What to glue mineral wool with foil on

Mineral wool with foil is produced in rolls and sheets. It is attached with universal construction adhesive.

Mineral wool with one-sided and two-sided foiling is available in rolls and sheets of various thicknesses. Mineral wool refers to all its varieties: from glass wool to. It, like polystyrene, is glued to the wall and is additionally reinforced with dowels. What to glue insulation with mineral wool foil on? For work, a universal plaster-adhesive mixture is used, which is suitable for both cotton wool and polystyrene foam.

When choosing how to glue foil insulation, you need to consider only high-quality mixtures from leading manufacturers:

- Knauf;

- Ceresit;

- Weber vetonit;

- Eunice.

If the surface on which the insulation is heated is even, then the adhesive is applied with a layer of 3 cm with a notched trowel around the entire perimeter of the thermal insulation sheets. If the cotton wool is glued to an uneven surface, then the glue is applied with a thickness of 4 cm with cakes, the diameter of which is at least 10 cm.

Is it necessary to lay a substrate under the IR floor?

- Creates a flat surface. Basically, an extruded polystyrene foam substrate is used for this purpose. Thanks to a special system of locks, it is possible to create a completely flat base.

- Does not allow heat loss. Infrared radiation is strictly directed in one direction, which avoids increased energy costs.

- Helps with the installation of the final floor covering. The base for infrared floor heating can vary depending on what kind of material will be laid on top.

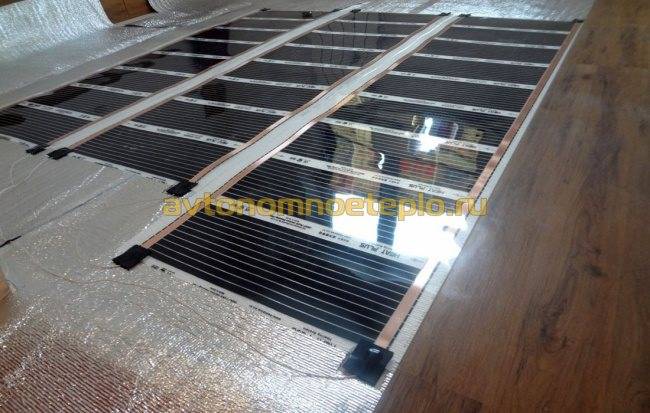

What does a layered “pie” look like under a film floor

Base. The plane is checked, if serious defects are found: drops, cracks, holes, it will be necessary to level the plane. A layer of waterproofing is preliminarily laid. Beacons are exposed and the screed is poured. Small irregularities can be leveled with leveling compounds. In this case, a waterproofing layer is not needed.

Aluminium foil. Mounted directly on the screed

Covering the base with foil is important to create a shielded surface that reflects radiation.

Fiberboard sheets, magnesite board. Installed on concrete surface

Insulation is placed directly under the warm film floor. Joints of rolled materials are glued with bituminous film or special adhesive tape.

IR floor film.

An additional layer of underlayment is laid on top of the mats, depending on the selected flooring. So, cork material is suitable for laminate. The substrate in this case will eliminate the likelihood of extraneous noise when walking on the board. The minimum thickness of the substrate is selected depending on how well the floors are leveled. For tiles, you will need to lay a reinforcing mesh.

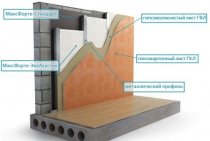

Which side to attach foamed polyethylene with foil

When the question arises of how to fix the foil insulation to the wall, then most often we are talking about penofol. This is insulation, which consists of two layers. The first layer is polyethylene foam, and the second layer is foil. In addition, there are products in which the foil is on both sides. The reflective surface can be glossy, like a mirror, or mint (embossed). It is believed that the relief allows you to slightly increase the reflection area, but not critically, so there is not much difference.

