold water from entering the house heating system into the heat exchanger and the water jacket of the boiler. This is possible in 2 cases:

- when heating is started;

- when the pump stops due to a power outage, the water in the pipelines cools down, and then the power supply resumes.

Important! The power outage situation is particularly dangerous for cast iron heat exchangers. A sudden supply of cold water from the system by the pump can lead to cracking and loss of tightness.

If the furnace and heat exchanger are made of steel, then connecting the solid fuel boiler to the heating system through a three-way valve protects them from low-temperature corrosion. The phenomenon occurs if condensation forms on the inner walls of the combustion chamber due to temperature differences. Mixing with volatile fractions and ash, moisture forms a layer of scale on the steel walls, which is very difficult to remove. In this case, the metal is exposed to corrosion and the service life of the product as a whole is reduced.

The scheme works according to this principle: while the water in the boiler jacket and in the system is cold, the three-way valve allows it to circulate along the small circuit. After reaching a temperature of 60 ºС, the unit starts mixing the coolant from the network at the unit inlet, gradually increasing its consumption. Thus, all the water in the pipes warms up gradually and evenly.

The basic principle of boiler protection against condensate

To protect the solid fuel boiler from the formation of condensate, it is necessary to exclude the situation in which this process is possible. To do this, do not allow cold coolant to enter the boiler. The return temperature must be 20 degrees less than the supply temperature. In this case, the supply temperature must be at least 60 C.

The easiest way is to heat a small amount of coolant in the boiler to the nominal temperature, create a small heating circuit for its movement and gradually mix the rest of the cold coolant with hot water.

The idea is simple, but it can be implemented in various ways. For example, some manufacturers offer to purchase a ready-made mixing unit, the cost of which can be 25 000

and more rubles. For example, the FAR company (Italy) offers similar equipment for 28500 rubles

, and the company Laddomat

sells a mixing unit for 25500 rubles

.

A more economical, but at the same time no less effective way to protect a solid fuel boiler from condensate is to control the temperature of the coolant entering the boiler using a thermostatic valve with a thermal head.

Practical recommendations for setting the temperature of a solid fuel boiler using a thermomechanical draft regulator

First you need to fully open the air supply damper (blower), melt the boiler and wait for the temperature on the boiler thermometer to reach 60 ° C. After that, it is necessary to set the gap of the air supply damper to about 1-2 mm using the adjusting screw.

Next, set the temperature on the draft regulator to 60 ° C - either on a white scale or on a red one - depending on the mounting position of the regulator and tighten the chain until it stops sagging (with a minimum stretch). Now you should experiment with the temperature on the regulator knob and the temperature that the boiler maintains. Based on the test results, we adjust the length of the chain.

Solid fuel boiler temperature control with fan and controller

Second way solid fuel boiler temperature control

consists of using a fan and a controller, and can be attributed to the case active

air supply regulation. The essence of this method is the direct dosing of the amount of air entering the combustion chamber of the boiler.The actuator in this case is a fan that pumps air into the combustion chamber. By changing the fan speed, you can smoothly and in a wide range change the volume of air entering the combustion chamber of a solid fuel boiler. The controller controls the fan. The essence of the control is to smoothly change the fan supply voltage, depending on the difference between the set temperature and the one that is currently in the boiler.

Consider the parameters that a standard controller can provide:

- the final temperature of the boiler is the set temperature that the automation must provide;

- fan operation hysteresis - this is the temperature difference from the set temperature, within which the fan speed will be linearly controlled (proportional law);

- the minimum fan speed is the minimum speed in the operating mode (minimum heat output of the boiler);

- maximum fan speed - this is the speed in the maximum power mode according to the controller (maximum heat output of the boiler);

- purge time - this is the time the automation turns on the fan when the boiler has reached the set temperature so that the flame in the boiler does not go out;

- pause time between purges - so as not to overheat the boiler when it has reached temperature;

- heating system pump activation temperature - the pump will turn on only when the set temperature is reached;

- pump hysteresis - the difference showing how many degrees from the setpoint the water temperature in the boiler can drop without turning off the pump. Determines the temperature at which the pump will turn off;

- correction of temperature indicators - if the sensor is not mounted correctly and its indicators are incorrect;

- boiler shutdown temperature – the temperature at which there is no fuel in the boiler and the fan is turned off;

- test mode allows you to check the operation of the pump and fan in manual mode.

As we see this method adjustment

air supply has the ability to more accurately provide the desired temperature of the coolant in a solid fuel boiler

. However, with sufficient sealing of the air supply door and the blower, this automation system can lead to the attenuation of the boiler in the absence of power supply, because a gravitational air supply valve is mounted on the fan, when the fan is not working, the valve does not allow air to be supplied to the combustion chamber.

