Production stages

The process of making biofuels is simple. All work is divided into several stages:

- First, the components of the raw material, cleaned of dirt, are crushed using a chipper.

- Then the raw material is put into the dryer. The output humidity range should be between 6 and 12%. This is an important production step, as good drying affects the quality of the finished product.

- The crushed and dried material is pressed under high pressure and at high temperature.

- At the final stage, briquettes of a certain shape are formed. They cool down, acquire strength and are transported to storage facilities.

The technology for the production of eurofirewood from sawdust does not involve the addition of any components to the mixture. During pressing at elevated temperatures, a chemical reaction occurs. Particles of the substance are glued together by lignin, which is contained in the plant cells of wood.

https://youtube.com/watch?v=P1WkqM98H4w

Production of fuel briquettes and pellets

Press equipment for the production of fuel briquettes

For the production of straw briquettes, different types of presses can be used:

- Impact-mechanical briquetting press. The most popular type of straw briquetting presses. His trailer is quite simple and reliable. The straw mass is knocked down in layers into the shape of a dense cylinder, which gradually moves along the stabilizer. At its end, the cylinder breaks off with a special knife or under its own weight. Such briquettes are usually obtained in different lengths. They retain all the advantages of the ecological solid fuel of straw briquettes, but lose their aesthetic visual properties.

Hydraulic press for briquetting. The briquettes produced by this group of pressing machines have cylindrical or RUF shapes (a patented shape that gives additional properties to the briquette: uniform burning with greater heat transfer, increased resistance to moisture, etc.). Due to the much greater pressure, briquettes of this type are more compact and, as a rule, do not crumble. They are the optimal fuel for fireplaces, but nothing prevents their use in any other heating devices.

Screw press for extrusion (continuous) briquetting. This type of press is distinguished by its special performance and good quality of straw mass compression. In fact, these presses form pallets - these are thin cylindrical briquettes of the highest quality (pencil thickness). The disadvantage of screw presses is higher requirements for operation and increased wear of working units. During briquetting, chopped straw is subjected to high pressure obtained by pressing with a screw in a sleeve (similar to the principle of a meat grinder). But the final shape is given by a special sleeve at the end of the auger. At the same time, the end surface of the briquette is sealed with an electric heater. It helps release more water vapor from an already dry material. And also this additional process allows you to increase the resistance to moisture of the finished product.

Additional features

The choice and configuration of equipment for the production of briquettes depends on the tasks and volumes of production.

Technical equipment may additionally include:

- Movable floor with automatic feed of raw materials to the conveyor for further processing.

- Battery cyclone, where dry sawdust is separated from the exhaust gases obtained in the process of heating the drying drum.

- Screw conveyor for moving raw materials from one device to another.

- Briquetting area with an automatic saw for cutting briquettes and a container for feeding products into packaging.

- Packing machines that allow forming briquettes into shrink film.

- Pallet strapping device.

Many practical people involved in the household make products with their own hands on homemade hand-operated machines. In their opinion, the main thing in the equipment is a mechanism that creates pressure, and an element that allows you to give the briquettes a certain shape.

Related video: DIY fuel briquettes

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Technical equipment of the workshop

The manufacturing process is not difficult. Basically, all operations are carried out by special equipment. Suppliers offer consumers various lines that differ from each other in power and price.

The standard package includes the following units of machines and devices:

- Apparatus for grinding. The machines grind the raw materials delivered to the workshop for processing. This is the first stage of the technological process. Depending on what type of raw material will be used at this stage, the following equipment for the production of fuel briquettes is distinguished: chip cutters (for processing large parts of a tree), crushers (for processing tree branches up to 50 mm in diameter), straw cutters (for processing straw).

The cheapest of the listed types of equipment is crushers (from 100,000 rubles), and the most expensive of all are straw cutters (from 400,000 rubles). Experts advise to purchase several devices for grinding at once. Then you will not "depend" on 1 type of raw material, but will be able to use many of its types.

From what you decide to buy equipment for the production of fuel briquettes for crushing will largely depend on the properties and characteristics of the finished product.

- Dryer. After the grinding procedure, the raw materials must be thoroughly dried. Otherwise, eco-briquettes will not meet the declared characteristics. The humidity of the components for production should not exceed 10%. Price - from 500,000 rubles.

- Press machine (extruder). A special press for the production of fuel briquettes compresses the crushed raw materials into briquettes under high pressure and elevated temperatures. In the course of a chemical reaction, lingin is released from the biomass. It also serves as an excellent natural binder of the components used. As a result, eco-briquettes, which are made by extruders for the production of fuel briquettes, have a higher density, and, accordingly, they burn longer and release more energy into the environment. Price - from 600,000 rubles.

- Packing machine. The machine in one way or another packs the resulting briquettes. Price - from 600,000 rubles.

When choosing equipment for the production of fuel briquettes, first of all, start from the planned production volumes. If you are somewhat constrained in finances, then opt for a low-power line (up to 200 kg / h). The average price of a line for the production of fuel briquettes of such a plan will cost about 2,000,000 rubles. The cost of more powerful equipment can reach up to 6,000,000 rubles.

To save on the technical equipment of the workshop, consider leasing. So you don't have to spend money on equipment. But in this case, the level of monthly expenses will increase. You can also buy equipment in China.They differ little in quality, but their price is not so “terrible” for novice entrepreneurs.

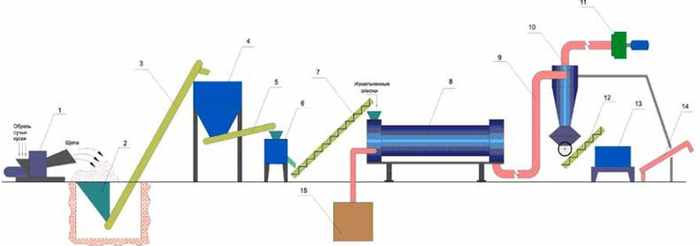

Composition of a complete line for the production of fuel briquettes

- chipping machine;

- scraper conveyor bunker;

- scraper conveyor;

- consumable bunker;

- scraper conveyor;

- hammer crusher;

- screw conveyor;

- drum dryer SB;

- material pipeline;

- battery cyclone;

- fan;

- screw conveyor;

- briquetting press;

- cooling conveyor;

- solid fuel heat generator.