Unlike mats for floor insulation, regarding penofol, the answer to the question: “Which side to fix the insulation with foil?” sounds like this: the base (foamed polyethylene) to the wall or other insulation.

The thing is that this material is used for both internal and external insulation.It turns out that during the thermal insulation of the facade, putting penofol with the shiny side inward will not work, it will look outward. What will this give us:

- such insulation will not reflect heat from the room, since there is no ventilation gap between the foil and polyethylene;

- the insulation will not let the summer heat into the house.

Two-layer reflective insulation, where foamed polyethylene acts as a damper and reinforcement.

It is precisely because of the absence of any significant shifts towards increasing the thermal insulation qualities of the room that experts do not use penofol for external insulation. How to properly lay foil insulation penofol:

- you need to put it from the inside of the room with the shiny side to the heat source;

- between the foil and the finish there should be an air buffer zone (ventilated gap);

- the material is laid end-to-end;

- fastened either with nails or staples;

- the joints are glued with aluminum (not ordinary, but aluminum) tape.

These manipulations are performed in order to create a sealed reflective screen, which additionally acts as a vapor barrier, as it does not allow steam or moisture to pass through. Why, when answering the question of how to properly install insulation with foil, do we focus on the ventilation gap? The fact is that without it, the material will not perform its functions. The airspace allows the foil to repel exactly the IR radiation from the front standing structures (gypsum board, lining, siding, whatever).

If there is no air gap, then heat will be transferred to the foil not by means of IR rays, but by direct contact of materials. The thermal conductivity of aluminum is exceptionally high, so the process of removing heat outside the room in this case will even accelerate. A thin layer of foamed polyethylene does not create a special barrier to heat loss, and its main function is different: it acts as a damper and reinforcement for the foil, everything else is indirect.

In this case, an undesirable side effect will appear - condensate. The foil does not let steam through, and it settles on it in the form of condensate. If there is a ventilation gap, then micro droplets of moisture simply evaporate. In the absence of an air buffer zone, moisture collects and soaks into the finish, causing fungus to form. This is what ignorance of which side to put insulation with foil can lead to.

Despite the fact that there is plenty of information about heating a house from sip panels, many can still decide on a method of heating a home from this material. Although there are a lot of approaches that have a lot of advantages and benefits.

Properties of isolon CALEO

The operation of CALEO heat-reflecting isolon is convenient, durable and safe, thanks to its advantages:

- lightness

- ease of installation

- strength

- environmental friendliness

- surface smoothness

- ability to withstand high temperatures (over 100°C)

- resistance to cyclic temperature jumps (from -60 to 100°C).

Plus, CALEO isolon is a dielectric, that is, it does not conduct electricity and therefore is perfect for electric underfloor heating.

Production features

Isolon CALEO is marked with the letters PPE, which means that polyethylene foam is physically crosslinked. It is made by the method of foaming the foam. This is a special chemical compound that does not emit harmful compounds during the production process. The result is thermal insulation with a high foaming ratio, i.e. it has many small bubbles between a large number of lintels of the honeycomb structure, so this material is resistant to stress and does not lose its properties for a long time. The shiny reflective layer is made of Dacron instead of the cheaper, less durable and short-lived aluminum foil.

What is the difference between CALEO isolon and NPE thermal insulation?

There are various types of NPE (non-crosslinked polyethylene foam) thermal insulation on the market, which are cheaper than CALEO isolon. Their low cost is due to inexpensive production technology and the lower quality of the heat-reflecting material.

- NPE thermal insulation has a large-cell structure, therefore, under mechanical loads, the bubbles filling the material burst, which leads to a loss of heat-reflecting properties.

- Non-crosslinked polyethylene foam melts when the temperature reaches only 60 - 80 °C.

- The thermal conductivity coefficient is inferior to PPE materials by 20%, amounting to 0.045-0.055W, against 0.036W for PPE. This means that NPE retains heat worse and when using it with a warm floor, there will be more costs for paying for electricity.