Conclusion

Assessing the technological capabilities of modern solid fuel boilers, one should think not only about its operating power, but also foresee the installation of protection elements for the entire system. Overheating of the boiler is a frequent and well-known phenomenon for the inhabitants of private houses. Using the available means to ensure protection will not only avoid emergency situations, but also extend the operation of the heating units. Everyone is free to choose the means and method of protection. It will be enough for one to install an electric generator, which, together with the UPS, will not allow the circulation of water in the system to stop. Other owners of a private house, on the contrary, will need to install a bypass or equip a spare, emergency circuit for safety reasons.

According to experts, installing a buffer tank or installing a bypass are the most effective ways to protect the heating system from overheating.

Note: in the USA and in European countries, the operation of solid propellant devices without a buffer tank is prohibited.

Many manufacturers of boiler equipment require that at the inlet to the boiler there be water not lower than a certain temperature, since the cold return has a bad effect on the boiler:

-

- the efficiency of the boiler is reduced,

- condensation on the heat exchanger increases, which leads to boiler corrosion,

- due to the large temperature difference at the inlet and outlet of the heat exchanger, its metal expands in different ways - hence the stress and possible cracking of the boiler body.

The first method is ideal, but expensive.

Esbe

offers a ready-made module for adding to the boiler return and controlling the load of the heat accumulator (relevant for solid fuel boilers) - the LTC 100 device is an analogue of the popular Laddomat unit (Laddomat).

Phase 1. The beginning of the combustion process. The mixing device allows you to quickly increase the temperature of the boiler, thus starting the circulation of water only in the boiler circuit.

Phase 2: Start loading the storage tank. The thermostat, opening the connection from the storage tank, sets the temperature, which depends on the version of the product. High, guaranteed return temperature to the boiler, maintained through the entire combustion cycle

Phase 3: The storage tank is in the process of being loaded. Good management ensures efficient loading of the storage tank and proper stratification in it.

Phase 4: The storage tank is fully loaded. Even at the end of the combustion cycle, the high quality of the regulation ensures good control of the return temperature to the boiler while simultaneously fully loading the storage tank

Phase 5: End of the combustion process. By completely closing the top opening, the flow is directed directly to the storage tank, using the heat in the boiler

The second method is simpler, using a high quality three-way thermal mixing valve.

For example valves from ESBE or or VTC300. These valves differ depending on the capacity of the boiler used. VTC300 is used with boiler power up to 30 kW, VTC511 and VTC531 - with more powerful boilers from 30 to 150 kW

The valve is mounted on the bypass line between the boiler supply and return.

The built-in thermostat opens input "A" when the temperature at the output "AB" is equal to the thermostat setting (50, 55, 60, 65, 70 or 75°C). Inlet "B" closes completely when the temperature at inlet "A" exceeds the nominal opening temperature by 10°C.

When the temperature of the coolant at the outlet of the valve "AB" is less than 61°C, the inlet "A" is closed, hot water flows through the inlet "B" from the boiler supply to the return. If the temperature of the coolant at the outlet "AB" exceeds 63°C, the bypass inlet "B" is blocked and the coolant from the return of the system through the inlet "A" enters the return of the boiler. Bypass outlet "B" reopens when the temperature at outlet "AB" drops to 55°C

When the coolant passes through outlet “AB” with a temperature of less than 61°C, inlet “A” from the return of the system is closed, and hot coolant is supplied to outlet “AB” from bypass “B”. When the outlet “AB” reaches a temperature of more than 63°C, the inlet “A” opens, and the water from the return is mixed with the water from the bypass “B”. To equalize the bypass (so that the boiler does not work constantly on a small circle of circulation), a balancing valve must be installed in front of the input "B" on the bypass.

A solid fuel boiler, unlike gas, electric or liquid fuel boilers, does not work constantly, but periodically, especially if it is designed to heat a country house or cottage.

Conclusion

Assessing the technological capabilities of modern solid fuel boilers, one should think not only about its operating power, but also foresee the installation of protection elements for the entire system. Overheating of the boiler is a frequent and well-known phenomenon for the inhabitants of private houses. Using the available means to ensure protection will not only avoid emergency situations, but also extend the operation of the heating units. Everyone is free to choose the means and method of protection. It will be enough for one to install an electric generator, which, together with the UPS, will not allow the circulation of water in the system to stop. Other owners of a private house, on the contrary, will need to install a bypass or equip a spare, emergency circuit for safety reasons.

According to experts, installing a buffer tank or installing a bypass are the most effective ways to protect the heating system from overheating.

Note: in the USA and in European countries, the operation of solid propellant devices without a buffer tank is prohibited.

A solid fuel boiler, unlike gas, electric or liquid fuel boilers, does not work constantly, but periodically, especially if it is designed to heat a country house or cottage.