- The reflective layer is made of a foil that conducts electric current, which is strictly prohibited when installed with an electric underfloor heating (you will get the effect of a "capacitor").

NPE thermal insulation is produced by many manufacturers, both in Russia and in the near abroad, but PPE isolon is produced only by the Izhevsk Plastics Plant. It is necessary to carefully approach the choice of thermal insulation, since very often NPE can be sold under the guise of PPE.

Application of Izolon CALEO

Heat-reflecting material CALEO is recommended to be laid over the entire area of the room where underfloor heating is installed. This method of laying allows you to eliminate differences in height and keep more heat in the room. Isolon CALEO is recommended for use under all types of electric underfloor heating.

You can buy an IZOLON CALEO underlay for infrared film underfloor heating with delivery to the following locations - Moscow, St. Zuyevo, Shchelkovo, Domodedovo, Zhukovsky, Sergiev Posad, Pushkino, Ramenskoye, Noginsk, Dolgoprudny, Voskresensk, Reutov, Lobnya, Klin, Dubna, Egorievsk, Chekhov, Ivanteevka, Stupino, Pavlovsky Posad, Dmitrov, Naro-Fominsk, Fryazino, Vidnoe, Klimovsk, Lytkarino, Solnechnogorsk, Dzerzhinsky, Kashira, Kotelniki, Nakhabino, Krasnoznamensk, Protvino, Istra, Shatura, Tomilino, Likino-Dulyovo, Mozhaisk and other cities. To deliver goods to your city, we use any transport company convenient for you.

Which side to put the insulation with foil. Views and installation

- isolate the walls from the entry of excess heat into the room;

- and keep the interior warm.

The solution can be found in various ways, because today there are many thermal insulators, each of which has unique properties.

In the photo, foil insulation is laid on the wall.

One of the highest quality and innovative materials are foil insulation, one side of which is a reflector, keeping the room warm by reflecting IR rays. At the same time, the foil side is also a high-quality vapor and water insulator, which protects the insulation from the effects of condensate.

Features of use

The use of floor insulation allows you to increase the insulation characteristics of structures without increasing the height and thickness. It can be used on its own or in combination with other types. In each case, it is necessary to consider the feasibility of laying, based on the tasks of the technology. When mounted on a wooden floor, a noticeable thermal effect is obtained. The surface heats up quickly, retains energy for a long time, without additional thick layers.

Interfloor ceilings are classified as the most susceptible to extraneous sounds and cold penetration. The best way to eliminate the shortcomings is to insulate with foil Izolon. It reliably protects engineering systems, ventilation, pipelines and gas pipelines. For such work, it is recommended to use a foil stamp.Self-adhesive film is easily placed on a metal surface, holds securely and provides high-quality insulation and noise isolation of the carrier. Isolon is suitable for floor insulation during the operation of electrical and water structures. Effectively functions under the coating of laminate, parquet, linoleum, carpet.

Izolon laying scheme is performed in different ways, depending on the base, and according to the instructions:

1. Insulation for a wooden floor.

Under the structure of the boards make a concrete screed. Extruded polystyrene foam is placed on the pre-cleaned surface, then the solution is poured. The base must be free of cracks and defects. If they formed after the mixture hardened, it is necessary to treat with putty and sand. After that, the plane is cleaned, the thermal insulation of the floor is carried out using Izolon. The protective film is removed from the roll, rolled out and fixed with adhesive or fasteners. Joints are sealed with foil tape.

When using mineral wool as a heater, it is better to plan the construction of a lag. The formation is covered with a special membrane on both sides to prevent moisture from entering from the soil and the room. They start laying wooden beams, on which boards are placed, then Isolon. The sheets are connected to the logs with a stapler, the top coat is mounted on top.

If the crate was installed earlier, beams are placed on the rough base, then plywood panels. Insulation is rolled out on the finished flooring, on top - a layer of waterproofing.

2. Concrete floor insulation.

The main drawback of such grounds is that they always pull cold if you do not take action. The scheme is similar to the technology in a wooden house, but it should be noted that the construction of a log in an apartment is accompanied by a decrease in area by 10 cm, so you should follow the guide. A moisture-proof membrane must be placed on the screed. The distance between the bars is 50 cm, Isolon is laid in between.

To reduce energy losses, the joints of the rolls are sealed with tape. According to Izolon's instructions for use, it is not recommended to use soft topcoats. For carpet and linoleum, you will have to equip an additional solid layer of plywood. When installing water systems, the construction of a crate is required, on which insulation is laid. It is fixed to the frame with a stapler, the attachment points are glued with foil tape or construction tape.

Of all modern materials, Izolon is the most effective as a floor insulation, due to the peculiarities of production. Grades without a metallized component are designed more to absorb noise and protect against condensation; they are often used as a substrate for laminate and parquet. Foil Izolon is an excellent protection against heat loss, provides a reflection of energy into the room, comfortable living.

Warming the loggia is not such an impossible task.

Floor insulation on the loggia is the best way to turn additional square ones.

The foam block house is very comfortable, because the porous building material is.

Overview of Thermex water heaters

Do-it-yourself water-heated floor

Basalt insulation

Overview of thermal insulation brand Techno-Nicole

Types of heaters

There is a wide variety of foil insulation.

They differ in the materials used in the manufacture.

The characteristics of insulation with a layer of foil are described in the table:

| № | foil material | Characteristic |

|---|---|---|

| 1 | Styrofoam | Strong, reliable insulating material produced in the form of rigid boards. It is used for thermal insulation of water and electric underfloor heating. Operation in the temperature range from -180 to +180 degrees |

| 2 | Mineral wool | Environmentally friendly, fireproof material, 50-100 mm thick.It is produced in plates, rolls, cylinders. It is applied in all spheres of thermal insulation works. |

| 3 | Foamed polyethylene | Available in rolls, covered with aluminum foil. The material has a small thickness from 2 to 10 mm. The bottom layer can be self-adhesive. |

| 4 | Foamed polyethylene | Available in rolls, covered with aluminum foil. The material has a small thickness from 2 to 10 mm. The bottom layer can be self-adhesive. |

Application

Penefol (closed-cell polyethylene foam) is versatile in use. They isolate walls, floors in residential premises.

Foil insulation for pipes and roofs - foilizol. It is also used in the construction of industrial facilities.

Rolls of mineral wool with an aluminum layer are used in the same way as conventional insulation mats: for insulating walls, floors and other structures. The difference between foil mineral wool and ordinary wool is built-in waterproofing, aluminum does not let moisture into the fibers, preventing the material from getting wet.

An ideal foil insulation for a bath based on basalt: it has a low heat transfer coefficient, is not afraid of humidity and large temperature changes. As you know, stone wool is a hard material. To roll it into a roll, basalt is sawn into lamellas, and they are laid on an aluminum base. This insulation is used to isolate various social and industrial facilities.

Foiled polystyrene foam is used for floor insulation.

Production and sale of heat-sound-vapor-waterproofing mats, self-adhesive foil, adhesive tape, etc.

Stizol-Penofol is a modern thermal insulation, insulation based on foamed polyethylene. An improved analogue of penofol, energy flex, isolon, which has a complex of unique properties. Advantages of Stizol are denser closure of cells 45 kg/m3, high mechanical stability and durability, fire extinguishing additives. Factory quality and low prices.

Stizol belongs to the class of reflective thermal insulation. Like Thermaflex, as well as Energoflex, it has one-sided and two-sided foiling. Aluminum foil plays the role of a kind of screen that reflects up to 98 percent of the radiant energy, due to which the thermal insulation ability of Steizol increases dramatically. Thermal insulation systems using Stizol are 20-70% more efficient than conventional thermal insulation systems. This is because when insulating pipes or other structures with penofol, a so-called. thermos effect. Stizol is durable and environmentally completely safe.

Stizol-penofol properties:

- effectively insulates, insulates at small thicknesses

- resilient, elastic, mechanically stable, does not conduct electricity

- has good soundproofing properties

- resistant to moisture, water vapor absorption

- does not support combustion, does not emit toxic substances in fire conditions

- environmentally friendly (made of food grade polyethylene)

- durable, not subject to rotting, rust, UV radiation, resistant to cement, lime, gypsum; various fungi, bacteria, oil-benzo racks

– easy to use, does not require protective clothing and expensive equipment

- thanks to the adhesive layer, it is quickly and easily mounted on any surface (iron, aluminum, wood, etc.), even on dusty, not degreased ones.

STIZOL is multifunctional.

Has a wide range of applications:

• Thermal insulation of engineering systems of buildings and structures. Thermal insulation of pipes, insulation and sound insulation of ventilation, air conditioning and sewerage systems

• Thermal insulation and sound insulation of wall enclosing structures, roofs, floors and ceilings. Systems "Warm floor" as a substrate for floor coverings

• Soundproofing of civil and industrial premises

• Insulation and soundproofing of apartments, country houses, cottages, roofing and wall structures

• Thermal insulation of isothermal vans and refrigerators

• Noise isolation of interiors of cars and other vehicles

• Heat and sound insulation and fire protection of structures in shipbuilding, mechanical engineering, nuclear industry and electric power industry

• Warming of baths, saunas

Floor insulation. Which side to lay foil insulation on the floor

Svarog (Expert Builderclub)

Foil (reflecting side) towards a warm room (that is, if these are the floors of the first floor - foil up). From the point of view of heat loss, the use of a reflective layer gives very good results - like in a thermos. From the point of view of ventilation - the same thermos, that is, it is necessary to design ventilation taking into account the very low air permeability of enclosing structures insulated with false insulation. The structures are poorly ventilated, if you have wooden floors you need to take this into account, otherwise they can quickly rot.

Absolutely correct advice - with the foil side towards the room. The only thing I want to add is that you should not literally take advertising information about this material (that one of its layers replaces a lot of mineral wool and other heaters). We already had a discussion on this topic on our website, you can see it in the topic “Insulation. Insulation of the walls from the inside with the help of foil foamed polyethylene. There we are talking about the construction of the wall, but the properties of this insulation are the same, both in the wall and in the floor, and the features of its application too.

Svarog (Expert Builderclub)

Valeria is right about the thermal insulation properties of this insulation. A little theory, if you will:

Heat transfer can occur in three types of heat transfer: 1) Thermal conductivity (solid, liquid, gaseous media), due to elastic waves or diffusion of atoms, molecules, electrons. 2) Convection (liquid gaseous media), due to the transfer of heat by moving particles. 3) Radiation (gaseous medium or void), due to the transfer of electromagnetic waves.

This type of insulation (according to manufacturers) isolates immediately from 3 of these heat transfers. But in practice: it is difficult to ensure airtightness - the effectiveness of isolation from convection is sharply reduced. The thickness of such heaters is small, and if you follow the assurances of the manufacturers, it can replace a much thicker insulation, respectively, their direct "thermal conductivity" is not high. I can’t say anything about the reflective ability of the foil coating, it depends on what material (the low emissivity affects) it is made of. The literature only mentions a significant increase in the thermal insulation properties of the air gap if the surfaces are coated with aluminum (silver plating in devices). A large (60-79%) amount of heat is transferred by radiation in large air gaps (1-20cm). An air gap is required for this insulation to work, and the gap should ideally be 4 cm (or in the range of 1-5 cm) based on experimental data.

You also need to understand that this is a building material - it is difficult to protect it from dirt and debris, which will negate all the reflective abilities of the material, not to mention dust.

The manufacturer cites data that 50-90% of heat transfer goes through radiation, this will not happen in real construction.